Supported catalyst for preparing NOx through ammonia low-temperature catalytic oxidization, preparation and application thereof

A supported catalyst and low-temperature catalysis technology, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, nitrogen compound, etc., can solve the problems of platinum consumption increase and platinum loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 0.5g MnOx was impregnated in 0.3wt% chloroplatinic acid solution, dried at 80°C for 10h, then reduced with hydrogen at 300°C for 4h, washed and dried to obtain the MnOx-loaded Pt catalyst, denoted as MOP-300.

[0030]

Embodiment 2

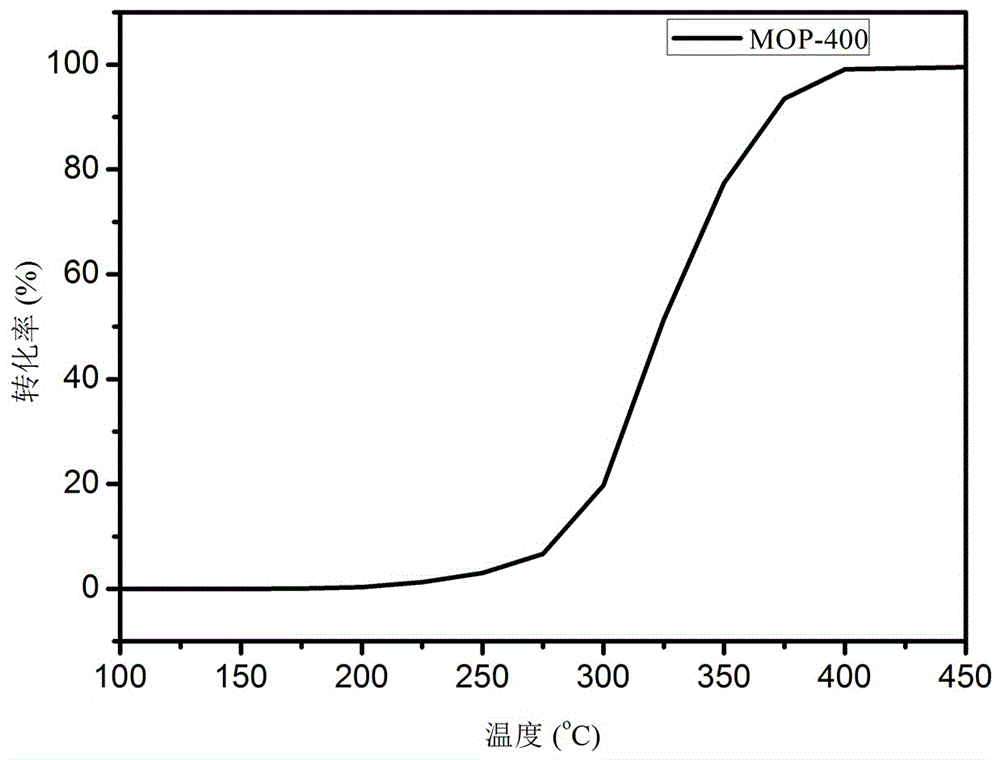

[0032] 0.5g MnOx was impregnated in 0.3wt% chloroplatinic acid solution, dried at 80°C for 10h, then reduced with hydrogen at 400°C for 4h, washed and dried to obtain MnOx-loaded Pt catalyst, denoted as MOP-400.

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com