Polyurethane flexible foam and preparation method thereof

A polyurethane soft foam and prepolymer technology, applied in the field of polyurethane materials, can solve the problems of oily polyurethane foam surface, low bio-based content, low reactivity of plant polyols, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

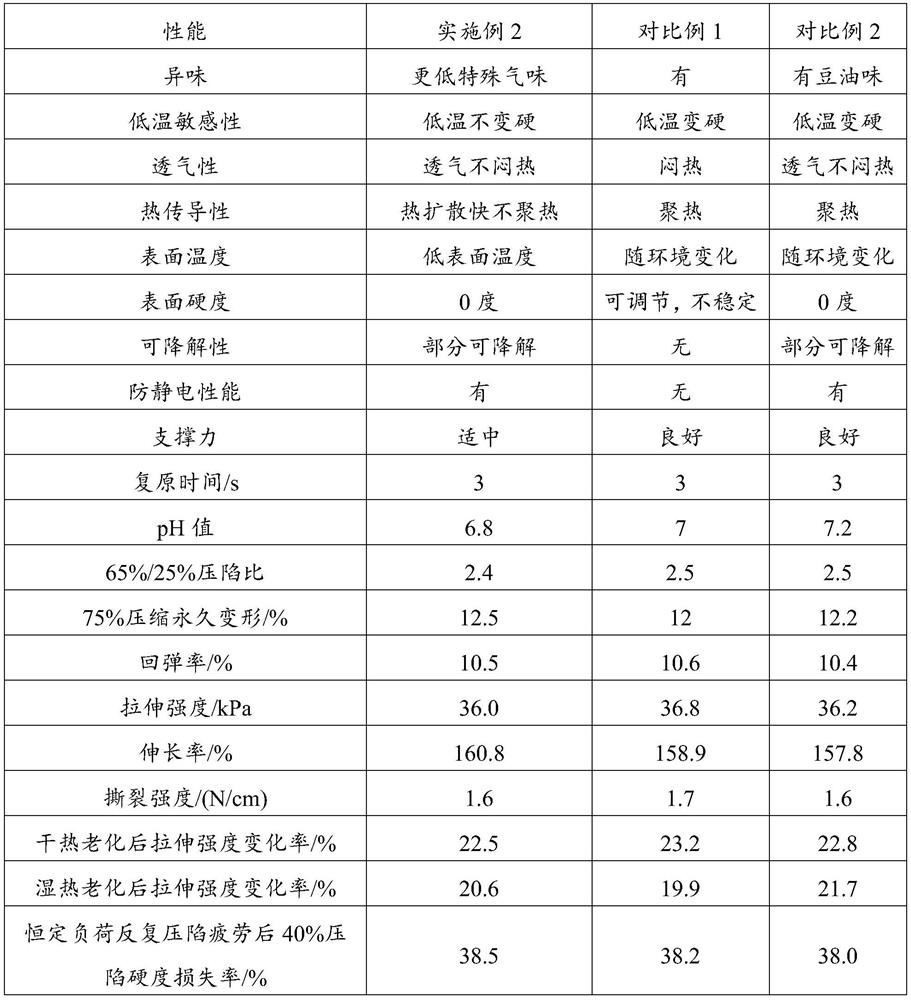

Examples

preparation example Construction

[0024] The invention provides a kind of preparation method of flexible polyurethane foam, comprises the following steps:

[0025] First mixing the first vegetable oil polyol and isocyanate to obtain a prepolymer; the molar ratio of -OH on the first vegetable oil polyol to -NCO on the isocyanate is 1:6-17;

[0026] The second vegetable oil polyol, polyether polyol, foam stabilizer, blowing agent and catalyst are mixed for the second time to obtain a premix;

[0027] After the third mixing of the prepolymer and the premix, foaming is performed to obtain the flexible polyurethane foam;

[0028] The mass ratio of the first vegetable oil polyol and the second vegetable oil polyol to the polyurethane flexible foam is (50-70): (95.8-143.5).

[0029] In the present invention, unless otherwise specified, all preparation materials are commercially available products well known to those skilled in the art.

[0030] In the present invention, the first mixing of the first vegetable oil p...

Embodiment 1

[0064] 1000g epoxy rapeseed oil (epoxy value 5.85%), 0.5g mass fraction are 85% phosphoric acid and 40g water join in autoclave and mix, then be heated to 95 ℃ and carry out ring-opening reaction, reaction pressure is 0.3MPa, and the reaction time is 5h; the obtained product is subjected to vacuum distillation to remove residual moisture and phosphoric acid, and then filtered to obtain a rapeseed oil-based polyol, the hydroxyl value of which is 102 mgKOH / g , the functionality is about 2;

[0065] Add 1000g of toluene diisocyanate to a reactor filled with nitrogen, heat it to 40°C at a speed of 100r / min, then add 350g of rapeseed oil-based polyol to the reactor at a speed of 20g / min, and heat up to 85 Insulate at ℃ for 1 hour, cool to obtain a prepolymer; the molar ratio of -OH on rapeseed oil-based polyol to -NCO on toluene diisocyanate is 1:16.43;

[0066] Mix 60g of rapeseed oil-based polyol, 40g of polyether 330N, 0.8g of silicone oil, 1.5g of deionized water and 1.8g of t...

Embodiment 2

[0069] 1000g epoxidized soybean oil (epoxy value 6.25%), 2.0g mass fraction are that 98% sulfuric acid and 200g water are added in the autoclave and mixed, then heated to 115°C to carry out the ring-opening reaction, the reaction pressure is 0.4MPa, the reaction time is 5h; the obtained product is subjected to vacuum distillation to remove residual moisture and sulfuric acid, and then filtered to obtain soybean oil-based polyol, the hydroxyl value of the soybean oil-based polyol is 216mgKOH / g, functionality about 4;

[0070] 1000g of diphenylmethane diisocyanate is added to a reactor filled with nitrogen, heated to 45°C at a speed of 150r / min, then 300g of soybean oil-based polyol is added to the reactor at a speed of 25g / min, and the temperature is raised to Insulate at 80°C for 1.5h, cool to obtain a prepolymer; the molar ratio of -OH on soybean oil-based polyol to -NCO on diphenylmethane diisocyanate is 1:6.67;

[0071] 55 g of soybean oil-based polyol, 45 g of polyether 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com