Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Increase the specific surface area of the reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

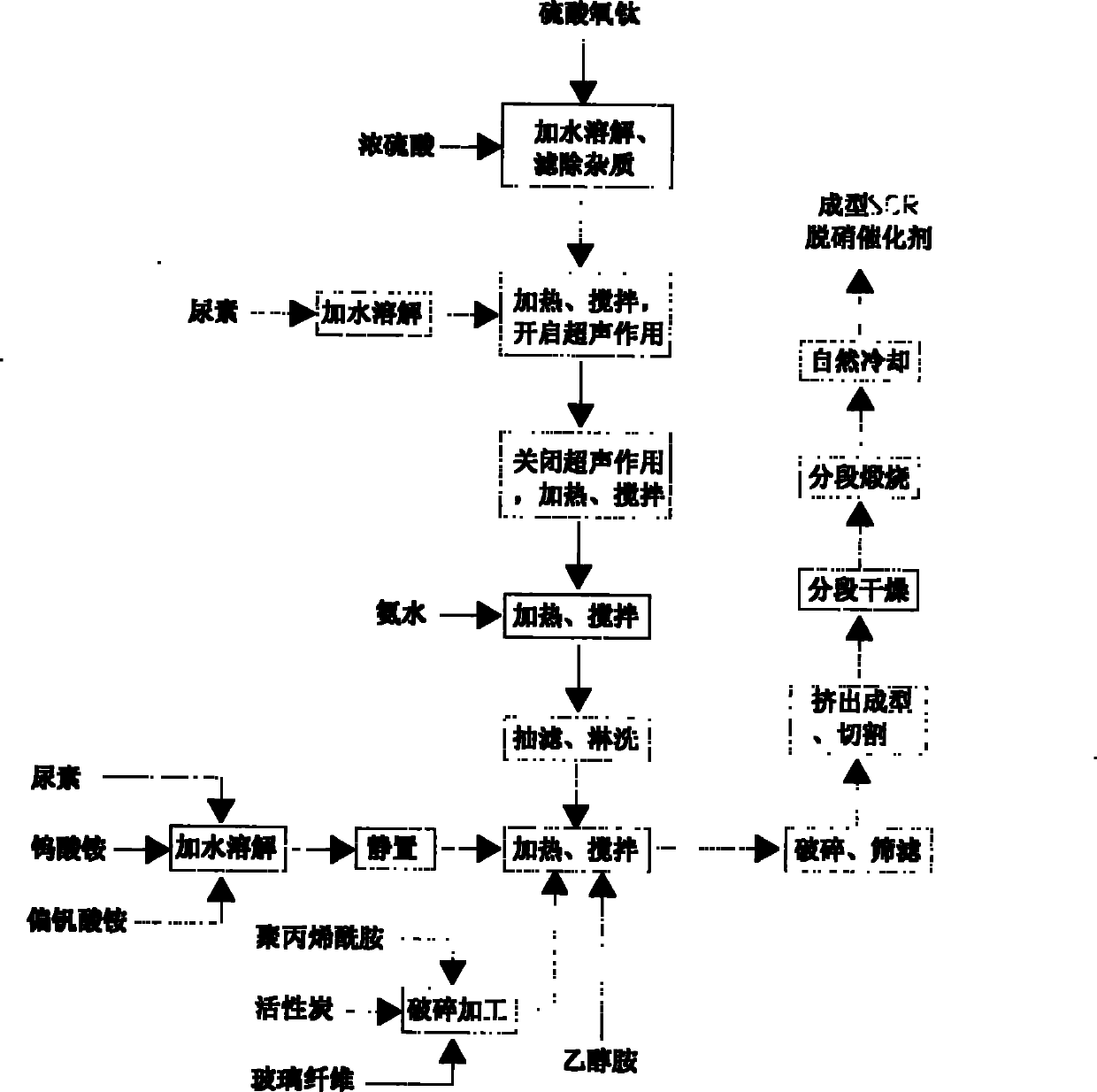

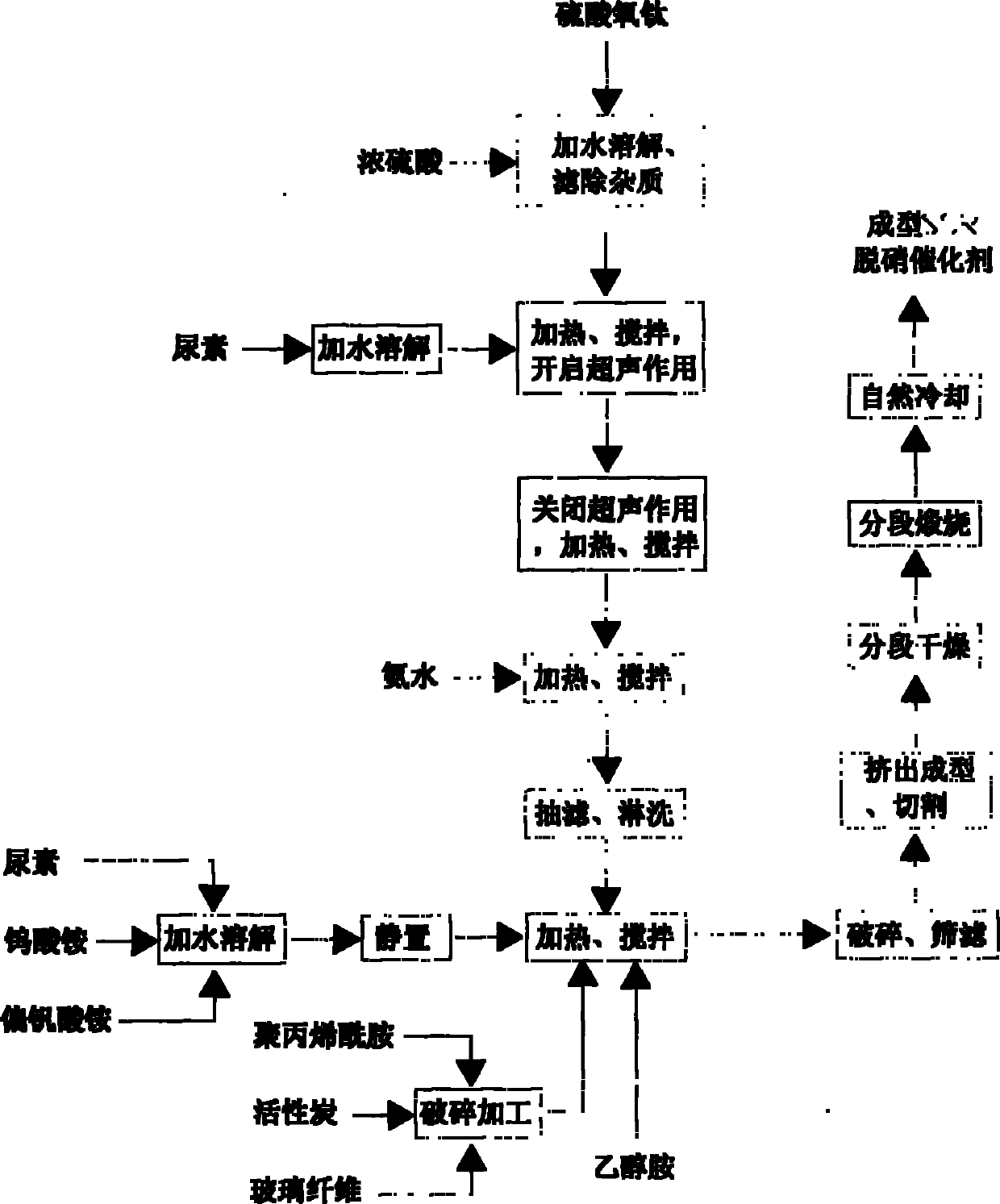

Method for preparing formed selective catalytic reduction denitration catalyst by using ultrasonic mixing sedimentation method

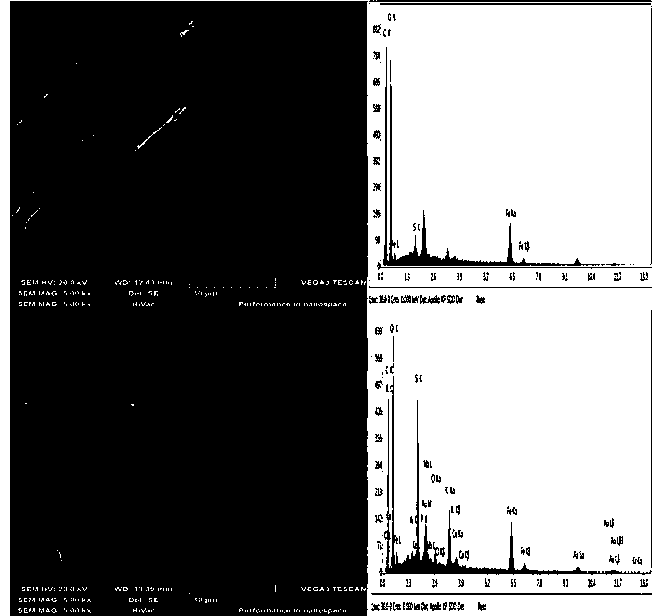

InactiveCN101791549ASmall particle sizeGood dispersionDispersed particle separationCatalyst activation/preparationTungstateAmmonium metavanadate

The invention discloses a method for preparing a formed selective catalytic reduction (SCR) denitration catalyst by using an ultrasonic mixing sedimentation method, comprising the following steps of: preparing metatitanic acid as a dipping carrier by using the processes of uniform sedimentation and direct sedimentation sequentially and being assisted by an ultrasonic strengthened reaction process by taking industry titanyl sulfate as a raw material; then mixing with an ammonium metavanadate-ammonium tungstate-oxalate solution, a flocculating agent comprising polyacrylamide and glass fibre, a structure promoter, and the like, and stirring to finish the processes of active component dipping and loading and plastic pasty master batch preparation synchronously. The prepared master batch is processed by a vacuum-extruder after finely crushed to obtain a formed catalyst green body, and finally the preparation process of the formed SCR denitration catalyst is finished through drying and sintering operations. Compared with the traditional preparation process of the SCR denitration catalyst, the method has simple and clear process and high production efficiency, and the raw materials for preparing the carrier of the catalyst have wide sources and low cost, thereby lowering the production cost to a certain extent.

Owner:SOUTHEAST UNIV

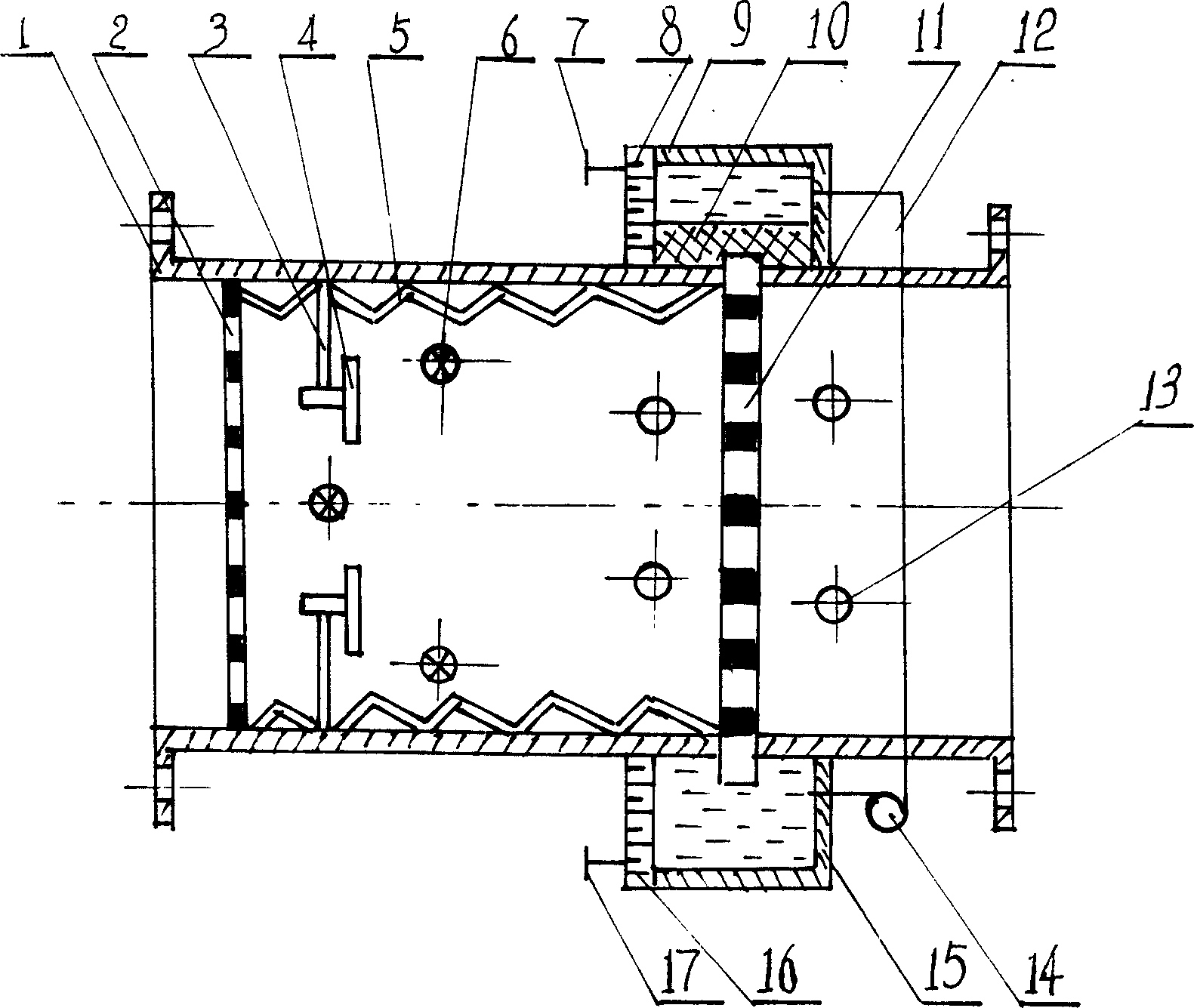

Supersonic synergic nano light catalytic air-sterilizing-purifying apparatus

InactiveCN1850283AImprove performanceImprove dust removal efficiencyDeodrantsRadiationAir cleaningPhotocatalysis

The present invention relates to an ultrasonic synergistic nano photocatalytic air sterilization and purification equipment. It includes the following several portions: shell body, upper water tank, lower water tank, water inlet valve, water outlet valve, miniature water pump, filtering screen, ultrasonic air energy transducer, filter, photocatalysis three-dimensional screen, ultrasonic reflecting plate and sterilization UV-light. Said invention also provides the connection mode of all the above-mentioned portions and the working principle of said air sterilization and purification equipment.

Owner:SHAANXI NORMAL UNIV

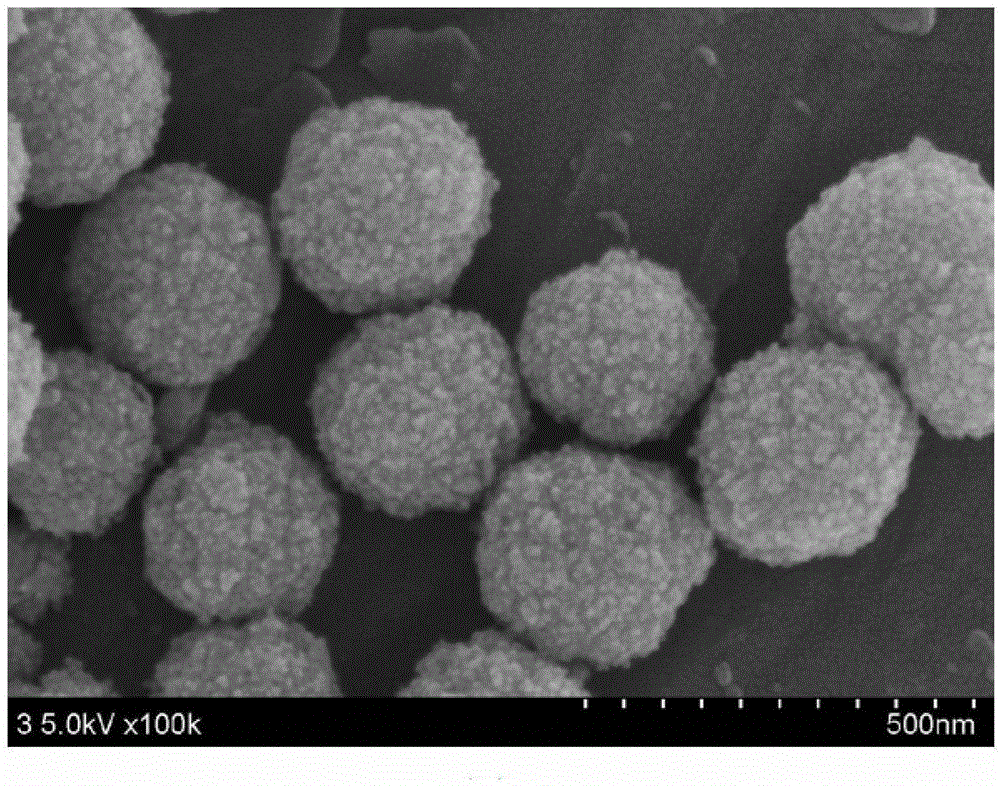

Method for preparing conductive polymer based electromagnetic composite material

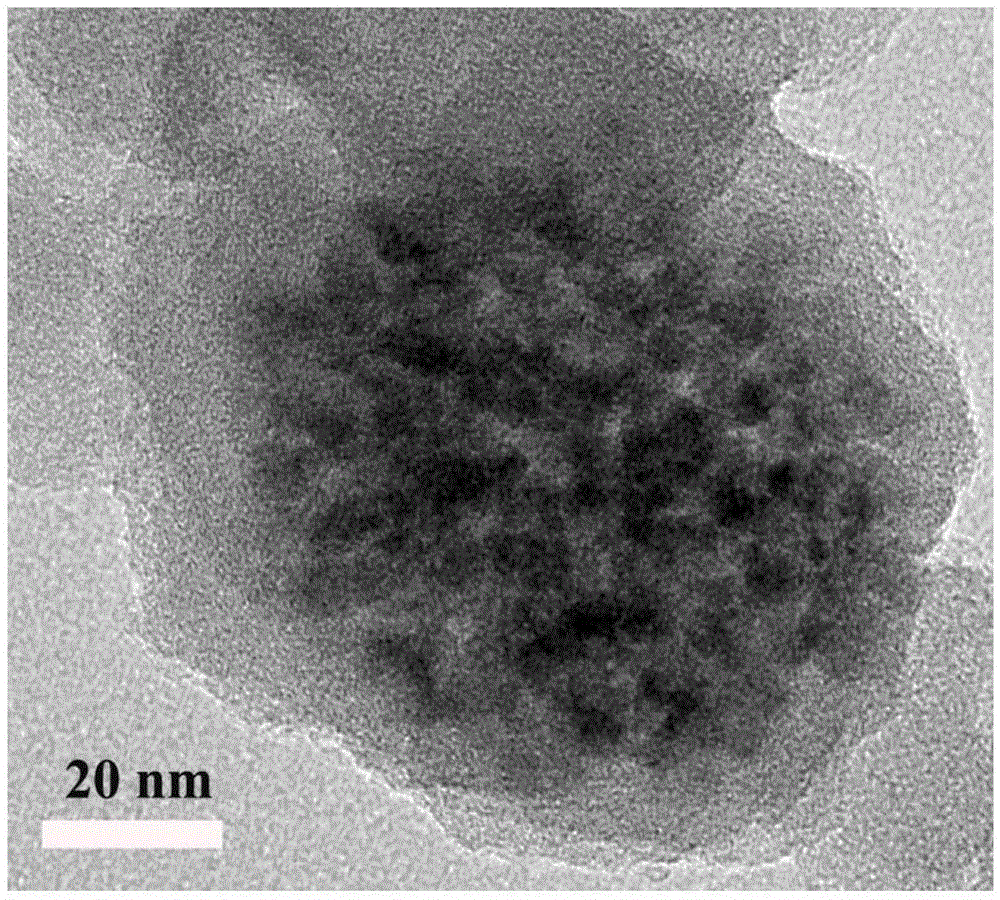

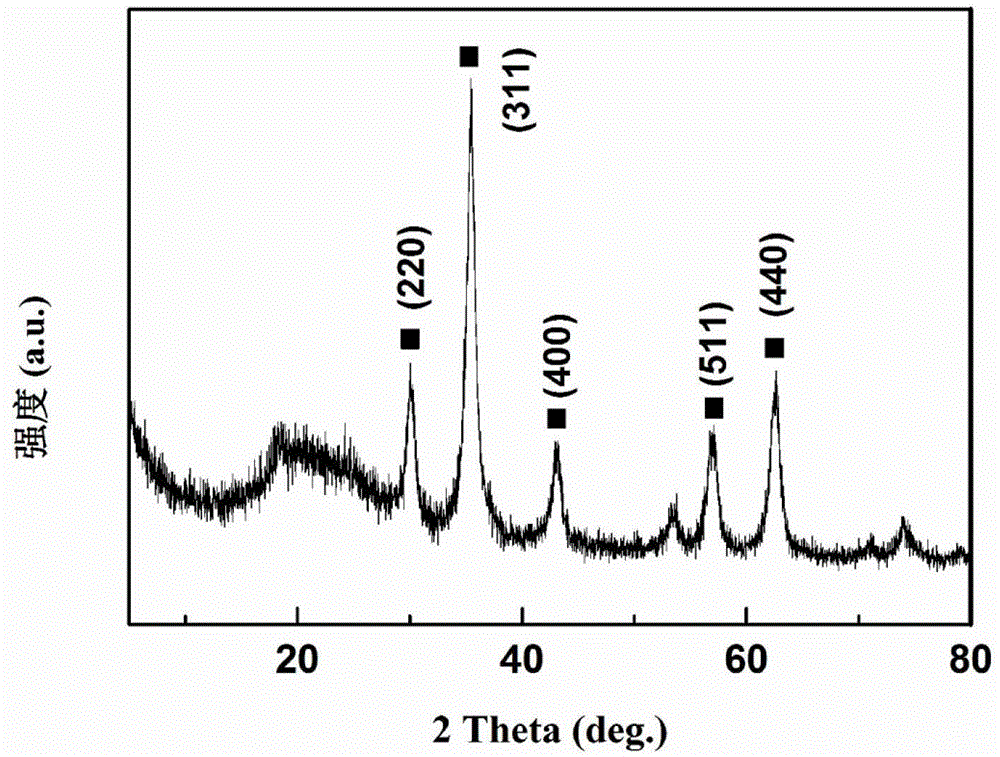

The invention relates to a method for preparing a conductive polymer based electromagnetic composite material. The method comprises the following steps of: respectively preparing magnetic powder suspending liquid, monomer dispersion liquid and an initiator solution, filling the magnetic powder suspending liquid, the monomer dispersion liquid and the initiator solution into three injectors, and continuously injecting the magnetic powder suspending liquid, the monomer dispersion liquid and the initiator solution into respective microtubules at a constant pushing speed respectively; mixing the reaction solutions in a reaction tube after the reaction solutions flow through the microtubules, and performing fluid reaction polymerization at room temperature under ultrasound assistance; and performing magnetic separation, washing, and freeze-drying on the product to obtain the conductive polymer based electromagnetic composite material. The method is simple, low in energy consumption, good in repeatability, capable of realizing continuous and fast preparation of the product, and easy to realize industrial production; and the prepared conductive polymer based electromagnetic composite material is uniform in particle size, large in specific area, stable in physical and chemical properties, difficult to agglomerate, good in dispersity and excellent in electromagnetic comprehensive performance, and has a good application prospect.

Owner:DONGHUA UNIV

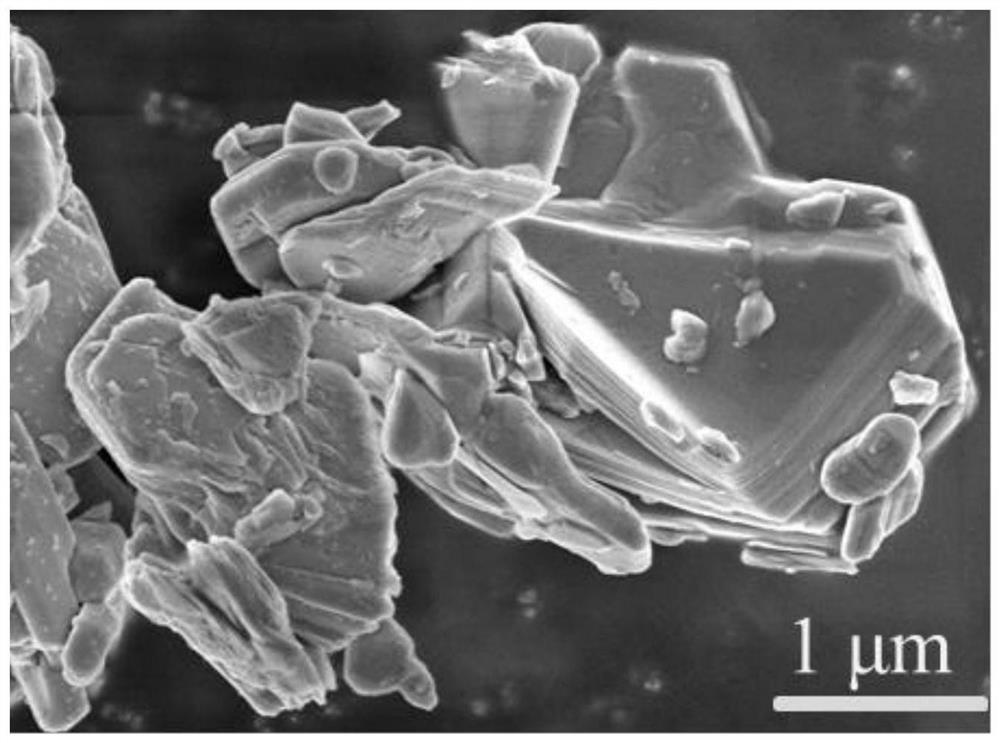

Preparation and applications of biocarbon supported thermally activated iron containing ore composite material

InactiveCN110841594ALow priceSimple manufacturing methodOther chemical processesWater contaminantsOxidation-Reduction ActivityMining engineering

The invention relates to preparation and applications of a biocarbon supported thermally activated iron containing ore composite material. Thermally activated iron containing ores are loaded on the surface of biocarbon. The preparation method comprises following steps: grinding iron containing ores and a biomass material, then evenly mixing ores and the biomass material according to a certain massratio, evenly pressing and moulding the mixture, burning the mixture in a reductive atmosphere, naturally cooling, and milling the mixture in an anaerobic atmosphere to obtain fine powder, namely thebiocarbon supported thermally activated iron containing ore composite material. The prepared biocarbon supported thermally activated iron containing ore composite material has the characteristics oflarge specific surface area, high stability, and strong oxidizing-reducing activity. Compared with biomass or thermally activated iron containing ores, the composite material has a prominently improved performance on removing or stabilizing heavy metal ions in water and soil, and thus can be used to process heavy metal pollution of water and soil.

Owner:CENT SOUTH UNIV

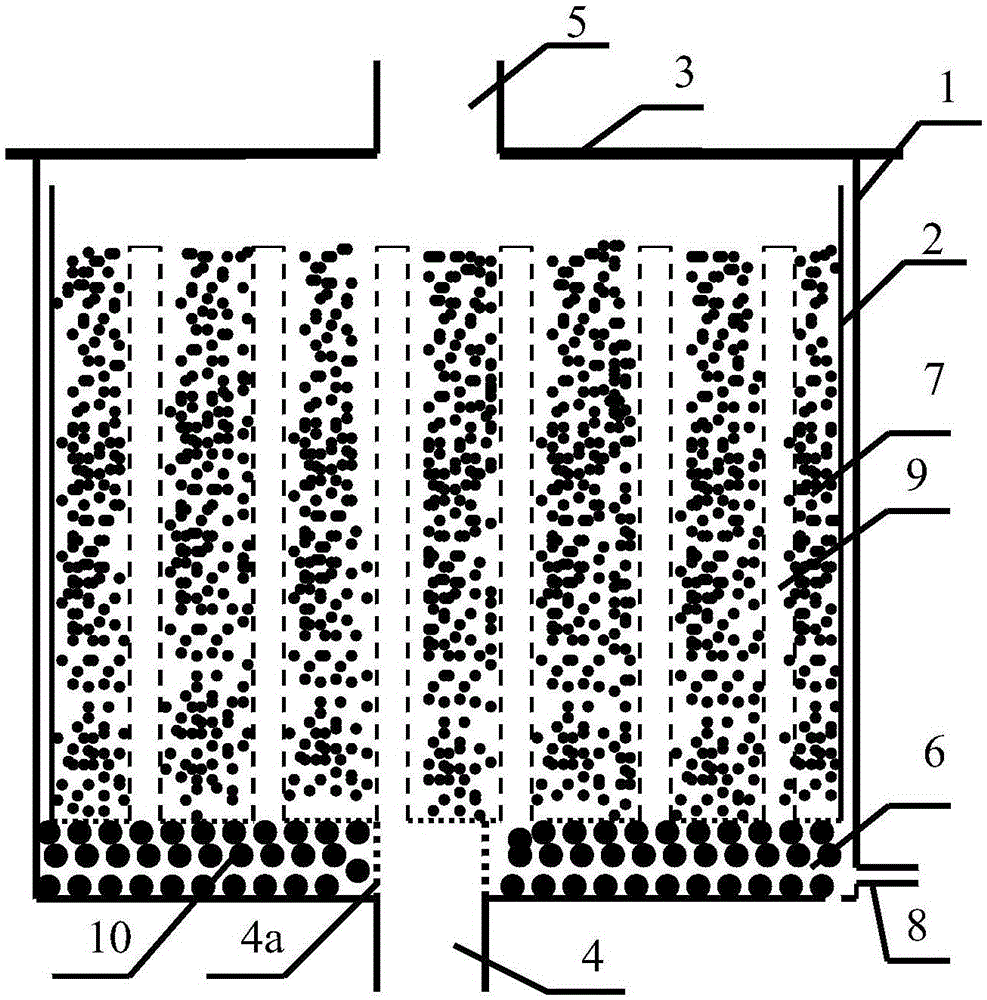

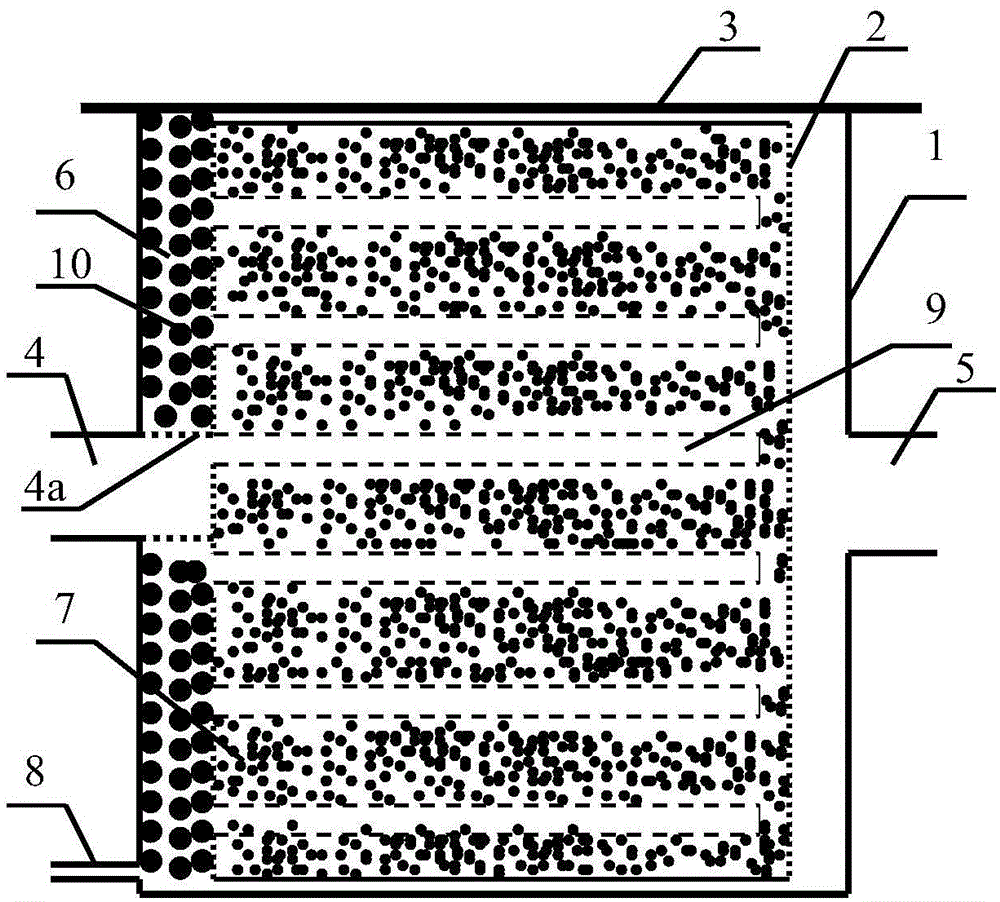

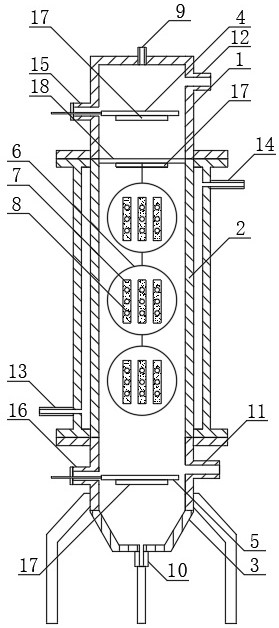

Purification device and method for strongly acidic components in exhaust gas

ActiveCN105107369AEliminate airway blockageIncrease responsivenessDispersed particle separationExhaust gasChemical engineering

The invention discloses a purification device and method for strongly acidic components in exhaust gas. The purification device is characterized by comprising a reactor shell, an active material filling container arranged in the reactor shell and a bearing layer arranged between the reactor shell and the active material filling container. The top of the reactor shell is sealed through a sealing cover plate. The reactor shell is provided with a gas inlet, a gas outlet and a liquid outlet. A gas guide pipe is inserted into the active material filling container. According to the purification device, the exhaust gas containing the strongly acidic components is distributed through the bearing layer, enters the gas guide pipe and then enters the active material filling container through gas holes distributed in the gas guide pipe to make contact with an active material, the strongly acidic components are reacted with the active material to form salt, and purified exhaust gas is exhausted through an exhaust pipe.

Owner:HEFEI UNIV OF TECH

Method for preparing powdery selective catalytic reduction denitration catalyst by using sol impregnation method

InactiveCN101695656AImprove thermal stabilityHigh activityDispersed particle separationCatalyst activation/preparationOxalateFlue gas

The invention discloses a method for preparing powdery selective catalytic reduction denitration catalyst by using a sol impregnation method, which is a method for preparing powdery SCR denitration catalyst by utilizing sol type meta-titanic acid as an impregnation carrier. The method comprises the following steps of: by taking the sol type meta-titanic acid as the carrier, carrying out first impregnation loading on the sol type meta-titanic acid and ammonium tungstate-oxalic acid solution; finishing secondary impregnation loading on a prepared composite powder and ammonium metavanadate-oxalic acid solution after procedures including calcining, grinding and screening; and finally, finishing a preparation process of the powdery SCR denitration catalyst through treatments including secondary calcining, secondary grinding and secondary screening. Compared with a traditional SCR denitration catalyst preparation technology, the method has the advantages of simple technology and low economic cost and is suitable for an integral production mode of a titanium dioxide preparation technology and an SCR denitration catalyst production technology. In addition, the catalyst prepared by the method has the advantages of large specific surface area, uniform and reasonable micro hole structure, favorable thermal stability, ideal catalytic conversion efficiency to Nox component in flue gas and the like.

Owner:SOUTHEAST UNIV

Heavy metal wastewater treatment material and method thereof

InactiveCN105858832AIncrease capacityIncrease the specific surface area of the reactionWater contaminantsWater/sewage treatment by neutralisationDolostonePhysical chemistry

The invention discloses a heavy metal wastewater treatment method. The heavy metal wastewater treatment method is characterized in that a heavy metal wastewater treatment material is formed through mixing a granular material A with a granular material B according to a certain ratio. A preparation method of the material A comprises the following steps: calcining magnesite at 700-900DEG C, crushing the calcined magnesite, sieving the crushed magnesite by a 200 mesh sieve, adding water, forming 2-10mm particles, and naturally curing the particles to obtain the granular strength composite material formed by magnesium oxide, magnesium carbonate and sodium hydroxide. The material A is a 2-10mm granular material obtained through crushing and screening attapulgite and dolostone. The material A and the material B are mixed according to a mass ratio of 1:1-10:1, and the obtained mixture is used to treat heavy metal-containing wastewater.

Owner:HEFEI UNIV OF TECH

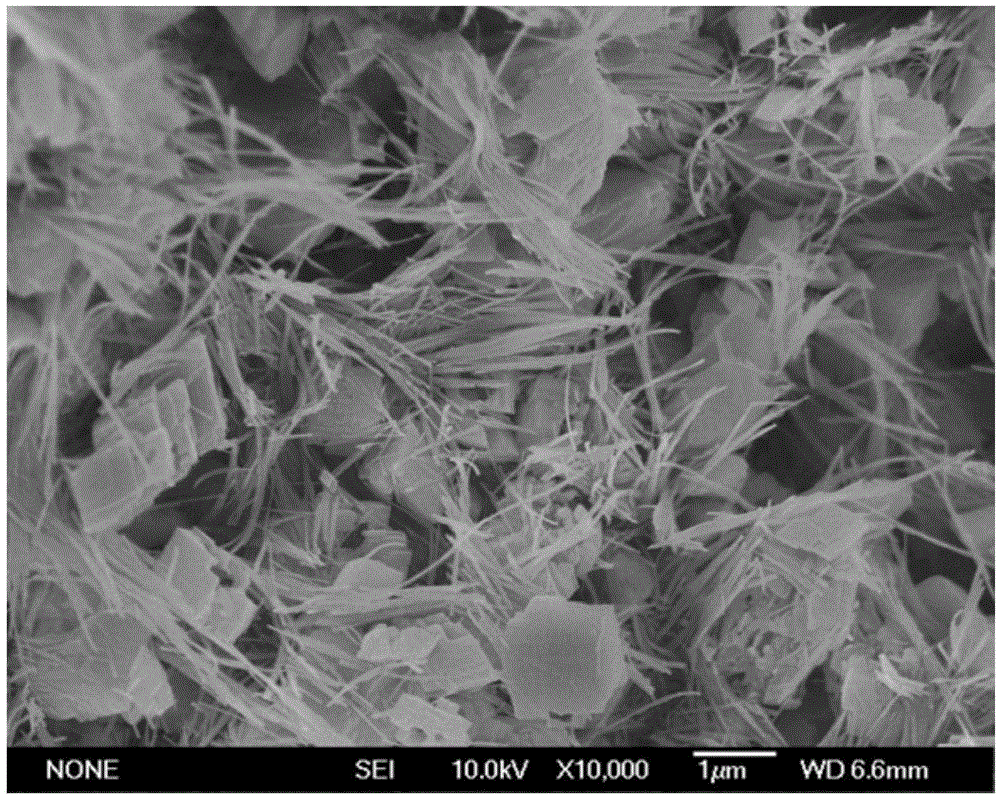

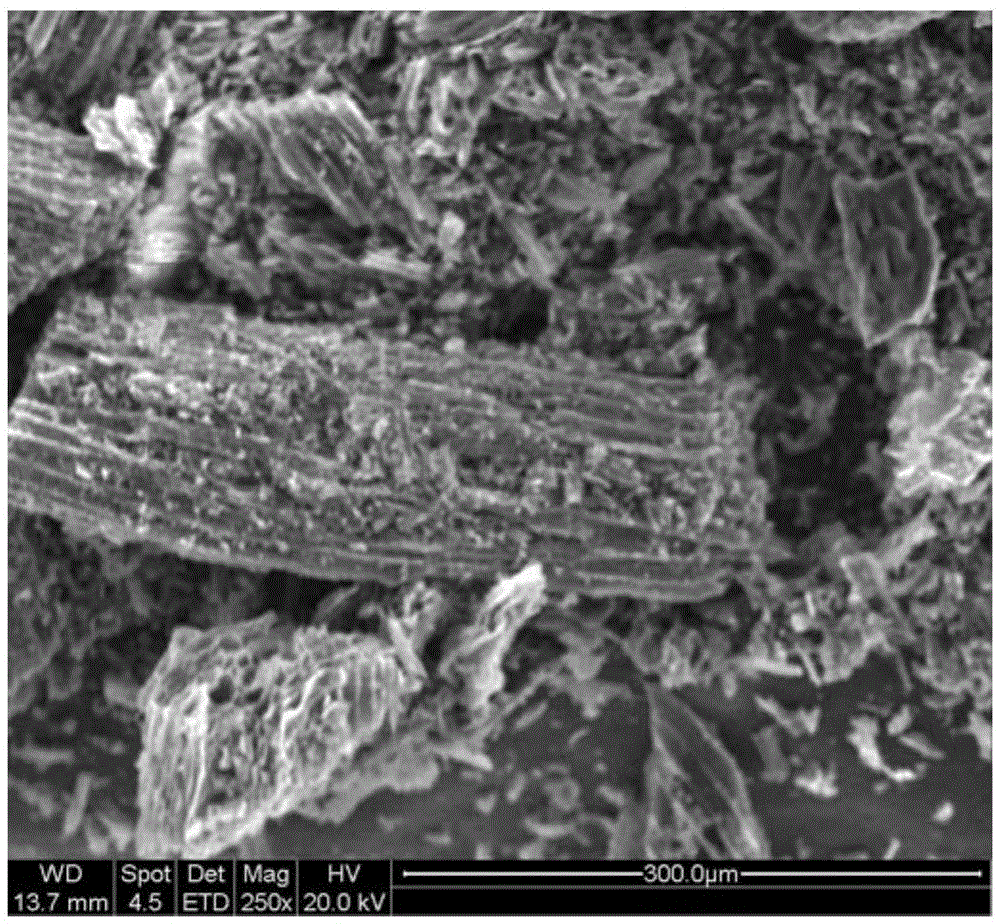

Method for treating heavy metal wastewater

ActiveCN105110445AIncrease the specific surface area of the reactionWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationParticulatesEmission standard

The invention discloses a method for treating heavy metal wastewater. The method is characterized in that argillaceous dolomite ore is crushed and screened to obtain 0.5-2 mm particulate matter, a filter chamber or a filter column is filled with the particulate matter and / or a high-temperature calcination product thereof, and the heavy metal wastewater is treated in a filtered mode. As argillaceous dolomite is composed of nanometer mineral attapulgite and dolomite and has a natural nanometer porous structure characteristic, a water-mineral interface reaction occurs in particles, the nanometer dolomite induces heavy metal hydrolysis to form hydroxide or subcarbonate precipitation, the nanometer rodlike attapulgite has adsorption and condensation effects on the hydrolyzed colloidal particles, and the pH value and the heavy metal content of the treated wastewater reach the emission standard; heavy metal waste obtained after treatment can be used for metal recovery, or be converted into stable silicate by means of thermotechnical treatment at the temperature of 500 DEG C-700 DEG C.

Owner:HEFEI UNIV OF TECH

Processing method of lignite

ActiveCN101787301AImprove conversion rateMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationLiquid fuelPhenyl hydroxide

The invention discloses a processing method of lignite, comprising the following steps: A, taking methyl alcohol as extractant to carry out supercritical extraction processing to the lignite to obtain extraction liquid and raffinate; B, carrying out hot melt catalysis liquefaction processing to the raffinate to obtain liquid fuel. The invention has the beneficial effect: 1, the invention has moderate reaction condition, simple operation technology, high liquid oil yield, high domestication degree, low input and low cost and is safe and stable, and higher conversion rate of lignite; 2, the invention can obtain humic acid, organic acid methyl ester and phenol substances (phenyl hydroxide, cresol, dimethyl phenol and the like) and increase the additional value of products; 3, the supercritical methyl alcohol adopted by the invention removes R-OH and R-COOH class micromolecule substances in the lignite, which can reduce hydrogen consumption amount in the process of hot melt catalysis liquefaction so as to reduce hydrogen consumption; meanwhile, CO2 discharge amount in the process of hot melt catalysis liquefaction can be greatly reduced so as to achieve the purpose of greenhouse gas emission reduction; and 4, the invention performs swelling pretreatment to the lignite, changes lignite micropore structure, amplifies response ratio superficial area and improves the conversion rate of the lignite.

Owner:ZHAOQING SHUNXIN COAL CHEM TECH

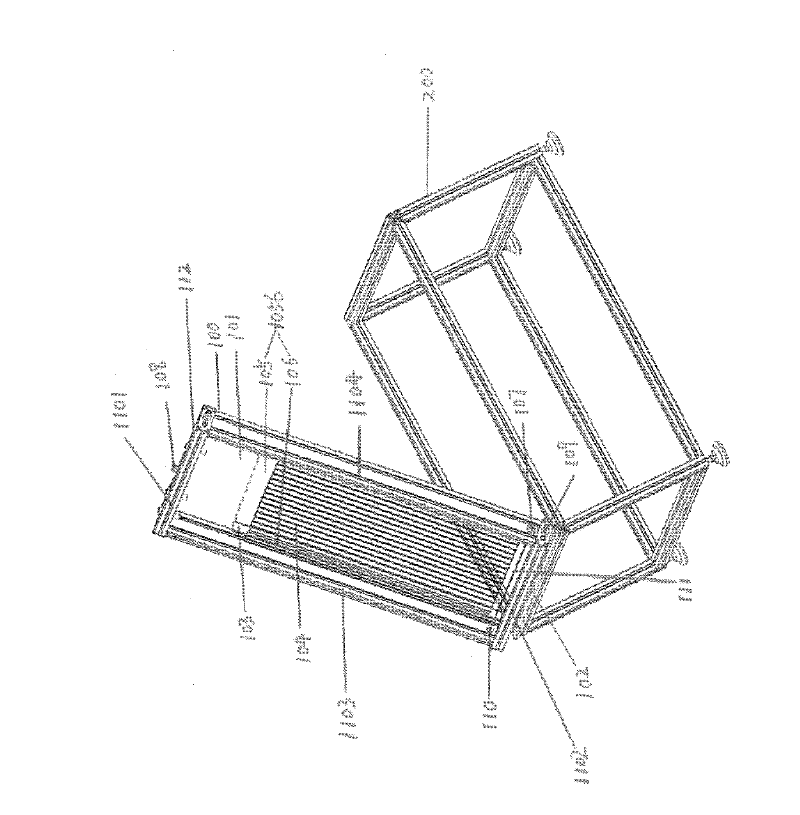

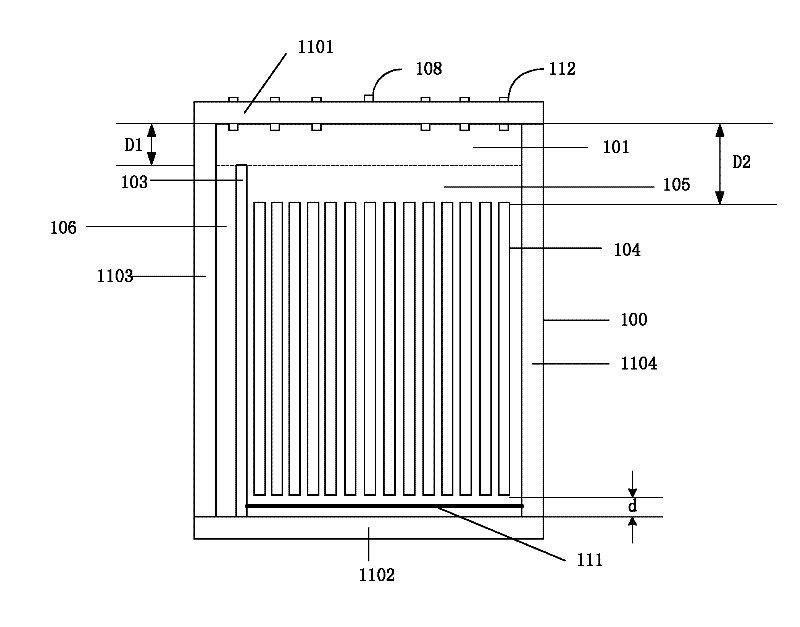

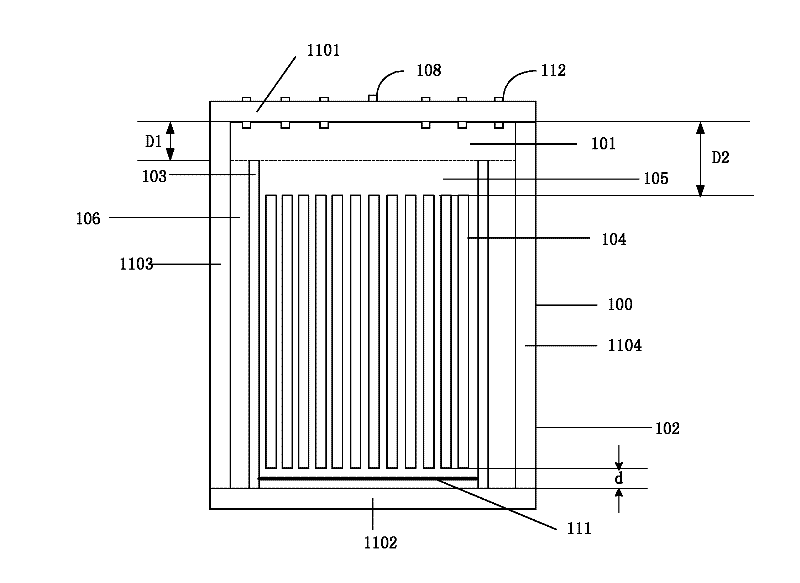

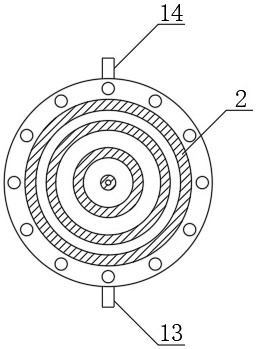

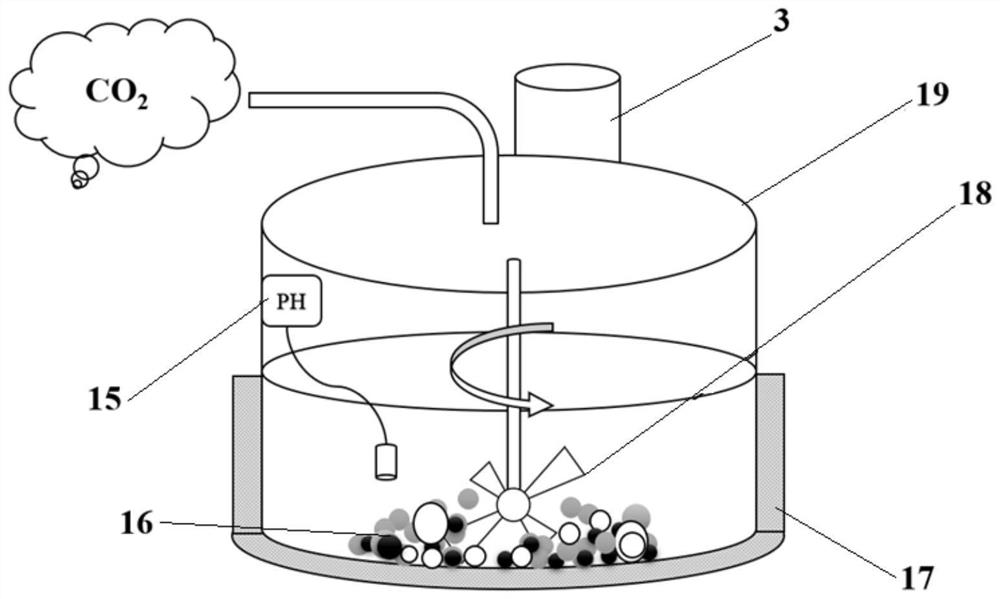

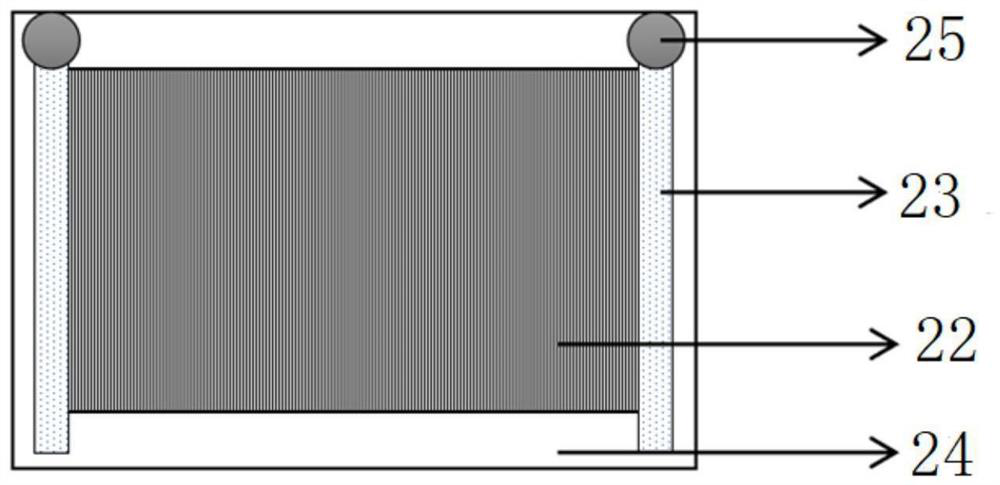

Reaction zone structure of light-energy living being culture system and method for culturing light-energy living beings

InactiveCN102465088AIncrease the specific surface area of the reactionImprove ventilationBioreactor/fermenter combinationsBiological substance pretreatmentsReaction zoneLight energy

The invention discloses a photoreaction zone structure of a light-energy living being culture system. A photoreactor comprises a photoreactor body, a rotatable mechanical shaft and a supporting base, wherein a photoreaction zone is located inside the photoreactor. The photoreactor is characterized in that the photoreaction zone is provided with a long clapboard structure and a short clapboard structure, which are arranged in parallel; one end of the long clapboard structure and an inner surface of a top border of the photoreactor body are spaced by a certain distance D1; and the short clapboard structure and the inner surface of the top border are spaced by a certain distance D2, wherein D2 is more than D1. The invention further discloses a method for culturing light-energy living beings.The photoreaction zone structure of the light-energy living being culture system and the method for culturing the light-energy living beings, disclosed by the invention, have the advantages of large photoreaction specific surface area, good air permeability, uniformity in reactant mixing, and good circularity.

Owner:ZHEJIANG QICHENG TECH

Annular pipe rotational flow layer of desulfurizing tower and working method thereof

InactiveCN103007729ASmall diameterSimplify the tower structureDispersed particle separationFlue gasEngineering

The invention discloses an annular pipe rotational flow layer of a desulfurizing tower and a working method thereof. The annular pipe rotational flow layer comprises a desulfurizing tower wall, wherein an annular slurry pipeline is distributed on the desulfurizing tower wall in an attaching mode, more than one efficient atomization nozzle is arranged in the tangential direction of the annular slurry pipeline, and the efficient atomization nozzles are arranged below the annular slurry pipeline. Slurry is filled in the annular pipe rotational flow layer; because the annular slurry pipeline is distributed on the desulfurizing tower wall in an attaching mode, and more than one efficient atomization nozzle is arranged in the tangential direction of the annular slurry pipeline, the slurry is formed into a downward spiral turbulence flow flied; and flue gas with a higher sulfur concentration, after passing through a flue gas inlet, moves upwards, so that the flue gas is in contact with superfine mist particles produced by the action of the efficient atomization nozzles, thereby achieving an effect of efficient desulfurization.

Owner:GUANGDONG YIKE ELECTRIC POWER TECH

Al-LiH composite fuel for unmanned underwater vehicle and preparation method thereof

InactiveCN111825507AImprove combustion efficiencyBurn quicklyHydrogen productionPressure gas generationAl powderMechanical engineering

The invention provides an Al-LiH composite fuel for an unmanned underwater vehicle and a preparation method thereof, and belongs to the technical field of fuel for underwater vehicles. The Al-LiH composite fuel is powder comprising main phase aluminum (Al) and dispersed phase lithium hydride (LiH), wherein the LiH is uniformly dispersed in aluminum powder. The preparation method comprises the following steps of: weighing aluminum powder and lithium hydride, mixing the substances uniformly, putting the mixture into a ball milling tank, performing sealing, and carrying out ball milling in a ballmill to obtain the Al-LiH composite fuel. The Al-LiH composite fuel prepared by the invention has micro-explosion performance when being subjected to combustion reaction with high-temperature water vapor, and Al2O3 on the surface of Al powder can be continuously removed, therefore, the Al-LiH composite fuel has the characteristics of high energy, high density, quick start with water, high-efficiency combustion and high hydrogen yield.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

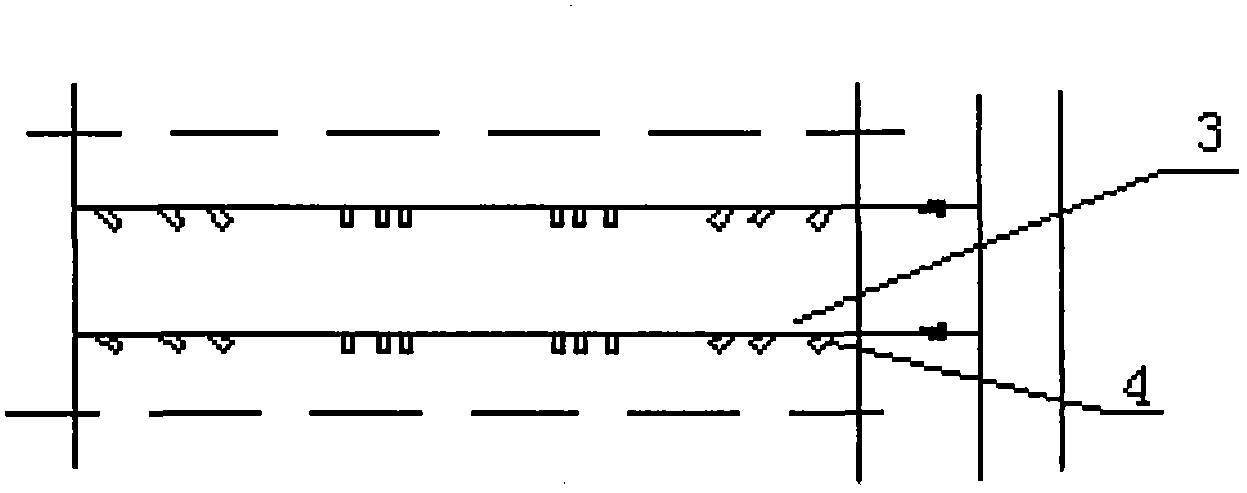

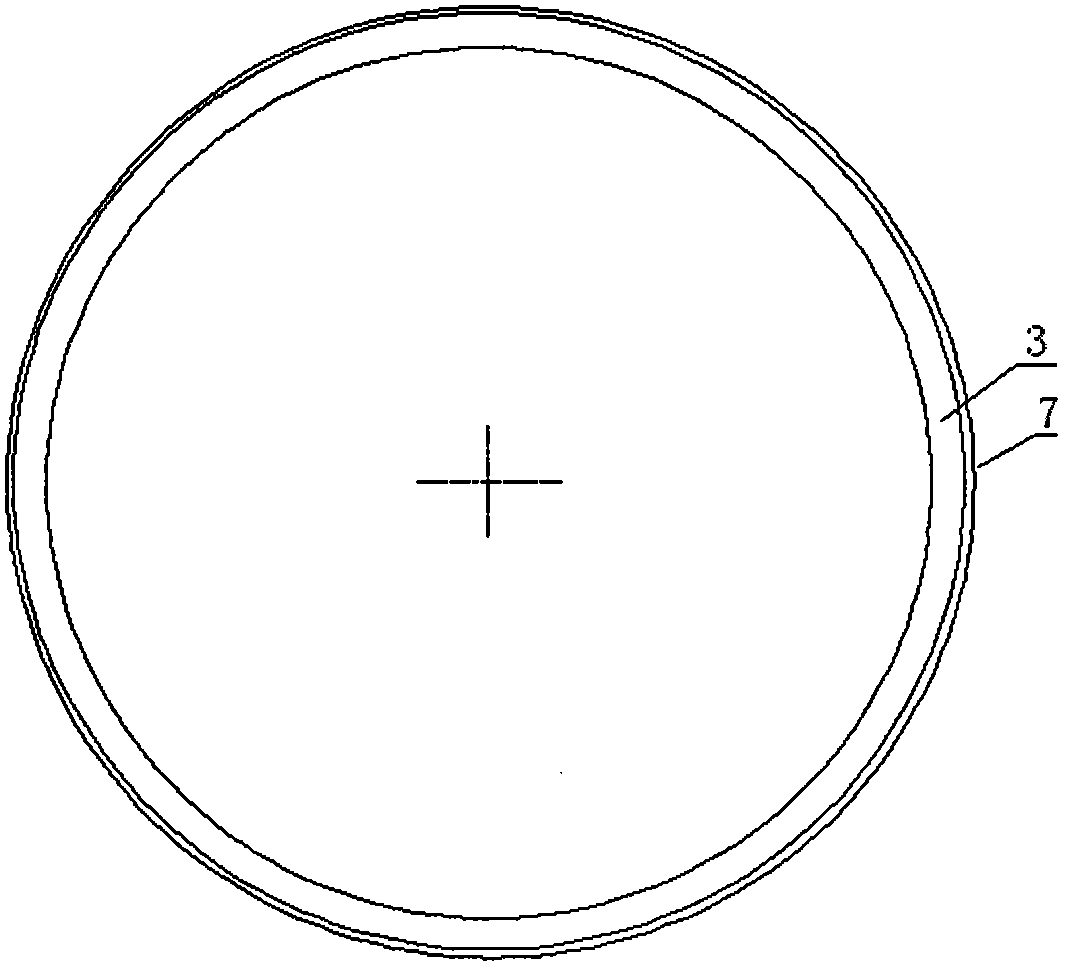

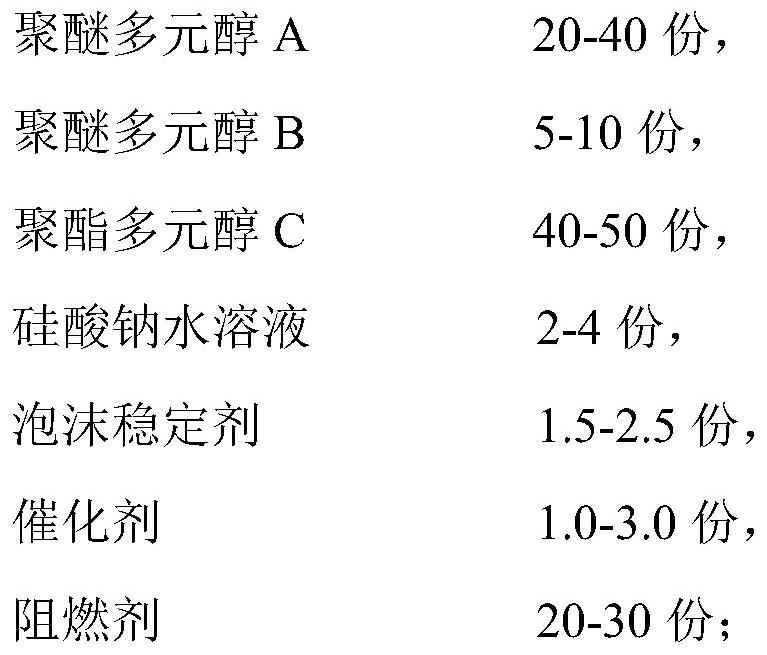

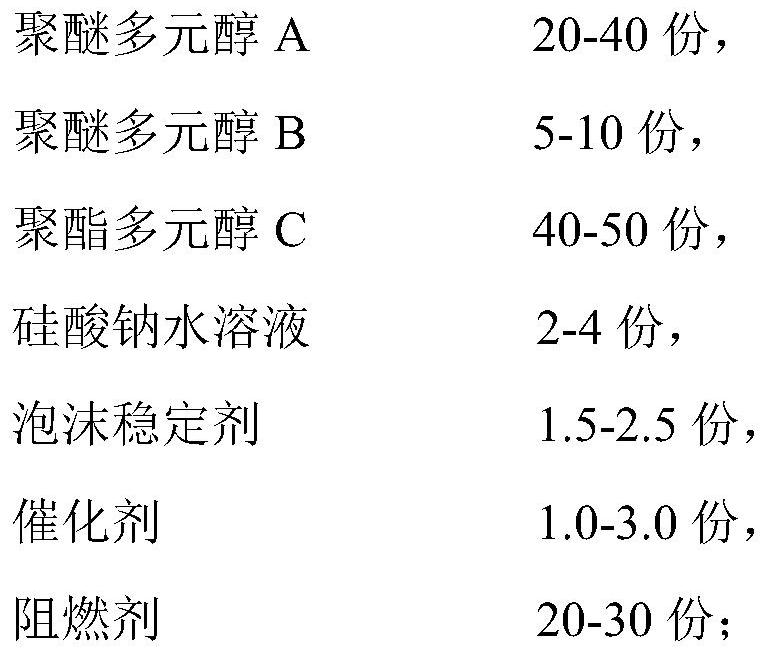

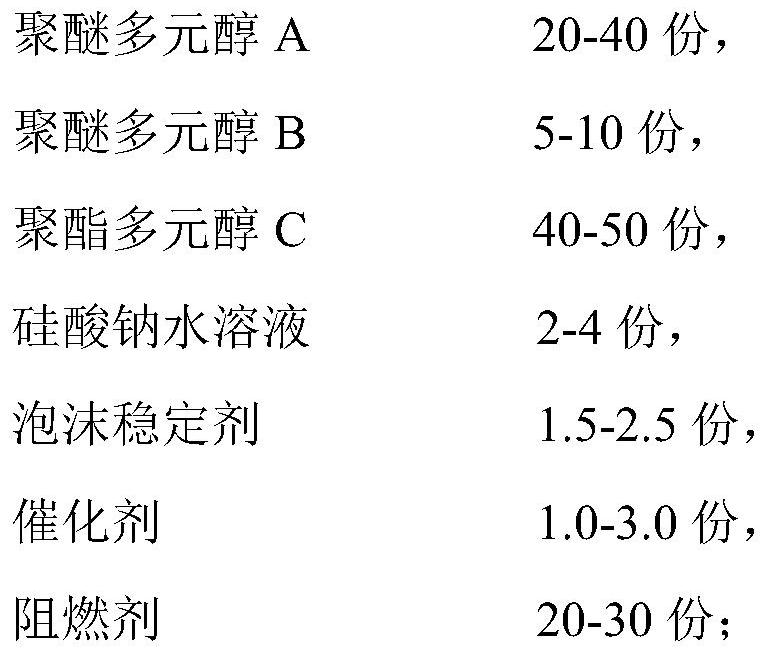

Hard polyisocyanurate node material for deep sea transmission pipeline interface heat preservation and preparation method thereof

The invention belongs to the technical field of polyurethane, and particularly relates to a hard polyisocyanurate node material for deep sea transmission pipeline interface heat preservation and a preparation method thereof. The hard polyisocyanurate node material for deep sea transmission pipeline interface heat preservation is composed of a component A and a component B according to a mixing mass ratio of 1:1.3-1.7, wherein the component A is composed of polyether polyol A, polyether polyol B, polyester polyol C, a foam stabilizer, a catalyst, a flame retardant and a sodium silicate aqueous solution; the component B is formed by mixing isocyanate and a prepolymer according to the ratio of (50-80):(20-50); wherein the polyether polyol A is special polyether polyol with a hydroxyl value of 425+ / -3mgKOH / g. The hard polyisocyanurate node material for deep sea transmission pipeline interface heat preservation is low in foam heat, high in aperture ratio, high in compressive strength and good in flame retardant property; the invention also provides a preparation method of the hard polyisocyanurate node material.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

A method for treating heavy metal wastewater

ActiveCN105110445BIncrease the specific surface area of the reactionWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationParticulatesEmission standard

The invention discloses a method for treating heavy metal wastewater. The method is characterized in that argillaceous dolomite ore is crushed and screened to obtain 0.5-2 mm particulate matter, a filter chamber or a filter column is filled with the particulate matter and / or a high-temperature calcination product thereof, and the heavy metal wastewater is treated in a filtered mode. As argillaceous dolomite is composed of nanometer mineral attapulgite and dolomite and has a natural nanometer porous structure characteristic, a water-mineral interface reaction occurs in particles, the nanometer dolomite induces heavy metal hydrolysis to form hydroxide or subcarbonate precipitation, the nanometer rodlike attapulgite has adsorption and condensation effects on the hydrolyzed colloidal particles, and the pH value and the heavy metal content of the treated wastewater reach the emission standard; heavy metal waste obtained after treatment can be used for metal recovery, or be converted into stable silicate by means of thermotechnical treatment at the temperature of 500 DEG C-700 DEG C.

Owner:HEFEI UNIV OF TECH

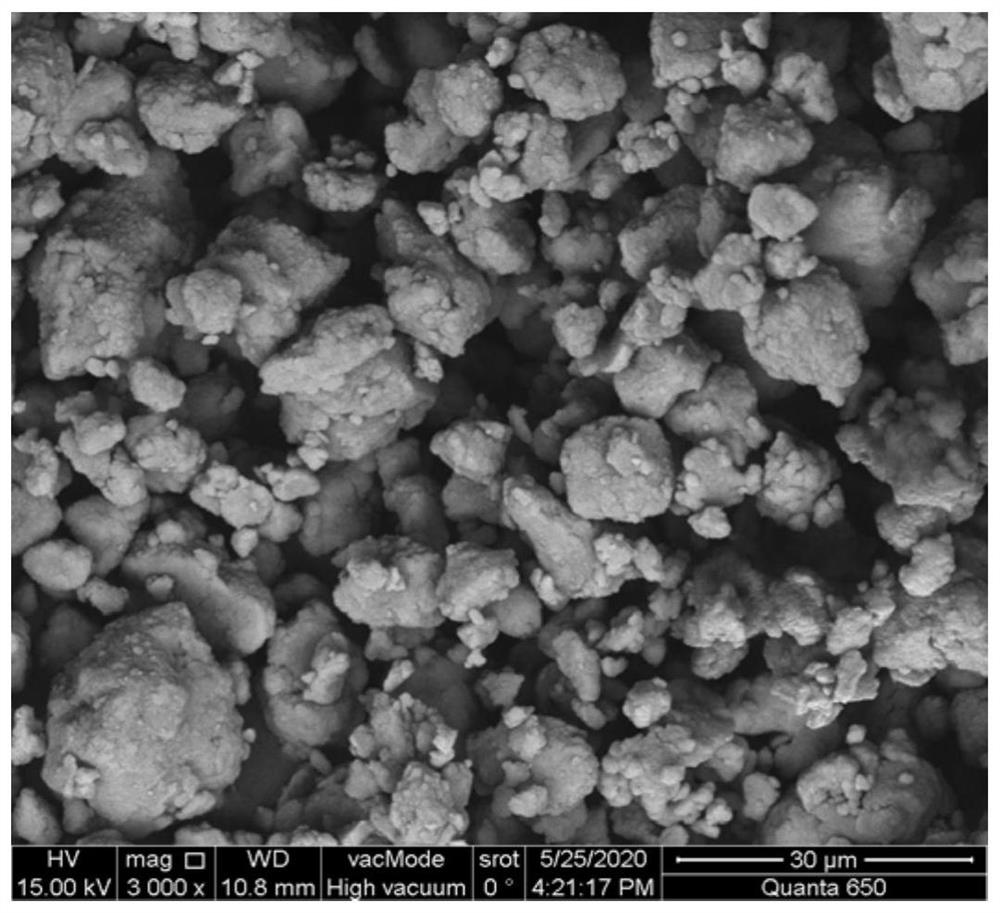

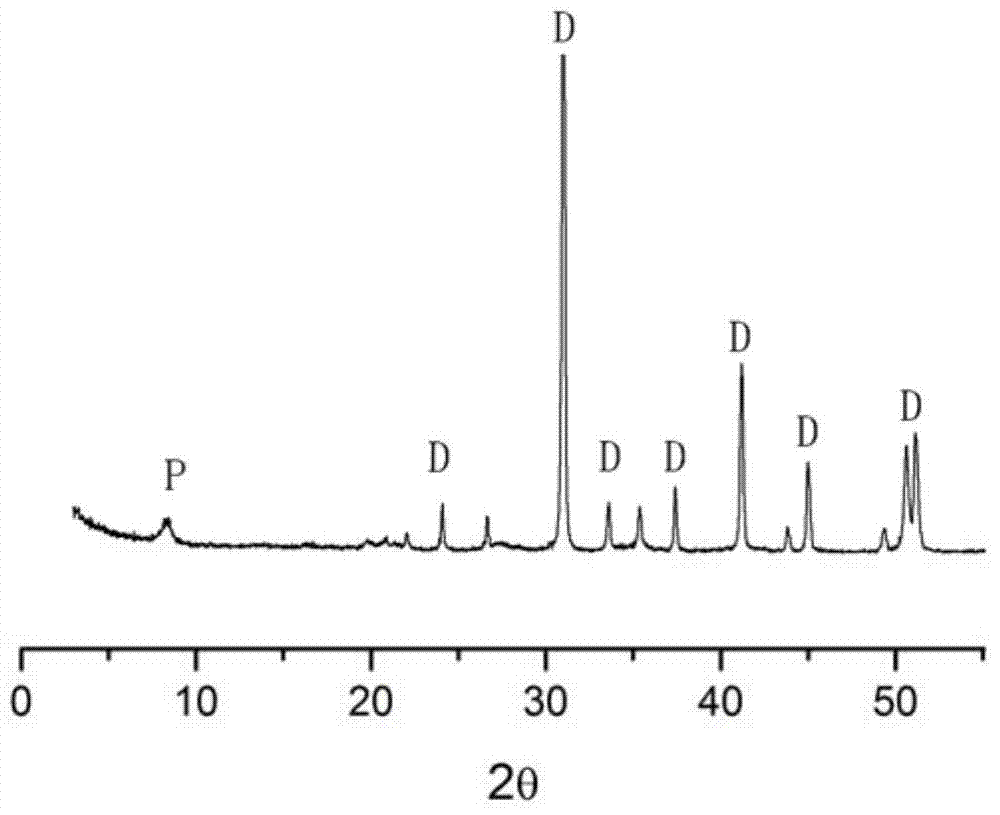

Preparation method of high-purity sodium chromite

ActiveCN114195188ASmall particle sizeHigh purityCrystallization separationCell electrodesCompression moldingUltrasonic vibration

The invention discloses a preparation method of high-purity sodium chromite. The method comprises the following steps: firstly, carrying out nitric acid-high-pressure closed digestion pretreatment on chromic oxide, and carrying out ultrasonic vibration recrystallization purification pretreatment on sodium carbonate; mixing the pretreated chromic oxide and sodium carbonate according to a certain proportion, carrying out ultralow-temperature liquid nitrogen ball-milling, crushing and mixing, and then carrying out compression molding; then carrying out high-temperature solid-phase reaction in an inert atmosphere; and finally, washing the cooled reactant with a polar solvent, filtering, and carrying out vacuum drying to obtain the high-purity sodium chromite. The chromium oxide and the sodium carbonate are pretreated before the high-temperature solid-phase reaction of the chromium oxide and the sodium carbonate, so that the purity of the prepared sodium chromite is improved; through ultralow-temperature liquid nitrogen ball milling and mixing treatment, the particle sizes of chromic oxide and sodium carbonate are reduced, the reaction specific surface area is increased, reactants are mixed more uniformly, and the reaction is more thorough. The sodium chromite material prepared by the method is high in purity, uniform in particle size distribution and good in crystal integrity.

Owner:四川省绵阳市华意达化工有限公司 +1

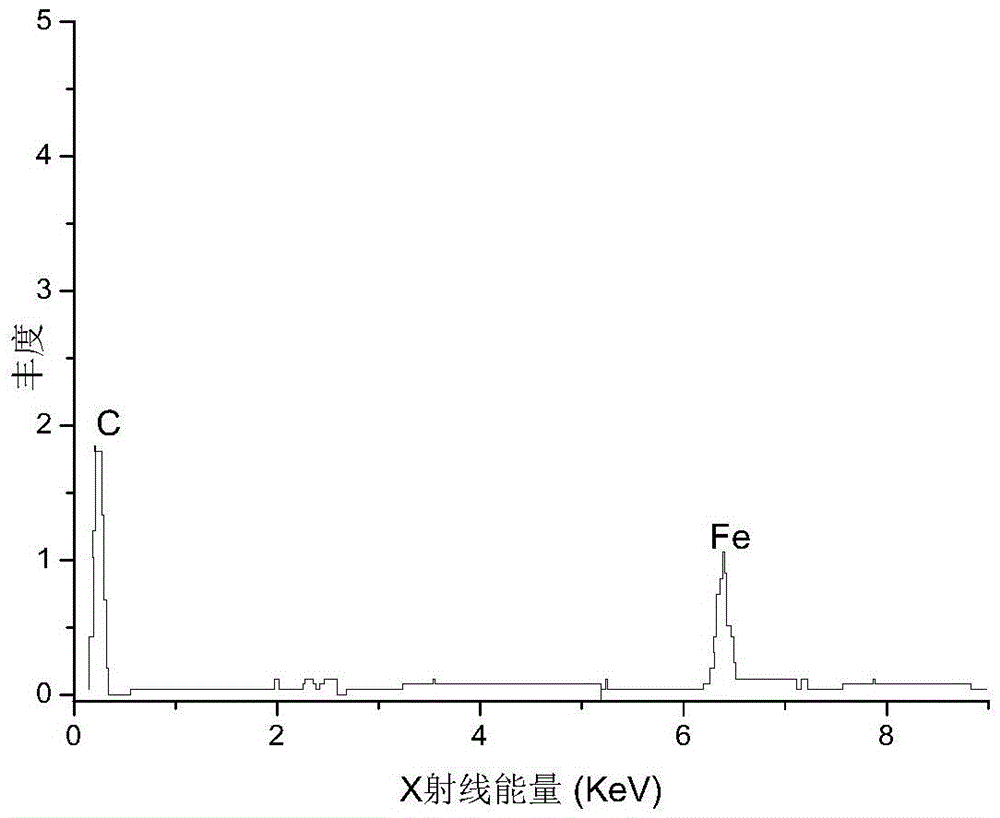

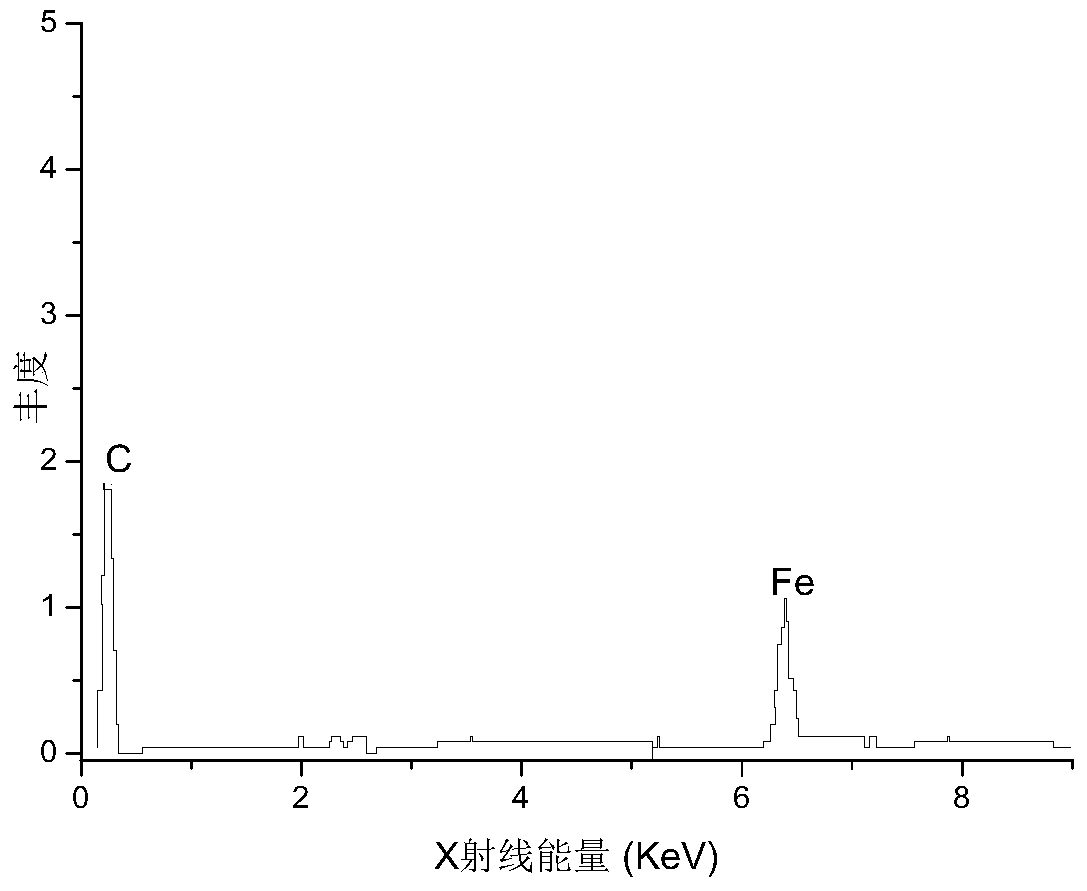

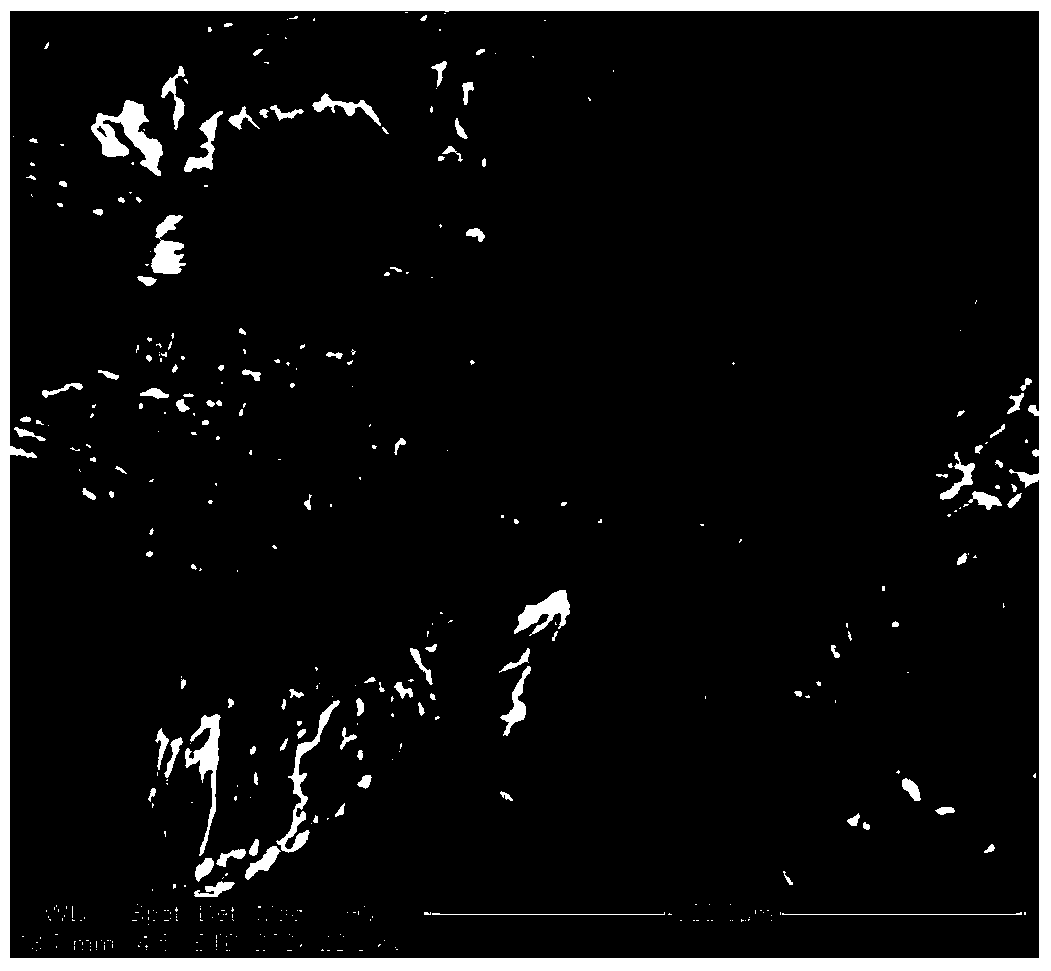

Preparation method of ferric-carbon internal electrolysis filler

ActiveCN105540751AImprove redox abilityIncrease the specific surface area of the reactionWater/sewage treatmentNature of treatment waterActivated carbonElectrolysis

The invention discloses a preparation method of a ferric-carbon internal electrolysis filler; the preparation method comprises the steps of taking cold-rolled oil sludge and pulverized coal as raw materials, mixing the raw materials evenly, then carrying out dry distillation under the protection of inert gas to obtain iron-doped activated carbon, and thus obtaining the ferric-carbon internal electrolysis filler. The iron and steel industry common pulverized coal and cold-rolled oil sludge are sintered into iron-containing activated carbon particles comprising micron-sized iron and reduced iron components, and a pore forming phenomenon appears in ferric-carbon internal electrolysis filler particles, so that the reaction efficiency of a primary battery is improved and the cost is low.

Owner:武汉钢铁有限公司

Processing method of lignite

ActiveCN101787301BImprove conversion rateMild reaction conditionsOrganic compound preparationCarboxylic acid esters preparationLiquid fuelPhenyl hydroxide

The invention discloses a processing method of lignite, comprising the following steps: A, taking methyl alcohol as extractant to carry out supercritical extraction processing to the lignite to obtain extraction liquid and raffinate; B, carrying out hot melt catalysis liquefaction processing to the raffinate to obtain liquid fuel. The invention has the beneficial effect: 1, the invention has moderate reaction condition, simple operation technology, high liquid oil yield, high domestication degree, low input and low cost and is safe and stable, and higher conversion rate of lignite; 2, the invention can obtain humic acid, organic acid methyl ester and phenol substances (phenyl hydroxide, cresol, dimethyl phenol and the like) and increase the additional value of products; 3, the supercritical methyl alcohol adopted by the invention removes R-OH and R-COOH class micromolecule substances in the lignite, which can reduce hydrogen consumption amount in the process of hot melt catalysis liquefaction so as to reduce hydrogen consumption; meanwhile, CO2 discharge amount in the process of hot melt catalysis liquefaction can be greatly reduced so as to achieve the purpose of greenhouse gas emission reduction; and 4, the invention performs swelling pretreatment to the lignite, changes lignite micropore structure, amplifies response ratio superficial area and improves the conversion rate of the lignite.

Owner:ZHAOQING SHUNXIN COAL CHEM TECH

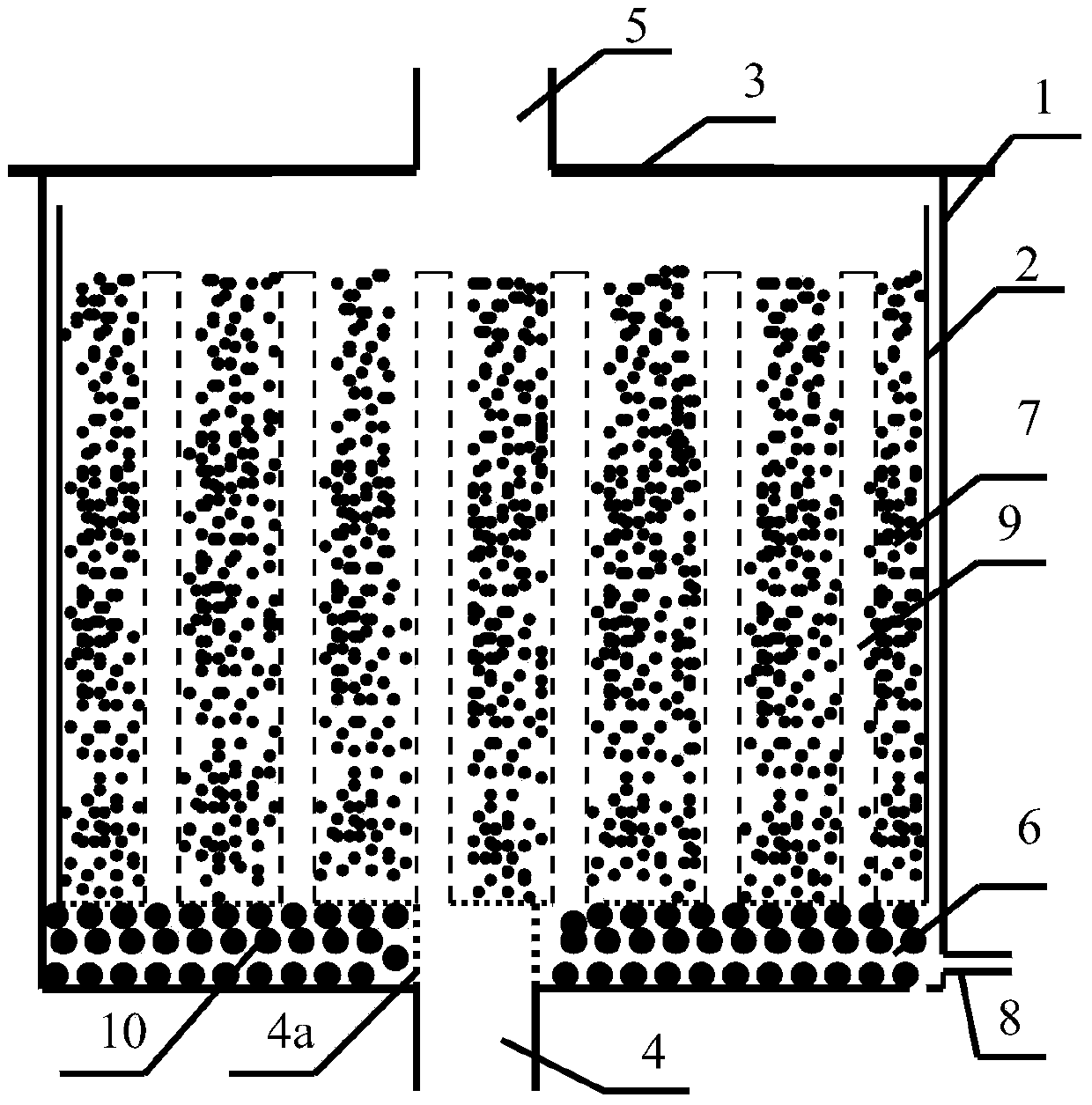

Device for efficiently treating aged landfill leachate through biological membrane and electric flocculation

PendingCN112390478ASolve pollutionEasy to operateWater contaminantsWater/sewage treatmentBiofilmMicroorganism

The invention discloses a device for efficiently treating aged landfill leachate through a biological membrane and electric flocculation. The device comprises a shell, a cathode, an anode, suspended ball filler, a carrier and a magnet. According to the invention, electric flocculation, electric flotation and microbial degradation processes can be efficiently carried out at the same time, various pollutants difficult to treat can be effectively removed. The device has the advantages of simple operation, long-term operation and convenient maintenance, solves the problems of low utilization efficiency of sacrificial electrodes, larger space between polar plates, higher energy consumption, low ammonia nitrogen removal efficiency and the like in a double-electrode electrocoagulation method, simultaneously solves the problems of pollutants which are difficult to treat by microorganisms and biomembrane pollution in a biomembrane method, and is particularly suitable for treating old garbage percolate.

Owner:KUNMING UNIV OF SCI & TECH

A kind of preparation method of electrolytic filler in iron carbon

ActiveCN105540751BImprove redox abilityIncrease the specific surface area of the reactionWater/sewage treatmentNature of treatment waterActivated carbonElectrolysis

The invention discloses a preparation method of a ferric-carbon internal electrolysis filler; the preparation method comprises the steps of taking cold-rolled oil sludge and pulverized coal as raw materials, mixing the raw materials evenly, then carrying out dry distillation under the protection of inert gas to obtain iron-doped activated carbon, and thus obtaining the ferric-carbon internal electrolysis filler. The iron and steel industry common pulverized coal and cold-rolled oil sludge are sintered into iron-containing activated carbon particles comprising micron-sized iron and reduced iron components, and a pore forming phenomenon appears in ferric-carbon internal electrolysis filler particles, so that the reaction efficiency of a primary battery is improved and the cost is low.

Owner:武汉钢铁有限公司

Treatment method of diacyl peroxide

PendingCN112851489AGood dispersionReduce pollutionPreparation from carboxylic acid saltsOrganic compound preparationBenzoyl peroxideActive agent

The invention provides a treatment method of diacyl peroxide, and belongs to the technical field of organic peroxide preparation. Benzoyl peroxide in the benzoyl peroxide waste is treated through the oxidation-reduction reaction of the benzoyl peroxide waste and sodium hydroxide, meanwhile, the dispersion effect of materials in the oxidation-reduction reaction process is enhanced through the surfactant, the reaction specific surface area is increased, the treatment efficiency is improved, the method provided by the invention is beneficial to treatment of (di)benzoyl peroxide which has no utilization value or is seriously polluted, is mild in treatment means, low in risk and good in treatment effect, can obviously reduce the generation of solid wastes and reduce environmental pollution, and is a recycling and harmless treatment mode.

Owner:常熟市滨江化工有限公司

Method for preparing conductive polymer based electromagnetic composite material

The invention relates to a method for preparing a conductive polymer based electromagnetic composite material. The method comprises the following steps of: respectively preparing magnetic powder suspending liquid, monomer dispersion liquid and an initiator solution, filling the magnetic powder suspending liquid, the monomer dispersion liquid and the initiator solution into three injectors, and continuously injecting the magnetic powder suspending liquid, the monomer dispersion liquid and the initiator solution into respective microtubules at a constant pushing speed respectively; mixing the reaction solutions in a reaction tube after the reaction solutions flow through the microtubules, and performing fluid reaction polymerization at room temperature under ultrasound assistance; and performing magnetic separation, washing, and freeze-drying on the product to obtain the conductive polymer based electromagnetic composite material. The method is simple, low in energy consumption, good in repeatability, capable of realizing continuous and fast preparation of the product, and easy to realize industrial production; and the prepared conductive polymer based electromagnetic composite material is uniform in particle size, large in specific area, stable in physical and chemical properties, difficult to agglomerate, good in dispersity and excellent in electromagnetic comprehensive performance, and has a good application prospect.

Owner:DONGHUA UNIV

Rigid polyisocyanurate node material for thermal insulation of deep sea transmission pipeline interface and preparation method thereof

The invention belongs to the technical field of polyurethane, and in particular relates to a rigid polyisocyanurate node material for thermal insulation of a deep-sea transmission pipeline interface and a preparation method thereof. The rigid polyisocyanurate node material for thermal insulation of the interface of the deep-sea transmission pipeline is composed of the A component and the B component in a mixed mass ratio of 1:1.3-1.7, and the A component is composed of polyether polyol A, poly Ether polyol B, polyester polyol C, foam stabilizer, catalyst, flame retardant, sodium silicate aqueous solution; B component is isocyanate and prepolymer mixed according to (50-80): (20-50); Polyether polyol A is a special polyether polyol with a hydroxyl value of 425±3 mgKOH / g. The rigid polyisocyanurate node material for thermal insulation of a deep-sea transmission pipeline interface of the present invention has low foam heat, high porosity, high compressive strength and good flame retardancy; the invention also provides a preparation method thereof.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

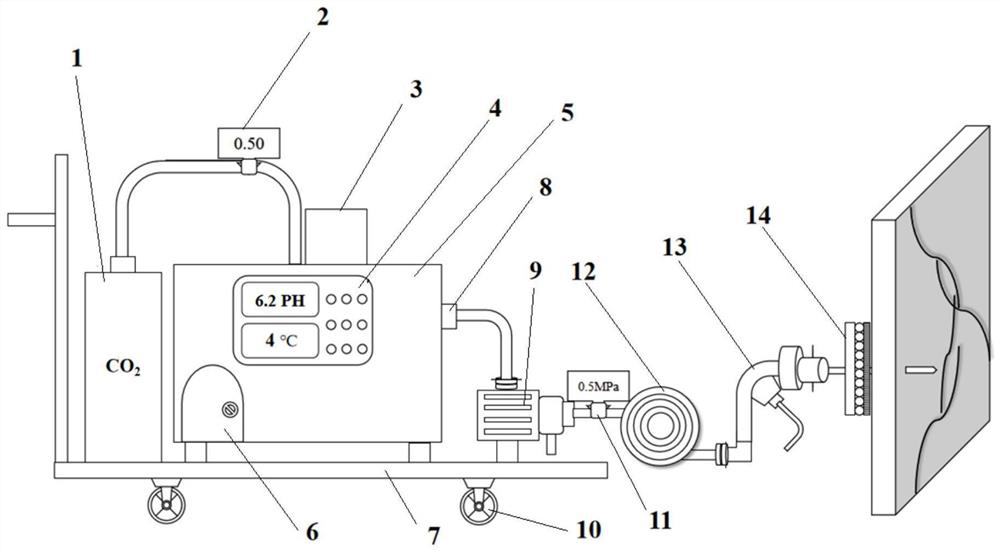

Concrete micro-crack grouting repairing device based on industrial calcium-based solid waste and carbon dioxide tail gas and working method

PendingCN114776073AStrengthen resource technology innovationAchieve reuseCalcium/strontium/barium carbonatesSolid waste disposalCalcium bicarbonateLiquid storage tank

The invention relates to a concrete micro-crack grouting repairing device based on industrial calcium-based solid waste and carbon dioxide tail gas and a working method, and belongs to the field of concrete repairing. Comprising a repairing agent preparation device, a repairing agent conveying device and a grouting repairing device. A water filling nozzle is arranged above the liquid storage tank, the liquid storage tank is filled with a mixed solution of a calcium-based industrial solid material and deionized water which are proportionally prepared, and the carbon dioxide gas tank is connected to the liquid storage tank through a pipeline; the repairing agent conveying device comprises a water pump and a conveying hose, the grouting repairing device comprises a liquid injection gun, the water pump conveys a solution in the liquid storage tank to the liquid injection gun through the conveying hose, and a heating plate is arranged on the liquid injection gun. According to the invention, carbon dioxide can be sealed, and the prepared calcium bicarbonate solution is used as a concrete microcrack repairing agent, has high fluidity, can generate calcium carbonate crystals with a cementing effect in concrete microcracks, fills gaps, builds a net-shaped structure, and gradually forms an integral structure with original concrete to complete crack repairing.

Owner:SHANDONG UNIV +1

A method for preparing para-aramid fiber by spray method

ActiveCN113045750BIncrease removalSafe and efficient preparationPolyamide coatingsPolymer sciencePyrrolidinones

The invention discloses a method for preparing para-aramid fibers by spraying method. By using p-phenylenediamine and terephthaloyl chloride as monomers and nitrogen methyl pyrrolidone as solvents, the monomers are dissolved in an inert gas environment. The dispersed phase is formed through spray gun atomization, and the mist clusters collide to quickly undergo polycondensation reaction, and the product is directly sprayed on the material panel, and after high-temperature drying, an aramid coating is formed in one step. During the reaction process, the atomization state is used to increase the contact specific surface area of the reactants, so as to realize the rapid removal of reaction heat and improve the process safety. The invention realizes rapid removal of reaction heat in the aramid fiber polymerization process, the production process is safe and controllable, and the thermal insulation coating material can be manufactured more efficiently.

Owner:NANJING TECH UNIV

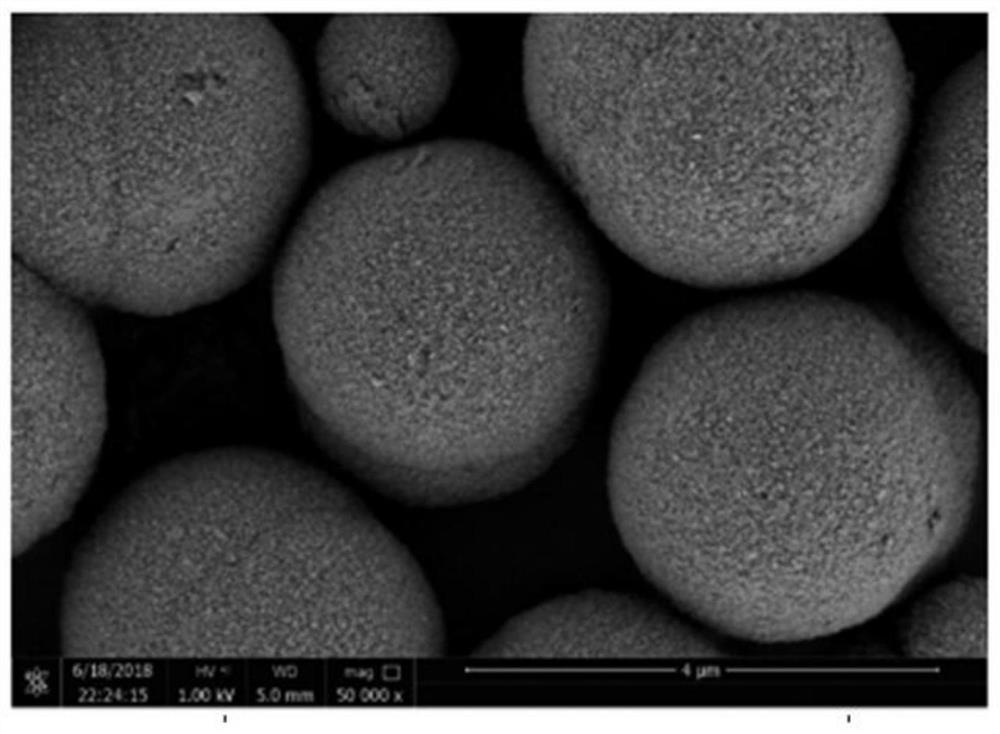

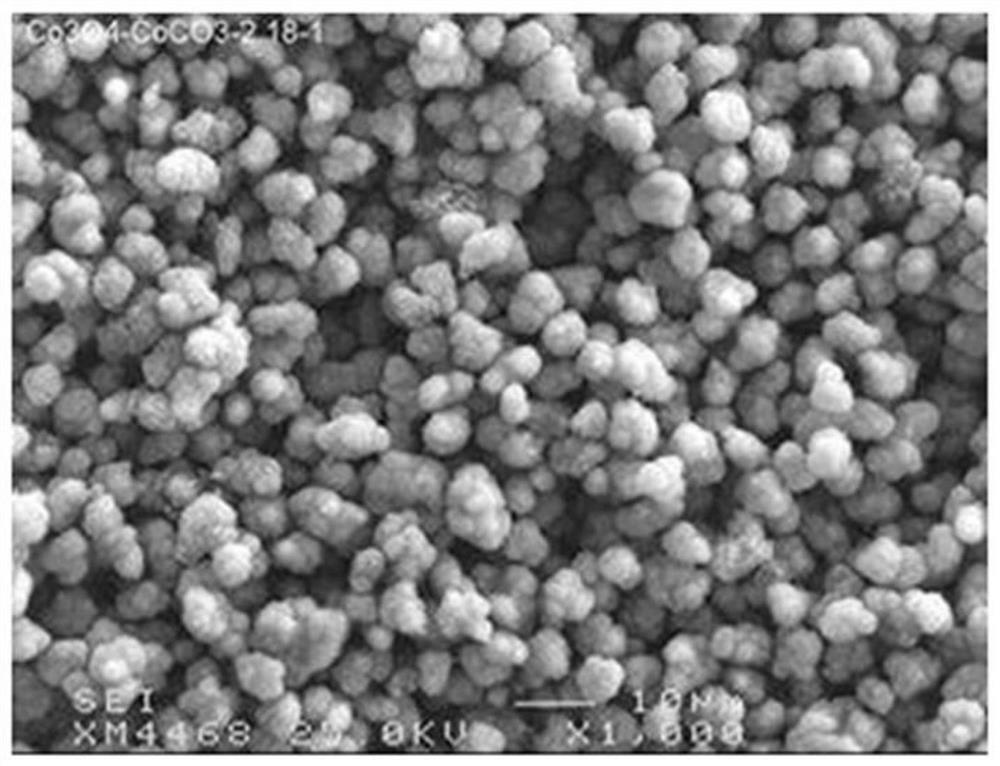

A kind of preparation method of tricobalt tetroxide with small and uniform particle size

ActiveCN109678215BDense surfacePrevent sinteringCobalt oxides/hydroxidesFiltrationCobalt(II,III) oxide

The invention discloses a method for preparing a cobaltosic oxide with a small and uniform particle size and belongs to the technical field of inorganic chemicals. The method comprises the following steps: (1) dissolving a cobalt salt into hot water so as to obtain a 1.0-2.0mol / L cobalt salt solution, and dissolving a precipitant into hot water so as to obtain a 10-15mol / L base solution, wherein the precipitant is ammonium carbonate or ammonium bicarbonate; (2) rapidly stirring the base solution under a normal temperature condition, and uniformly putting the cobalt salt solution into the stirred base solution at a uniform speed to generate uniform flocculent colloid, wherein the mole ratio of the cobalt salt to the precipitant is 1:3; (3) rapidly heating the flocculent colloid to 40-60 DEGC, leaving to stand and age under a heat preservation condition so as to obtain an aged liquid with a cobaltosic oxide precursor, and carrying out steps of filtration, pulping, washing and calcining,thereby obtaining the cobaltosic oxide. By adopting the method, complexing reactions of the precipitant and a polycondensation reaction of the flocculent colloid of an extreme large supersaturation degree are sufficiently utilized, a microwave technique is creatively used, and a product of a uniform and controllable particle size, a complete sphericity degree and a large specific surface area canbe produced.

Owner:张甘泉

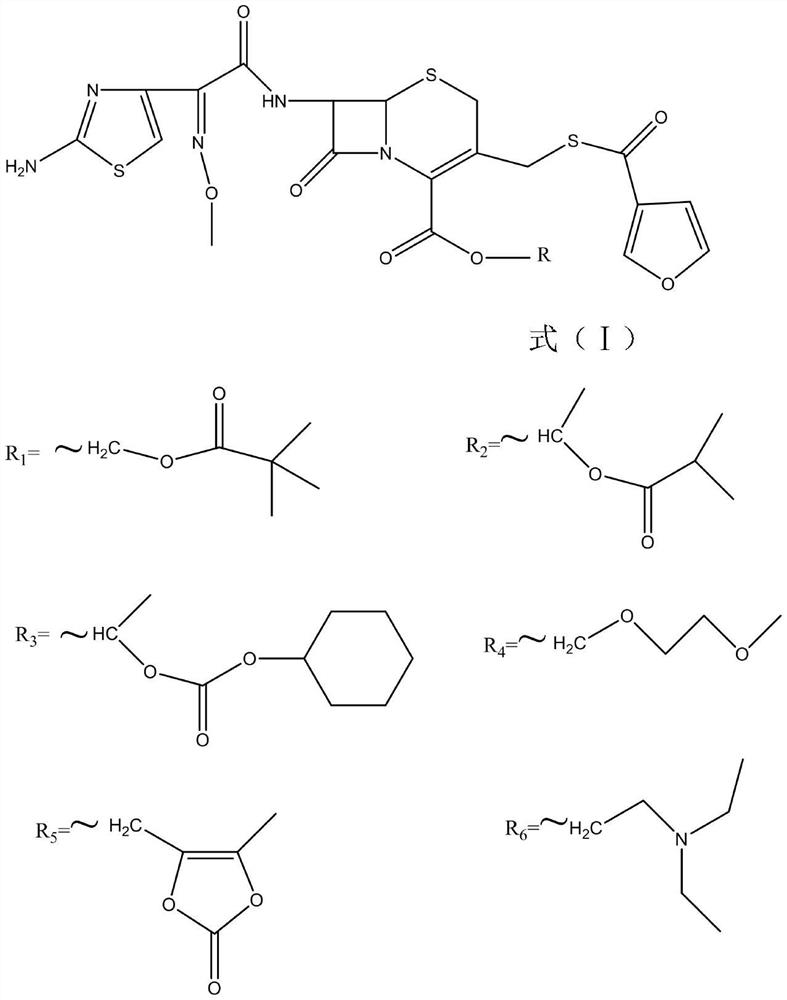

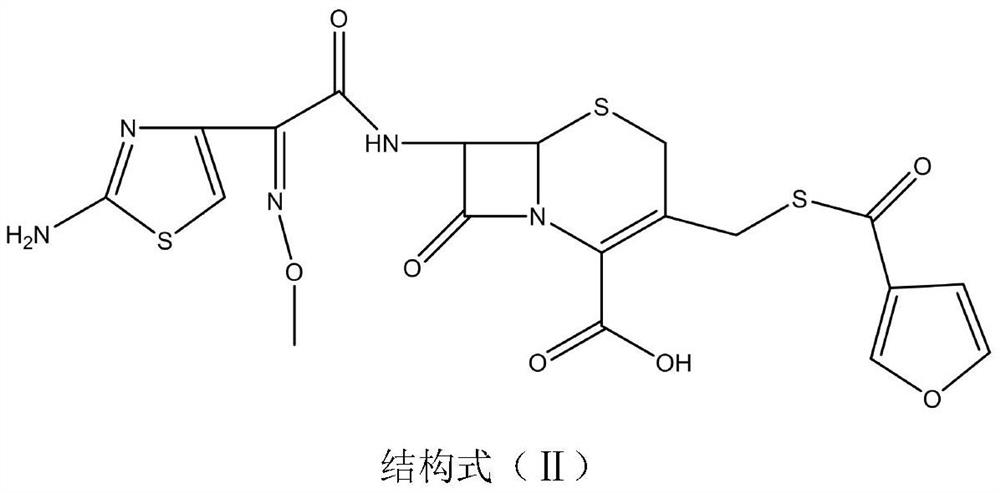

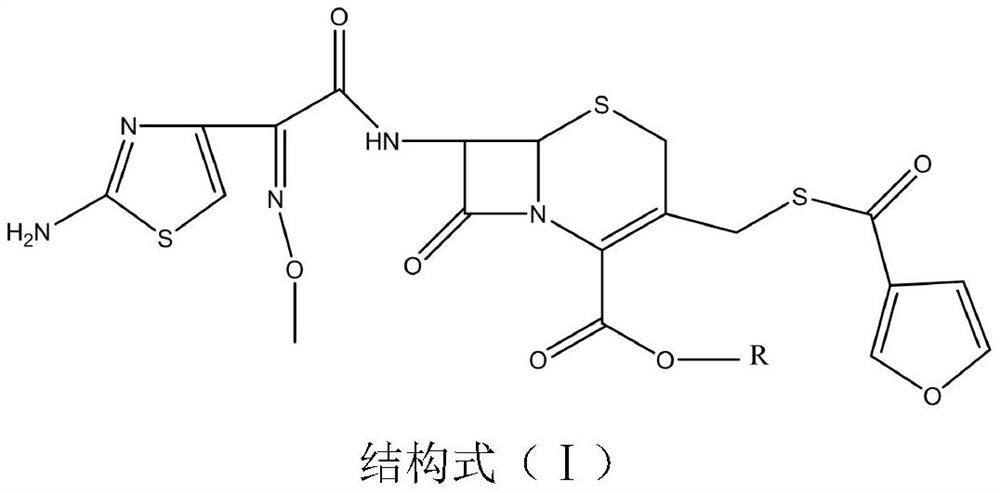

Preparation method of ceftiofur axetil compound or its halogen salt

ActiveCN108440570BLarge apertureGood dispersionAntibacterial agentsOrganic chemistryEthyl groupMethyl palmoxirate

The invention provides a ceftiofur ester type compound or halogen salt thereof as well as a preparation method and application of the ceftiofur ester type compound or the halogen salt thereof. The ceftiofur or sodium salt thereof takes anion exchange resin as a reaction carrier, and an esterification reagent, such as chloro(iodo)methyl pivalate, 1-iodoethyl isopropyl carbonate, 1-iodoethyl cyclohexyl carbonate, methoxyethoxychloromethyl ether, 4-chloromethyl-5-1,3-dioxole-2-one, 1-iodoethyl cyclohexyl carbonate, 2-chlorotriethylamine and hydrochloride thereof, is added into an organic solvent;then ultrasonic reaction is carried out to prepare an ester type compound corresponding to the ceftiofur; furthermore, the halogen salt of the ceftiofur is prepared. In a preparation process, DMF (Dimethyl Formamide) is not used so that the pollution is reduced; the anion exchange resin is used as the reaction carrier so that the reaction speed is improved, a technology is saved and the preparation method is simple.

Owner:济宁市化工研究院 +1

Method for efficiently co-producing maltose syrup and rice protein by rice processing by-products

ActiveCN106755204BHigh extraction rateImprove solubilityMicroorganism based processesFermentationBiotechnologyAmylase

The invention discloses a method for realizing efficient co-production of malt syrup and rice protein by adopting rice processing by-products. Broken rice and rice bran are adopted as the raw materials. The method comprises the following processing steps: (1) carrying out mechanical pretreatment; (2) carrying out ultrasonic treatment; (3) carrying out mild biological activating; (4) carrying out degreasing pretreatment; (5) carrying out hydrolysis and liquefying by adopting alpha-amylase; (6) carrying out separating, namely, carrying out centrifugalizing on the liquefied liquid obtained in the step (3) at 3200r / min, thus obtaining the supernate and sediment; (7) preparing broken rice and rice brain protein; (8) carrying out modified treatment on saccharifying enzyme; and (9) preparing the broken rice and rice bran malt syrup. With the adoption of the method provided by the invention, the malt syrup and rice protein by-products with good quality can be prepared, and the utilization value of the rice processing by-products is favorably improved.

Owner:无锡甜丰食品有限公司

Treatment method of pasty diacyl peroxide

PendingCN112851495AFully dispersedReduce pollutionPreparation from carboxylic acid saltsOrganic compound preparationActive agentAcyl group

The invention provides a treatment method of pasty diacyl peroxide, and belongs to the technical field of organic peroxide preparation. According to the method, the bis(2, 4-dichlorobenzoyl) peroxide in the bis(2, 4-dichlorobenzoyl) peroxide waste is treated through the oxidation-reduction reaction of the bis(2, 4-dichlorobenzoyl) peroxide waste and sodium hydroxide, meanwhile, the dispersion effect of materials in the oxidation-reduction reaction process is enhanced through the surfactant, the reaction specific surface is increased, and the treatment efficiency is improved; and full dispersion of the pasty peroxide bis(2, 4-dichlorobenzoyl) waste is achieved through shearing dispersion, pasty bis(2, 4-dichlorobenzoyl) which has no utilization value or is seriously polluted can be treated, the treatment means is mild, the risk is low, the treatment effect is good, generation of solid waste can be remarkably reduced, environmental pollution is reduced, and the method is a recycling and harmless treatment mode.

Owner:常熟市滨江化工有限公司

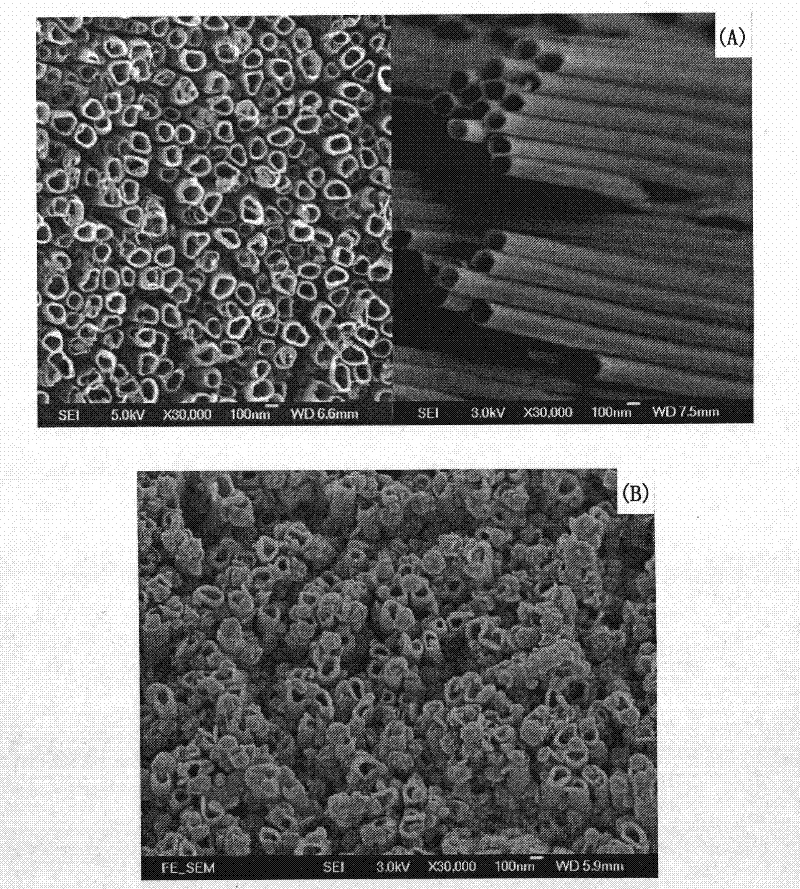

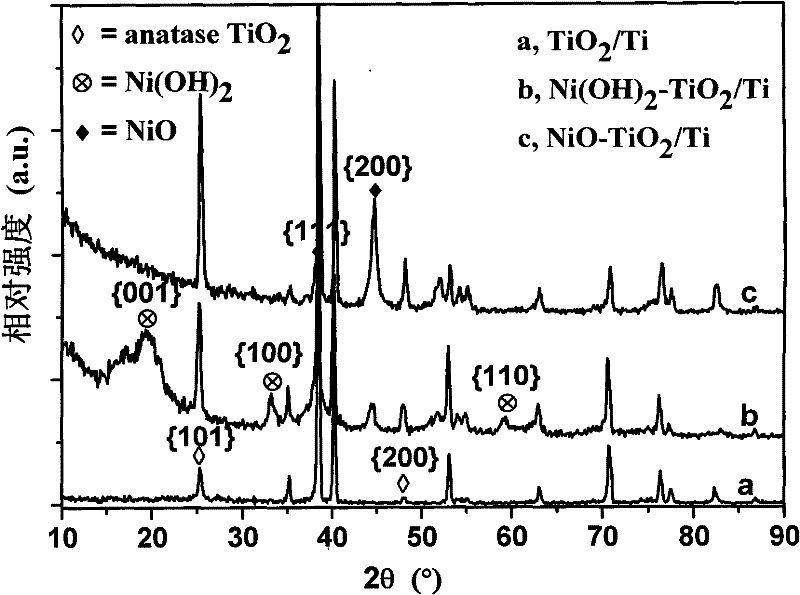

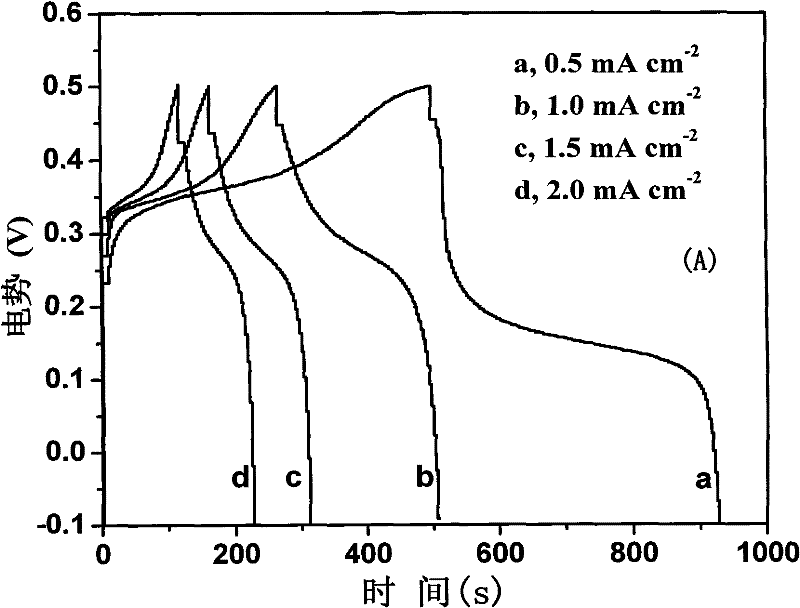

Ordered nano-tube array structure electrode material, preparation method and stored energy application

InactiveCN101625930BImprove energy storage efficiencyHigh capacity densityIndividual molecule manipulationCapacitor electrodesOxide coatingMaterials science

The invention relates to a preparation method for electrode material of a super capacitor of an ordered nano-tube array structure. A titanium-base titanium dioxide nano-tube is used as a carrier of the electrode; metallic oxide with electrochemical activity is loaded on the tube wall surface of the nano-tube; functional electrode material of the nano-tube array structure is built, wherein the tube diameter of the nano-tube is 50-200nm, the wall thickness is 10-20nm and the length is 0.2-50 mu m. The preparation method is as follows: firstly, adopting the titanium-base titanium dioxide electrode carrier of the ordered nano-tube array structure prepared by a self-template anodic oxidation reaction synthetic method; then, taking the titanium-base titanium dioxide electrode carrier of the ordered nano-tube array structure as a working electrode and transition metal ion or noble metal ion water solution as working electrolyte, carrying out electro reduction-electro oxidation reaction by circulation, synthesizing a metallic oxide coating layer on the wall surface of the nano-meter tube in situ, and preparing electrode material with the electrochemical activity. The electrode material ofthe ordered nano-tube array structure is used as the stored energy application of the electrode of the super capacitor.

Owner:SOUTHEAST UNIV

A purification device and purification method for strongly acidic components in exhaust gas

ActiveCN105107369BExtended service lifeEliminate cloggingDispersed particle separationActive componentProcess engineering

The invention discloses a purification device and purification method for strongly acidic components in exhaust gas, which is characterized in that it includes a reactor shell, an active material filling container installed in the reactor shell, and an The support layer between the material filling containers; the top of the reactor shell is sealed by a sealing cover plate, and an air inlet, an air outlet and a liquid discharge port are arranged on the reactor shell; an air guide tube is inserted into the active material filling container. In the purification device of the present invention, the exhaust gas containing strongly acidic components enters the air guide tube after being distributed by the supporting layer, and then enters the active material filling container through the air holes arranged on the air guide tube to contact with the active filler. The components react with active fillers to form salts, and the purified exhaust gas is discharged through the exhaust pipe.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com