Composite catalyst and method for catalyzing complete oxidation and elimination of formaldehyde via composite catalyst

A composite catalyst, catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of large size of active components, poor dispersion of active components, and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

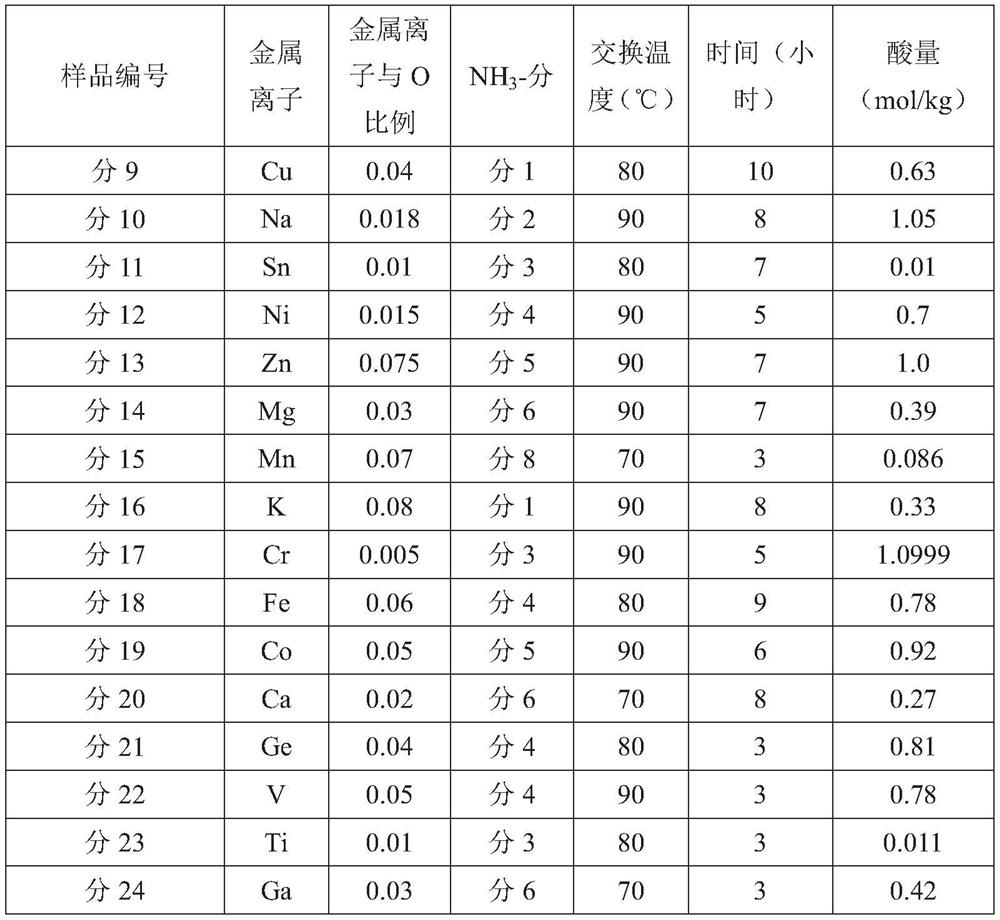

[0063] The preparation method of heteroatom-doped molecular sieves is similar to that of CHA and AEI topology molecular sieves, only a certain amount of corresponding metal salts are added to the synthetic raw materials. According to M:SiO 2 :Al 2 o 3 :H 3 PO 4 :R:H 2 O=0.001-0.1:4:16:32:55:150 Weigh the raw materials, wherein the metal element type of M is the same as the metal type of the above-mentioned ion exchange, and R is a template agent.

[0064] Mix the metal salt precursor, aluminum sulfate and sodium hydroxide solution, then add silica sol, phosphoric acid, TEA(R); deionized water, stir for 1 h to obtain a homogeneous initial gel, and then transfer it to a high-pressure synthesis kettle , high-temperature static crystallization, quenching, washing, and drying to obtain molecular sieve samples. The synthesis and properties of partially heteroatom-doped molecular sieves with CHA and AEI topological structures are shown in Table 3.

[0065] Table 3. Preparation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com