Concrete micro-crack grouting repairing device based on industrial calcium-based solid waste and carbon dioxide tail gas and working method

A technology of carbon dioxide and concrete, applied in the field of concrete repair, can solve the problems of not meeting the repairing requirements of concrete cracks, unsatisfactory long-term effect, poor durability and other problems, and achieve the effect of stable long-term effect, low production cost and short repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

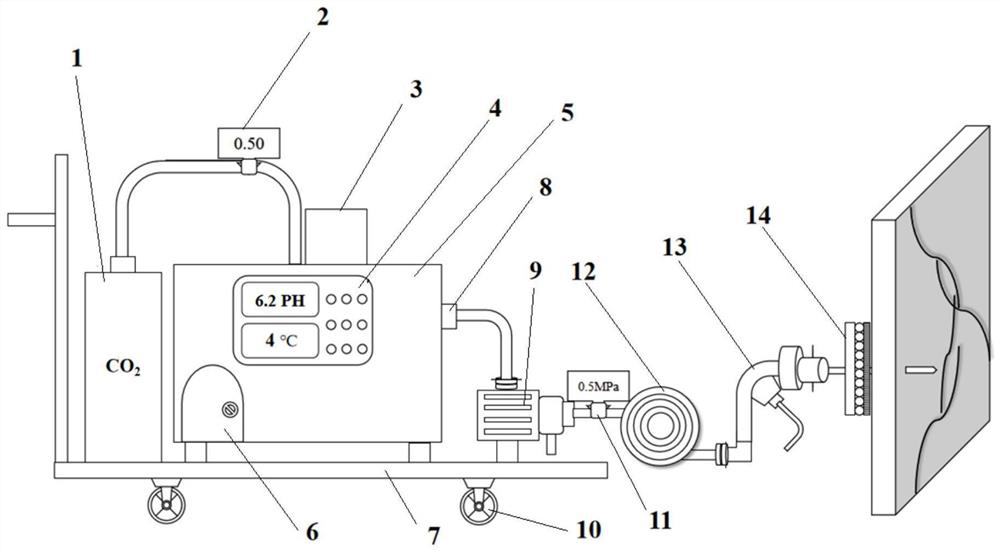

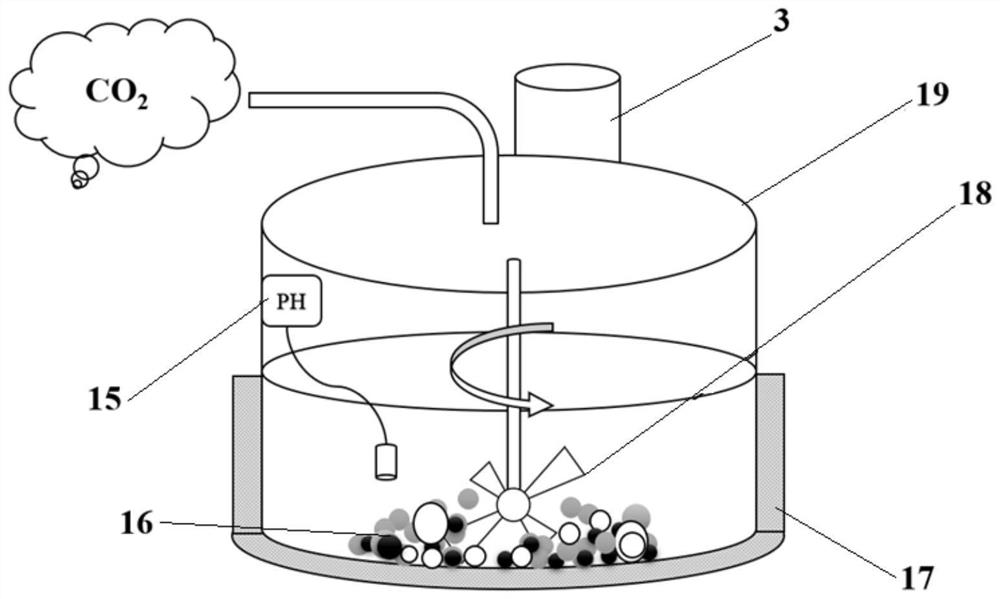

[0041] A concrete micro-crack grouting repair device based on industrial calcium-based solid waste and carbon dioxide tail gas, such as Figure 1-4 As shown, including a repair agent preparation device, a repair agent delivery device and a grouting repair device;

[0042] The repairing agent preparation device includes a carbon dioxide gas tank 1 and a slurry preparation box 5, a liquid storage tank 19 is placed in the slurry preparation box 5, a water injection port 3 is arranged above the liquid storage tank 19, and the calcium base in the liquid storage tank 19 is proportionally configured. The mixed liquid of industrial solid material 16 and deionized water, the carbon dioxide gas tank 1 is industrial waste gas containing carbon dioxide, and the carbon dioxide gas tank 1 is connected to the liquid storage tank 19 through a pipeline;

[0043] The repairing agent conveying device includes a water pump 9 and a conveying hose 12, and the grouting repairing device includes a li...

Embodiment 2

[0045] A concrete micro-crack grouting repairing device based on industrial calcium-based solid waste and carbon dioxide tail gas, as described in Example 1, the difference is that the liquid storage tank 19 is provided with a stirring device 18, a pH monitor 15 and a temperature control device. The gas flow rate monitor 2 is installed on the pipeline of the carbon dioxide gas tank 1 and the liquid storage tank 19 to monitor and control the gas flow in real time.

[0046] The repair agent preparation device and the water pump are all arranged on the mobile cart 7, and the bottom of the mobile cart 7 is provided with a pulley 10, which is convenient for moving the device;

[0047] The slurry preparation box is provided with a control panel 4. The control panel 4 is connected with the pH monitor 15 and the temperature controller 17. The control panel 4 can display the solution reaction temperature and pH value changes in real time through the control panel 4, and can adjust the s...

Embodiment 3

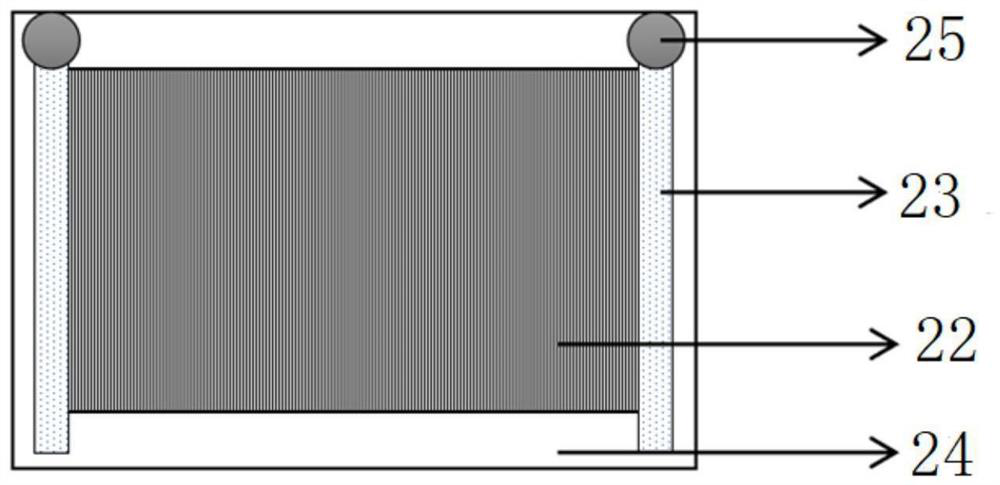

[0050] A concrete micro-crack grouting repairing device based on industrial calcium-based solid waste and carbon dioxide tail gas, as described in Example 1, the difference is, as image 3 , 4 As shown, the heating plate 14 is an infrared heating plate, a through hole is provided in the middle of the infrared heating plate, and a fixing ring 20 is arranged in the through hole to fix the infrared heating plate at a suitable position of the liquid outlet end 21 of the liquid injection gun. Under normal circumstances, the liquid outlet end 21 of the liquid injection gun extends into the crack for the same length. If the crack depth is too large or too small, the position of the infrared heating plate needs to be adjusted so that it is close to the concrete surface, and the liquid outlet end extends into the crack. After installation, the fixing ring 20 can be loosened, the heating plate can be adjusted to a position close to the concrete surface, and the fixing ring 20 can be tig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com