A kind of composite catalyst and method for catalyzing complete oxidation and elimination of formaldehyde

A composite catalyst and complete oxidation technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor dispersion of active components, large size of active components, unfavorable catalytic activity, etc., to achieve effective Good for dispersion, enhanced catalytic activity, good for reactivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

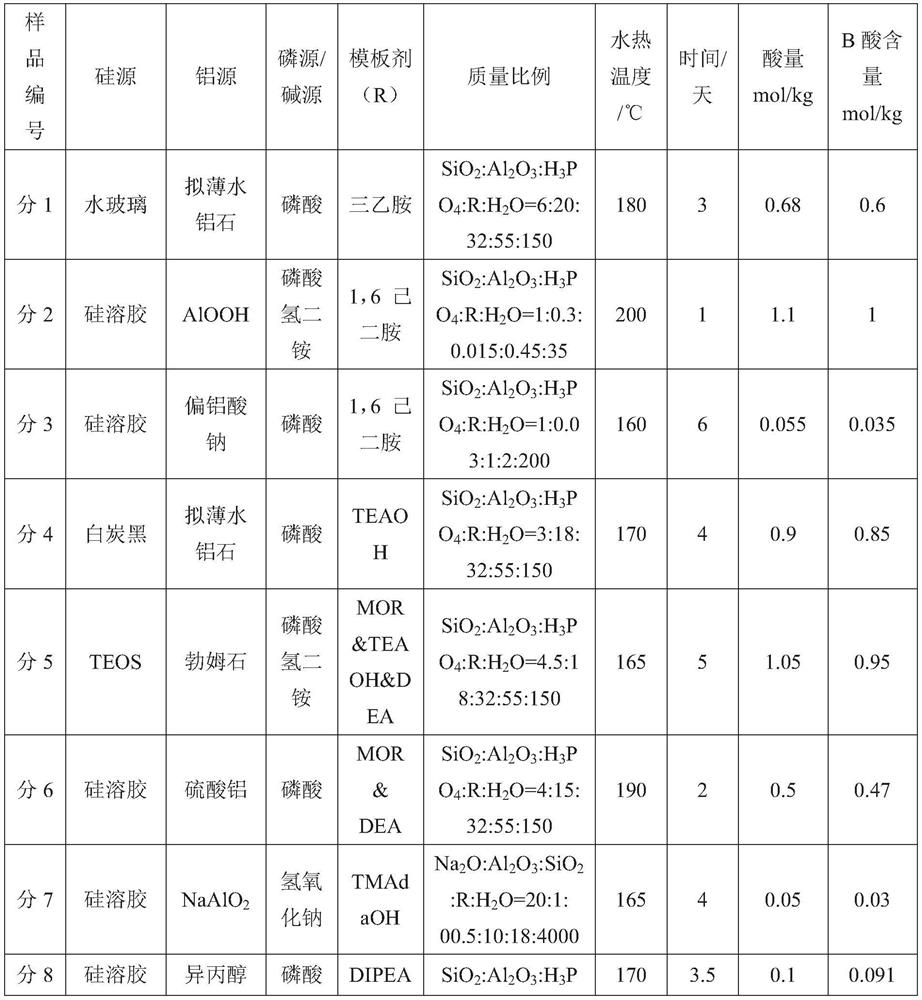

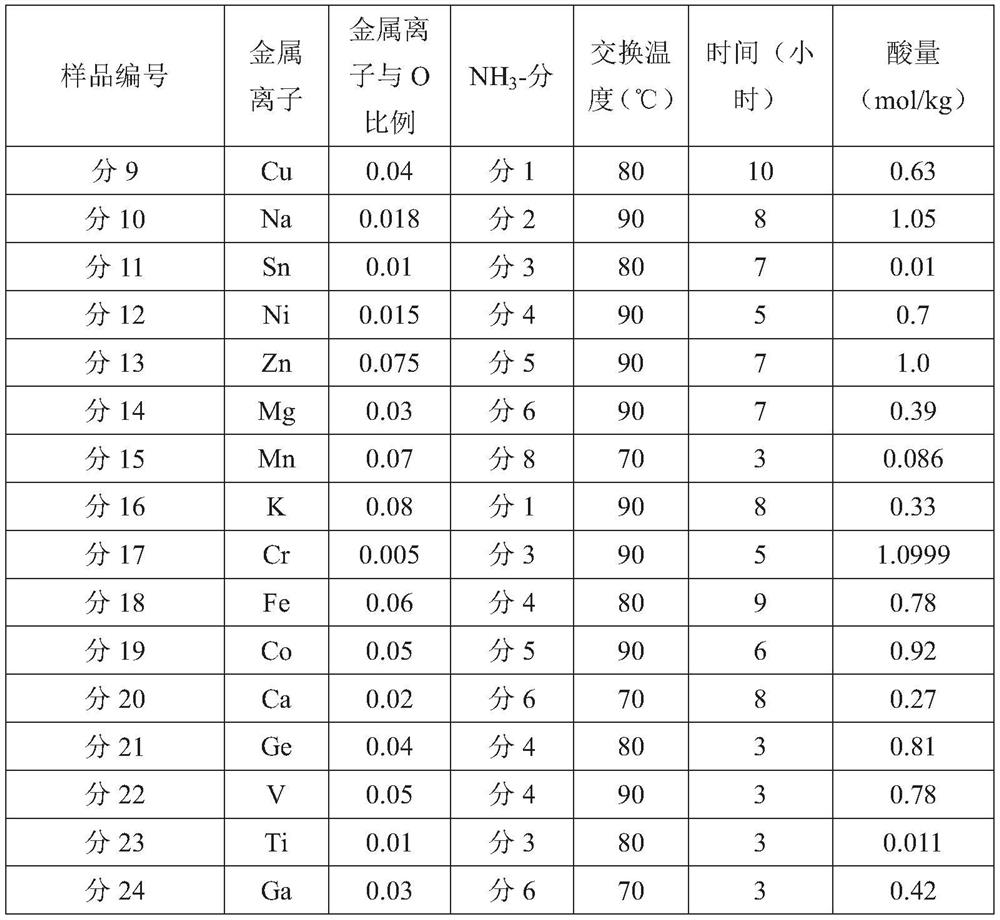

[0063] The preparation method of heteroatom-doped molecular sieves is similar to that of CHA and AEI topology molecular sieves, only a certain amount of corresponding metal salts are added to the synthetic raw materials. According to M:SiO 2 :Al 2 o 3 :H 3 PO 4 :R:H 2 O=0.001-0.1:4:16:32:55:150 Weigh the raw materials, wherein the metal element type of M is the same as the metal type of the above-mentioned ion exchange, and R is a template agent.

[0064] Mix the metal salt precursor, aluminum sulfate and sodium hydroxide solution, then add silica sol, phosphoric acid, TEA(R); deionized water, stir for 1 h to obtain a homogeneous initial gel, and then transfer it to a high-pressure synthesis kettle , high-temperature static crystallization, quenching, washing, and drying to obtain molecular sieve samples. The synthesis and properties of partially heteroatom-doped molecular sieves with CHA and AEI topological structures are shown in Table 3.

[0065] Table 3. Preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com