Efficient halogen-free flame retardant master batches special for polypropylene as well as preparation method and application of efficient halogen-free flame retardant master batches

A polypropylene and flame retardant technology, applied in the field of high-efficiency halogen-free flame retardant masterbatch for polypropylene and its preparation, can solve the problem of damage to material processing performance and physical and mechanical properties, moisture sensitivity of flame retardant materials, and dispersion of flame retardants. It can avoid problems such as poor performance and achieve the effects of avoiding the difficulty of carrier coating, high flame retardant efficiency and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

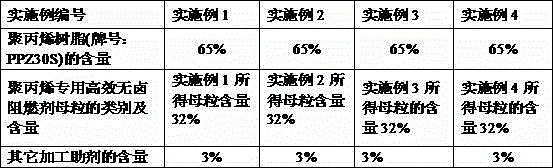

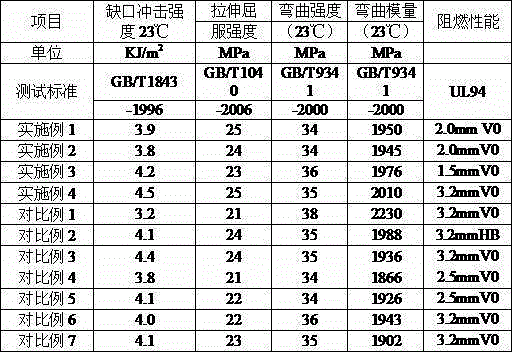

Embodiment 1

[0062] Proportioning is made according to the following mass percentages:

[0063] Ammonium polyphosphate 32% (brand: HT-208, Jinan Taixing Fine Chemical Co., Ltd.), pentaerythritol phosphate 17% (produced by Jiangsu Victory Chemical Co., Ltd.), melamine 22% (superior product, Chengdu Yulong Chemical Co., Ltd. production), bisphenol A bis(diphenyl phosphate) 8% (brand: WSFR-BDP, Zhejiang Wansheng Co., Ltd.), microporous polypropylene 19.8% (self-made, the preparation method is as above), pentaerythritol stearate 0.5% (GLYCOLUBE® P (ETS), Lonza Chemical Company, USA), Antioxidant 1010: 0.5% (Model: SONOX1010, Linyi Sanfeng Chemical Co., Ltd., Shandong Province), Antioxidant 168: 0.2% (Model: SONOX168, Sanfeng Chemical Co., Ltd., Linyi City, Shandong Province).

[0064] Each component in the above formula is accurately weighed, and then the bisphenol A bis(diphenyl phosphate) and the microporous polypropylene are evenly mixed, and left to stand for 5 hours. Then this blend, pe...

Embodiment 2

[0067] Proportioning is made according to the following mass percentages:

[0068] Ammonium polyphosphate 35.7% (brand: HT-208, Jinan Taixing Fine Chemical Co., Ltd.), pentaerythritol phosphate 15% (produced by Jiangsu Victory Chemical Co., Ltd.), melamine 20% (Sichuan Chemical Co., Ltd.), bis Phenol A bis(diphenyl phosphate) 8% (brand name: WSFR-BDP, Zhejiang Wansheng Co., Ltd.), microporous polypropylene 20% (self-made, the preparation method is as above), pentaerythritol stearate 0.6% (GLYCOLUBE ?P (ETS), Lonza Chemical Company, USA), Antioxidant 1010: 0.4% (Model: SONOX1010, Sanfeng Chemical Co., Ltd. Linyi, Shandong Province), Antioxidant 168: 0.3% (Model: SONOX168, Shandong Province Linyi Sanfeng Chemical Co., Ltd.).

[0069] Each component in the above formula is accurately weighed, and then the bisphenol A bis(diphenyl phosphate) and the microporous polypropylene are evenly mixed, and left to stand for 5 hours. Then this blend, pentaerythritol stearate, antioxidant 1...

Embodiment 3

[0072] Proportioning is made according to the following mass percentages:

[0073] Ammonium polyphosphate 38% (brand: HT-208, Jinan Taixing Fine Chemical Co., Ltd.), pentaerythritol phosphate 16.5% (produced by Jiangsu Victory Chemical Co., Ltd.), melamine 20% (superior product, Chengdu Yulong Chemical Co., Ltd. production), bisphenol A bis(diphenyl phosphate) 9% (brand: WSFR-BDP, Zhejiang Wansheng Co., Ltd.), microporous polypropylene 15% (self-made, the preparation method is as above), pentaerythritol stearate 0.8% (GLYCOLUBE® P (ETS), Lonza Chemical Company, USA), Antioxidant 1010: 0.3% (Model: SONOX1010, Linyi Sanfeng Chemical Co., Ltd., Shandong Province), Antioxidant 168: 0.4% (Model: SONOX168, Sanfeng Chemical Co., Ltd., Linyi City, Shandong Province).

[0074] Each component in the above formula is accurately weighed, then bisphenol A bis(diphenyl phosphate) and microporous polypropylene are evenly blended, and left to stand for 6 hours. Then this blend, pentaerythri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com