Preparation and applications of biocarbon supported thermally activated iron containing ore composite material

A composite material and biochar technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as difficult dispersion and general biochar adsorption effect, achieve increased dispersibility, simple and feasible preparation method, The effect of improving the efficiency of heavy metal restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

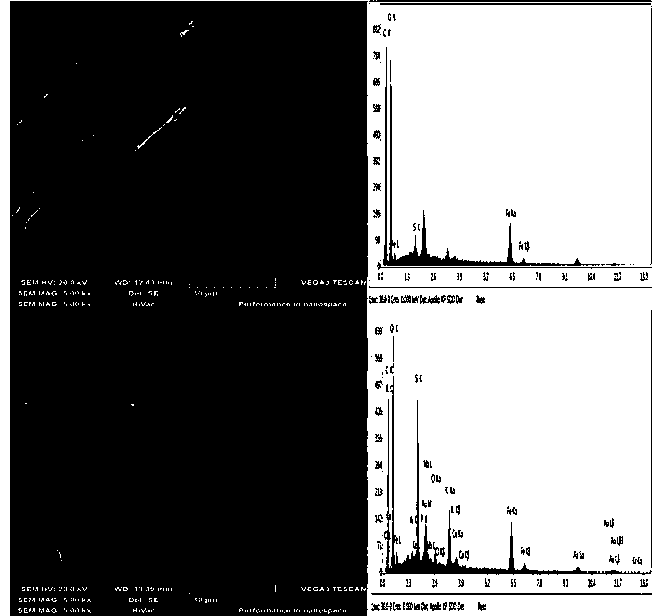

Image

Examples

Embodiment 1

[0028] A preparation method of biochar-loaded heat-activated iron-containing mineral composite material according to the present invention is as follows:

[0029] Firstly, the biomass raw materials (agricultural waste rice straw and bagasse) were washed and dried at 80 °C for 48 h to obtain biomass with a water content of 10-11%, and the mineral raw materials were preliminarily crushed. 1~3 cm, the selected iron-containing mineral is goethite, the crushing particle size is 0.5~1 cm, then the biomass and mineral raw materials are ground and mixed according to a certain mass ratio (3:1), and passed through 80~100 mesh The mixed material powder is obtained by sieving; the mixed material powder is put into a mold to obtain a biomass-loaded mineral complex with a diameter of 0.5-2 cm and a height of 1-1.5 cm;

[0030] The biomass-loaded mineral complex was placed in an atmosphere with hydrogen as the reducing atmosphere and nitrogen as the protective gas, the gas flow rate was cont...

Embodiment 2

[0033] The biochar-loaded heat-activated iron-containing mineral composite material of the present invention treats heavy metal ions Cr(VI) and Cu(II) in water, comprising the following steps:

[0034] Weigh 0.05 g of bagasse biochar (Z-Z) / straw biochar (J-Z) loaded thermally activated iron-containing mineral composites and place them in a 50 ml centrifuge tube, set the concentration gradient of heavy metals to 30, 50, 150, 250, 350 , 450 mg / L, adjust the pH value to about 6 with 1 mol / L sodium hydroxide and 30% nitric acid solution, put the centrifuge tube in a constant temperature shaker for 24 h, set the temperature at 30 °C, and rotate at 170 r / min. After 24 hours of reaction, 1 mL of the solution was taken for centrifugation, and the supernatant was taken into a centrifuge tube. The chromium ion content in the solution was measured by the diphenylcarbohydrazide (DPCI) method, and the copper ion content in the solution was determined by the BCO method. The results showed...

Embodiment 3

[0036] The biochar-loaded heat-activated iron-containing mineral composite material of the present invention treats Cr(VI) and Cu(II) of heavy metal ions in water, comprising the following steps:

[0037]Weigh 0.05 g of bagasse biochar (Z-Z) / straw biochar (J-Z) loaded heat-activated iron-containing mineral composites and place them in a 50 mL centrifuge tube, add 15 mL of deionized water into the centrifuge tube, and mix the materials and After the water is fully mixed, measure the initial pH value of the solution with a pH meter, and adjust the pH value of the solution with 1 mol / L sodium hydroxide and 30% nitric acid solution, and set the gradient to 4, 5, 6, 7, 8. After the pH value of the system was stabilized, 5 mL of copper solution and chromium solution with corresponding pH values were added respectively, and the centrifuge tube was placed in a constant temperature shaker for 24 h. The temperature was set at 30 °C and the rotation speed was 170 r / min. After the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com