A kind of multifunctional bio-based acrylate prepolymer and its preparation method and application

A bio-based acrylate and multi-functionality technology, which is applied in applications, sulfide preparation, household appliances, etc., can solve the problems of complex synthesis conditions and low bio-based content, and achieve easy-to-obtain materials, high cross-linking density, shorten The effect of reaction time and energy expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

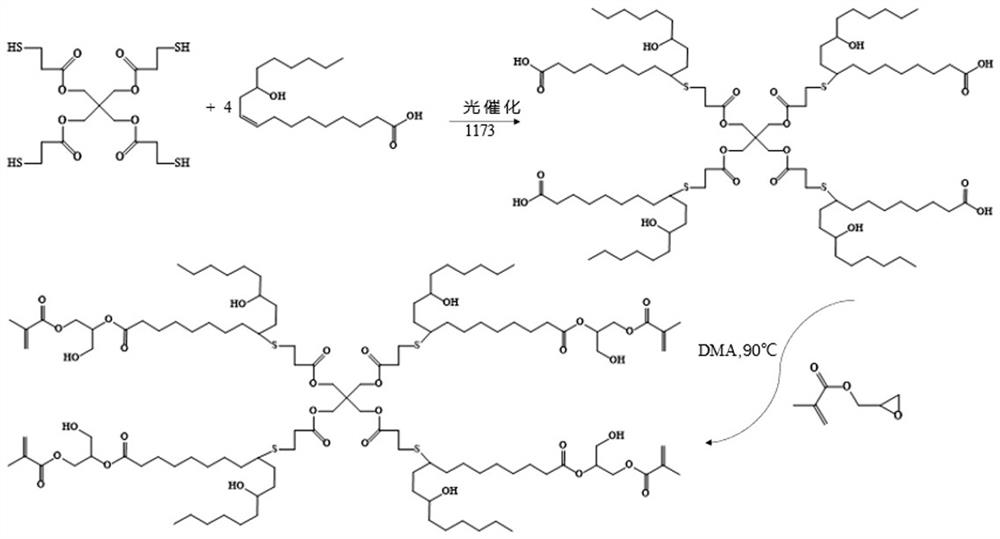

[0031] (1) Add 11.94g of ricinoleic acid and 4.89g of tetrakis(3-mercaptopropionic acid)pentaerythritol ester into the quartz tube, add 0.5g of photoinitiator benzoin dimethyl ether and 10g of butanone, and react in the photochemical reactor, The power of the light source is 360W, the wavelength is 365nm, the reaction is 3h, and the butanone is removed by rotary evaporation to obtain 16.67g of castor oil-based polycarboxylic acid.

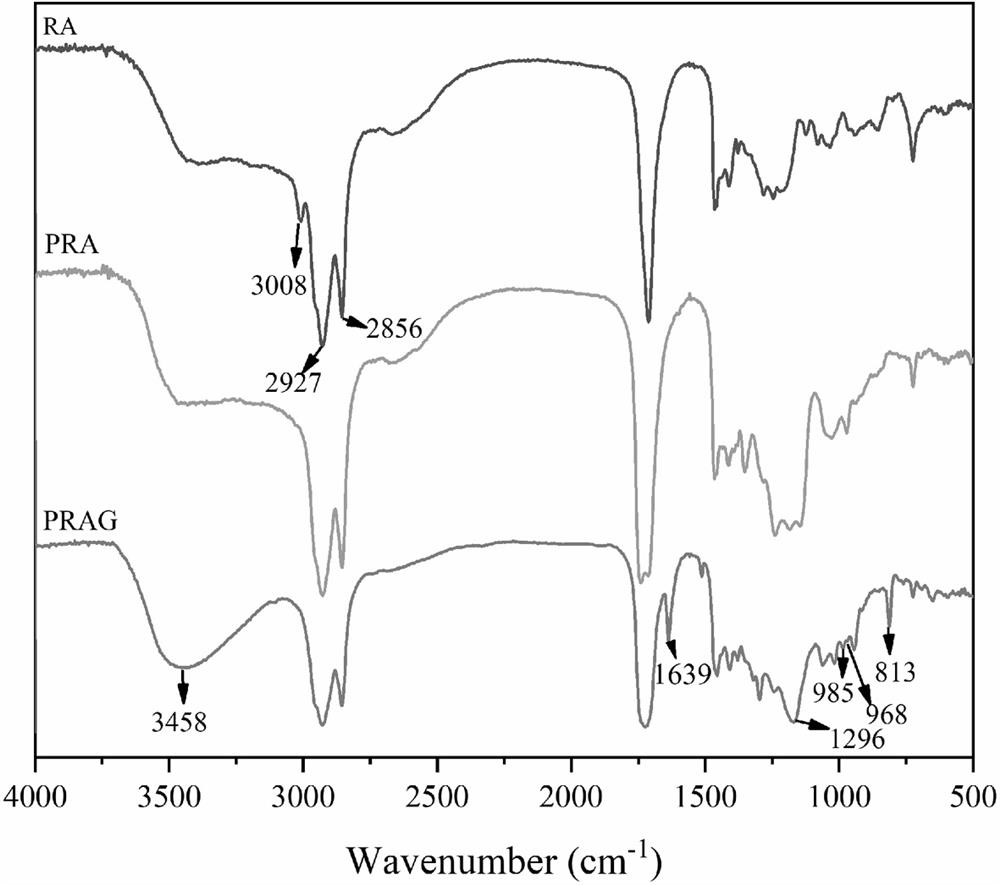

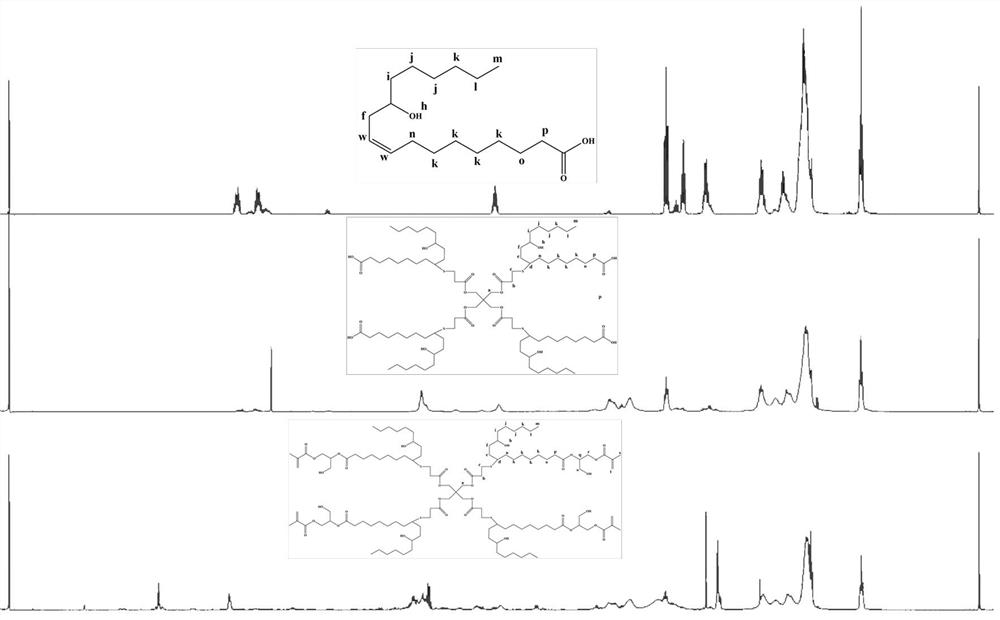

[0032] (2) Add 13.46g of castor oil-based polycarboxylic acid prepared in step (1) into the reaction kettle, stir and heat up to 50°C, add 0.18g of tertiary ammonium salt catalyst N, N-dimethylethanolamine, and then heat up to 70°C and dropwise add a mixture of 0.04g of hydroquinone and 4.55g of glycidyl methacrylate, react for 1h, then raise the temperature to 80°C for 3h, and obtain 17.98g of ricinoleic acid acrylate, which is the functional Bio-based acrylate prepolymer; its infrared spectrum is shown in figure 2 , see the NMR spectrum image...

Embodiment 2

[0035] (1) Add 11.94g of ricinoleic acid, 4.89g of tetrakis(3-mercaptopropionic acid) pentaerythritol ester, and 0.5g of photoinitiator bis-2,6-difluoro-3-pyrrolephenyl titanocene to the quartz tube React with 10g butanone in a photochemical reactor, light source power 360W, wavelength 365nm, react for 4h, and remove butanone by rotary evaporation to obtain 16.7g castor oil-based polycarboxylic acid.

[0036] (2) Add 13.46g of castor oil-based polycarboxylic acid prepared in step (1) into the reactor, stir and heat up to 60°C, add 0.18g of tertiary ammonium salt catalyst N, N-dimethylethanolamine, and then heat up to 90°C and dropwise add a mixture of 0.04g of hydroquinone and 4.55g of glycidyl methacrylate, react for 2h, and then raise the temperature to 100°C for 4h to obtain 17.97g of ricinoleic acid acrylate, which is the functional Bio-based acrylate prepolymer; the molar ratio between the carboxylic acid group in the castor oil-based polycarboxylic acid and the epoxy gro...

Embodiment 3

[0039](1) Add 11.94g ricinoleic acid, 4.89g tetrakis(3-mercaptopropionate) pentaerythritol ester, and 0.84g photoinitiator 2,4,6-trimethylbenzoylphenylphosphonic acid into the quartz tube Ethyl ester and 10g butanone were reacted in a photochemical reactor with a light source power of 360W and a wavelength of 365nm for 3h. The butanone was removed by rotary evaporation to obtain 16.69g of castor oil-based polycarboxylic acid.

[0040] (2) Add 13.46g of castor oil-based polycarboxylic acid prepared in step (1) into the reaction kettle, stir and raise the temperature to 65°C, add 0.18g of tertiary ammonium salt catalyst N, N-dimethylethanolamine, and then raise the temperature to 85°C and dropwise add 0.04g of hydroquinone and 4.55g of glycidyl methacrylate mixture, react for 2h, then raise the temperature to 95°C for 4h to obtain 17.97g of ricinoleic acid acrylate, which is the functional Bio-based acrylate prepolymer; the molar ratio between the carboxylic acid group in the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com