Preparation method of modified moisture-curable polyurethane hot melt adhesive

A polyurethane hot-melt adhesive and moisture-curing technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of low initial and final adhesive strength and low initial adhesive force, and achieve Ease of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

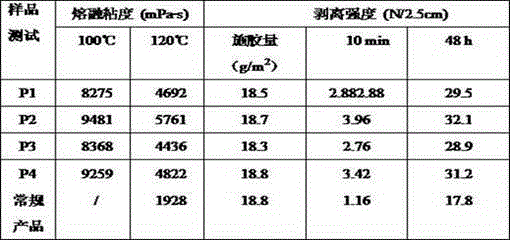

Embodiment 1

[0017] Weigh polyether 1000 (100g), polyether 4000 (72g), polyhexamethylene adipate diol (96g), terpene resin (80.1g), antioxidant CHINOX1010 (2.22g), add to a three-necked flask In the process of stirring, heat to 120-130°C, and dehydrate at a constant temperature of 80-150Pa under absolute pressure for 2.0h, then cool down to 90°C, and pass nitrogen to normal pressure; add 4,4'-MDI ( 85.65g), catalyst stannous octoate (0.44g), then reacted at 90-100°C and 80-100Pa absolute pressure for 45min, then passed nitrogen to normal pressure, and added pentaerythritol diacrylate (8.54g) under nitrogen protection, React for 1.0h at 95-105°C and absolute pressure 80-100Pa to obtain a prepolymer;

[0018] The above-mentioned prepolymer was discharged under nitrogen protection, sealed and packaged, and aged in an environment of 85° C. for 6 hours. The obtained sample number is P1.

Embodiment 2

[0020] Weigh polyether 1000 (100g), polyether 4000 (40g), polyhexamethylene adipate diol (69g), terpene resin (86.95g), antioxidant CHINOX1010 (1.89g), add to a three-necked flask In the process of stirring, it is heated to 120-130°C, and dehydrated at a constant temperature of 80-150Pa under absolute pressure for 2.0h, then cooled to 90°C, and nitrogen is passed to normal pressure; under the protection of nitrogen, add 2,4'-MDI ( 67.63g), catalyst stannous octoate (0.38g), then reacted for 45min at 90-100°C and 80-100Pa absolute pressure, then passed nitrogen to normal pressure, and added pentaerythritol diacrylate (12.2g) under nitrogen protection, React for 1.0h at 95-105°C and absolute pressure 80-100Pa to obtain a prepolymer;

[0021] The above-mentioned prepolymer was discharged under nitrogen protection, sealed and packaged, and aged in an environment of 85° C. for 6 hours. The obtained sample number is P2.

Embodiment 3

[0023] Weigh polyether 1000 (100g), polyether 4000 (80g), polyhexamethylene adipate diol (60g), terpene resin (113.1g), antioxidant CHINOX1010 (2.26g), add to a three-necked flask In the process of stirring, it is heated to 120-130°C, and dehydrated at a constant temperature of 80-150Pa under absolute pressure for 2.0h, then cooled to 90°C, and nitrogen is passed to normal pressure; under the protection of nitrogen, add 2,2'-MDI ( 86.94g), catalyst stannous octoate (0.45g), then reacted at 90-100°C and 80-100Pa absolute pressure for 45min, then passed nitrogen to normal pressure, and added pentaerythritol diacrylate (9.76g) under nitrogen protection, React for 1.0h at 95-105°C and absolute pressure 80-100Pa to obtain a prepolymer;

[0024] The above-mentioned prepolymer was discharged under nitrogen protection, sealed and packaged, and aged in an environment of 85° C. for 6 hours. The obtained sample number is P3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com