Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

794 results about "Pentaerithrityl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

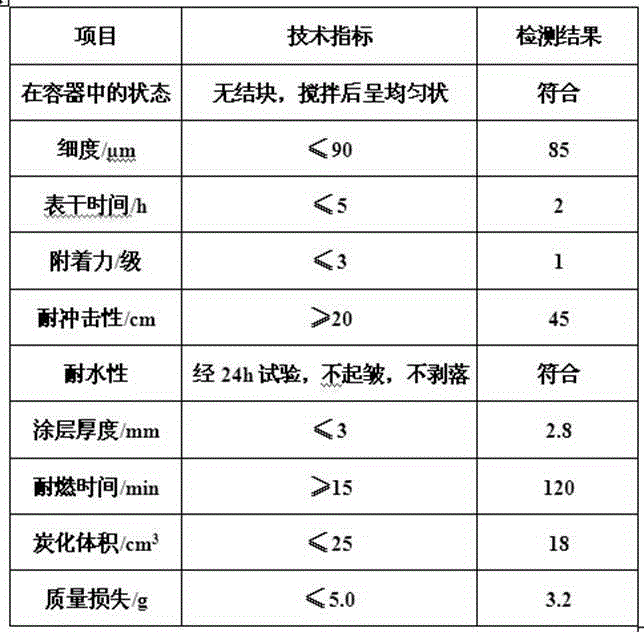

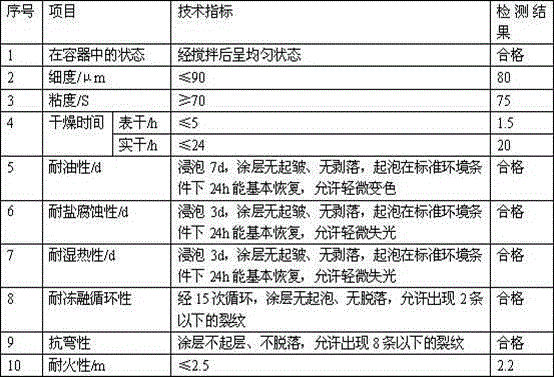

Aqueous ultrathin expansion-type fireproof coating for steel structure and preparation method thereof

ActiveCN104130671AImprove corrosion resistanceStrong adhesionFireproof paintsEpoxy resin coatingsPolymer sciencePentaerythritol

The invention discloses an aqueous ultrathin expansion-type fireproof coating for a steel structure and a preparation method thereof, and belongs to the technical field of fireproof coatings. The aqueous ultrathin expansion-type fireproof coating comprises, by mass, 10-35 parts of a modified aqueous epoxy emulsion, 1-8 parts of a curing agent, 5-15 parts of a styrene-acrylic emulsion or a silicone-acrylic emulsion, 10-20 parts of ammonium polyphosphate, 6-12 parts of melamine, 8-16 parts of pentaerythritol, 5-15 parts of a fire retardant, 5-15 parts of a pigment and a filling material, 2-8 parts of an assistant and 15-35 parts of water. The aqueous ultrathin expansion-type fireproof coating has the characteristics of low raw material cost, simple preparation process and environmental friendliness.

Owner:沈阳泰丰化工有限公司

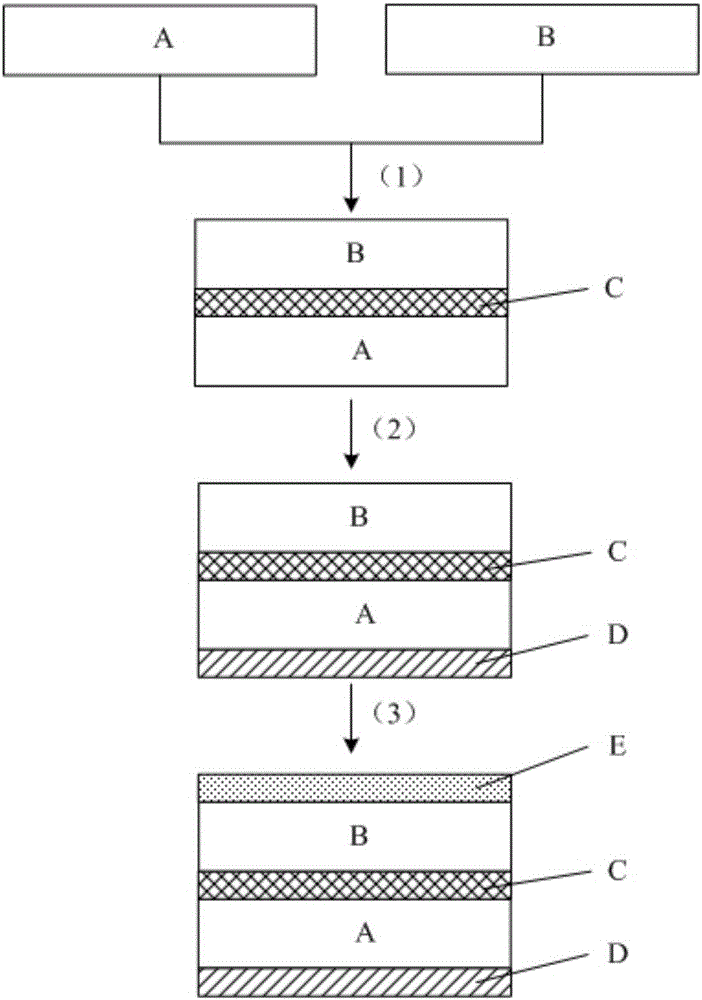

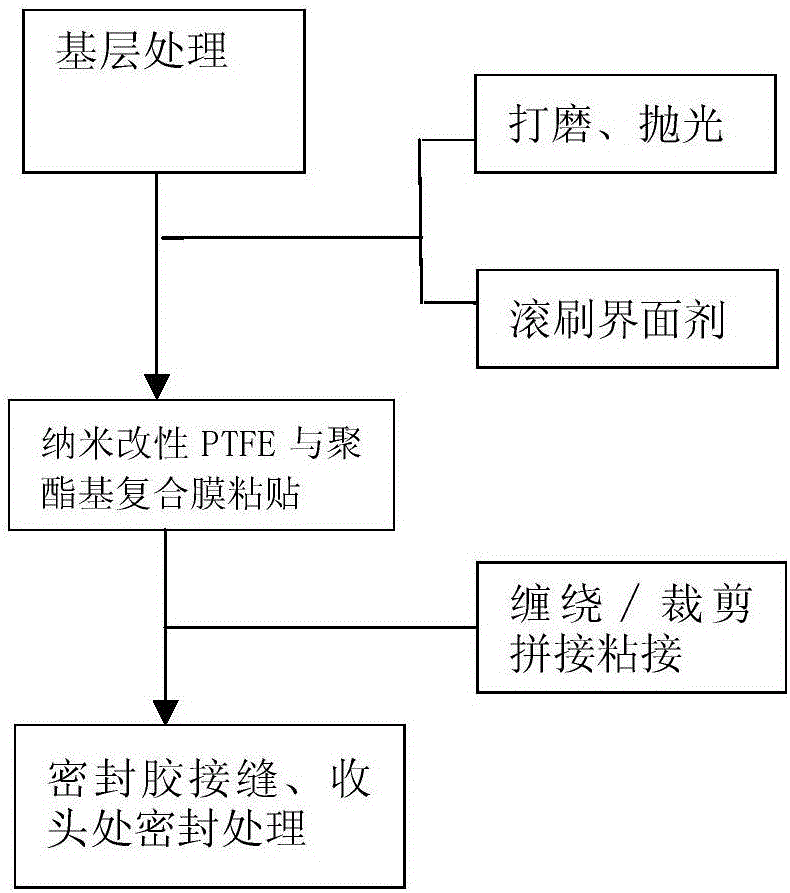

Preparation method and application of nano-modified PTFE and polyester-based composite film for preventing fan blades from icing

ActiveCN106313811ASolving non-adhesive technical problemsConvenient engineering constructionSynthetic resin layered productsLaminationPolyesterComposite film

The invention provides a preparation method and application of a nano-modified PTFE and polyester-based composite film for preventing fan blades from icing. The method includes the steps of PTFE film modification, lamination complexing and photo-crosslinked adhesive application. A modifier is prepared from antimony-doped tin oxide nano-crystals, nano-titanium dioxide, nano-silicon carbide, an organic fluorine waterproofing agent and pentaerythritol tri-(3-aziridinyl)-propionate; in lamination complexing, a bonding complexing agent is prepared from 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, vinyl acetate, ethyl carbamate, alpha-linolenic acid, (2)ethoxylated bisphenol A dimethacrylate, trimethylolpropane triacrylate and benzoyl peroxide; a photo-crosslinked adhesive is prepared from a poly[butyl acrylate-glycidyl methacrylate-n-butoxy methacrylamide]copolymer, vinyl acetate, butyl acrylate, an acrylate derivative, a photoinitiator and dimethylformamide. The method and the composite film solve the non-adhesion problem that a PTFE film can not be pasted on the surfaces of fan blades with an adhesive directly.

Owner:NANJING HAOHUI HI TECH CO LTD

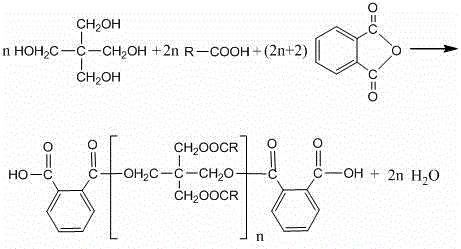

Alkyd resin for wood lacquer and preparation method thereof

The invention discloses alkyd resin for wood lacquer and a preparation method thereof. According to the raw material formula, the alkyd resin for the wood lacquer comprises the following components in percentage by mass: 18.3 to 28.3 percent of soybean oleic acid, 10.2 to 20.2 percent of glycerin, 3.8 to 7.8 percent of pentaerythritol, 17.6 to 21.6 percent of recycled terephthalic acid, 0.05 to 0.2 percent of color substration agent, 0.05 to 0.2 percent of antioxidant, 2.5 to 5.5 percent of phthalic anhydride, 3.2 to 7.2 percent of benzoic acid, 2 to 5 percent of dimethylbenzene, 18 to 30 percent of thinning agent and 0.05 to 0.2 percent of wetting dispersant. Terephthalic acid is adopted, and the unique chemical performance of the terephthalic acid endows the resin with high dryness and weather resistance; waste and inferior terephthalic acid produced by a petrochemical enterprise is utilized, so that the production cost of the resin is lower than that of alkyd resin produced by the conventional method; simultaneously, waste of the petrochemical enterprise is reduced, the environment is prevented from being polluted, and wastes are utilized to save energy and reduce emission.

Owner:HUIZHOU CHANGRUNFA PAINT

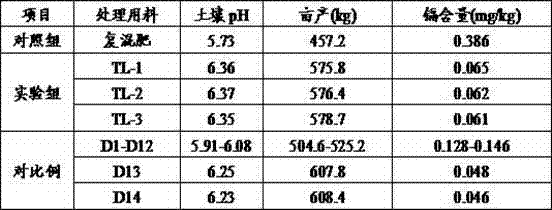

Composite soil conditioner and preparation method and use thereof

ActiveCN104263375APromote repairImprove convenienceAgriculture tools and machinesOther chemical processesTrehaloseIonic liquid

The invention relates to a composite soil conditioner, comprising biogas residues, pyroligneous acid, mineral powder, soluble chitosan, diethylene triaminepentaacetic acid pentasodium, a surfactant, tobacco powder, trehalose, di-rhamnolipid, a flocculating component, a penetrating agent, enteromorpha powder, modified zeolite, boron-zinc-magnesium-containing fungicide, a nano additive, an accelerant, pentaerythritol triacrylate and ionic liquid, preferably also comprising 4-methyl phenyl valerate which is equal to the ionic liquid in weight. The novel composite soil conditioner has excellent soil improvement and recovery performance, the utilization rate of the fertilizer by the crop is greatly increased, and the composite soil conditioner can significantly increase the yield, simultaneously also can improve the permeability of the soil and avoids side effects of heavy metals such as cadmium; thus, the composite soil conditioner is beneficial to crop growth and has a wide industrial application prospect.

Owner:山东乐美生物科技有限公司

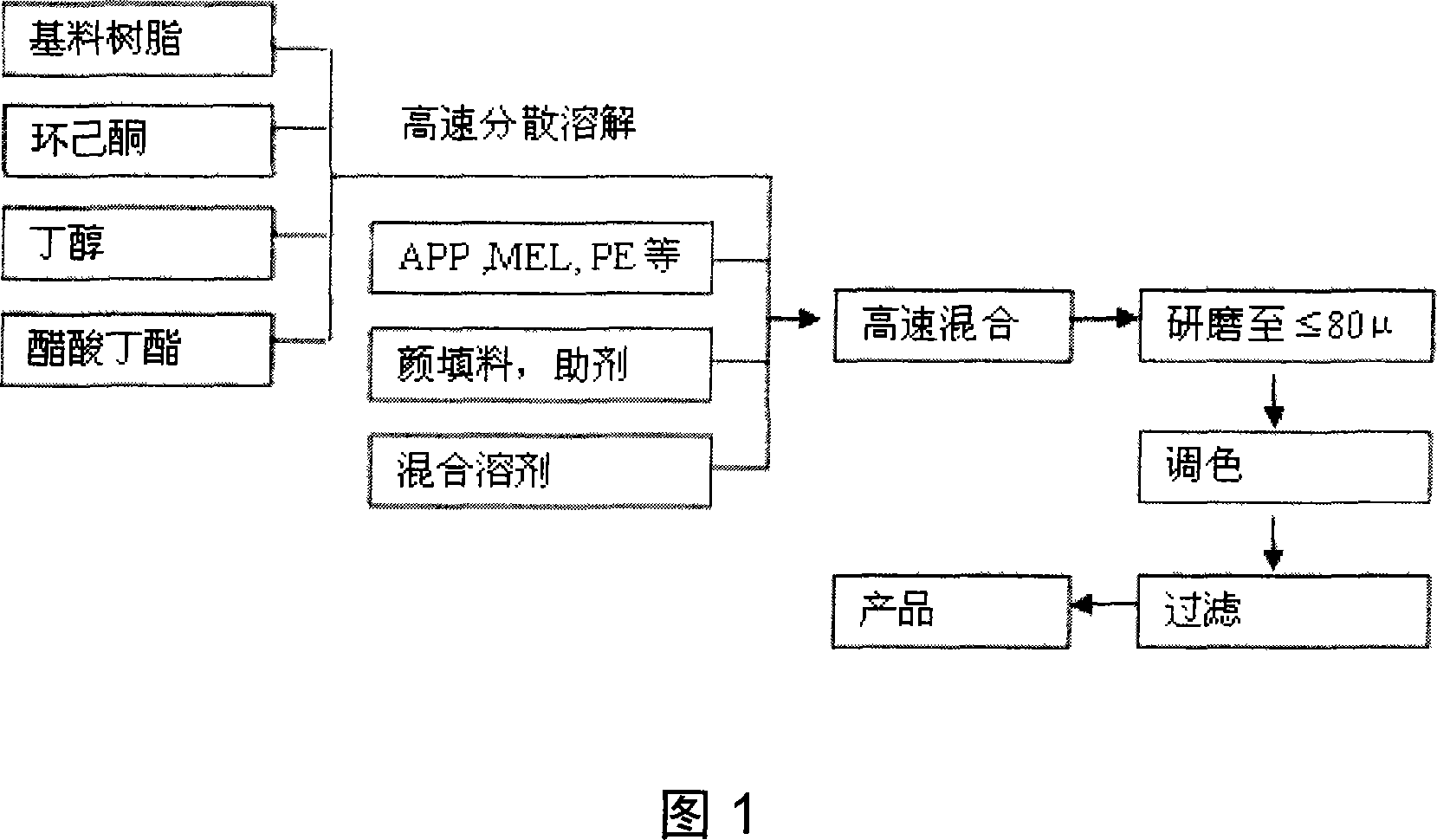

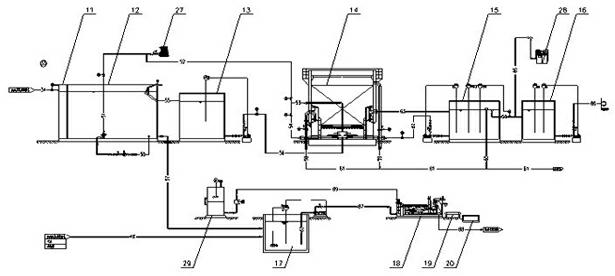

Fireproof paint for super-thin steel structure and preparation method thereof

InactiveCN101058693AStrong adhesionGood film formingFireproof paintsLiquid surface applicatorsTetrabromobisphenol APolyvinyl chloride

The invention discloses a method preparing for an ultra-thin inflatable steel structure fire-proof paint, which is characterized by the following: the allocation of tetrabromo-bisphenol A epoxide resin contains epichlorohydrin and tetrabromo-bisphenol A with weight rate at 1. 3-1. 5:1 and epichlorohydrin and sodium hydroxide with weight rate at 1. 0-1. 05:1; the allocation of fireproof painting is tetrabromo-bisphenol A epoxide resin and hyperchlorinated polyvinyl chloride with weight rate at 3: 1, polyphosphate, melamine, pentaerythritol with weight rate at 3:2:1, antimony trioxide and paraffin chloride with weight rate at 3:7, aluminium hydroxide and zinc borate smoke suppressor with weight rate at 10: 3. The method comprises the following steps: adding epichlorohydrin and tetrabromo-bisphenol A to the autoclave; mixing and heating at 90 Deg. C; adding caustic soda solution; keeping 7. 5 hours; washing and removing thylbenzene by heating;getting tetrabromo-bisphenol A epoxide resin; adding the mixed solvent to tetrabromo-bisphenol A epoxide resin and perchlorinated polyethylene; mixing and dissolving; adding ammonium polyphosphate, melamine, pentaerythrite, titanium dioxide, antimony oxide, aluminum hydroxide, zinc borate separately, adding chlorcosane; grinding after high-speed dispersing uniformly; mixing polyamide uniformly according to 10:1; getting the fire-proof paint.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

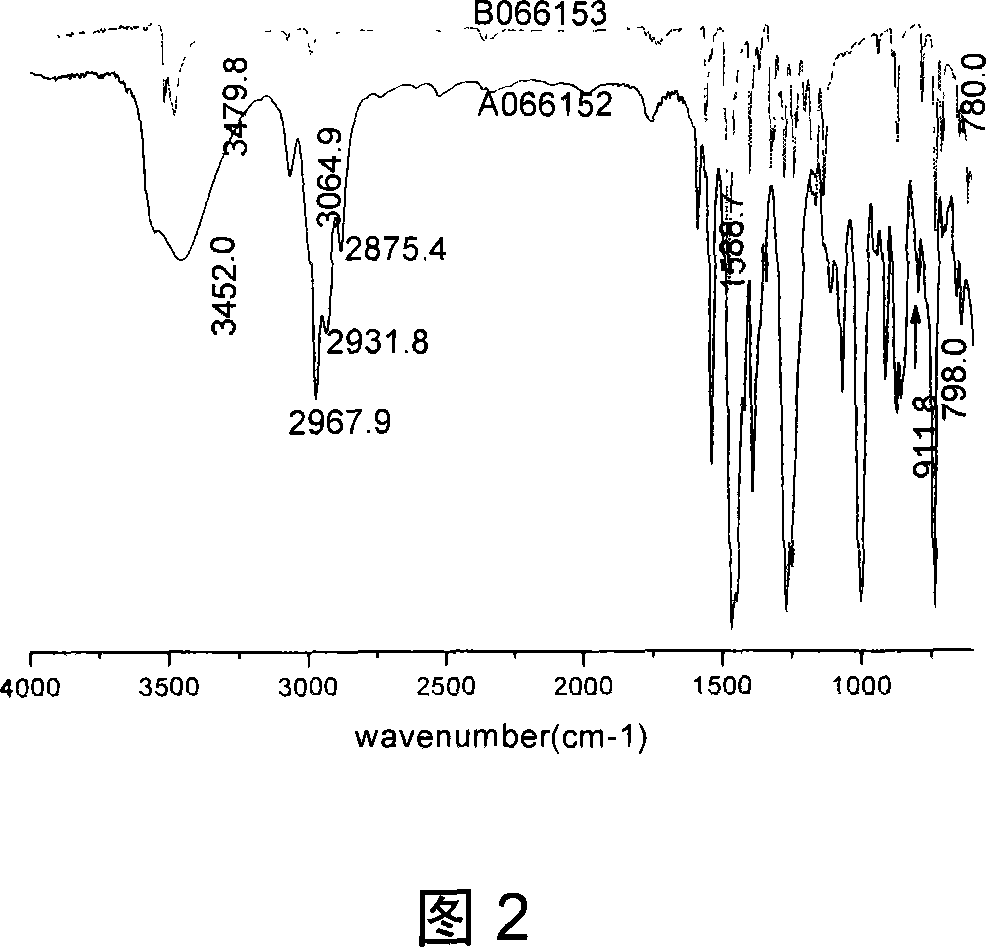

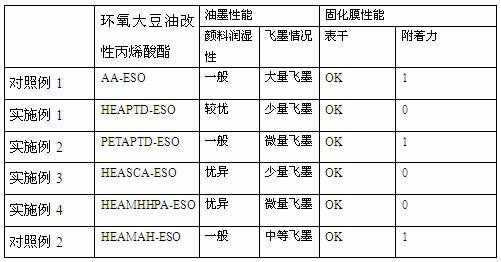

Acrylic acid ester modified epoxy soybean oil, its preparation method and application thereof

ActiveCN102660387ANovel structureImprove adhesionOrganic chemistryFatty acid chemical modificationPolymer scienceMeth-

The invention discloses an acrylic acid ester modified epoxy soybean oil, its preparation method and an application thereof. According to the preparation method of the acrylic acid ester modified epoxy soybean oil, acrylate monomer bearing a hydroxyl group reacts with acid anhydride to obtain a half-ester intermediate, and the half-ester intermediate reacts with epoxy soybean oil to obtain the acrylic acid ester modified epoxy soybean oil. The acrylate monomer bearing a hydroxyl group is hydroxyethyl acrylate, hydroxyethyl methacrylate, pentaerythritol triarylate, hydroxypropyl acrylate, hydroxypropyl methacrylate, trimethylol propane diacrylate or trimethylol propane dimethacrylate. Acid anhydride is o phthalic anhydride, succinic anhydride, methyl hexahydrophthalicanhydride, hexahydrophthalic anhydride or tetrahydrophthalic anhydride. The acrylic acid ester modified epoxy soybean oil has a novel structure. When applied in paper printing ink, the acrylic acid ester modified epoxy soybean oil can improve adhesive force of a cured film and also can improve wetability of pigments and remarkably minimize occurrence of misting. The preparation method helps widen the application range of the modified epoxy soybean oil.

Owner:GUANGDONG BOSSIN NOVEL MATERIALS TECH CO LTD

Halogen-free intumescent compound flame retardant and application thereof in high-density polyethylene

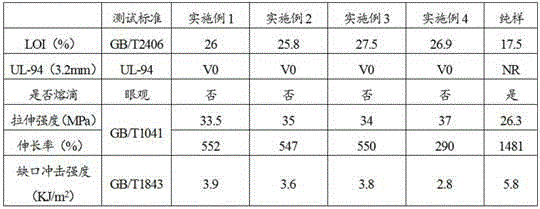

The invention relates to a halogen-free intumescent compound flame retardant which is prepared by mixing the following components in weight percentage at high speed by means of a high mixing machine: 55-65 wt% of acid source, 18-28% of carbon source, 2-12% of gas source and 5-15% of synergist; the acid source is one or a mixture of ammonium polyphosphate, melamine phosphate and melamine polyphosphate; the carbon source is one or a mixture of dipentaerythritol, pentaerythritol phosphate and triazine char-forming agent; the gas source is melamine or melamine cyanurate or a mixture thereof; and the synergist is one or a mixture of hypophosphite, pyrophosphate, phosphate, silicon dioxide and lanthanum oxide. The halogen-free intumescent compound flame retardant is high in flame retardant efficient, low in cost, good in compatibility with matrixes and simple in preparation process; when the halogen-free intumescent compound flame retardant is applied to LDPE (Low-density Polyethylene), the obtained LDPE material has excellent flame retardant performance and is capable of maintaining mechanical property and effectively controlling molten drops.

Owner:苏州安鸿泰新材料有限公司

3D printing-based photo-curing material and preparation method thereof

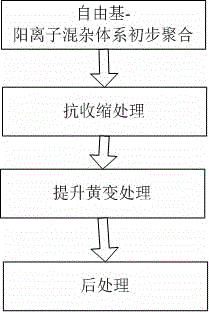

The invention discloses a 3D printing-based photo-curing material and a preparation method thereof. The 3D printing-based photo-curing material comprises the following components in parts by weight: 50-55 parts of aqueous polyurethane acrylic resin, 20-30 parts of hydrogenated bisphenol A epoxy resin, 10-15 parts of alkoxylated pentaerythritol hexaacrylate, 10-15 parts of three-ring decane dimethyl carbinol dimethacrylate, 8-10 parts of hydroxyl ethyl methacrylate, 8-10 parts of vinyl ether, 3-5 parts of 1-hydroxy cyclohexyl phenyl ketone, 3-5 parts of 4,4'-bis(p-toly) iodonium hexafluorophosphate and 0.5-1 part of an 1080 antioxidant. The method comprises the following preparation steps: primary polymerization of a free radical-cation hybrid system, anti-shrinkage treatment, anti-yellowing treatment and post-treatment. The obtained material has the characteristics of excellent performance, low cost, good consistency and the like; and the used preparation method has the characteristics of being environment-friendly, short in production cycle and good in batch stability.

Owner:河源然生新材料有限公司

High gloss high abrasion resistance ultra-violet curing overprinting varnish of mobile phone and preparation method thereof

InactiveCN101967338AImprove wear resistanceHigh gloss and high wear resistancePolyurea/polyurethane coatingsPolyester coatingsIsooctyl acrylatePolyester

The invention discloses a high gloss high abrasion resistance ultra-violet (UV) curing overprinting varnish of mobile phone and a preparation method thereof. The method of the invention uses low-viscosity polyester acrylate and aliphatic polyurethane acrylate as base resin which combines with ethoxylated pentaerythritol tetraacrylate, Trimethylolpropane triacrylate, Tri(propylene glycol) diacrylate, 1,6-hexanediol diacrylate and 2-ethylhexyl acrylate which are used as active diluent, alcohol and ethyl acetate which are used as diluent, benzophenone and 1-hydroxycyclohexyl phenyl ketone which are used as photoinitiator, reactive amine coinitiator, defoaming agent, flatting agent, slip agent and other agents to mix evenly and prepare the UV overprinting varnish. The overprinting varnish of the invention adopts the special raw material formula and has good lustrousness, adhesive force and mechanical stability; as some polyfunctional resins and resins with special functional groups are added, the crosslink density of the UV varnish is increased in the curing process and the hardness of the product is up to 5-7H; and as solid wax powder used as the slip agent is added, the coefficients of friction can be reduced and the product can have extremely high wear resistance.

Owner:苏州凯康化工科技有限公司

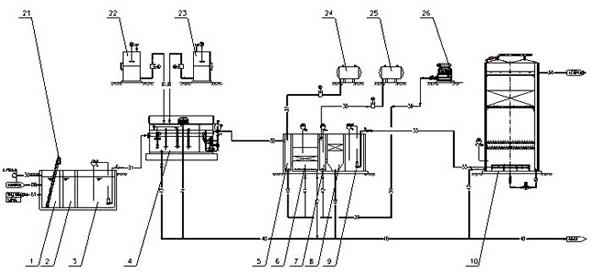

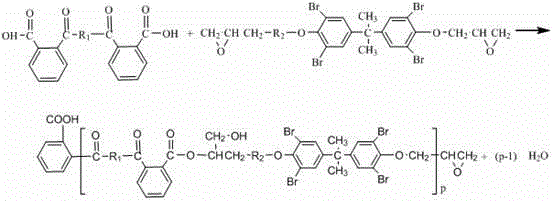

Device for treating wastewater during production of pentaerythritol

ActiveCN102557359AImprove biodegradabilityEfficient removalMultistage water/sewage treatmentElectrolysisPentaerythritol

The invention relates to a device for treating wastewater during production of pentaerythritol. The device comprises a grille groove, a mechanical grille, an oil isolating pool, an adjusting pool, a combined air floater, an aerated micro-electrolysis system, a high-efficiency anaerobic reactor, an improved SBR reaction tank, a water-collecting pool, an anaerobic biological filter, a monitoring pool, a recycling water pool, an acid adding system, an alkali adding system, a polyaluminum chloride (PAC) dosing system, a polyacrylamide (PAM) dosing system, a sludge pool, a sludge pressing filter system, a blast blower and on-lien monitoring instruments such as PH, COD, a liquidometer, a thermometer and the like, wherein the aerated micro-electrolysis system comprises an acid adjusting pool, a micro-electrolysis reaction tank, a neutral coagulation reaction tank, a settling pool and an intermediate water pool; and all the systems are connected with one another sequentially through pipelines. The device treats the wastewater during production of the pentaerythritol by a combined air floatation, aerated micro-electrolysis, biological treatment and aerated biological filter combined method, so that the effluent quality meets the requirement.

Owner:贵州绿色环保设备有限公司 +1

Polymerizable composition for optical material, optical material and method for producing optical material

Disclosed is a polymerizable composition for o an optical material containing tolylene diisocyanate, hexamethylene diisocyanate, and one or more polythiol compounds selected from the group consisting of 4-mercaptomethyl-1,8-dimercapto-3,6-dithiaoctane,4,8-, 4,7- or 5,7-dimercaptomethyl-1,11-dimercapto-3,6,9-trithiaundecane, pentaerythritol tetrakismercaptoacetate, pentaerythritol tetrakismercaptopropionate, 2,5-bis(mercaptomethyl)-1,4-dithiane, bis(mercaptoethyl)sulfide, 1,1,3,3-tetrakis(mercaptomethylthio)propane, 4,6-bis(mercaptomethylthio)-1,3-dithiane and 2-(2,2-bis(mercaptomethylthio)ethyl)-1,3-dithietane.

Owner:MITSUI CHEM INC

Bromine carbon alkyd resin cable fireproof paint and its preparation method

InactiveCN102746775AImprove fire performanceReduce lossesFireproof paintsPolyester coatingsPentaerythritolZinc borate

The invention relates to a bromine carbon alkyd resin cable fireproof paint and its preparation method. The fireproof paint comprises the following components of: bromine carbon alkyd resin, ammonium polyphosphate, melamine, pentaerythritol, antimony trioxide, zinc borate, bentonite, titanium dioxide, chlorinated paraffin, molybdenum sesquioxide, dimethyl silicon oil, a drier, and a solvent. The preparation method consists of the steps of: adding the formula required amounts of the solvent, the ammonium polyphosphate, the melamine, the pentaerythritol, the antimony trioxide, the zinc borate, the bentonite, the titanium dioxide, the chlorinated paraffin, and the molybdenum sesquioxide into a multi-purpose dispersion mill in order, conducting high speed dispersion for 30-60min, reducing the stirring speed, adding the bromine carbon alkyd resin to carry out further dispersion for 20-40min, adding the dimethyl silicon oil, using a cone mill to mill the mixture to a desired degree of fineness, then performing dispersion in the multi-purpose dispersion mill for 10-20min, and adding the drier which is then dispersed uniformly, thus obtaining the product.

Owner:甘肃西北之光电缆有限公司

Carbon dioxide-epoxy propane copolymer and polybutylene succinate polyblend and preparation method

This invention relates to mixture of carbon dioxide / propylene oxide copolymer and poly- succinic acid butanediol ester and preparation method. It is composed by carbon dioxide / propylene oxide copolymer, poly- succinic acid butanediol ester and antioxidant four ( beta - ( 3, 5 - di- tertiary butyl - 4 - hydroxy) propanoic acid) pentaerythritol ester ( ky - 7910). These materials blend in Banbury mixer, temperature control at 120 to 160 deg, and time for 10 minutes. The product has biodegradability, useful for preparing film, plates, sheet, effervesce and plastic piece and so on.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Flame-resistant polyvinyl chloride cable material

InactiveCN102993598AImprove flame retardant performanceImprove insulation performanceInsulated cablesInsulated conductorsPentaerythritolAluminium hydroxide

The invention discloses a flame-resistant polyvinyl chloride cable material which is characterized in that the polyvinyl chloride cable material is prepared by the following ingredients in parts by weight: 100 parts of polyvinyl chloride resin, 10-19 parts of plasticizer, 15-25 parts of calcium carbonate, 30-40 parts of filler, 8-15 parts of intumescent flame retardant, 1-6 aprts of calcium-zinc stabilizer, 6-8 parts of antimonous oxide, 5-10 parts of magnesium hydroxide, 5-10 parts of aluminium hydroxide and 0.1-1.5 parts of an antioxidant 1010, wherein the flame retardant can be inorganic flame retardants magnesium hydroxide and aluminium hydroxide, and the intumescent flame retardant pentaerythritol, and the provided flame-resistant polyvinyl chloride cable material has excellent flame-retardant property and good insulating property, and the service life of the cable can be prolonged.

Owner:JIANGSU CHENDIAN SOLAR PHOTOELECTRIC TECH

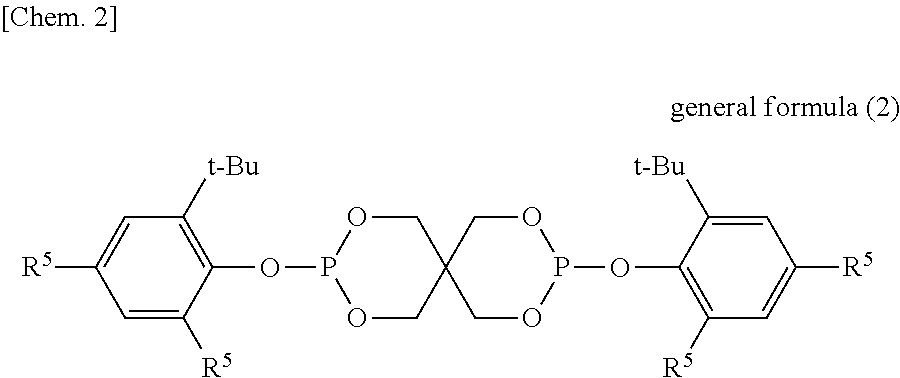

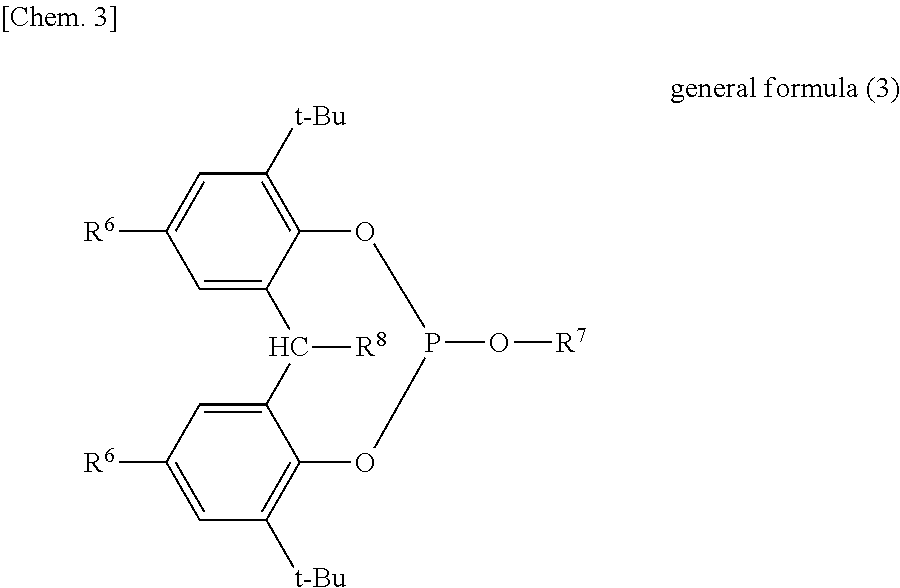

Ultraviolet absorber composition with improved heat resistance and synthetic resin composition containing the same

ActiveUS20110272648A1Excellent heat resistance and colorabilityGroup 5/15 element organic compoundsSynthetic resin layered productsAlcoholPentaerythritol

Owner:ADEKA CORP

High-water-resistance quick-photocuring pearlescent water-based UV paint, and preparation method and application method thereof

ActiveCN105969161AHigh hardnessImprove wear resistancePretreated surfacesPolyurea/polyurethane coatingsEpoxyWater based

The invention relates to a water-based UV paint, particularly a high-water-resistance quick-photocuring pearlescent water-based UV paint, and a preparation method and application method thereof. The paint is prepared from a water-based polyurethane acrylate resin, a water-based epoxy acrylic resin, a functional monomer, a photoinitiator, a leveling agent, an anti-settling agent, pearl powder and a solvent, wherein the functional monomer comprises at least one of dipentaerythritol hexaacrylate, pentaerythritol triacrylate and trimethylolpropane triacrylate. The number of the functional groups of the dipentaerythritol hexaacrylate, pentaerythritol triacrylate and trimethylolpropane triacrylate is 3 or above. The photocured paint film has the advantages of high crosslinking density, excellent hardness, excellent tensile strength and excellent mechanical properties. The water-based epoxy acrylic resin is introduced on the basis of the water-based polyurethane acrylic resin, thereby enhancing the water resistance of the paint film. By introducing the pearl powder and anti-settling agent, the paint film has gorgeous pearl effects.

Owner:深圳市嘉卓成科技发展有限公司 +1

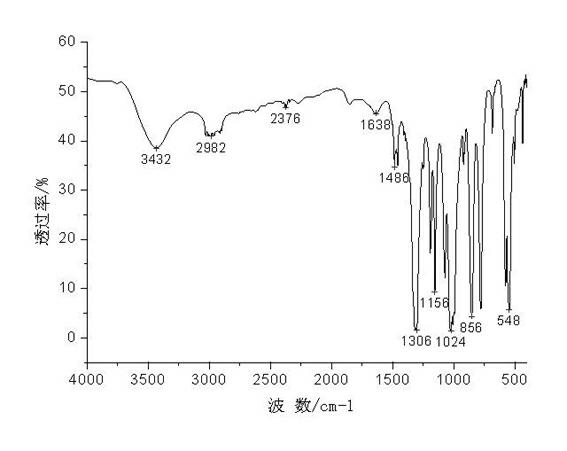

Pentaerythritol diphosphonate dichloride ethylenediamine macromolecular flame retardant and preparation method thereof

The invention discloses a preparation method of a pentaerythritol diphosphonate dichloride ethylenediamine macromolecular flame retardant. The method is characterized by comprising the following steps of: (1) reacting phosphorus oxychloride with pentaerythritol to obtain pentaerythritol diphosphonate dichloride; and (2) dissolving the pentaerythritol diphosphonate dichloride obtained in the step (1) into dimethylfomamide to obtain a solution A, dropwise adding ethylenediamine into the solution A, raising the temperature to 150-155 DEG C, reacting for 2-4 hours, cooling, filtering, washing and drying to obtain the pentaerythritol diphosphonate dichloride ethylenediamine macromolecular flame retardant. The macromolecular flame retardant is synthesized by introducing nitrogen, phosphorus and carbon elements into the same macromolecular structure, so that the stability and the macromolecular compatibility of the flame retardant are improved.

Owner:SUZHOU UNIV OF SCI & TECH

Oil film bearing lubricating oil with high water separation performance

The invention relates to an oil film bearing lubricating oil with high water separation performance. The invention is characterized in that the oil film bearing lubricating oil comprises the following materials of: bi-polyisobutene succimide, phytic acid, 6-tert-butyl-3-methyl phenol, triphenyl thiophosphate, dialkyl pentasulfide, triazole octadecylamine salt, di(2, 4-ditert-butyl phenyl) pentaerythritol biphosphite ester, butyl isooctylphosphate laurylamine salt, dodecene hydrocarbon butane diacid, oxozone trimethylene derivates of amine, petroleum acid polyether ester, polyacrylic ester, oil-soluble polyether macromolecular compound, bisphenyl propyl dimethyl siloxane and base oil. The product has excellent water separation performance and good extreme-pressure abrasion resistance, and can meet the special requirements of working conditions of humidity and wateriness.

Owner:CHINA PETROLEUM & CHEM CORP

Marine methanol fuel oil and preparation method thereof

The invention relates to the technical field of fuel oil, particularly a marine methanol fuel oil and a preparation method thereof. The marine methanol fuel oil is prepared from the following raw materials in percentage by mass: 10-50% of methanol, 30-80% of 0# diesel, 1-10% of oleamide, 1-10% of methylene ammonium salt, 0.5-5% of antioxidant, 1-10% of thiadiazole derivative, 1-10% of pentaerythritol ester, 0.5-15% of phthalate ester, 1-15% of unsaturated fatty acid soap, 5-35% of low-carbon fatty alcohol, 1-5% of cosolvent, 1-10% of naphthenate, 1-10% of cetane number improver and 3-15% of combustion improver. The marine methanol fuel oil is used on ships, and can reduce the consumption of diesel. The product provides similar power to 0# diesel, and can effectively lower the carbon emission. The swelling capacity for rubber is equivalent to 0# diesel. The corrosivity of the marine methanol fuel oil for engines is low, and satisfies the Chinese Standard requirement for 0# diesel corrosivity.

Owner:钦州聚力新能源科技有限公司

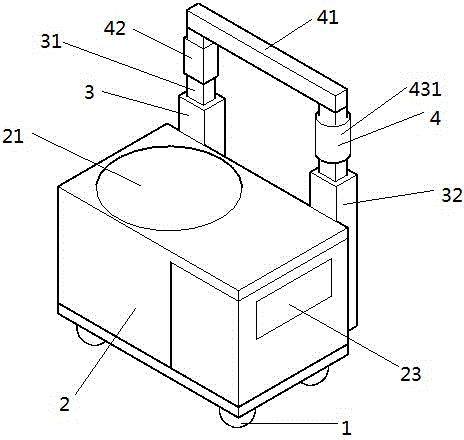

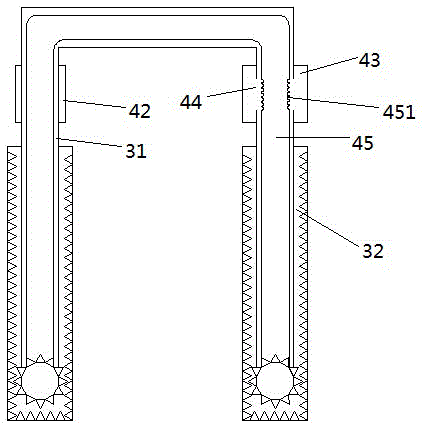

Brushing method of functional environment-friendly paint

InactiveCN104962183AAntioxidantFunctionalLiquid surface applicatorsAnti-corrosive paintsGlycerolAdipic acid

The invention discloses a brushing method of a functional environment-friendly paint, which comprises a mobile device, a carrying box arranged on the mobile device, a lifting device and a wall brushing device, wherein the lifting device is arranged on one side in the carrying box and used for lifting; the wall brushing device is arranged on the lifting device and used for wall brushing; a containing cavity for containing the paint and a power unit are arranged in the carrying box; one side of the carrying box is provided with a display control system; the lifting device comprises a first lifting bracket and a second lifting bracket; and the functional environment-friendly paint is automatically brushed on the wall surface through an automatic wall brushing machine. The paint comprises a raw material glycerol, pentaerythritol, trimethylolpropane, phthalic acid, adipic acid, trimellitie anhydride, maleic acid, triethylamine, a first solid additive, a second solid additive, a first composite regulator, a second composite regulator and a third composite regulator. The method has the advantages of low manufacturing cost and favorable wall brushing effect, and is suitable for wide application in the market.

Owner:ZHEJIANG QIAOXING CONSTR GRP

Pentaerythritol ester base oil and synthesis method thereof

ActiveCN105219480AHigh viscosity indexLowering the freezing pointBase-materialsPentaerythritolSynthesis methods

The invention provides pentaerythritol ester base oil and a synthesis method thereof. The concrete synthesis method comprises the following steps of adding a catalyst A into pentaerythritol serving as a reaction raw material to carry out self-polymerization reaction to generate pentaerythritol rich in a dipolymer; adding fatty acid or arylcarboxylic acid into pentaerythritol rich in the dipolymer to carry out esterification reaction to obtain a crude product; and deacidifying and decolorizing the crude product to obtain the pentaerythritol ester base oil. The dipolymer of pentaerythritol ester and corresponding esters are introduced to a mixture, so that the viscosity and viscosity-temperature characteristics of the base oil are improved, and the condensation point of the base oil is reduced; and the obtained base oil is particularly suitable for the fields of aircraft engine lubricating oil, gear oil and the like.

Owner:GUANGHAN TIANZHOU AERO ENGINE FUEL TECH CO LTD

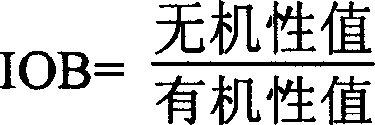

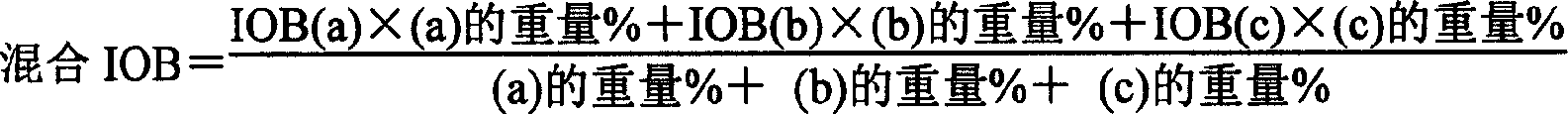

Cleansing cosmetic

InactiveCN1642519AReduce cleaningCosmetic preparationsNon-ionic surface-active compoundsActive agentEngineering

The invention provides a water-resistant cleansing preparation which takes the form of a transparent liquid and does not cause lowering in the cleansing power or deterioration in the appearance or the feelings in use even when contaminated with water, specifically, a transparent liquid cleansing preparation which consists of a composition comprising the following components (A) to (D) and does not turn cloudy even when 50 parts by weight of water is added per 100 parts by weight of the composition: (A) at least one nonionic surfactant selected from among (a) monoglycerol fatty acid esters wherein the fatty acid residue has 12 to 18 carbon atoms, (b) polyglycerol fatty acid esters wherein the fatty acid residue has 12 to 18 carbon atoms, (c) isostearyl pentaerythryl glyceryl ether, and (d) liquid nonionic surfactants having polyalkylene glycol chains and exhibiting IOB of 0.75 to 1.05, (B) a nonionic surfactant except the component (A), exhibiting IOB of 1.1 or above, (C) a liquid oil component, and (D) at most 12% by weight of water.

Owner:KAO CORP

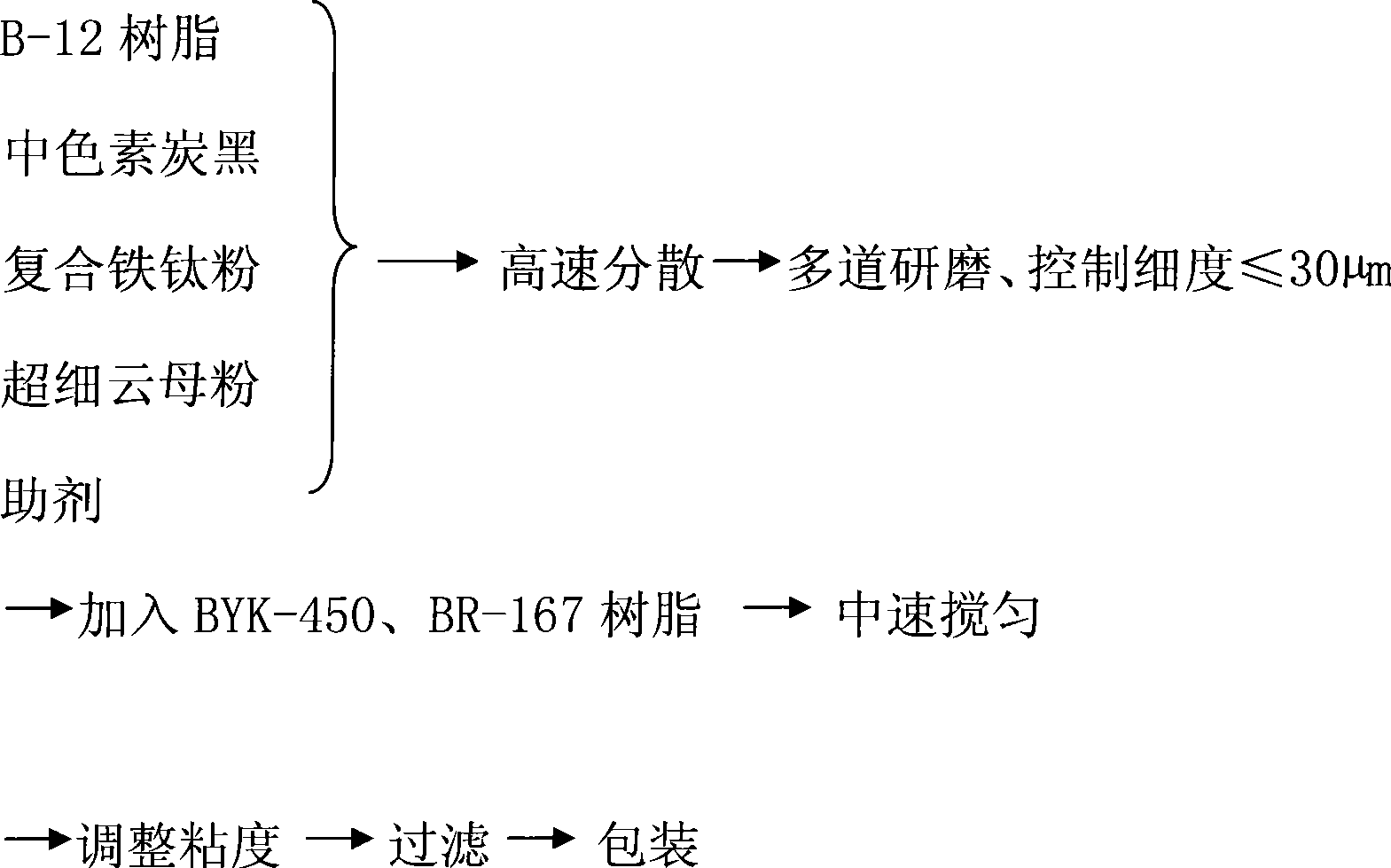

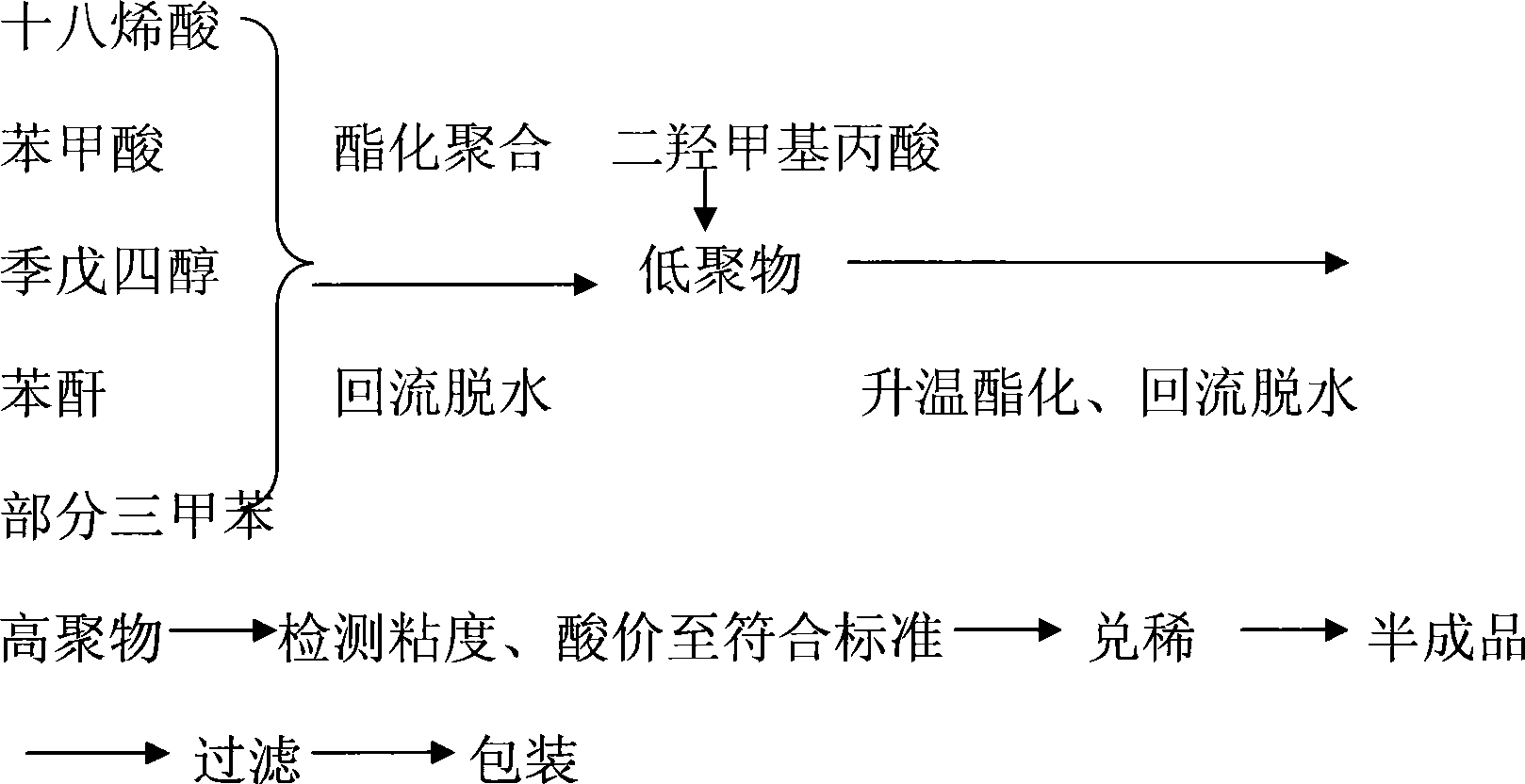

Low temperature quick-drying amino paint for automobile chassis and production method thereof

ActiveCN101434809AImprove efficiencyImprove coating efficiencyPolyester coatingsBenzoic acidPropanoic acid

The invention provides a low-temperature fast-dry amino automobile chassis paint and a production method thereof, wherein, the paint consists of B-12 resin, medium pigment carbon black, compound ferrotitanium powder, ultra-fine mica powder, an auxiliary agent, sealed paratoluenesulfonic acid BYK-450 and BR-167 amino resin; B-12 resin is prepared by octadecenoic acid, benzoic acid, pentaerythritol, phthalic anhydride, dimethylol propionic acid, and trimethyl benzene. The automobile chassis paint adopts special B-12 resin synthetic route to lead the polymer chain to have more active functional groups simultaneously to be matched with the blocked paratoluenesulfonic acid, reduces the baking temperature of the existing amino paint from 130 DEG C to 90 DEG C and reduces the curing film-forming time from 1 hour to half an hour. As the paint film has high crosslinking density, compound ferrotitanium powder and squamous anti-rust pigment are matched for use, and the polyaniline is used for improving the anticorrosive potentials, thus leading the salt spray resistance of the paint to achieve 150 hours and improving the protection performance and the coating efficiency.

Owner:ANQING LINGHU PAINT

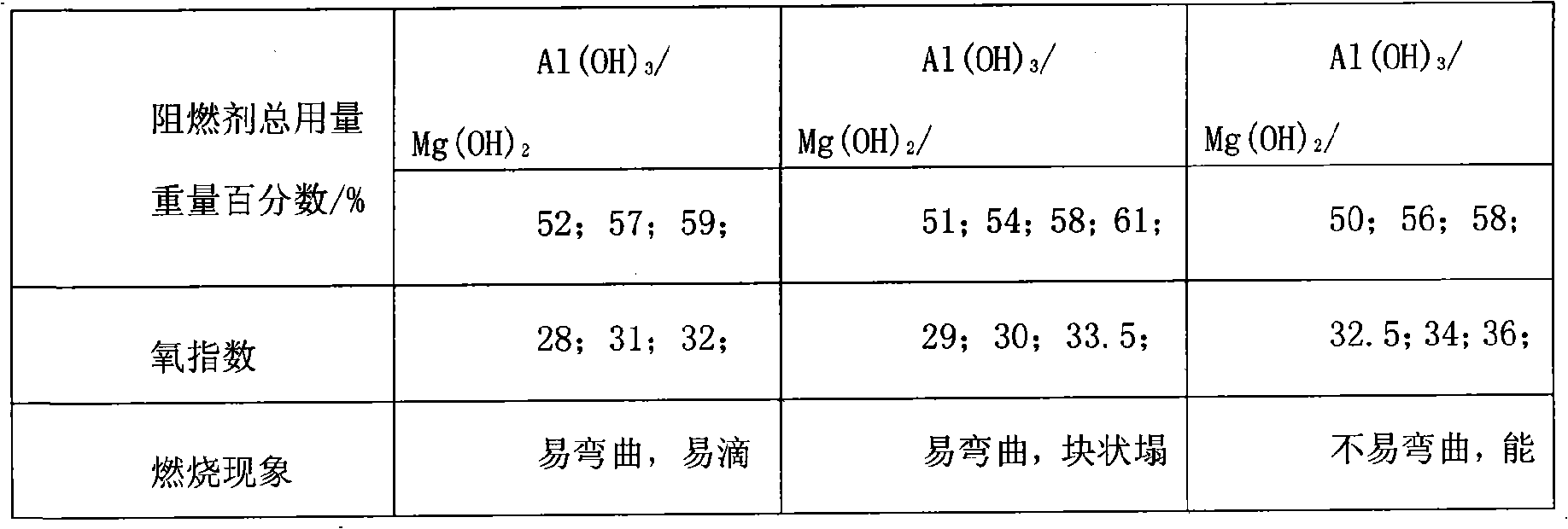

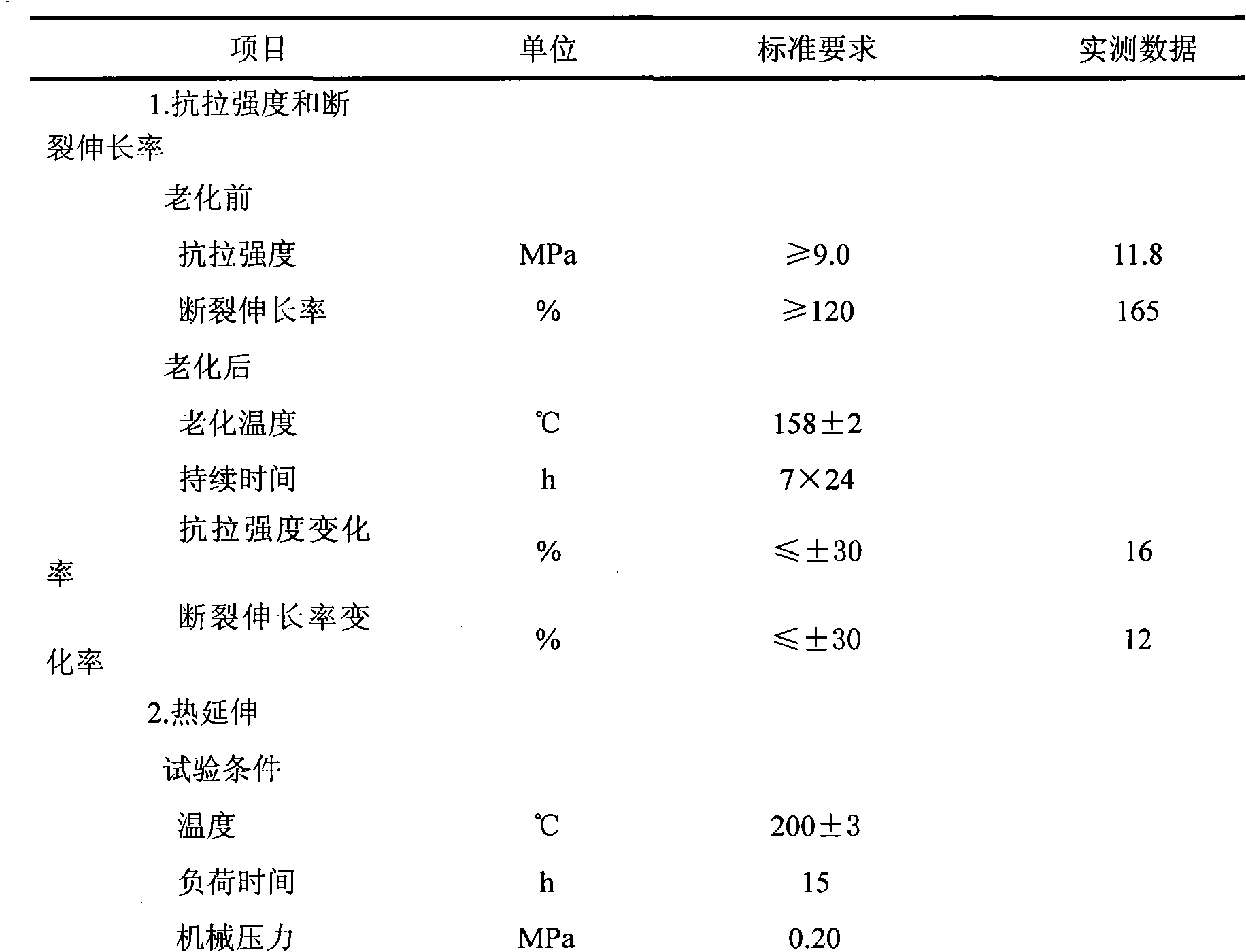

Highly effective flame-retardant environment-protective thermoplastic plastic and making process thereof

InactiveCN101323688AHigh mechanical strengthImprove flame retardant performanceInsulated cablesInsulated conductorsPolyolefinFire retardant

The invention particularly relates to a highly-effective flame-retardant environmental friendly thermoplastic plastic used in wires and cables and a making technology thereof. The formula of the thermoplastic plastic of the invention comprises the following materials by weight portion: 55 portions to 65 portions of ethylene-vinyl acetate copolymer, 5 portions to 25 portions of high-density polyethylene, 70 portions to 140 portions of Al(OH)3, 30 portions to 70 portions of Mg(OH)3, 6 portions to 10 portions of organic flame retardant with synergy of flame retardancy, 20 portions to 30 portions of maleic anhydride compatilizer, 0.5 portion to 1 portion of pentaerythritol ester antioxidant, 0.5 portion to 2 portions of lubricant and 3 portions to 10 portions of nano-char master batch. The thermoplastic plastic of the invention adopts polyolefin as basic resin and hydroxide as a main flame retardant by combining auxiliary agents such as a compatilizer, a flame retardant synergist, a char catalyst, etc. to prepare environmental friendly materials used in PE wires and cables and having good overall properties such as low smoke zero halogen, high mechanical strength, good flame retardancy, etc, through the pelleting after plasticization and blending.

Owner:广东电缆厂有限公司 +1

Preparation method of pentaerythritol ester

ActiveCN103539664AHigh purityOrganic compound preparationCarboxylic acid esters separation/purificationPentaerythritolFatty acid

The invention provides a preparation method of pentaerythritol ester. The preparation method comprises following steps: pentaerythritol, a fatty acid and active carbon are reacted for a first time at a temperature of 150 to 220 DEG C, under a pressure of -0.03 to -0.07MPa so as to obtain a first reaction product; the first reaction product is subjected to reflux at a temperature of 220 to 250 DEG C, under a pressure of -0.05 to -0.095MPa so as to obtain a second reaction product; and the second reaction product is subjected to third reaction under a pressure of -0.098MPa so as to obtain pentaerythritol ester. Technological parameters of the esterification step are adjusted, so that residual catalyst is removed, production technology is simplified, purity of the obtained product is increased, more excellent combination properties of the obtained product are ensured, and coking resistance at high temperature and low temperature stability of the obtained product under harsh conditions are achieved.

Owner:CHINA PETROLEUM & CHEM CORP

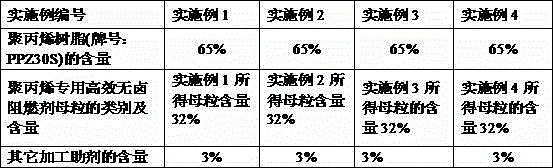

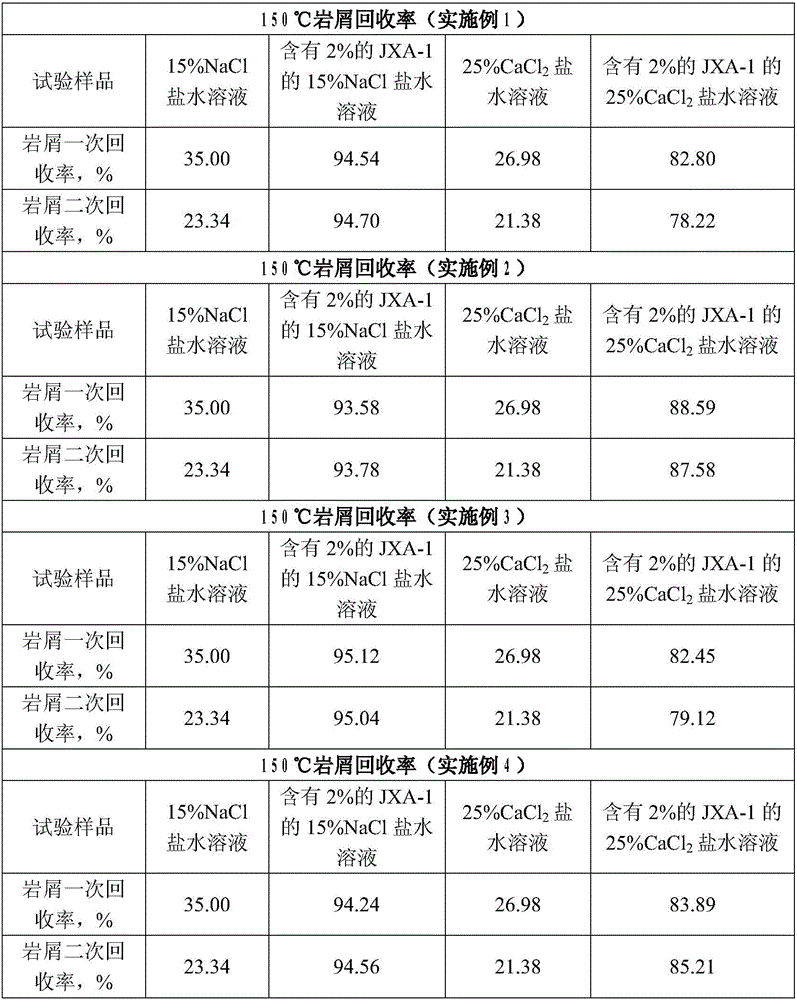

Efficient halogen-free flame retardant master batches special for polypropylene as well as preparation method and application of efficient halogen-free flame retardant master batches

ActiveCN105255016AAdd lessReduce the impact of physical and mechanical propertiesDiphenyl phosphatePolymer science

The invention provides efficient halogen-free flame retardant master batches special for polypropylene. The efficient halogen-free flame retardant master batches consist of the following raw materials in percentage by weight: 30-40% of ammonium polyphosphate, 10-20% of pentaerythritol octahydrogen tetraphosphate, 15-25% of melamine, 5-15% of bisphenol-A bis(diphenyl phosphate), 10-30% of microporous polypropylene, 0.1-1% of pentaerythritol stearate, 0.1-0.5% of an antioxidant 1010 and 0.1-0.5% of an antioxidant 168, wherein the microporous polypropylene is a particle with the size of 3-5mm, the size of cells on surfaces of the particles is 10-100 microns, and the cell density is more than 10<5> / cm<3>. The efficient halogen-free flame retardant master batches special for polypropylene have the characteristics of easy dispersing, easy processing, high flame-retardant efficiency and low production cost, and can be widely applied to production of a flame-retardant polypropylene material for extrusion molding, injection molding and membrane blowing.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

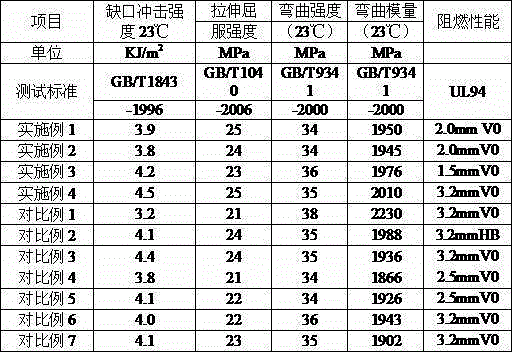

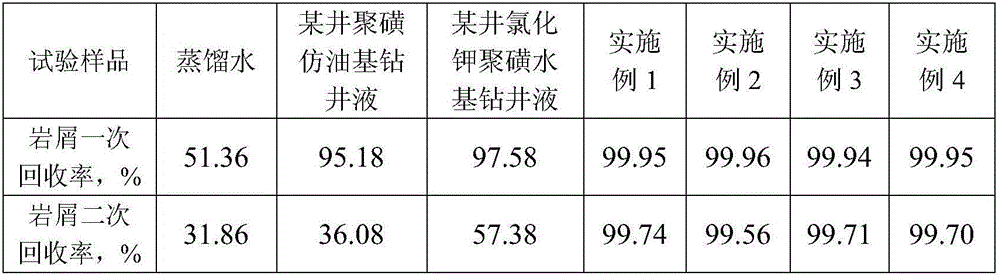

Amide polymer shale inhibitor for drilling fluid and preparation method of shale inhibitor

ActiveCN106279520AAddresses issues with poor suppressionReduce hydration repulsionDrilling compositionCetyldimethylbenzylammonium chlorideChemical inhibition

The invention provides an amide polymer shale inhibitor for drilling fluid. The amide polymer shale inhibitor is characterized by being prepared from, by mass, 10%-20% of acrylamide, 5%-10% of 300# liquid wax, 10%-20% of hexadecyl dimethyl benzyl ammonium chloride, 2%-8% of dimethyl diallyl ammonium chloride, 20%-30% of methacryloyloxyethyl trimethyl ammonium chloride, 15%-25% of acrylic acid, 2%-5% of emulsifiers, 0.03%-0.6% of an initiator and 20%-40% of water, wherein the emulsifiers are any two of Span60, Tween80, Span80, Tween60 and hexadecyl trimethyl ammonium bromide, and the initiator is any one of ammonium persulfate-ethanol, ammonium persulfate-pentaerythritol, ammonium persulfate-sodium hydrogen sulfite and ammonium persulfate-sodium sulfite. By means of a synergistic effect of chemical inhibiting and enveloping and blocking of hydrophobic groups, the good inhibition effects can be achieved, integral inhibition is achieved, and the problem that an original shale inhibitor is bad in inhibition effect under the complex condition is solved.

Owner:成都西油华巍科技有限公司

Flame-retardant PC (Poly Carbonate)/ABC composite material capable of shielding high-frequency electromagnetic wave and preparation method thereof

The invention relates to the technical filed of PC (Poly Carbonate) / ABC composite materials and particularly relates to a flame-retardant PC / ABC composite material capable of shielding high-frequency electromagnetic wave and a preparation method thereof. The flame-retardant PC / ABC composite material capable of shielding high-frequency electromagnetic wave comprises PC, ABS, a surface-treated silver-coated copper fiber, a carbon fiber, conductive carbon black, bromotriazine, bisphenol A bis(diphenyl phosphate), polytetrafluoroethylene, an antioxidant 168, an antioxidant 1076, pentaerythritol stearate, an ethylene vinyl acetate copolymer, a silicone-acrylic copolymer toughening agent and gamma-aminopropyl triethoxysilane. Due to the silver-coated copper fiber, the disadvantages that not only the copper fiber is easily oxidized but also silver powder is relatively expensive are avoided, the same effect is achieved and the cost is reduced; the conductivity and the shielding effectiveness are more stable and the flame retardancy is significantly improved. The preparation method disclosed by the invention is simple and mature and high in production efficiency and is conducive to being universally popularized and applied.

Owner:SILVER AGE ENG PLASTICS DONGGUAN

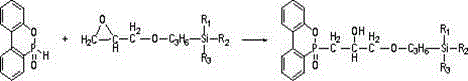

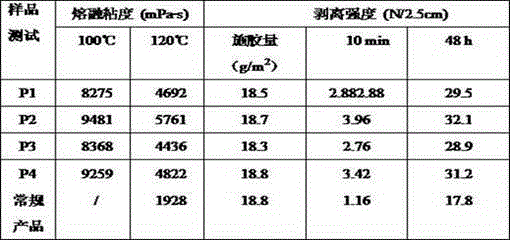

Preparation method of modified moisture-curable polyurethane hot melt adhesive

ActiveCN105255434AStripping strong and excellentEasy constructionPolyureas/polyurethane adhesivesAdhesive cementPolymer science

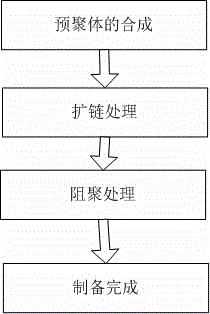

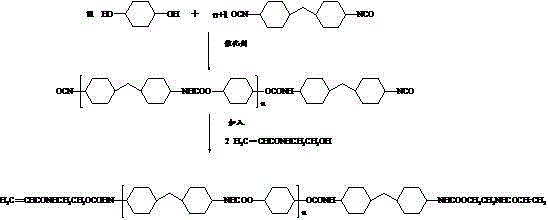

The invention discloses a preparation method of a modified moisture-curable polyurethane hot melt adhesive and belongs to the technical field of synthesis of polyurethane adhesives. The preparation method of the modified moisture-curable polyurethane hot melt adhesive has the innovations that pentaerythritol diacrylate is applied for modifying the traditional moisture-curable polyurethane hot melt adhesive, the pentaerythritol diacrylate can serve as a chain extender as two hydroxyls are contained, usage amount of the pentaerythritol diacrylate is regulated, viscosity of a target product is controlled to be in a reasonable range, so that the pentaerythritol diacrylate is convenient for construction and has satisfactory initial adhesion; and meanwhile, the pentaerythritol diacrylate modifier contains a short branched chain functional group acrylate, so that final peeling strength of the target product is also better than that of the traditional conventional product.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

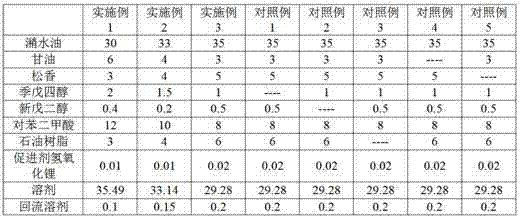

Method for preparing alkyd resin using illegal cooking oil

The invention discloses a method for preparing an alkyd resin using illegal cooking oil and belongs to the field of high polymer materials. The method includes the following steps of putting hogwash oil, rosin, glycerol, pentaerythritol, neopentyl glycol, and an accelerant into a reaction still, and performing heating and reaction; cooling acquired reactants, putting terephthalic acid in the reaction still, and performing heating and reaction; heating the reactants, adding a backflow solvent, and performing backflow heat preservation; cooling reactants, adding a petroleum resin, and performing even stirring; diluting an obtained material with a solvent. According to the method for preparing the alkyd resin using the illegal cooking oil, by means of a formulation design of the reclaimed illegal cooking oil and hogwash oil, the alkyd resin with high properties is prepared through synthetic reaction, manufactured antirust paint is excellent in antiseptic property, and ready mixed paint or enamel paint is excellent in weather fastness, glossy, bright-colored, and good in property.

Owner:JIANGSU HUAXIA PAINT MAKING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com