Annular pipe rotational flow layer of desulfurizing tower and working method thereof

A working method and desulfurization tower technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of the influence of the flow field distribution of the desulfurization tower, the negative effects of the safe and stable operation of the desulfurization system, and the adherence to the wall. Effects of pipes, reduced diameter, increased velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

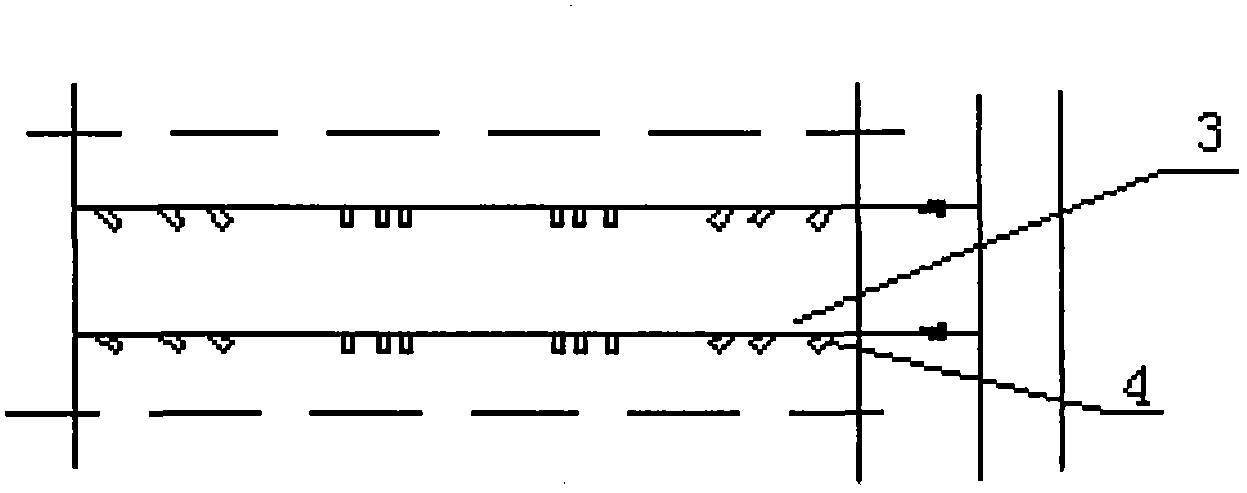

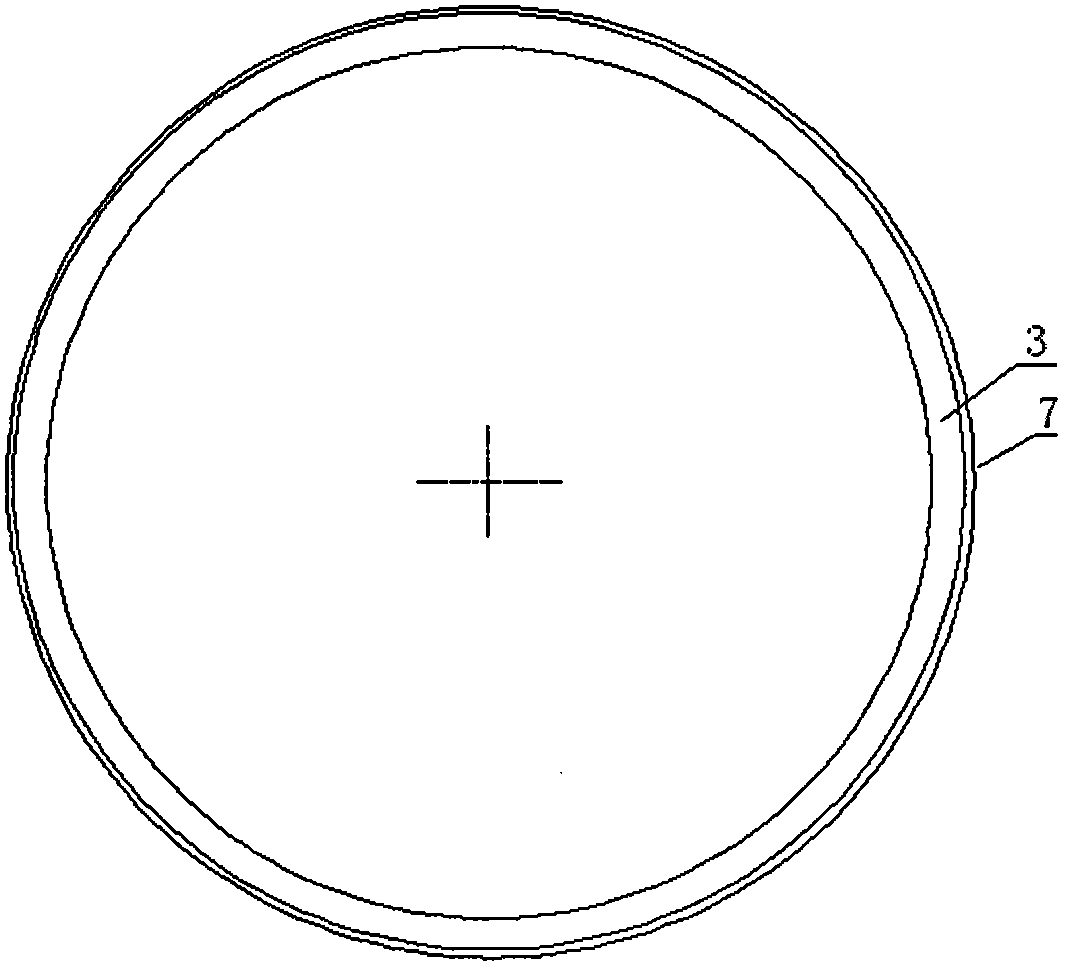

[0013] see figure 1 and figure 2 As shown, the ring pipe swirl layer of a desulfurization tower of the present invention includes a desulfurization tower wall 7, an annular slurry pipeline 3 is arranged on the desulfurization tower wall 7, and more than one high-efficiency atomizing nozzle is arranged tangentially on the annular slurry pipeline 3 4. The high-efficiency atomizing nozzle 4 is arranged below the annular slurry pipeline 3 . Tangential arrangement of the turbulent flow field generated by the high-efficiency atomizing nozzle 4 enhances the uniformity of reactant mixing, increases the specific surface area of the reaction, prolongs the reaction contact time, and accelerates the rate of the absorption reaction, thereby realizing efficient desulfurization.

[0014] Wherein, the diameter of the annular slurry pipe 3 is 0.8m, which acts like a rectifying member and can prevent the flue gas from escaping along the tower wall, making it easier for the flue gas to flow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com