A kind of preparation method of piezoelectric fiber composite structure layer

A piezoelectric fiber composite, piezoelectric fiber technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of low production efficiency, fiber The thickness of the interpolymer is difficult to control and other problems, so as to achieve the effect of uniform thickness, avoid filling difficulties and improve flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

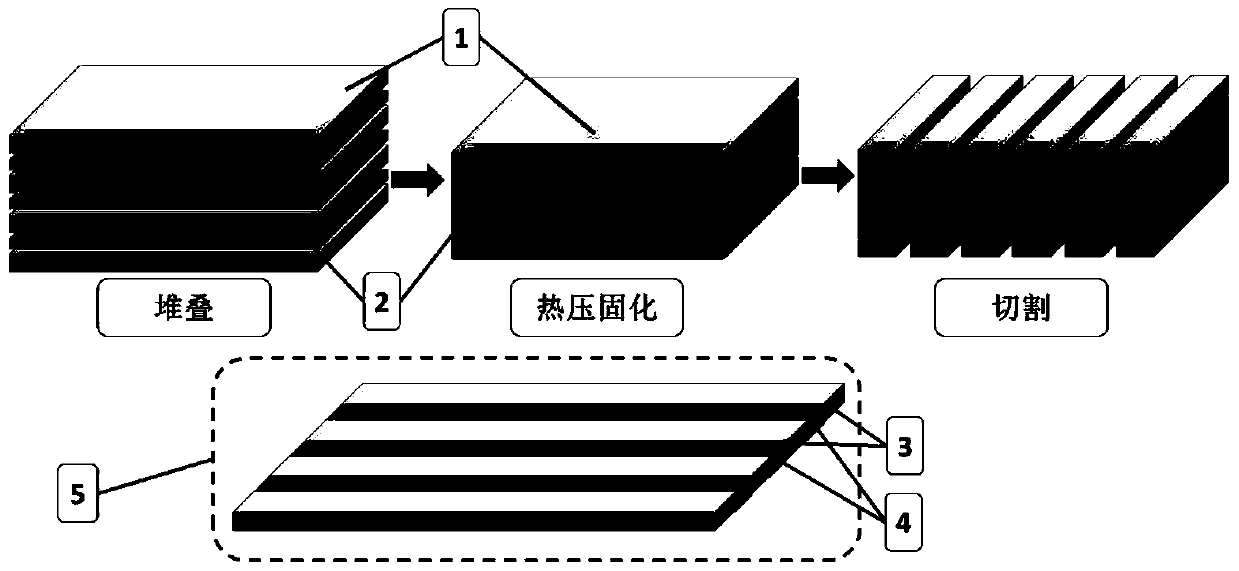

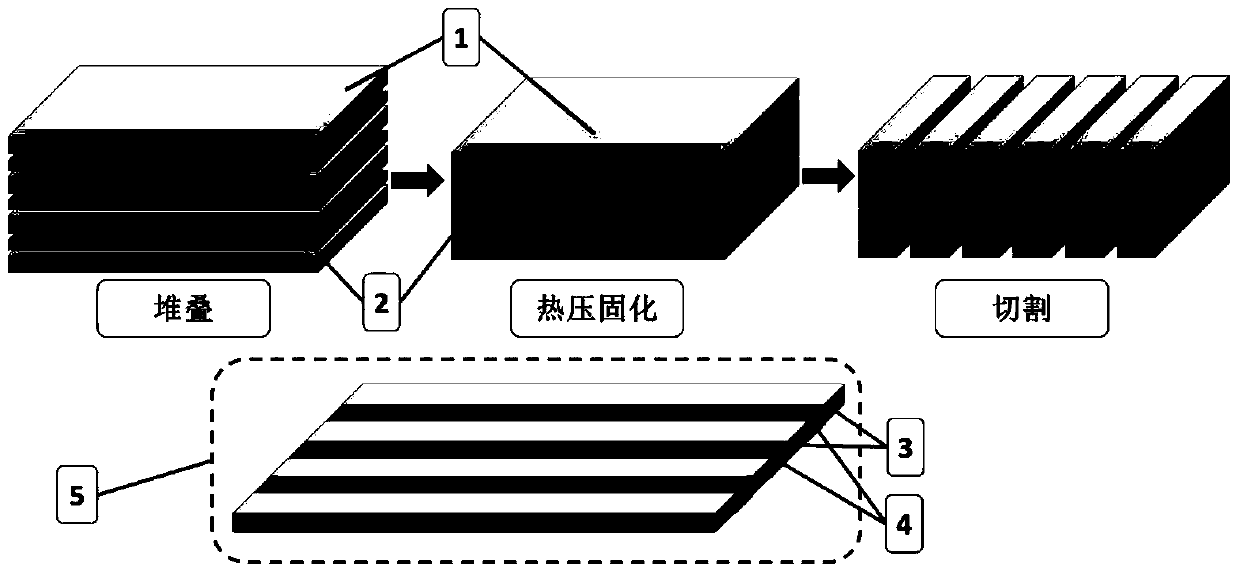

[0029] In this example, the preparation of the PZT-5H-based MFC structure piezoelectric fiber composite material is aimed at, and the piezoelectric fiber composite structure layer is prepared by the present invention. The specific process is as follows:

[0030] 1. Using PZT-5H piezoelectric ceramic powder as raw material, a piezoelectric ceramic block with a size of 60×20×20mm was prepared by solid-phase synthesis method, and cut into a piezoelectric thin layer with a size of 60×20×0.4mm Several.

[0031] 2. Using epoxy resin as raw material, prepare a thin layer of epoxy resin with a thickness of 0.1mm by hot pressing method, and cut it into several thin layers of epoxy resin with a size of 60×20×0.1mm.

[0032] 3. Take 10 pieces of the piezoelectric thin layer prepared in step 1, and take 9 pieces of the polymer thin layer prepared in step 2, and evenly coat the surfaces that need to be bonded in all piezoelectric thin layers and polymer thin layers. Cover a layer of epoxy...

Embodiment 2

[0036] In this example, the purpose of the preparation of PMnS-based MFC structure piezoelectric fiber composite material is to adopt the present invention to prepare piezoelectric fiber composite structure layer. The specific process is as follows:

[0037] 1. Using PMnS piezoelectric ceramic powder as raw material, a piezoelectric ceramic block with a size of 40×40×20mm was prepared by solid-phase synthesis, and cut into several piezoelectric thin layers with a size of 40×40×0.3mm.

[0038] 2. Using polyester resin as a raw material, prepare a polyester resin thin layer with a thickness of 0.05 mm by hot pressing method, and cut it into several polyester resin thin layers with a size of 40×40×0.05 mm.

[0039] 3. Get 11 pieces of the piezoelectric thin layer prepared in step 1, and get 10 pieces of the polyester resin thin layer prepared in step 2, and apply one layer on both sides of the piezoelectric thin layer and the polyester resin thin layer Polyester resin glue, accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com