High-temperature combustor

A technology of high-temperature combustion and rectification tube, which is applied in the field of coal gasification, can solve the problems of insufficient reaction between the imported crude gas and the gasification agent of the gasification burner, etc., so as to increase the residence time, facilitate disassembly and replacement, and ensure the service life of the equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

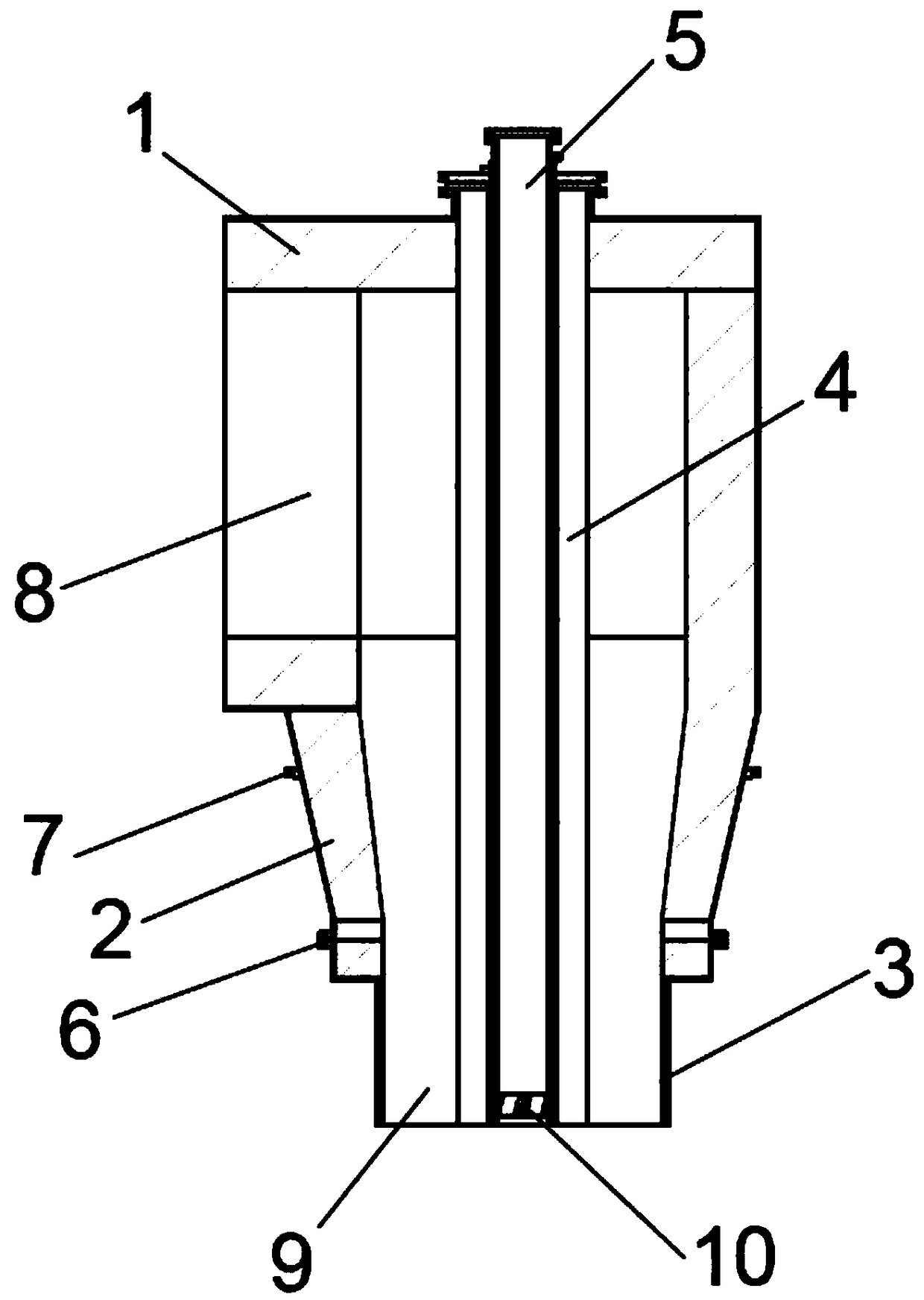

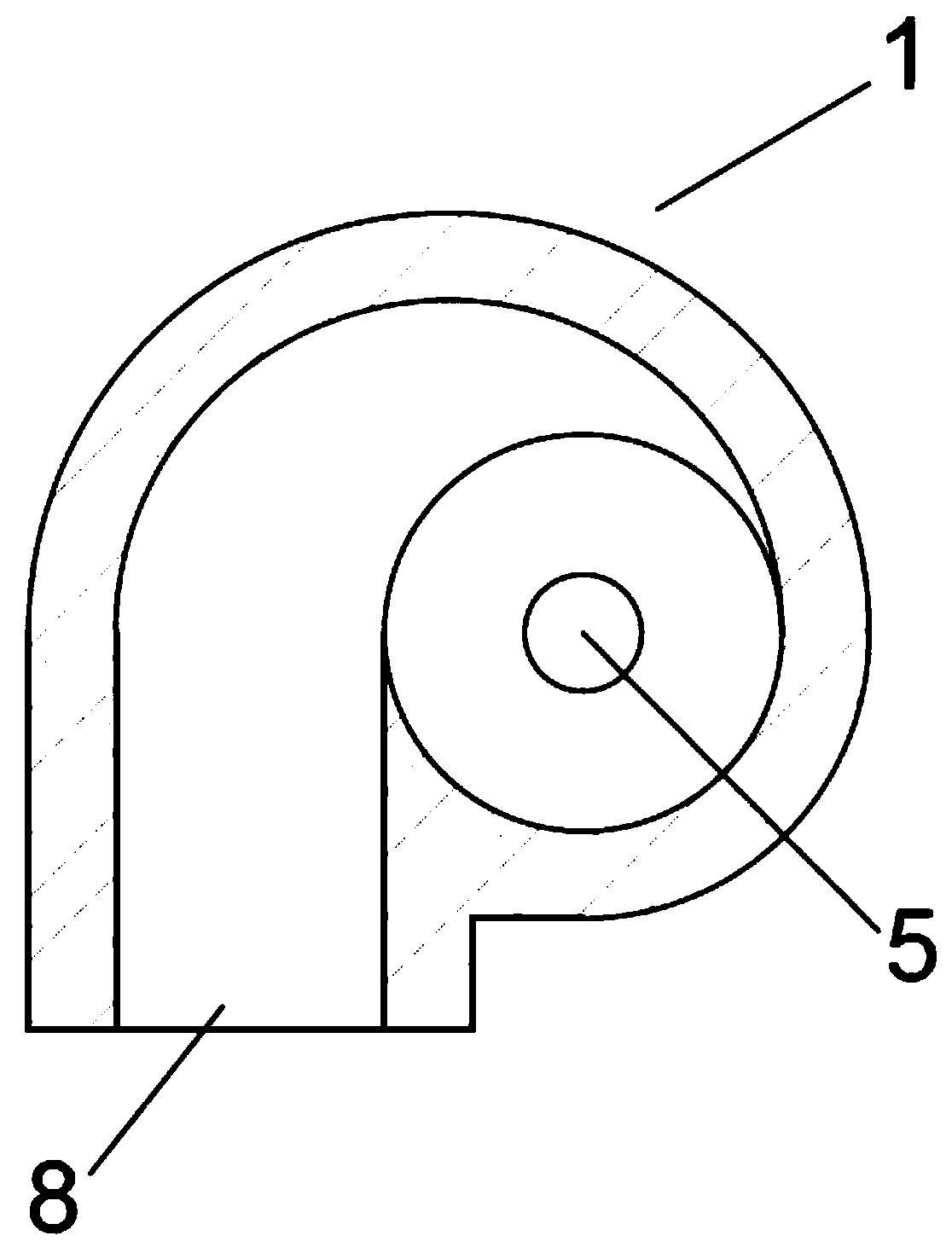

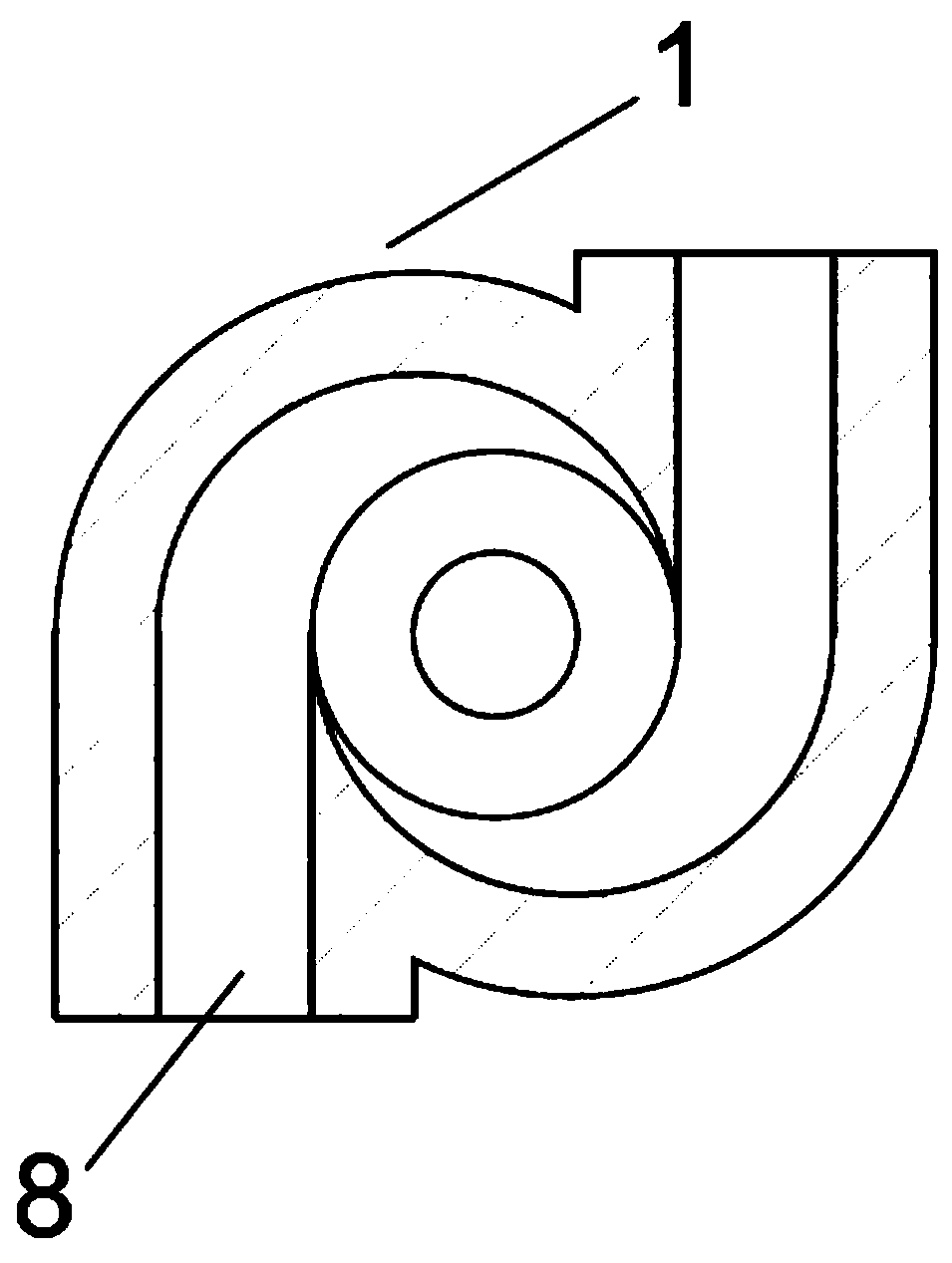

[0037] Such as Figure 1-2 As shown, a high-temperature burner in this embodiment includes: a swirl volute 1, a rectifying cylinder 2 and a gasification burner 5, the rectifying cylinder 2 is connected to the bottom of the swirl volute 1 and arranged coaxially therewith, and the gasification The burner 5 is located at the center of the swirl volute 1 .

[0038] The existing entrained entrained gasification technology is usually in the form of four-burner side-firing or top-mounted single-burner structure. The temperature of the gasification agent is relatively low, and the pulverized coal needs to be sent by pneumatic conveying or coal-water slurry. Into the burner, and a series of valves (such as pulverized coal angle valve, three-way valve, nuclear flow meter, etc.) need to be set on the pipeline to ensure the stability of its continuous delivery. At the same time, it is necessary to install ignition burners and start-up burners in the gasifier. The cost of these pipeline v...

Embodiment 2

[0045] refer to figure 1 , a kind of high-temperature burner of the present embodiment, its structure is basically the same as embodiment 1, further:

[0046]The rectifying cylinder 2 is a conical cylinder or a circular cylinder. Since the structure of rectifying cylinder 2 depends on the choice of gas flow rate at the outlet of the burner, the flow rate at the outlet of the lower passage is small, so the circular cylinder used for rectifying cylinder 2 can ensure the same flow rate at the upper and lower sides, and the conical cylinder used for rectifying cylinder 2 can speed up the outlet flow velocity , these two options need to be decided based on the simulated calculation of the outlet flow rate. It is further ensured that the imported crude gas reacts uniformly and fully with the gasification agent of the gasification burner 5 .

[0047] Among them, the rectifier 2 is provided with a wear-resistant and heat-insulating inner lining layer to prevent social security damag...

Embodiment 3

[0049] Since the combustion reaction temperature at the lower end of the burner is above 1500°C, a reasonable cooling structure is required to ensure the service life of the equipment. The difference from Embodiment 1 or 2 is that in this embodiment, a water cooling jacket is provided at the bottom of the rectifier 2 3. The water-cooling jacket 3 itself is a cooling structure, and the wall surface temperature is low.

[0050] In order to increase the wear resistance, further, the inner wall of the water cooling jacket 3 is provided with a wear-resistant inner lining layer, the upper part of the water cooling jacket 3 is a steel cylinder, the interior is provided with a wear-resistant and heat-insulating inner lining, and the upper end is provided with a connecting flange , is connected with the rectifier 2, which can be easily disassembled and maintained. The lower part of the water-cooling jacket 3 is a water-cooling structure. Since the gasification reaction occurs when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com