A method for treating heavy metal wastewater

A technology of heavy metals and heavy metal ions, which is applied in water/sewage treatment, chemical instruments and methods, and neutralized water/sewage treatment, etc. It can solve the problems of unstable water treatment effect, large amount of sludge and limited adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment prepares Pb-containing 2+ , Zn 2+ , Mn 2+ , Fe 2+ Each 5mg / L of heavy metal wastewater, adjust the pH value of the wastewater to 4.5-5, as a simulated heavy metal wastewater, according to the following steps:

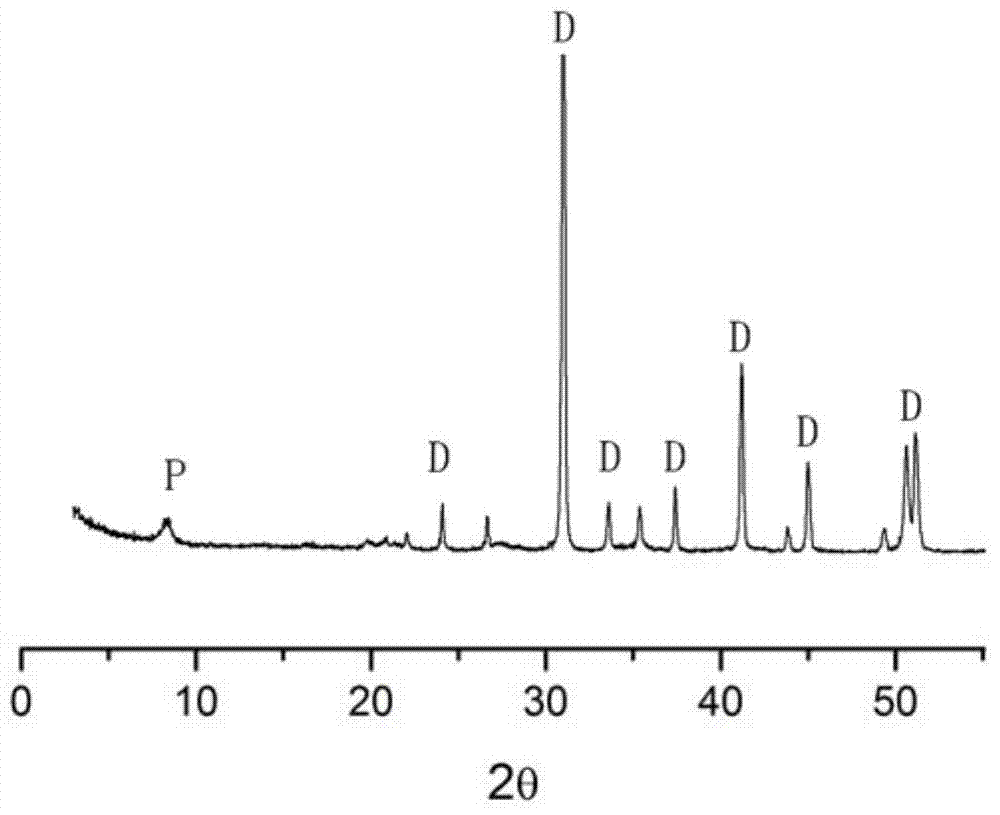

[0026] a, select the clayey dolomite composed of nano mineral attapulgite-dolomite, the content of dolomite is 60%, the content of attapulgite and opal is 40%;

[0027] b. Clay dolomite is crushed and sieved to obtain clay dolomite particles of 0.5 to 1 mm;

[0028] c. Pack the clayey dolomite particles into a filter column with a diameter of 20mm and an effective height of 500mm;

[0029] d. Filtrate simulated heavy metal wastewater with a hydraulic retention time of 1h, and take water samples twice a week to detect Pb in the water 2+ , Zn 2+ , Mn 2+ , Fe 2+ Concentration, which lasted 110 days, the test results showed that Pb 2+ 2+ 2+ 2+ <0.1mg / L, the pH value of the effluent and the concentration of heavy metal ions meet the discharge ...

Embodiment 2

[0032] This example prepares Cu-containing 2+ 50mg / L heavy metal wastewater, adjust the pH value of the wastewater to 4.5-5, as a simulated heavy metal wastewater, and process it according to the following steps:

[0033] a, select the clayey dolomite composed of nano mineral attapulgite-dolomite, the content of dolomite is 65%, the content of attapulgite and opal is 35%;

[0034] b. Crushing and sieving the clayey dolomite to obtain clayey dolomite particles of 0.5 to 1 mm; taking part of the clayey dolomite and calcining at 900° C. for 120 minutes to obtain calcined clayey dolomite particles;

[0035] C, packing clayey dolomite particles and calcined clayey dolomite particles into a filter column with a diameter of 20mm and an effective height of 500mm according to a mass ratio of 2:1;

[0036]d. The simulated heavy metal wastewater was filtered and treated with a hydraulic retention time of 10 minutes, and Cu was detected by atomic absorption spectrophotometry. 2+ , pH, t...

Embodiment 3

[0039] The present embodiment gets heavy metal-containing acidic water from a certain porphyrite iron ore acid reservoir as simulated heavy metal wastewater, which contains 47 mg / L of copper and a pH value of 2.8, and is processed according to the following steps:

[0040] a, select the clayey dolomite composed of nano mineral attapulgite-dolomite, the content of dolomite is 55%, the content of attapulgite and opal is 45%;

[0041] b. Crushing and sieving the clayey dolomite to obtain clayey dolomite particles of 0.5 to 2 mm in size, and calcining at 600° C. for 120 minutes to obtain calcined clayey dolomite particles;

[0042] c, the calcined clay dolomite particles are loaded into a filter column with a diameter of 20mm and an effective height of 500mm;

[0043] d. Treat the simulated heavy metal wastewater with a filtration rate of 1 h, in which the calcined clay dolomite particles slowly hydrate to release hydroxyl groups, increase the pH value of the water to between 8 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com