Preparation method and application of metallic Ag nano-particle deposited NiCo-LDH composite photocatalyst

A nanoparticle and composite light technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low electron-hole pair separation efficiency and photoresponse Narrow range, low photocatalytic degradation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of NiCo-LDH material:

[0030] Weigh 0.45 mmol of nickel nitrate, 0.3 mmol of cobalt nitrate, 4 mmol of ammonium chloride and 2.06 mmol of sodium hydroxide and dissolve them in deionized water, stir at room temperature to form a mixed solution; Finally, it was centrifuged, washed alternately with water and ethanol, and dried at 60°C to obtain the NiCo-LDH material.

[0031] (2) Preparation of Ag nanoparticles modified NiCo-LDH composite photocatalyst:

[0032] 0.011 g of silver nitrate and 0.1 g of NiCo-LDH were dispersed in deionized water, irradiated under ultraviolet light for 30 min, centrifuged, washed alternately with water and ethanol, and dried at 60 °C to obtain Ag nanoparticles modified NiCo-LDH composite photocatalyst.

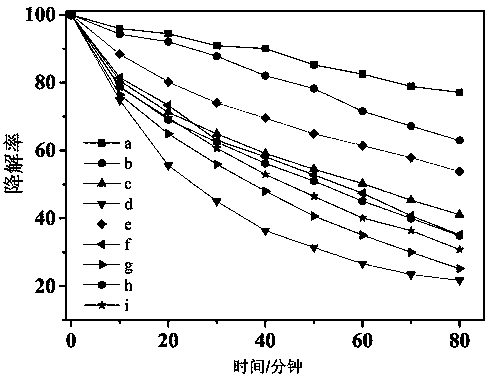

[0033] (3) Evaluation of photocatalytic activity:

[0034] The NiCo-LDH composite photocatalyst sample modified by Ag nanoparticles in step (2) was taken, and the photocatalytic degradation test was carried out in a photoche...

Embodiment 2

[0036] (1) Preparation of NiCo-LDH material:

[0037] Weigh 0.45 mmol of nickel nitrate, 0.3 mmol of cobalt nitrate, 4 mmol of ammonium chloride and 2.06 mmol of sodium hydroxide and dissolve them in deionized water, stir at room temperature to form a mixed solution; Finally, it was centrifuged, washed alternately with water and ethanol, and dried at 60°C to obtain the NiCo-LDH material.

[0038] (2) Preparation of Ag nanoparticles modified NiCo-LDH composite photocatalyst:

[0039] 0.016 g of silver nitrate and 0.1 g of NiCo-LDH were dispersed in deionized water, irradiated under ultraviolet light for 30 min, centrifuged, washed alternately with water and ethanol, and dried at 60 °C to obtain Ag nanoparticles modified NiCo-LDH composite photocatalyst.

[0040] (3) Evaluation of photocatalytic activity:

[0041]The NiCo-LDH composite photocatalyst sample modified by Ag nanoparticles in step (2) was taken, and the photocatalytic degradation test was carried out in a photochem...

Embodiment 3

[0043] (1) Preparation of NiCo-LDH material:

[0044] Weigh 0.45 mmol of nickel nitrate, 0.3 mmol of cobalt nitrate, 4 mmol of ammonium chloride and 2.06 mmol of sodium hydroxide and dissolve them in deionized water, stir at room temperature to form a mixed solution; Finally, it was centrifuged, washed alternately with water and ethanol, and dried at 60°C to obtain NiCo-LDH material.

[0045] (2) Preparation of Ag nanoparticles modified NiCo-LDH composite photocatalyst:

[0046] 0.024 g of silver nitrate and 0.1 g of NiCo-LDH were dispersed in deionized water, irradiated under ultraviolet light for 30 min, centrifuged, washed alternately with water and ethanol, and dried at 60 °C to obtain Ag nanoparticles modified NiCo-LDH composite photocatalyst.

[0047] (3) Evaluation of photocatalytic activity:

[0048] The NiCo-LDH composite photocatalyst sample modified by Ag nanoparticles in step (2) was taken, and the photocatalytic degradation test was carried out in a photochemica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com