Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Low oxidation temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

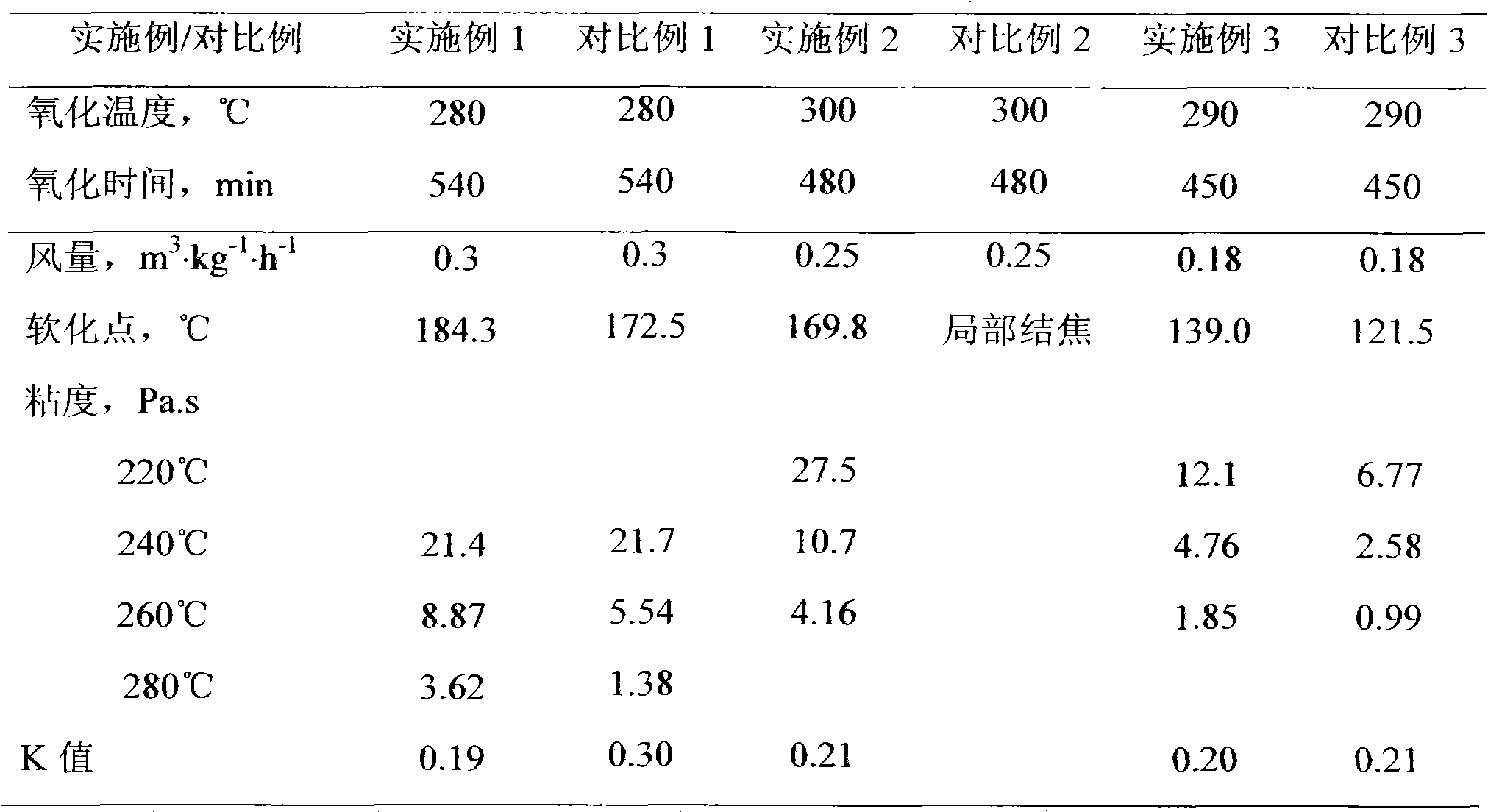

Preparation method of high softening point asphalt

ActiveCN102464989AIncrease profitQuality improvementWorking-up pitch/asphalt/bitumen by chemical meansMolten stateTemperature control

The invention provides a preparation method of high softening point asphalt, and the method comprises: heating an asphalt raw material to a molten state, subjecting the asphalt raw material, reaction additives accounting for 0.01%-5% of the total mass of the asphalt raw material, as well as air to full premixing reaction, with the mixing temperature controlled at 80-180DEG C and the mixing time controlled at 1min-40min; then introducing the mixture to an oxidation reactor for air blowing oxidation at a temperature of 200-340DEG C for 3-10h, with the air blowing rate of an oxidation tower maintained at 0.05-0.5m<3>.kg<-1>.h<-1>, thus obtaining a high softening point asphalt product with excellent high temperature performance and temperature susceptibility resistance. The method of the invention solves the problems of overlong reaction time, nonuniform air distribution, easy coking, short oxidation tower operation cycle, and poor product performance, etc. existing in current high softening point asphalt production processes by oxidation method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Silver-copper-based metal oxide electrical contact material containing additive elements and preparation method thereof

The invention discloses a silver copper based metal oxide electrical contact material containing adding elements and a preparation method thereof. The electrical contact material is characterized by comprising the following components in percentage by weight: (20-50)% of silver metal oxide alloy, (0.3-9)% of electric conductive ceramics, (0.7-1.8)% of lanthanum nickel alloy, (0.7-4.9)% of adding elements, and the balance of silver copper alloy; and the contact material provided by the invention comprises the following simple substance elements in percentage by weight: (15-63)% of silver, (4-25)% of metal oxide, (0.3-9)% of electric conductive ceramics, (0.01-5)% of rear earth, (0.7-4.9)% of adding elements, and the balance of copper. The preparation method is characterized by comprising the following steps: smelting, pulverizing and milling (silver metal alloy power, and silver copper alloy powder) in proportion for optimization performances of the material, cladding electric conductive ceramic micro powder by silver, mixing powder of the adding elements in a certain mass ratio, pressing an ingot blank, sintering and extruding, rolling or drawing, thus obtaining the contact material. The electrical contact material provided by the invention has the advantages of low cost and excellent overall performance.

Owner:张树堂

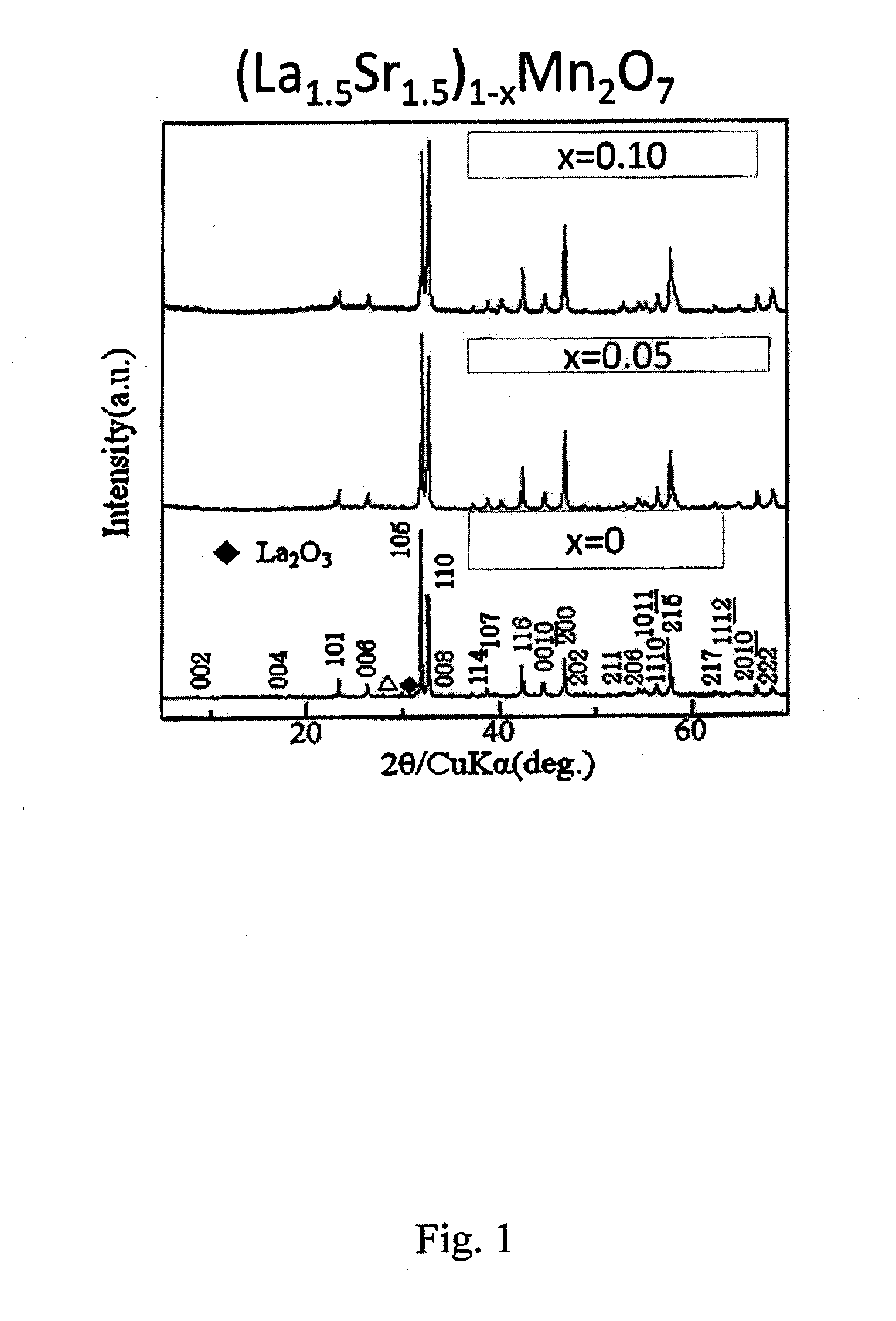

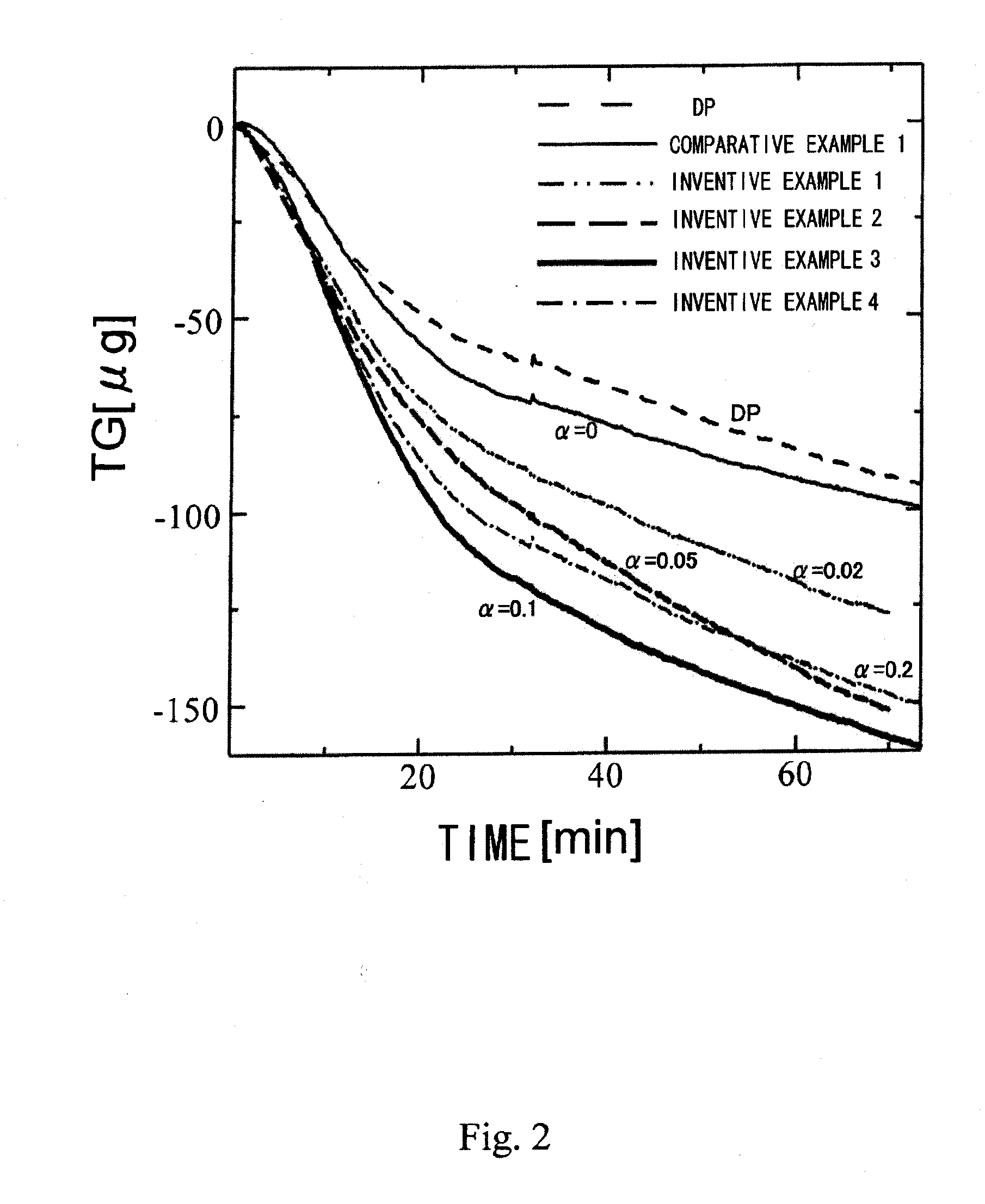

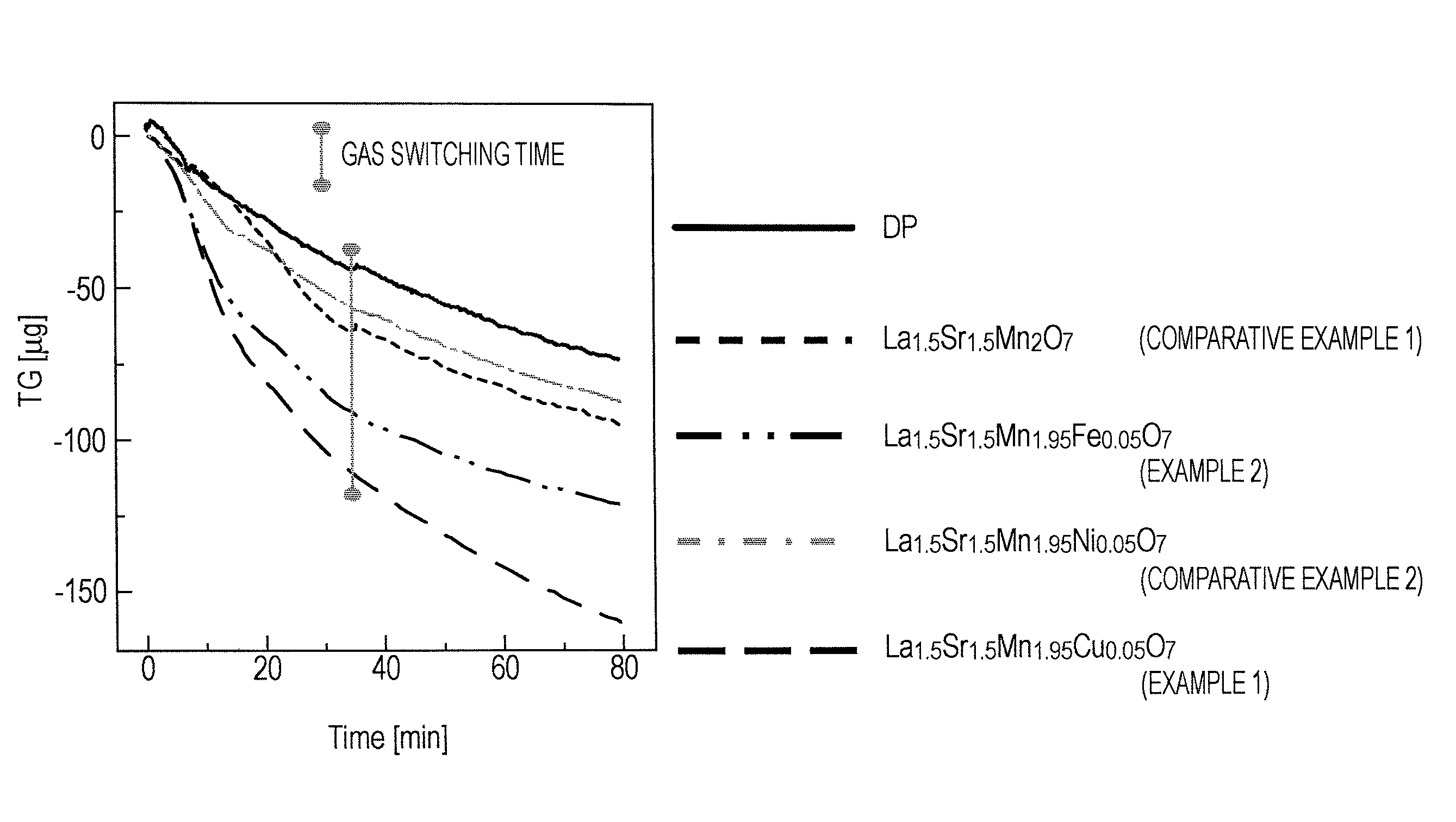

Layered complex oxide, oxidation catalyst and diesel particulate filter

InactiveUS20140050629A1Improve catalytic performanceLow oxidation temperatureCombination devicesInternal combustion piston enginesNitrogen oxideTernary catalyst

Provided are a layered complex oxide that can lower PM oxidation temperature and increase oxidation rate, and a nitrogen oxides reduction catalyst, a three-way catalyst, a DPF and an oxidation catalyst, each of which includes the layered complex oxide. The layered complex oxide has a layered perovskite structure and has a composition represented by the formula: (Ln3-xAx)1-αMn2O7-δ (wherein Ln is La and / or Nd, A is Sr and / or Ca, α is degree of A-site deficiency, δ is the oxygen deficit amount, and X, δ and α satisfy 0<X<3, 0<α<1 and δ<1.4), which are included in the catalysts and DPF.

Owner:NISSAN MOTOR CO LTD

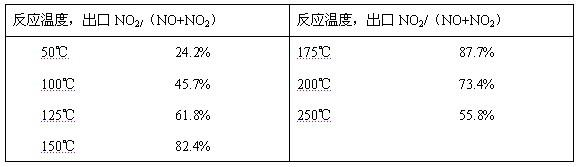

Catalyst and preparation method thereof

InactiveCN102068994ALow oxidation temperatureImprove oxidation efficiencyCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationReaction temperature

The invention provides a catalyst and a preparation method thereof, wherein the catalyst comprises the following compositions in percentage by mass: 20 to 60% of Fe2O3, 20 to 60% of MnO2, 9.7 to 30% of Mn2O3, and 6 to 30% of Mn3O4; and the method for preparing the catalyst comprises the following steps of: adding a polyethylene glycol aqueous solution into a bivalent manganese salt aqueous solution at a certain temperature, then adding potassium permanganates and a ferric salt aqueous solution into the obtained mixed solution; stirring the obtained mixture so as to obtain a precipitate; filtering the obtained object so as to obtain a solid as the precursor of the catalyst; drying and then roasting the solid; and crushing the obtained solid subjected to roasting into particles so as to obtain the catalyst. The catalyst and the preparation method provided by the invention have the advantages that by using the prepared catalyst, at a reaction temperature of 100 DEG C, the rate of conversion between NO in tail gas and NO2 can achieve 91%; the prepared catalyst is larger in specific surface area and pore volume, and high in catalytic oxidation efficiency; and the prepared catalyst has a low-temperature catalytic activity, and can be used in the removal of NO in low-temperature oxygen-containing exhaust emission sources without performing the removal at a high temperature and addingoxidants, thereby saving energy and reducing consumption and cost.

Owner:KUNMING UNIV OF SCI & TECH

Production method for nickel oxide anode thin film used for full solid-state thin-film lithium ion battery

InactiveCN101174687AComplete structureUniform size distributionElectrode manufacturing processesVacuum evaporation coatingOxygenLithium-ion battery

The present invention provides a preparation method of a nickel oxide anode film used for the solid film lithium-ion battery, which adopts the vacuum vapor deposition method to deposit a Ni film on a substrate, and then adopts the heat oxidation method combining with the oxygen generator to prepare a NiO film material. The oxidation temperature for the preparation method of the nickel oxide anode film of the solid film lithium-ion battery provided by the present invention is low, the cost is low, the process and the equipments are simple, the deposition speed is higher than that of the traditional method, and a nano nickel oxide film with uniform granular size and complete structure is easy to obtain, which has good chemical performance, and can be used as the anode material of the solid film lithium-ion battery.

Owner:HENAN UNIV OF SCI & TECH

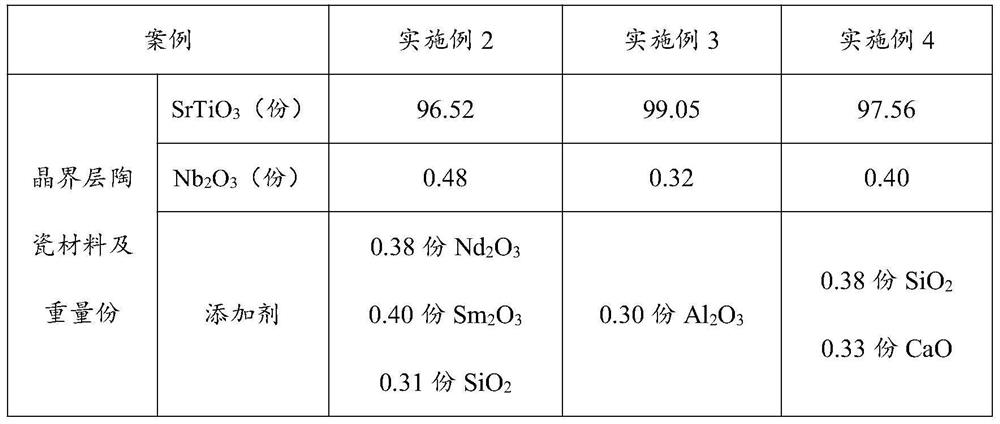

Preparation method and application of grain boundary layer ceramic material and grain boundary layer ceramic substrate

The invention provides a preparation method and application of a grain boundary layer ceramic material and a grain boundary layer ceramic substrate, and belongs to the technical field of chip capacitors. The grain boundary layer ceramic material provided by the invention is prepared from the following preparation raw materials in parts by mass: 95.35 to 99.30 parts of SrTiO3, 0.30 to 0.55 part ofNb2O3 and 0.30 to 5.00 part of a modification additive comprising one or more of BaCO3, Nd2O3, CaO, Sm2O3, Al2O3 and SiO2. The grain boundary layer ceramic material has excellent electrical propertiesand controllability, and a grain boundary layer ceramic substrate prepared from the grain boundary layer ceramic material has excellent repeatability and consistency.

Owner:GUANGZHOU AURORA TECHNOLOGIES CO LTD +1

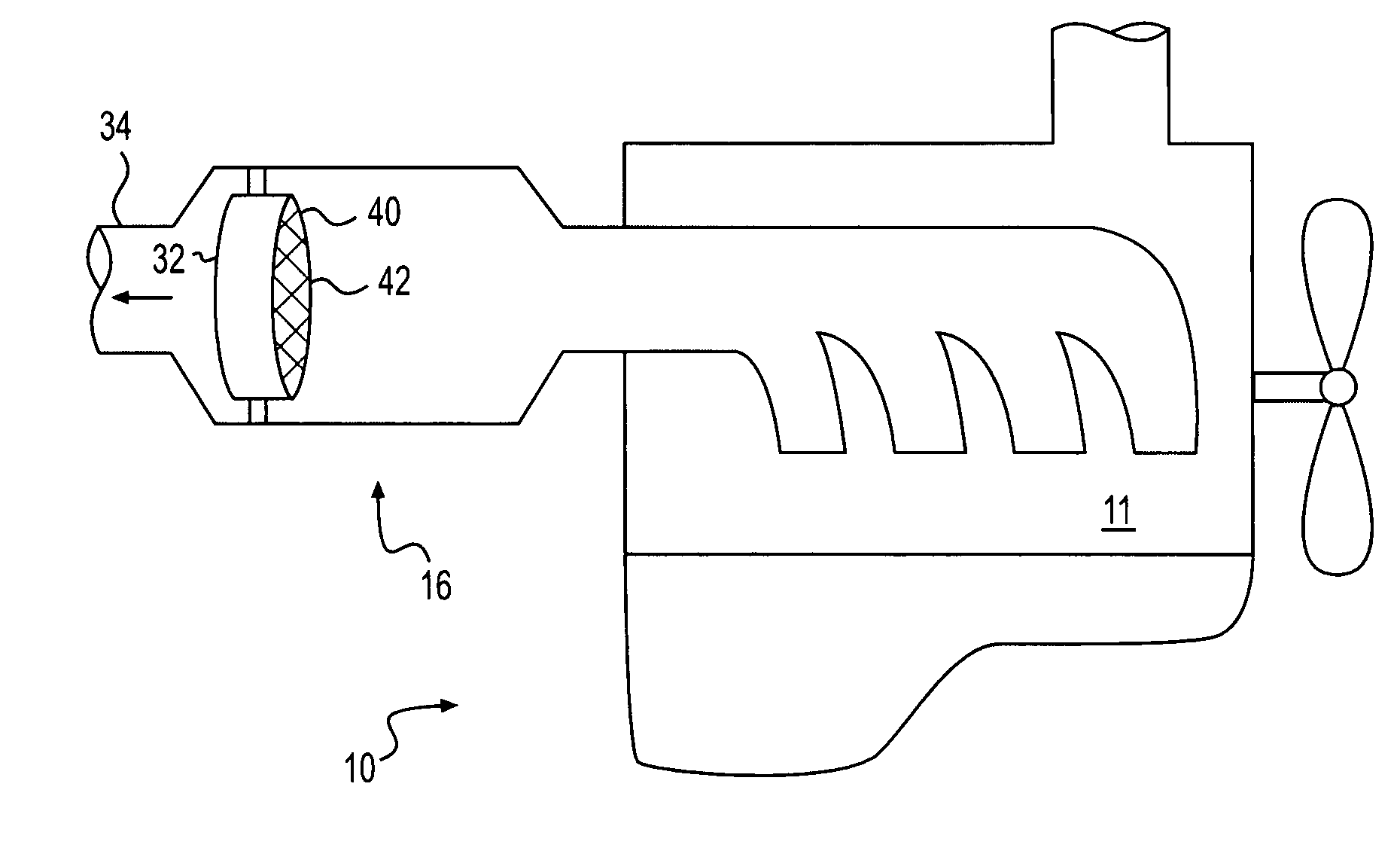

Exhaust system having a gold-platinum group metal catalyst

ActiveUS8071504B2Improve concentrationReduce concentrationCombination devicesGas treatmentParticulatesMetal catalyst

A method of providing an exhaust treatment device is disclosed. The method includes applying a catalyst including gold and a platinum group metal to a particulate filter. The concentration of the gold and the platinum group metal is sufficient to enable oxidation of carbon monoxide and nitric oxide.

Owner:CATERPILLAR INC

Preparation method for high-softening point asphalt

ActiveCN103805220AReduce dosageGood dispersionWorking-up pitch/asphalt/bitumen by chemical meansMolten statePotassium dichromate

The invention discloses a preparation method for high-softening point asphalt. The method includes: respectively spraying molten state asphalt and an oxidant into an oxidation reactor at the same time to undergo oxidation reaction, thus obtaining the high-softening point asphalt. Specifically, the oxidant is nanoscale potassium permanganate and / or nanoscale potassium dichromate. The asphalt and the oxidant are respectively sprayed into the oxidation reactor in the fog state at the same time by a high pressure pump and compressed air to undergo mixing. The method provided by the invention has the advantages of less oxidant consumption, low oxidation temperature, high reaction efficiency, convenient operation, environment-friendly reaction process, and low energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for surface oxidation treatment of uranium oxide powder

InactiveCN101254950AImprove the O/U atomic ratioIncrease surface areaNuclear energy generationReactors manufactureUranium oxideSurface oxidation

The invention relates to a method of oxidation treatment of a surface of a uranium dioxide, which is characterized that the method comprises the following steps: (1) taking the UO2 powder and putting the UO2 powder into a tube type atmosphere oven, heating the UO2 powder under the condition of oxidation medium while the heating rate is 5 to 20 degree centigrade per minute, heating the UO2 powder to 250 degree centigrade to 400 degree centigrade and insulating for 2 to 6 hours; (2) when the UO2 powder is cooled to 100 degree centigrade to the room temperature in the oven, taking the UO2 powder out and cooling the UO2 powder in the air, so as to obtain the uranium dioxide powder with the oxidized surface. The method puts the UO2 in different oxidation medium and the UO2 is insulated at a certain temperature, then the surface oxygen content is increased, the surface area is increased, and the O / U atomic ratio of uranium dioxide and the surface area of the UO2 powder are enhanced. The oxidation medium obtained by the method has rich resources, low oxidation temperature and less consumption and has the advantages of simple fabrication process and low cost.

Owner:CHONGQING UNIV

Method for purifying nano-diamond

The invention discloses a method for purifying nano-diamond. The method comprises the following steps: (1) adding nano-diamond black powder into a mixed liquor of a H2SO4 solution and a H3PO4 solution, heating and stirring, adding KMnO4, controlling the system temperature at 70-100 DEG C, and reacting for 2-3h; (2) cooling the solution after the reaction to room temperature, filtering, and washingwith water to obtain coarsely extracted nano-diamond; (3) adding the crudely extracted nano-diamond to an alkaline solution for stirring and reacting; (4) filtering the reacted solution, washing withwater, and drying to obtain pure nano-diamond. According to the invention, metal ions formed after removal of metal impurities are combined with phosphate anions to form a coordination compound, themetal ions precipitation can be avoided, so that the removal of the metal impurities and graphite can be simultaneously performed, the route is simplified, and the impurity removal efficiency is improved, and concentrated hot phosphoric acid can corrode silicon dioxide to achieve the purpose of preliminary removal of Si and improve the subsequent Si removal efficiency.

Owner:成都天成鑫钻纳米科技股份有限公司

Chemical heat treatment method capable of obviously improving corrosion resistance of gear

ActiveCN103789722AHigh hardnessImprove performanceSolid state diffusion coatingHardnessSurface chemical

The invention belongs to a metal surface chemical heat treatment technology and aims to provide a chemical heat treatment method capable of obviously improving the corrosion resistance of a gear. According to the method, ion oxidation treatment is carried out on the gear which is subjected to ion nitriding, wherein air is used as an air source, the ion oxidation treatment and the ion nitriding are carried out in the same furnace; and after the ion nitriding is carried out on the gear at 560 DEG C, and air is introduced for oxidization for 0.25-1 hour after the temperature is reduced to 350-450 DEG C. According to the chemical heat treatment method, one layer of a dense oxidized film which mainly contains Fe3O4 is generated on the surface of a nitriding layer of the gear; under the same condition, compared with a gear sample which is not oxidized, the gear which is subjected to ion oxidization has the advantages that the corrosion resistance can be obviously improved and the surface rigidity gradient of the nitriding layer is obviously slowed down. The chemical heat treatment method is simple to operate; compared with other oxidization methods, the method provided by the invention has the advantages that no auxiliary equipment is used, an oxidization medium is air, and the oxidization temperature is low and the consumption of energy sources is reduced; moreover, the chemical heat treatment method has the advantages of low treatment cost, high production efficiency and the like.

Owner:溧阳市永恒热处理有限公司

Carbon monoxide low-temperature oxidation catalyst

InactiveCN105195157ALow oxidation temperatureAchieve low temperature oxidationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationCoprecipitation

The invention relates to a carbon monoxide low-temperature oxidation catalyst, which belongs to the field of oxidation catalysts. The carbon monoxide low-temperature oxidation catalyst is characterized in that the chemical formula of the catalyst is La1-XPrXNi1-yCoyO3, wherein x is from 0.35 to 0.50, and y is from 0.28 to 0.36. The carbon monoxide low-temperature oxidation catalyst is prepared by adopting a hydrothermal-coprecipitation method and has the advantages of reducing the carbon monoxide oxidation temperature and realizing low-temperature oxidation. Additionally, in low-temperature oxidation reaction of carbon monoxide, the conversion rate of carbon monoxide is 98.7% at 83 DEG C, the conversion rate of the carbon monoxide is 96.5% after reaction for 200 h due to the catalyst, and good catalytic oxidation is realized in low-temperature oxidation of carbon monoxide.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Aluminum section bar surface brightening method

InactiveCN109913925AWith cleanReduce production speedAnodisationElectrophoretic coatingsPhosphoric acidColor changes

The invention discloses an aluminum section bar surface brightening method. The aluminum section bar surface brightening method comprises the steps of sand blasting, oil removing, water washing, polishing, oxidizing, coloring, medium-temperature hole sealing and electrophoresis curing, wherein the polishing is performed inside a three-acid polishing tank, the three-acid polishing tank contains theingredients of, in percentage by weight, 65-85% of phosphoric acid, 14-22% of sulfuric acid and 6-8% of nitric acid, the polishing is performed for 20-25 min under the condition of the polishing temperature being 100-110 DEG C, and by means of reduction of the oxidizing temperature and the oxidizing tank sulfuric acid concentration, the oxide film production speed can be reduced, a more uniform and compact oxide film is obtained, and appearance of flow marks in aluminum materials is reduced; and the aluminum materials are not prone to fading when being subjected to the water washing and electrophoresis after being subjected to the coloring and the hole sealing and high adhesion can be obtained when the electrophoresis is performed in a half hole sealing state, and when combination with the electrophoresis is performed, suitable voltage can slow down the paint film coating speed, in addition of an appropriate curing method, dye color changing and coating surface roughness and excessivebrittleness can be prevented, and the coating adhesion is improved.

Owner:佛山市南海区和顺超强铝型材有限公司

Method of producing a catalysed particulate filter and filter thus obtained

InactiveCN101018602ALow oxidation temperatureDispersed particle filtrationSilencing apparatusParticulatesPorosity

The invention relates to a method of producing a catalysed particulate filter. The invention is characterised in that, in order to lower the particulate oxidation temperature, the filter is provided with a cerium oxide, a zirconium oxide or a cerium / zirconium mixed oxide which can also comprise at least one rare earth oxide other than cerium. The porosity of said oxide or mixed oxide is such that at least 80 % of the pore volume comprises pores having a diameter of least 20 nm.

Owner:RHODIA CHEM SA

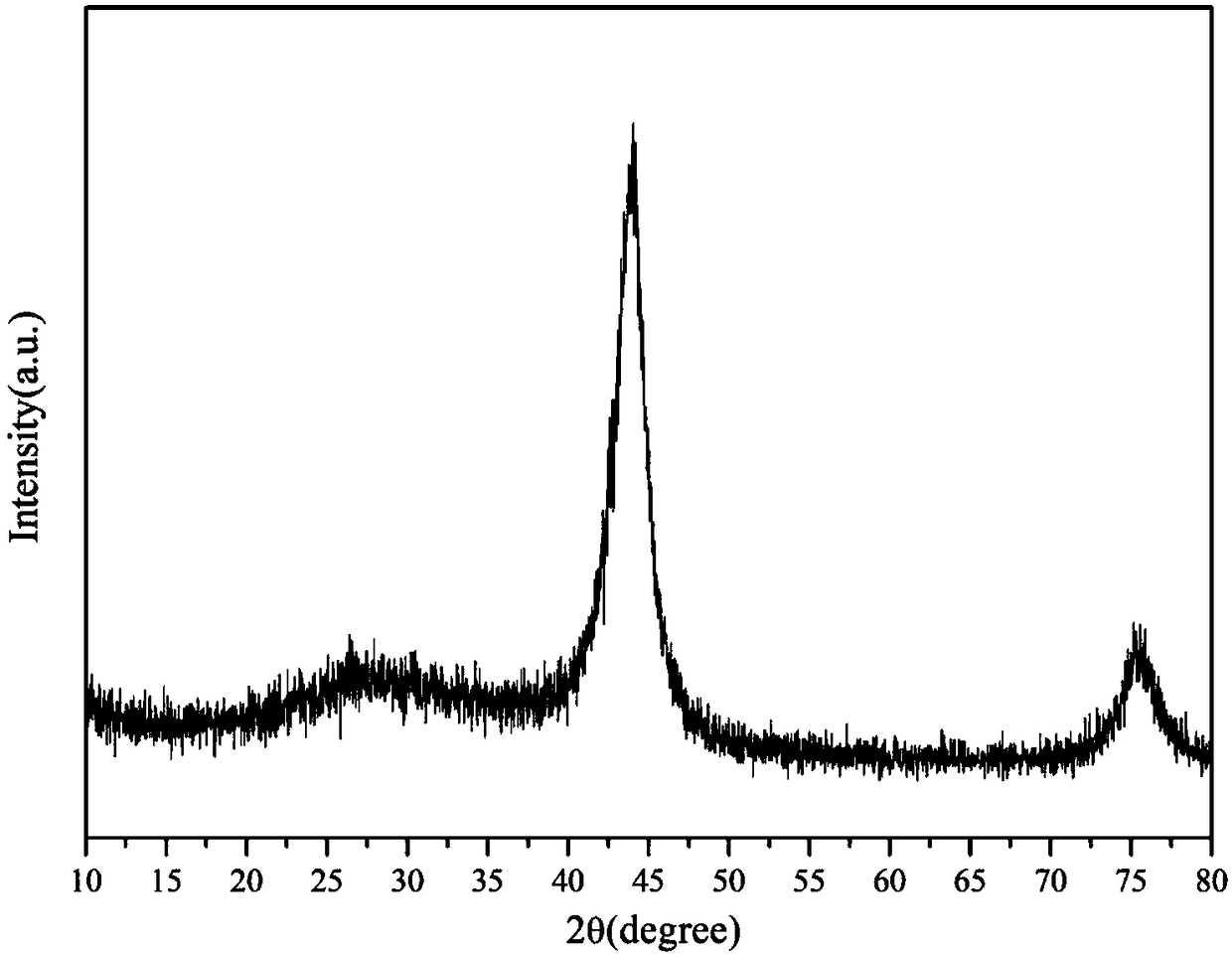

Layered composite oxide, oxidation catalyst, and diesel particulate filter

InactiveUS9091195B2Improve conductivityLow oxidation temperatureInternal combustion piston enginesCell electrodesPlatinumOxygen ions

A layered composite oxide is provided which is excellent in oxygen ion conductivity and, is capable of effectively decreasing a PM oxidation temperature without using a noble metal such as platinum or the like. The layered composite oxide is used in an oxidation catalyst, DPF, a ternary catalyst, and a NOx purification catalyst. The layered composite oxide has a composition represented by the following formula (1), La1.5Sr1.5Mn2-yByO7 . . . (1) (wherein B represents Cu and / or Fe, and y satisfies 0<y≦0.2).

Owner:NISSAN MOTOR CO LTD

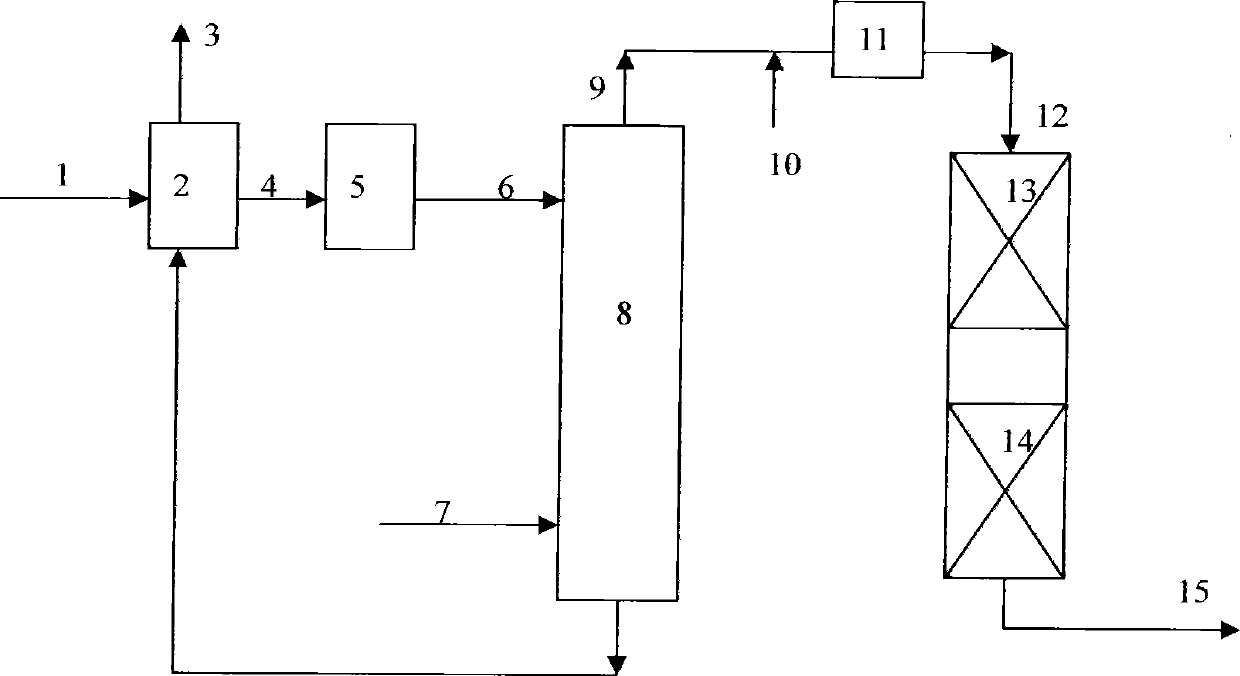

Method for treating sulfur-containing and hydrocarbon-containing waste gas

ActiveCN102441326BLow failure rateReduce energy consumptionDispersed particle separationCatalytic oxidationTower

The invention discloses a method for treating sulfur-containing and hydrocarbon-containing waste gas, in particular to a method for treating the exhausted gas which is generated from a sour water tank, a slop oil tank and an oxidized sweetening device of an oil refinery. The sulfur-containing and hydrocarbon-containing waste gas firstly enters into an absorption tower to be subjected to absorption and dehydrocarbon by low-temperature diesel oil, and then enters into a catalytic oxidation reactor, and then respectively passes through a catalytic oxidation desulfurization layer and a catalytic oxidation dehydrocarbon bed layer to be purified and finally exhausted. The method guarantees the hydrocarbon components of the waster gas to be effectively recycled and also guarantees the exhaust gas to be discharged up to the standard, thereby having good comprehensive treating effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

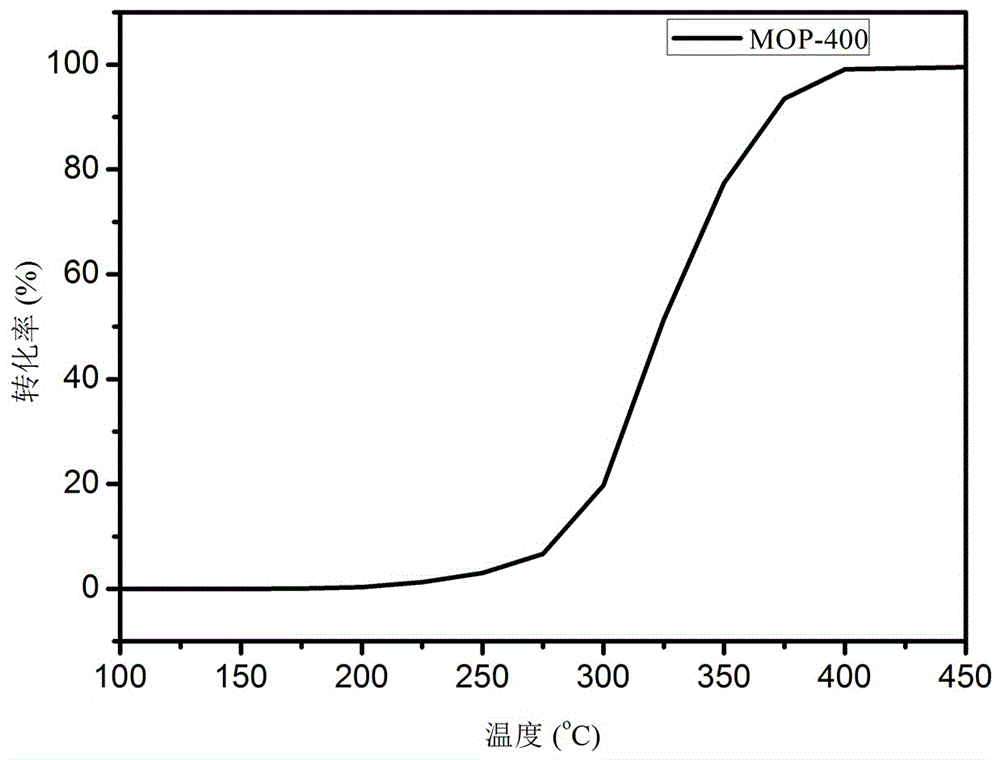

Supported catalyst for preparing NOx through ammonia low-temperature catalytic oxidization, preparation and application thereof

ActiveCN106179340ALow oxidation temperatureReduce dosageNitrogen compoundsMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationReaction temperature

The invention relates to preparation of a supported catalyst for preparing NOx through ammonia low-temperature catalytic oxidization. The supported catalyst is used in an ammonia oxidization process in nitric acid industry. The catalyst is prepared by supporting an active component, Pt, on manganese oxide in an impregnation manner, wherein the MnOx, as the supporter, can increase active sites of the Pt, so that the ammonia gas can be completely converted into the NOx just at 400 DEG C. The supported catalyst greatly reduces reaction energy consumption and has good market application prospect. The catalyst supported by MnOx has low reaction temperature and high activity, effectively reduces the use quantity of noble metal in ammonia oxidization and is reduced in cost.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Carbon fiber with low cost and high strength

InactiveCN111926414ALow costReduce energy consumptionArtifical filament manufacturePolymer scienceCarbon fibers

The invention relates to a carbon fiber with low cost and high strength. The carbon fiber is prepared from the components in parts by mass: acrylonitrile 10-50 parts, methyl acrylate 1-5 parts, itaconic acid 1-5 parts, an additive 0.1-5 parts, coagulation bath 0.1-2 parts, an initiator 0.1-1 part and a solvent 30-80 parts. The additive is at least one of carbon nanotubes and original graphene. Byadding at least one of carbon nanotubes and original graphene, the oxidation temperature of polyacrylonitrile precursor can be reduced, the energy consumption can be significantly reduced and cost inthe manufacturing process of carbon fiber can be reduced, and the produced carbon fiber has high tensile strength.

Owner:ANHUI XUSHENG NEW CONCEPT MATERIAL CO LTD

Method for industrially producing crotonic acid by adopting microchannel reactor

ActiveCN114560765AShort reaction timeImprove efficiencyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsRecyclable catalystCrotonaldehyde

The invention discloses a method for industrially producing crotonic acid by adopting a microchannel reactor, and relates to the technical field of chemical production of crotonic acid. A silicon carbide ceramic plate type micro-channel reactor is adopted, crotonaldehyde, a catalyst and an initiator are mixed and preheated according to a certain proportion, meanwhile, a gaseous oxidizing agent is introduced into the reactor, when the pressure in the reactor reaches 0.6-2.0 MPa, the mixed solution is injected into the micro-channel reactor through a metering pump for a reaction, the retention time of the materials is 8-30 min, and then the crotonaldehyde is obtained. The crotonic acid finished product can be obtained through the processes of material oxidation, crude product crystallization, crude product fine washing, fine product crystallization, drying granulation, catalyst regeneration and the like, the one-time yield of the product can reach 60%, and the mechanical application yield can reach 95%. The method has the advantages of good mass transfer and heat transfer effects, short oxidation reaction time, high product yield, high safety degree, few process steps, recyclable catalyst, low production cost, recyclable raw materials in each step, high reaction speed, low wastewater energy consumption and the like.

Owner:广西金源生物化工实业有限公司

Low-loss metallized film

InactiveCN107301917ALow oxidation temperatureSlow oxidationFixed capacitor electrodesThin/thick film capacitorAntioxidant capacityPolyolefin

The present invention relates to a low-loss metallized film comprising a dielectric base film. A silver-zinc-aluminum composite metal layer is arranged on the dielectric base film, an aluminum-plated layer is arranged on the surface of the silver-zinc-aluminum composite metal layer, the surface of the aluminum-plated layer is provided with a carbon nano tube layer, the surface of the carbon nano tube layer is provided with a seal oil protective layer, the dielectric base film is a polypropylene film or a polyolefin film, and the seal oil protective layer is made of methyl silicone oil. The metalized film of the invention has high anti-oxidation ability, prevents the film from being oxidized and broken during the process of making capacitors, has low metal layer loss, and solves the problem that the metalized film heat is hard to emit resulting in the continuous oxidative breakdown. The invention also discloses a processing method of the above low-loss metallized film.

Owner:ANHUI NINGGUO HAIWEI ELECTRONICS

Sulfur-tolerant catalyst for removing co and vocs and preparation method of sulfur-tolerant catalyst

InactiveCN113663695AGreat operating flexibilityHigh activityGas treatmentDispersed particle separationAmmonium sulphideActivated carbon

The invention discloses a sulfur-tolerant catalyst for removing co and vocs and a preparation method of the sulfur-tolerant catalyst. The sulfur-tolerant catalyst comprises a carrier, a coating, Pt, Pd, Ir, auxiliaries, Co, Mo and S. The method comprises the following steps of: dissolving cobalt salt, molybdenum salt and ammonium sulfide under an acidic condition, adding activated carbon into a dissolving solution for dipping, then performing aging, adding hydrazine hydrate for reflux, performing cooling, filtering, washing and drying in vacuum; soaking a carrier in a coating mixed solution, performing purging, drying, calcining, and soaking the carrier in a mixed solution of a chloroplatinic acid solution, a chloropalladic acid solution, a chloroiridic acid solution and a nitrate solution for more than 6 hours by adopting an equivalent-volume impregnation method; finally, adding a reducing agent at 40-80 DEG C, taking out the carrier, washing and drying the carrier so as to obtain a target product, putting the target product and a Co-Mo-S catalyst into a porous container together. The catalyst reduces the activation energy of organic matter, enables the oxidation temperature of the organic matter to be reduced to 300 DEG C to be subjected to oxygenolysis, and is good in sulfur-resistant effect and good in poison resistance to other harmful substances.

Owner:南京宇清环境科技有限公司 +1

Silver copper based metal oxide electrical contact material containing adding elements and preparation method thereof

The invention discloses a silver copper based metal oxide electrical contact material containing adding elements and a preparation method thereof. The electrical contact material is characterized by comprising the following components in percentage by weight: (20-50)% of silver metal oxide alloy, (0.3-9)% of electric conductive ceramics, (0.7-1.8)% of lanthanum nickel alloy, (0.7-4.9)% of adding elements, and the balance of silver copper alloy; and the contact material provided by the invention comprises the following simple substance elements in percentage by weight: (15-63)% of silver, (4-25)% of metal oxide, (0.3-9)% of electric conductive ceramics, (0.01-5)% of rear earth, (0.7-4.9)% of adding elements, and the balance of copper. The preparation method is characterized by comprising the following steps: smelting, pulverizing and milling (silver metal alloy power, and silver copper alloy powder) in proportion for optimization performances of the material, cladding electric conductive ceramic micro powder by silver, mixing powder of the adding elements in a certain mass ratio, pressing an ingot blank, sintering and extruding, rolling or drawing, thus obtaining the contact material. The electrical contact material provided by the invention has the advantages of low cost and excellent overall performance.

Owner:张树堂

Preparation method of high softening point asphalt

ActiveCN102464989BIncrease profitQuality improvementWorking-up pitch/asphalt/bitumen by chemical meansMolten stateTemperature control

The invention provides a preparation method of high softening point asphalt, and the method comprises: heating an asphalt raw material to a molten state, subjecting the asphalt raw material, reaction additives accounting for 0.01%-5% of the total mass of the asphalt raw material, as well as air to full premixing reaction, with the mixing temperature controlled at 80-180DEG C and the mixing time controlled at 1min-40min; then introducing the mixture to an oxidation reactor for air blowing oxidation at a temperature of 200-340DEG C for 3-10h, with the air blowing rate of an oxidation tower maintained at 0.05-0.5m<3>.kg<-1>.h<-1>, thus obtaining a high softening point asphalt product with excellent high temperature performance and temperature susceptibility resistance. The method of the invention solves the problems of overlong reaction time, nonuniform air distribution, easy coking, short oxidation tower operation cycle, and poor product performance, etc. existing in current high softening point asphalt production processes by oxidation method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of high-softening-point asphalt particles for drilling fluid

ActiveCN102464988BImprove reaction efficiencySimple processWorking-up pitch/asphalt/bitumen by chemical meansWorking-up pitch/asphalt/bitumen by solidifying/disintegratingWell drillingDissolution

The invention provides a preparation method of high-softening-point asphalt particles for drilling fluid. The preparation method comprises the following steps of: (1) preparing high-softening-point asphalt; and (2) placing the high-softening-point asphalt in a closed container, heating to 80-190 DEG C, adding a solvent for dissolution, mixing uniformly, introducing inert gas to regulate the pressure of the closed container to be 3.0-10.0MPa, stabilizing for 10-80min, then feeding into a separator through a throttling valve to form asphalt particles, and recovering the solvent in a gaseous-state form. According to the invention, the problem that the high-softening-point asphalt is difficult to smash into fine particles is solved. The asphalt particles can be widely applied to deep oil gas well drilling operation processes to serve as an important constituent part of the drilling fluid and play the roles in preventing collapse, stopping leakage, reducing filter loss and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic oxidation catalyst for methyl acetate in organic waste gas and preparation method thereof

ActiveCN102247867BEasy to makeSuitable for large-scale productionMetal/metal-oxides/metal-hydroxide catalystsCeriumCatalytic oxidation

The invention discloses a catalytic oxidation catalyst for methyl acetate in organic waste gas and a preparation method thereof. The catalyst is a supported noble metal alloy catalyst, wherein the noble metal alloy is an arbitrary metal combination of two or more of Pd, Pt, Rh, Au and Ag; the vector is activated alumina and / or titanium dioxide, as well as at least one transition metal oxide whichcomprises metal oxide of manganese, cerium, nickel, lanthanum, copper, vanadium, tungsten, iron, cobalt or chrome; and the weight ratio of the noble metal alloy to the vector is (1:2,000)-(1:5). The catalyst provided by the invention can be used for treating organic waste gas containing methyl acetate, especially for treating waste gas of a PTA (purified terephthalic acid) device, by a catalytic oxidation method; and the catalyst has the advantages of simple preparation, high catalytic oxidation activity, good stability, excellent halogenated hydrocarbon poisoning resistance and high practical application value.

Owner:CHINA PETROLEUM & CHEM CORP +1

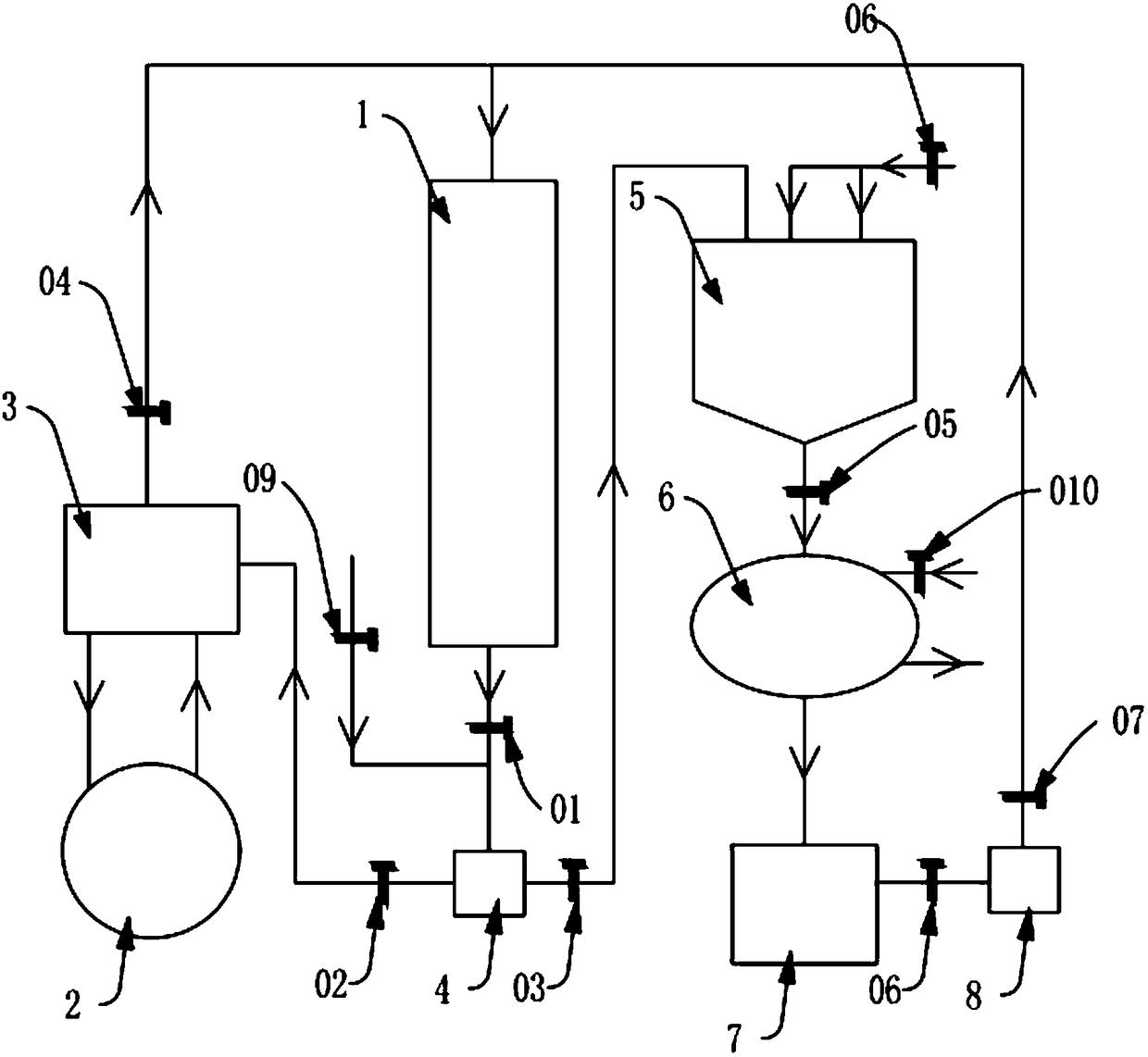

Recovery of aluminum ions and sulfuric acid from oxidation tank and energy-saving system and process of switching to pulse power supply

ActiveCN106757256BHigh densityReduce the amount of dissolutionAnodisationCellsAluminum IonHigh energy

The invention discloses an oxidation tank aluminum ion and sulfuric acid recovery and modification pulse power supply energy saving system and a process, and solves the problems of high temperature on an oxidation interface, high dissolving quantity of an oxide film and high energy oxidation consumption in traditional aluminum alloy oxidation. A modification pulse power supply energy saving device comprises an oxidation tank, a refrigerator, a titanium exchanger, a pump 1, an overflow tank and a pipe, and further comprises a movable oxidation polar plate device; the movable oxidation polar plate device includes multiple driving motors, a mobile positioning device, a mobile cathode cooling pipe, an anode electric conducting base and a cathode electric conducting device; and a communicated oxidation power supply of the anode electric conducting base is a frequency / amplitude-adjusted pulse direct-current oxidation power supply. A main system using the energy saving device further comprises an aluminum ion crystallization product recovery system, a sulfuric acid oxide liquid recovery system, a gas stirring system and a defrosting system. A recovery process using the energy saving main system comprises an oxide liquid circular cooling step, an aluminum ion crystallization product recovery step, a sulfuric acid oxide liquid recovery step, a gas stirring step and a defrosting step.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

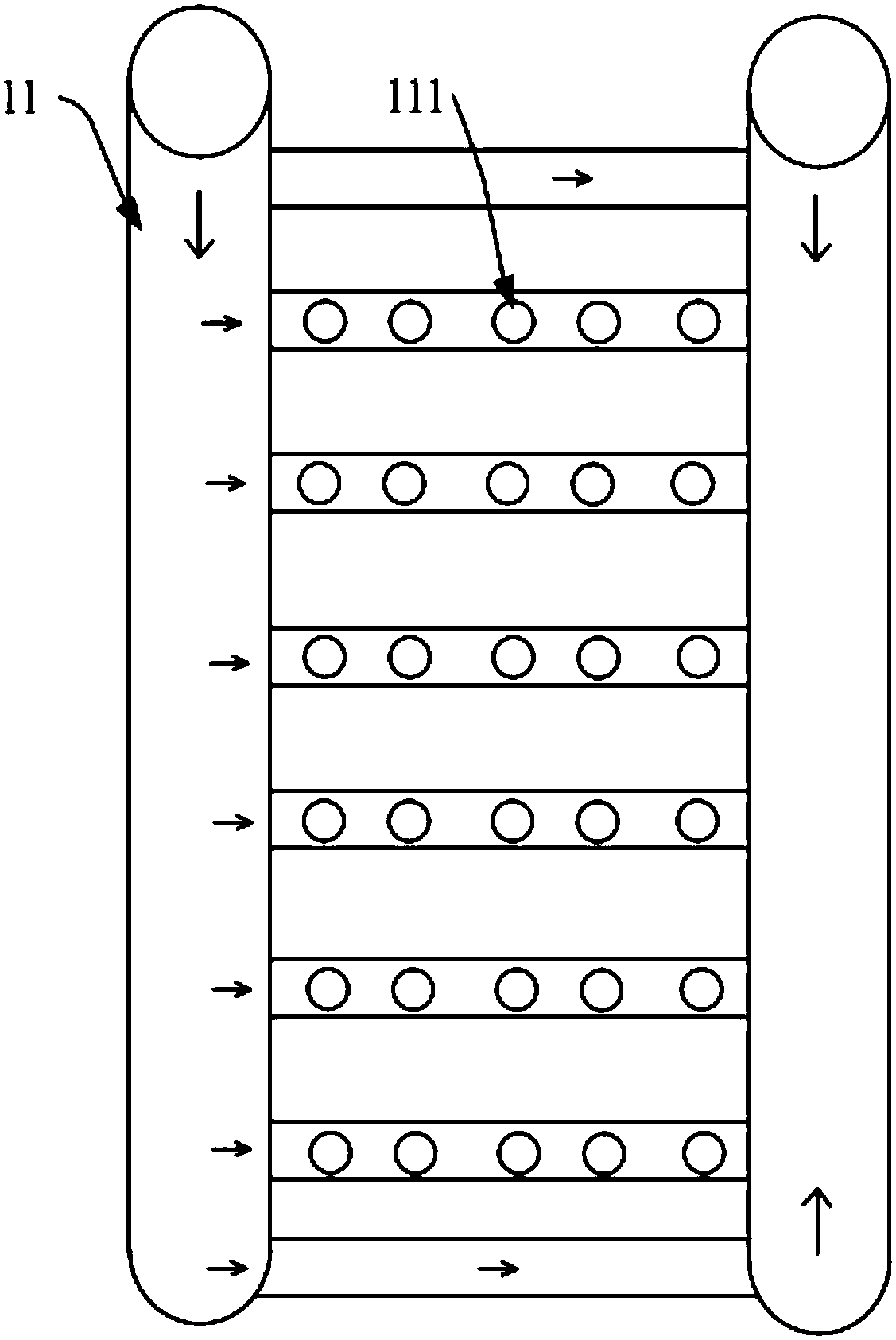

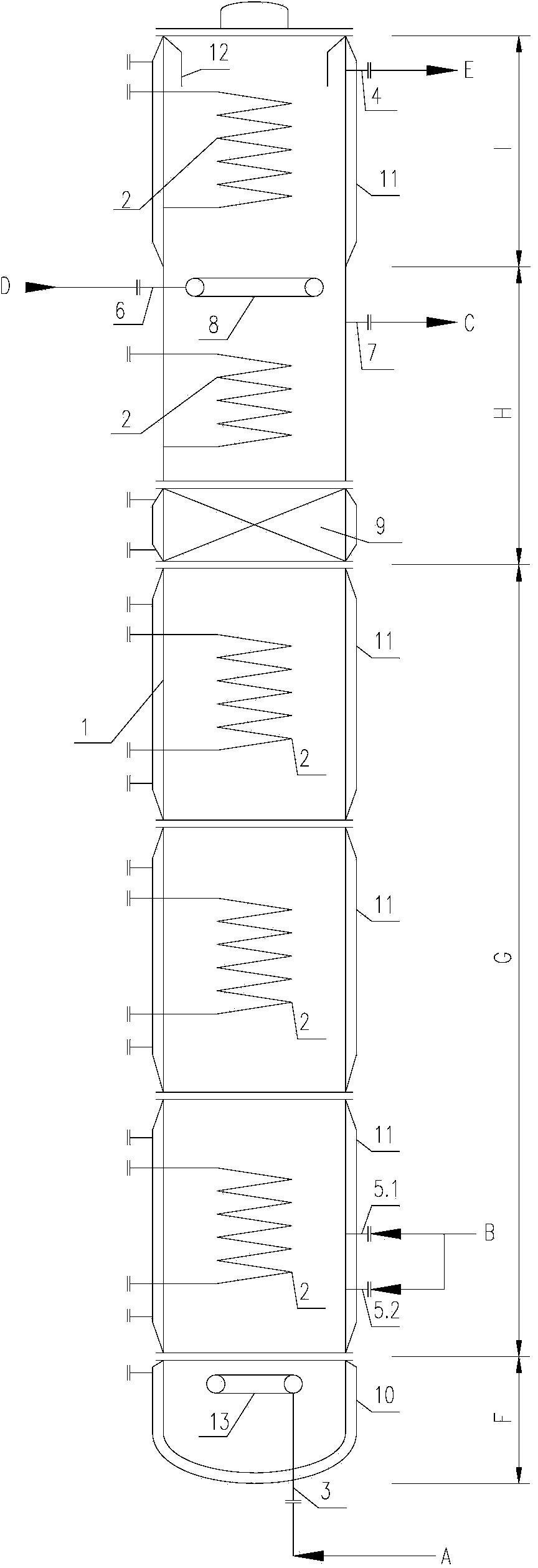

Thioether oxidation tower for producing dimethyl sulfoxide

InactiveCN104275132ALiquid level stabilityLow oxidation temperatureOrganic chemistryOrganic compound preparationGas phaseNitric oxide

The invention discloses a thioether oxidation tower for producing dimethyl sulfoxide, for solving the problems of the existing oxidation tower that liquid level in the tower is not stable, safety is poor, the content of nitric oxide in tail gas is high, and the control difficulty is high. According to the technical scheme of the invention, the thioether oxidation tower comprises a tower body; the tower body is divided into a heating area, a reaction area, a sub-cooling area and a cooling area from bottom to top; each of the reaction area, the sub-cooling area and the cooling area is internally provided with a cooling water coil pipe and a cooling water jacket on the wall of the tower; the heating area is provided with an oxidation air inlet; the reaction area is provided with a thioether feeding point; a tail gas outlet is formed at the upper section of the cooling area; the sub-cooling area is provided with a sulfoxide outlet under the liquid level; the upper section of the sub-cooling area is provided with a compressed air inlet. The thioether oxidation tower is simple in structure, simple and convenient to operate, good in reliability and low in oxidizing temperature; in addition, the liquid level in the tower is stable, no gas-phase reaction is generated and the content of nitric oxide in the tail gas is low.

Owner:武汉江汉化工设计有限公司

Composite catalyst and method for catalyzing complete oxidation and elimination of formaldehyde via composite catalyst

ActiveCN112808301AIncrease the active siteHigh catalytic activityMolecular sieve catalystsDispersed particle separationMolecular sievePtru catalyst

The invention relates to the technical field of environmental catalysis, and aims to provide a composite catalyst and a method for catalyzing complete oxidation and elimination of formaldehyde via the composite catalyst. According to the invention, formaldehyde and air are used as reaction raw materials and are subjected to a conversion reaction on a fixed bed or a moving bed; and a used catalyst is the composite catalyst and is formed by compounding a component I and a component II in a mechanical mixing mode, wherein the active component of the component I is a molecular sieve with medium-strong acid sites, the active component of the component II is a noble metal catalyst, a weight ratio of the component I to the component II is in a range of 0.01-20, and the axis distance between particles of the component I and the component II is in a range of 50 nm-40 mm. The composite catalyst is high in the activity of low-temperature catalysis of formaldehyde oxidation, and can oxidize formaldehyde in the atmospheric environment into non-toxic and harmless CO2 and H2O via O2 molecules in air within a temperature range of 20-80 DEG C; and the concentration of formaldehyde in the treated air is lower than a room concentration required by national environmental protection in China.

Owner:DALIAN UNIV OF TECH

Method of producing a catalyzed particulate filter and filter thus obtained

InactiveCN100553760CLow oxidation temperatureDispersed particle filtrationSilencing apparatusPorosityRare-earth element

The invention relates to a method for the production of a catalytic particle filter, characterized in that, in order to lower the oxidation temperature of the particles, cerium oxide, zirconium oxide or a mixed oxide of cerium and zirconium is used to introduce it into the filter, the cerium and zirconium The mixed oxide may additionally include at least one oxide of a rare earth element other than cerium. The porosity of such oxides or mixed oxides is such that at least 80% of the pore volume consists of pores with a diameter at least equal to 20 nm.

Owner:RHODIA CHEM SA

A kind of composite catalyst and method for catalyzing complete oxidation and elimination of formaldehyde

ActiveCN112808301BIncrease the active siteHigh catalytic activityMolecular sieve catalystsDispersed particle separationMolecular sievePtru catalyst

The invention relates to the technical field of environmental catalysis and aims to provide a composite catalyst and a method for catalyzing the oxidation and elimination of formaldehyde. It takes formaldehyde and air as the reaction raw materials, and carries out the conversion reaction on a fixed bed or a moving bed. The catalyst is a composite catalyst, which is composed of component I and component II by mechanical mixing. The active ingredient of component I is Molecular sieve with medium-strong acid sites, the active ingredient of component II is a noble metal catalyst; the weight ratio of component I to component II is in the range of 0.01-20, and the axial distance between the particles of component I and component II is between Between 50nm‑40mm range. The composite catalyst has high catalytic formaldehyde oxidation activity at low temperature, and can utilize O in the air in the temperature range of 20-80°C 2 Molecules oxidize formaldehyde in the atmosphere to non-toxic and harmless CO 2 and H 2 O. The formaldehyde concentration in the air after treatment is lower than the indoor concentration required by the national environmental protection.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com