Al-LiH composite fuel for unmanned underwater vehicle and preparation method thereof

A technology of composite fuel and aluminum powder, applied in chemical instruments and methods, inorganic chemistry, offensive equipment, etc., can solve the problems of reducing reaction rate and reaction conversion rate, large specific surface area of nano-aluminum powder, and hindering the continuous progress of reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

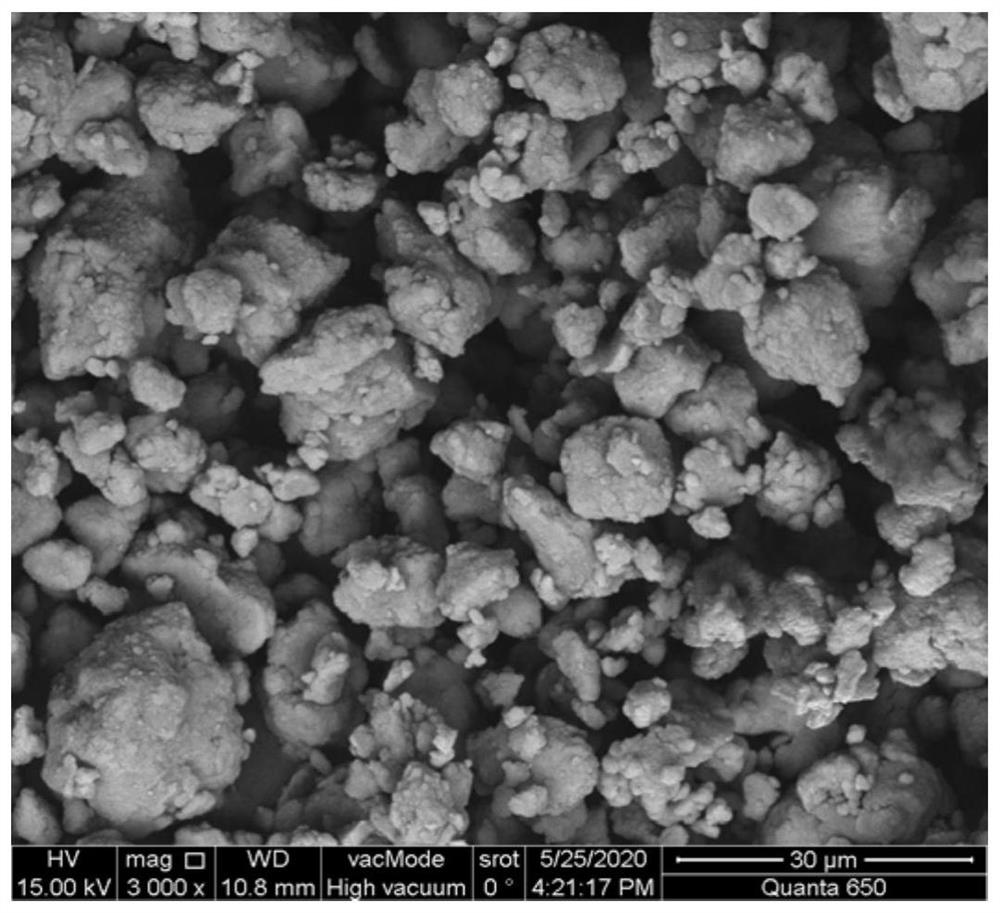

[0025] According to a second aspect of the present invention, a method for preparing Al-LiH composite fuel for unmanned underwater vehicles is provided, for preparing the Al-LiH composite fuel described in the first aspect above, comprising: weighing aluminum powder and Lithium hydride is evenly mixed and put into a ball mill tank, sealed and ball milled in a ball mill to prepare Al-LiH composite fuel.

[0026] Among them, the aluminum powder is micron aluminum powder, and its specifications are FLQT1 (median particle size 29±3μm), FLQT2 (median particle size 24±3μm), FLQT3 (median particle size 13±2μm), FLQT4 (median particle size 6±1.5μm), FLQT5 (median size 2±1μm) or a combination of several.

[0027] Among them, the lithium hydride is in the micron order, and the median particle diameter D50 is 1 μm to 2 μm.

[0028] In the present invention, the ball mill is any one of a planetary ball mill, a horizontal ball mill or a conical ball mill.

[0029] When grinding, the ball...

Embodiment 1

[0034] In the glove box, mix 9.7g FLQT5 aluminum powder and 0.3g LiH (D50 is 2μm) evenly, pour it into the ball mill jar, seal the ball mill jar, take it out, and mill it on a planetary ball mill at a speed of 200r / min for 30min. 50:1, the prepared Al-LiH composite fuel, the median particle size of 2μm. Measured Al-LiH composite fuel density: 2.52g / cm 3 , Combustion reaction conversion rate with high-temperature steam: 83.0%, oxygen-filled combustion heat 30MJ / kg.

Embodiment 2

[0036] In the glove box, mix 5g FLQT3 aluminum powder and 5g LiH (D50 is 1.5μm) evenly, pour it into the ball mill jar, seal the ball mill jar, take it out, and mill it on a planetary ball mill at a speed of 300r / min for 5 hours, the ball-to-material ratio 40:1, the prepared Al-LiH composite fuel, the median particle size of 5μm. Measured Al-LiH composite fuel density: 1.23g / cm 3 , Combustion reaction conversion rate with high-temperature steam: 98.5%, oxygen-filled combustion heat 33.8MJ / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com