Industrial wastewater membrane treatment apparatus and use method thereof

A technology for industrial wastewater and membrane treatment, applied in water/sewage treatment, multi-stage water/sewage treatment, biological water/sewage treatment, etc. The effect of saving water resources and speeding up the response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

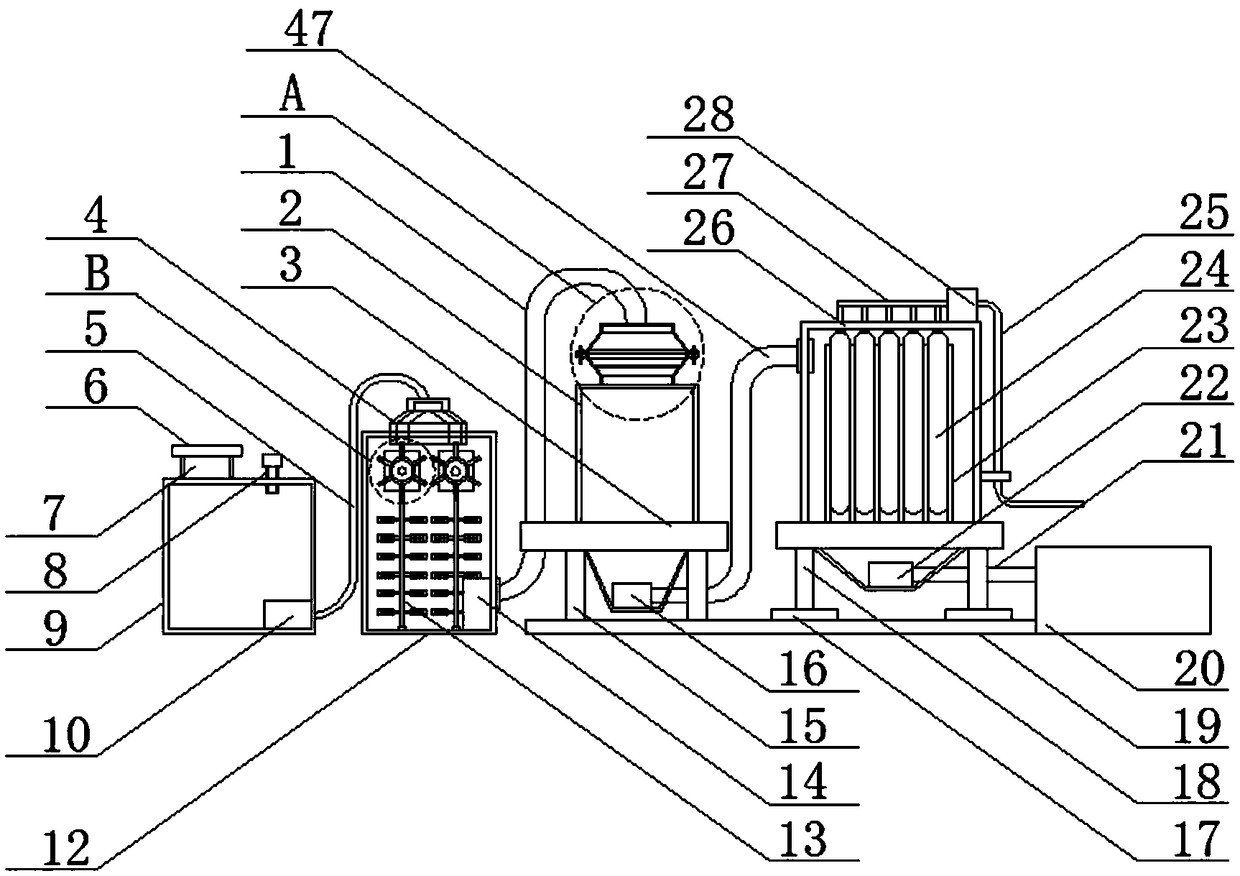

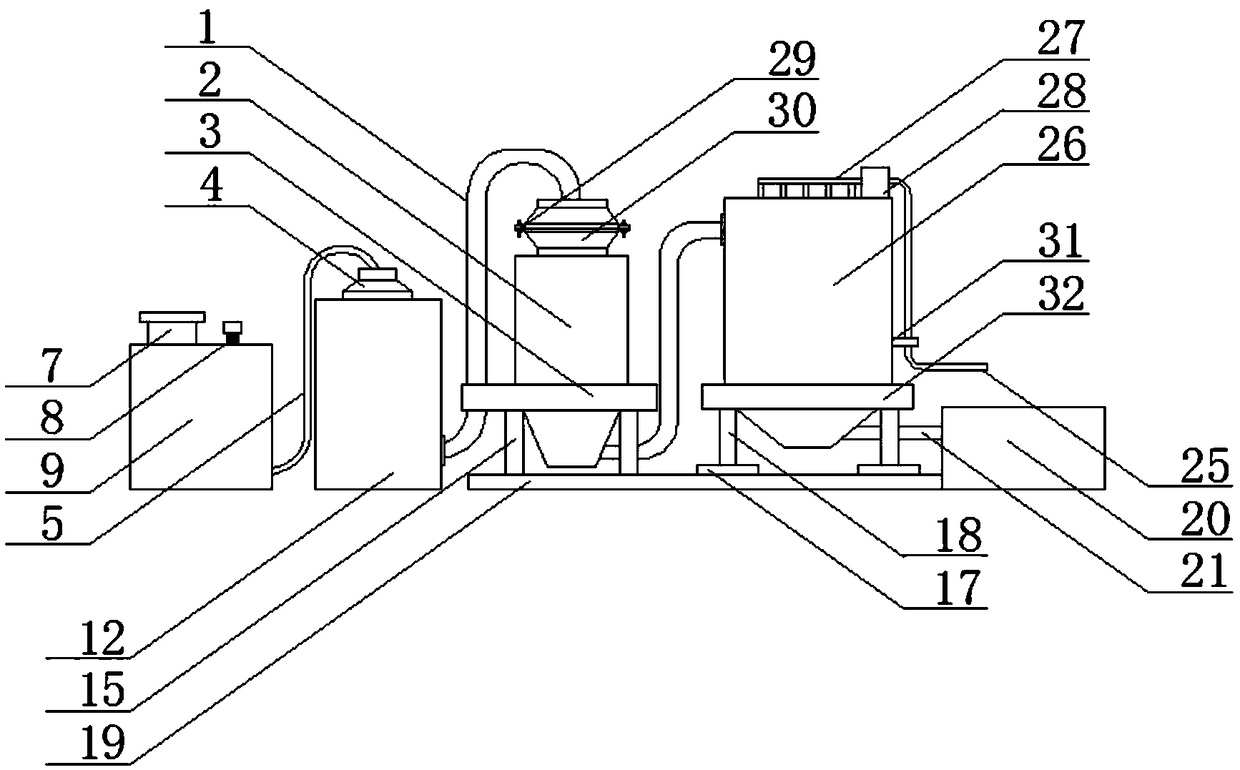

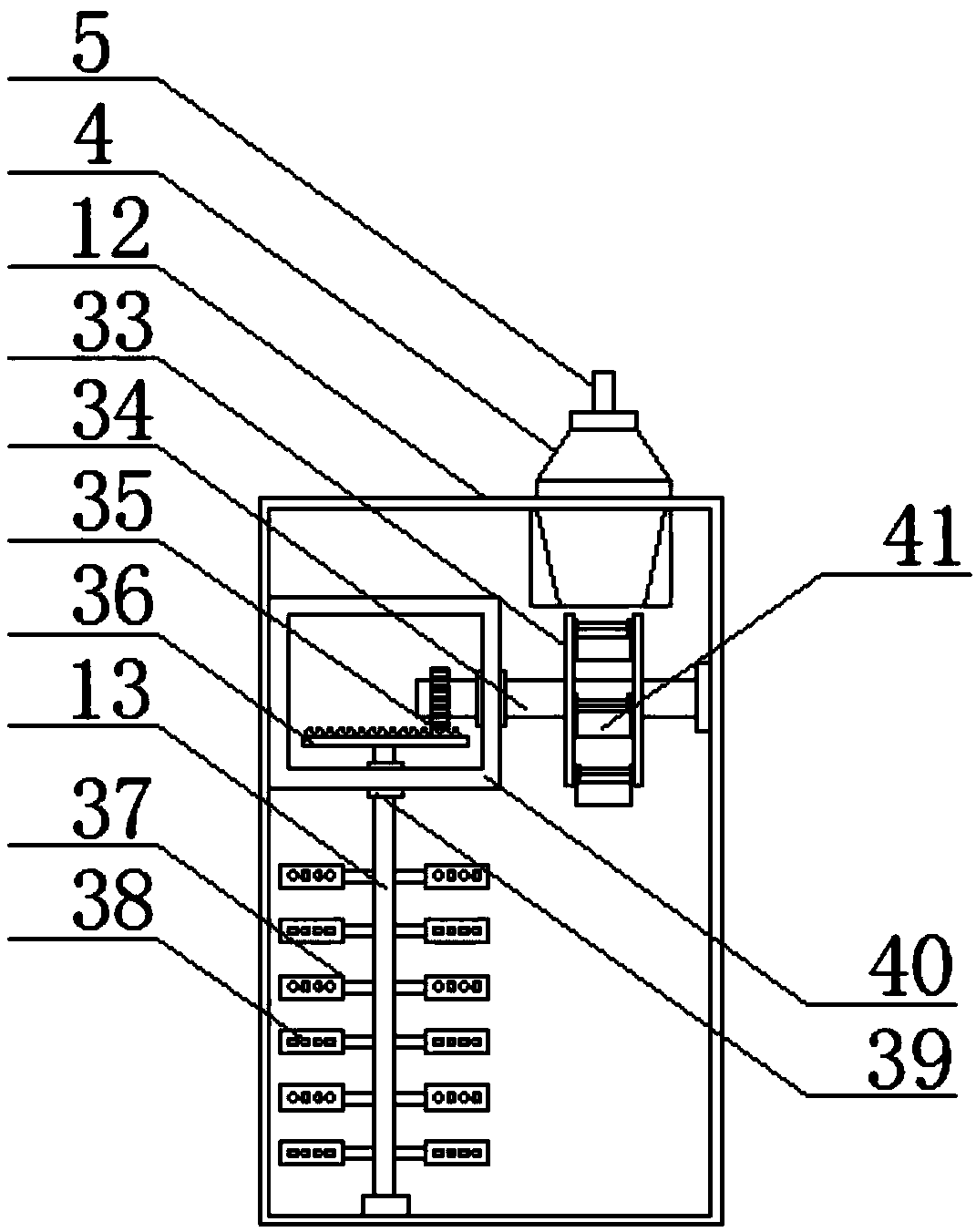

[0039] refer to figure 1 , 2 , 3, 4, a kind of industrial waste water membrane treatment device, comprises base plate 19, plays the effect of supporting and fixing, and the upper end side of base plate 19 is fixed with four support rods 15, and the upper end of four support rods 15 is jointly fixed with support Plate 3 plays a supporting role. The support plate 3 is provided with a first opening, and the first opening is penetrated and fixed with the sedimentation tank 2 to improve the stability of the sedimentation tank 2. The other side of the upper end of the bottom plate 19 is fixed with four Backing plate 17, the upper end of backing plate 17 is fixed with bearing rod 18, and the upper end of four bearing rods 18 is jointly fixed with bearing plate 32, plays the effect of bearing, and bearing plate 32 is provided with the second opening, and the second opening runs through And the purification box 26 is fixed, and the sedimentation box 2 and the purification box 26 are f...

Embodiment 2

[0054] refer to figure 1 , 2 , 3, 4, 5, a kind of industrial waste water membrane treatment device, comprises base plate 19, plays the effect of support and fixation, and the upper end side of base plate 19 is fixed with four support rods 15, and the upper ends of four support rods 15 are jointly fixed There is a support plate 3, which plays the role of support. The support plate 3 is provided with a first opening, and the first opening runs through and is fixed with a settling tank 2 to improve the stability of the settling tank 2. The other side of the upper end of the bottom plate 19 is fixed with a Four backing plates 17, the upper end of backing plate 17 is fixed with bearing bar 18, and the upper end of four bearing bars 18 is jointly fixed with bearing plate 32, plays the effect of bearing, and bearing plate 32 is provided with the second opening, and the second opening A purification box 26 is penetrated and fixed at the place, and the sedimentation box 2 and the puri...

Embodiment 3

[0070] refer to figure 1 , 2 , 3, 4, 6, a kind of industrial waste water membrane treatment device, comprise base plate 19, play the effect of supporting and fixing, the upper end side of base plate 19 is fixed with four support rods 15, and the upper ends of four support rods 15 are fixed together There is a support plate 3, which plays the role of support. The support plate 3 is provided with a first opening, and the first opening runs through and is fixed with a settling tank 2 to improve the stability of the settling tank 2. The other side of the upper end of the bottom plate 19 is fixed with a Four backing plates 17, the upper end of backing plate 17 is fixed with bearing bar 18, and the upper end of four bearing bars 18 is jointly fixed with bearing plate 32, plays the effect of bearing, and bearing plate 32 is provided with the second opening, and the second opening A purification box 26 is penetrated and fixed at the place, and the sedimentation box 2 and the purifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com