Rigid polyisocyanurate node material for thermal insulation of deep sea transmission pipeline interface and preparation method thereof

A technology of polyisocyanurate and transmission pipes, which is applied in the field of polyurethane, can solve the problems of unsatisfactory thermal insulation effect, low water absorption rate, high cost, etc., achieve the improvement of compressive strength, improve compressive strength and flame retardancy, and avoid The effect of foam breaking action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the polyether polyol A used is as follows:

[0037]In a 2.5L autoclave equipped with a stirrer, a meter, a heating and temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, 342g of sucrose, 33.54g of trimethylolpropane, and a catalyst of KOH3. 47g, nitrogen was replaced 5 times, and evacuated to a pressure of -0.08MPa, then stirred (rotation speed 500r / min) to heat up, when the temperature increased to 85 °C, 116.5g of ethylene oxide was added, and the initial pressure was controlled to 0.20Mpa, the reaction When the pressure is constant, the temperature is raised to 120°C, the pressure is controlled at 0.20MPa, 233.5g of propylene oxide is continuously added, and the remaining 389.5g of ethylene oxide is added continuously after the reaction until the pressure no longer changes, and the remaining 40g of ethylene oxide is added after aging for a period of time. Propylene oxide is conti...

Embodiment 1

[0039] The rigid polyisocyanurate node material for thermal insulation of deep-sea fuel transmission pipeline interface is prepared according to the following formula and method:

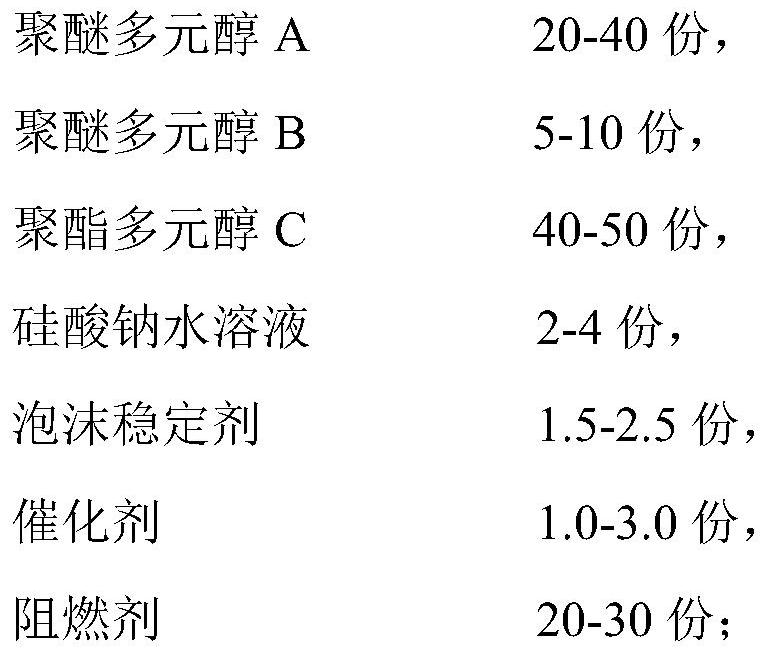

[0040] A component:

[0041]

[0042]

[0043] Component B:

[0044] PM200 1162kg

[0045] Prepolymer 290kg;

[0046] The mixing mass ratio of component A and component B is 1:1.3.

[0047] Preparation:

[0048] (1) Add the weighed polyether polyol A, INOVOL S210H, PS-2352, foam stabilizer L580, catalyst A-1, catalyst DMP-30, catalyst TMR-2, and flame retardant FR102 to the reaction kettle in turn , stir at room temperature for 1.5h, then add sodium silicate aqueous solution and stir for 20min to obtain component A;

[0049] (2) first use INOVOL S210H and PM200 as raw materials to synthesize a prepolymer with an NCO content of 21.5wt%, add the prepolymer and PM200 of the formula amount to the reaction kettle, and stir at room temperature for 1h to obtain component B;

[0050] (3) When us...

Embodiment 2

[0052] The rigid polyisocyanurate node material for thermal insulation of deep-sea fuel transmission pipeline interface is prepared according to the following formula and method:

[0053] A component:

[0054]

[0055]

[0056] Component B:

[0057] PM200 1027kg

[0058] Prepolymer 685kg;

[0059] The mixing mass ratio of component A and component B is 1:1.5.

[0060] The preparation method is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com