Nitrogen phosphorus co-doped porous carbon-coated copper phosphide composite catalyst and its preparation method

A cuprous phosphide and co-doping technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of less research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Synthesis of nitrogen and phosphorus co-doped porous carbon material coated cuprous phosphide composite electrocatalytic hydrogen production catalyst.

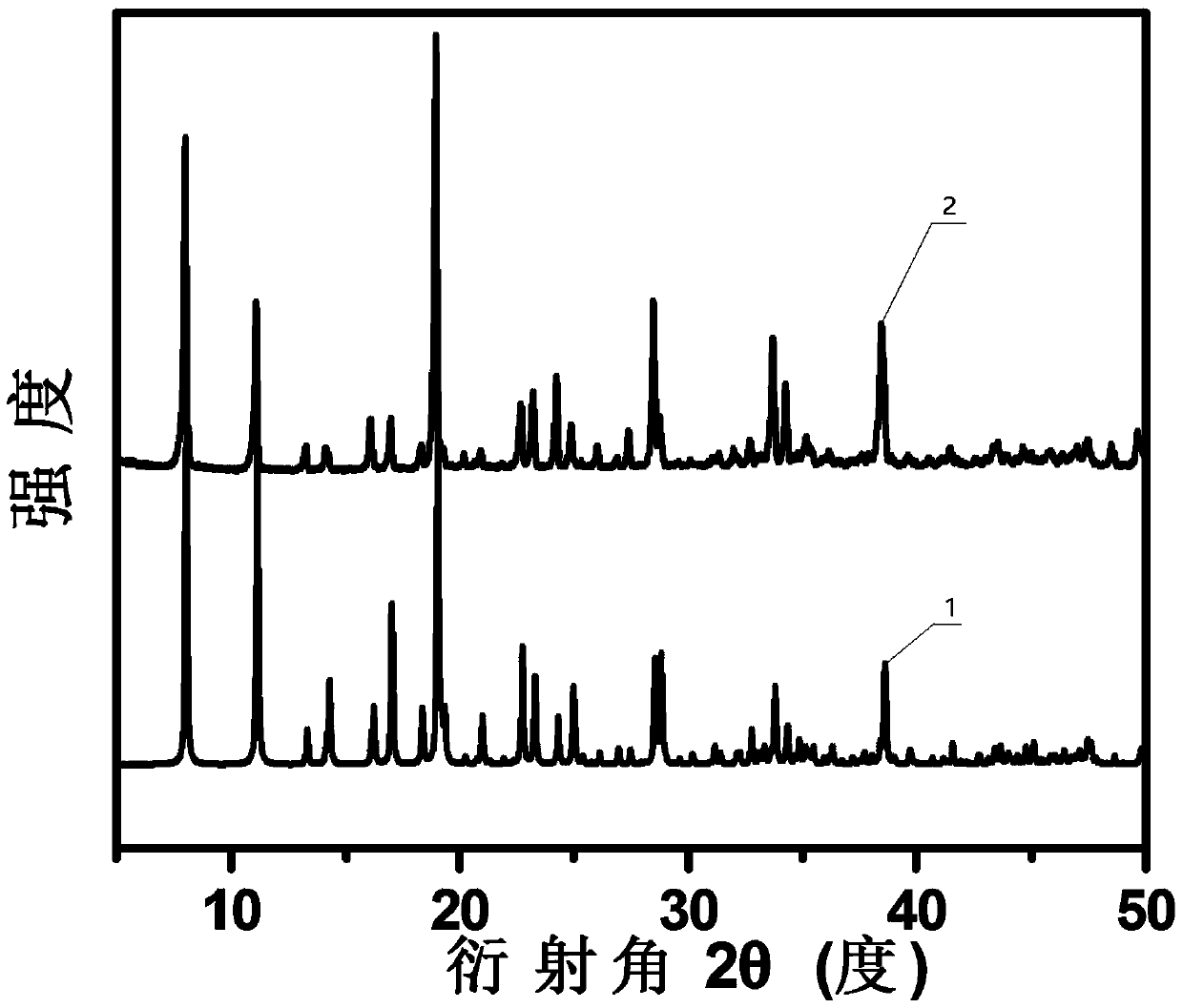

[0031] (1) Dissolve 0.52 g of copper nitrate trihydrate, 0.55 g of hydroxyethylidene diphosphonic acid and 0.16 g of pyrazine in 20 mL of deionized water, and add sodium hydroxide to the above solution to adjust the pH of the system to 3. Then stirred and refluxed at 140° C. for 6 h to obtain a blue turbid solution. After filtering, washing with water until the filtrate is neutral, the precursor (Cu-NPMOF) blue solid powder is obtained after vacuum drying. PXRD of the precursor such as figure 1 As shown, the prepared precursor has strong diffraction peaks and almost completely agrees with the PXRD peaks simulated by single crystal data, indicating that the prepared precursor has high crystallinity and purity.

[0032] (2) Put 200 mg of the blue solid powder obtained in step (1) into a quartz boat, place the...

Embodiment 2

[0036] Example 2: The performance test of the nitrogen-phosphorus co-doped porous carbon material coated cuprous phosphide composite material of the present invention as an electrocatalyst.

[0037] Preparation of electrocatalyst working electrode:

[0038] 2mg of Cu prepared by the present invention 3 The P@NPPC catalyst was added to a mixed solution of 400uL ethanol and 80uL deionized water, 20uL of 5% Nafion solution by mass percentage was added, and a uniformly dispersed catalyst slurry was obtained after ultrasonic dispersion for 30min. 5uL of the slurry was drop-coated on the glassy carbon electrode and dried at room temperature for use. The electrocatalyst performance test adopts a three-electrode system, and the electrolyte is 0.5mol L -1 of sulfuric acid solution. The test instrument is Shanghai Chenhua CHI660E Electrochemical Workstation.

[0039] like Image 6 Shown, at 0.5mol L -1 In the sulfuric acid electrolyte, the electrode loaded with the catalyst has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com