Electrocatalytic porous titanium filter membrane with micro nano structure and preparation method thereof

A technology of micro-nano structure and porous titanium, applied in chemical instruments and methods, chemical elements of heterogeneous catalysts, physical/chemical process catalysts, etc., can solve problems such as low specific surface area, restrictions on flat titanium electrodes, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

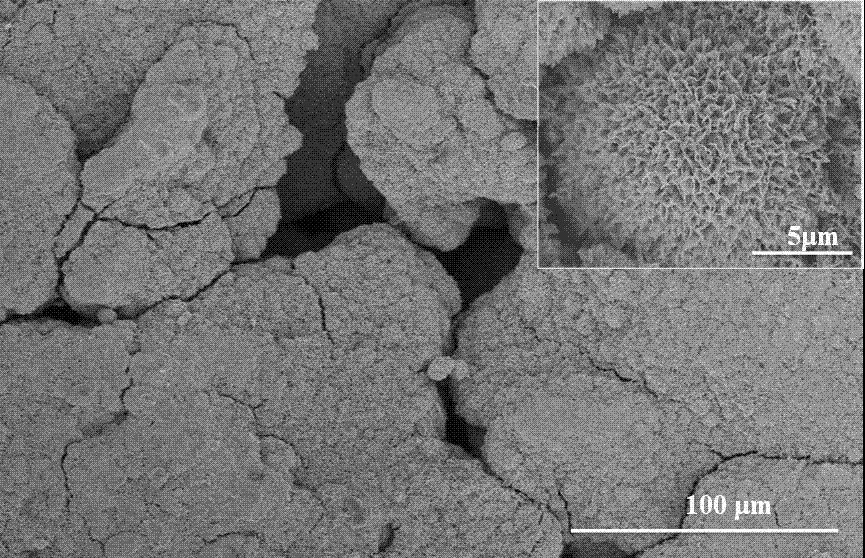

[0019] 1) Pretreatment of porous titanium substrate: select flat porous titanium as the substrate, with an average pore size of 30 μm, soak the porous titanium in a mixed acid solution of HF acid and HCl for 15 minutes, where the volume ratio of concentrated HF acid: concentrated HCl acid: deionized water The ratio is 1.5:1.5:200, and then washed with absolute ethanol and placed in a vacuum dryer, then vacuum-dried at 80°C, cooled to room temperature for use;

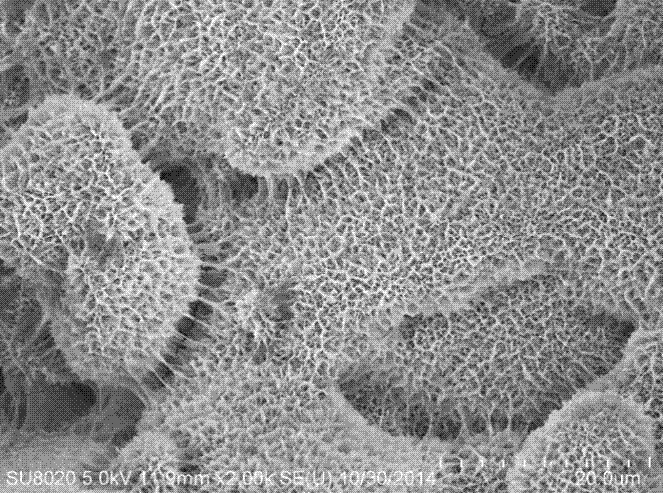

[0020] 2) Construction of micro-nano structure TiO by hydrothermal method 2 Nanowire middle layer: place the pretreated porous titanium in step 1) in a high-pressure reactor containing 5 mol / L NaOH solution, and conduct a hydrothermal reaction at 180°C for 24 h. After cooling, take out the porous titanium sample and remove it. Wash with deionized water, then soak in 0.1 mol / L HCl solution for 24 hours, dry at 80°C, and finally transfer to muffle furnace for sintering at 500°C for 2h, cool to room temperature for use;

...

Embodiment 2

[0023] 1) Pretreatment of porous titanium substrate: select tubular porous titanium as the substrate, with an average pore size of 50 μm, soak the porous titanium in a mixed acid solution containing HF acid and HCl acid for 15 min, in which concentrated HF acid: concentrated HCl acid: remove The volume ratio of ionic water is 1:1:200, and then washed with absolute ethanol and placed in a vacuum drying chamber, then dried in a vacuum at 80°C, and cooled to room temperature for use;

[0024] 2) Construction of micro-nano structure TiO by hydrothermal method 2 The middle layer of nanoflowers: place the pretreated porous titanium in step 1) in a high-pressure reactor containing 6 mol / L NaOH solution, and conduct a hydrothermal reaction at 180°C for 12 h. After cooling, take out the porous titanium sample and remove it. Wash with deionized water, then soak in 0.1 mol / L HCl solution for 24 hours, dry at 80°C, and finally transfer to muffle furnace for sintering at 500°C for 2h, cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com