Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Fast film formation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel nano-composite electrochromic material, device and preparation method thereof

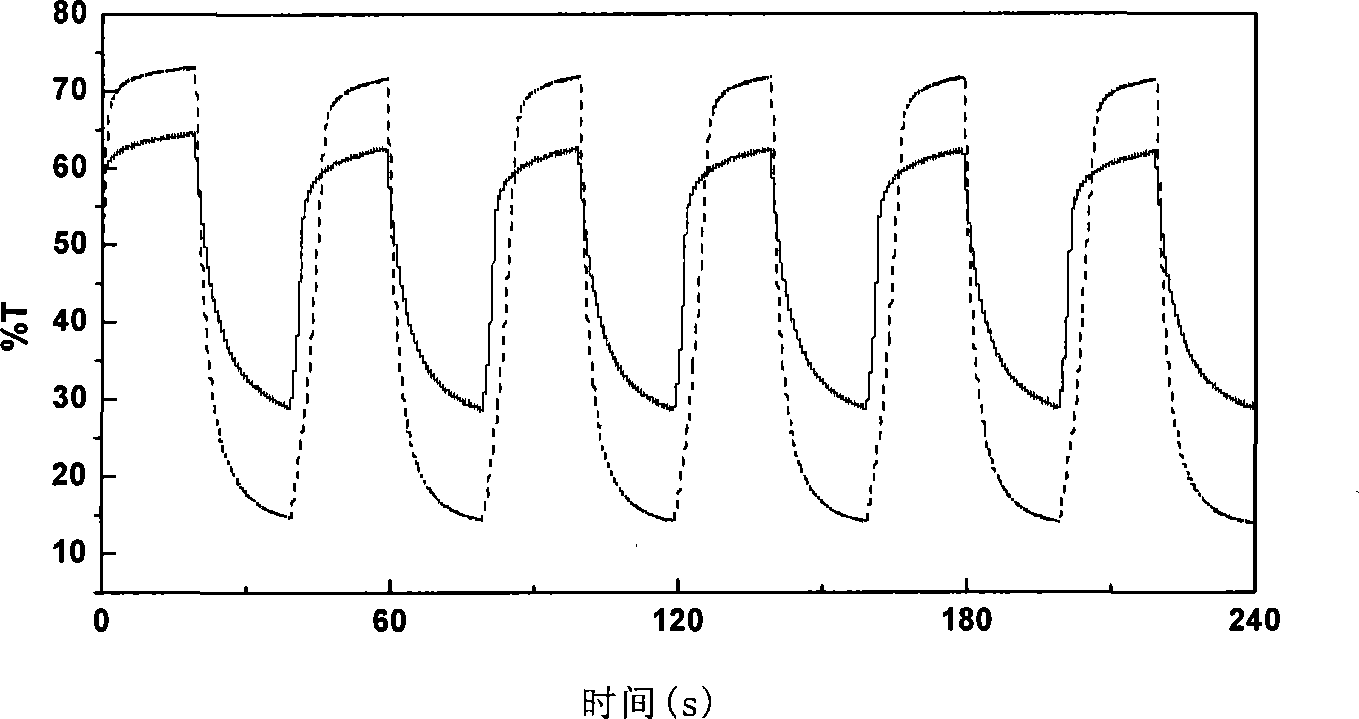

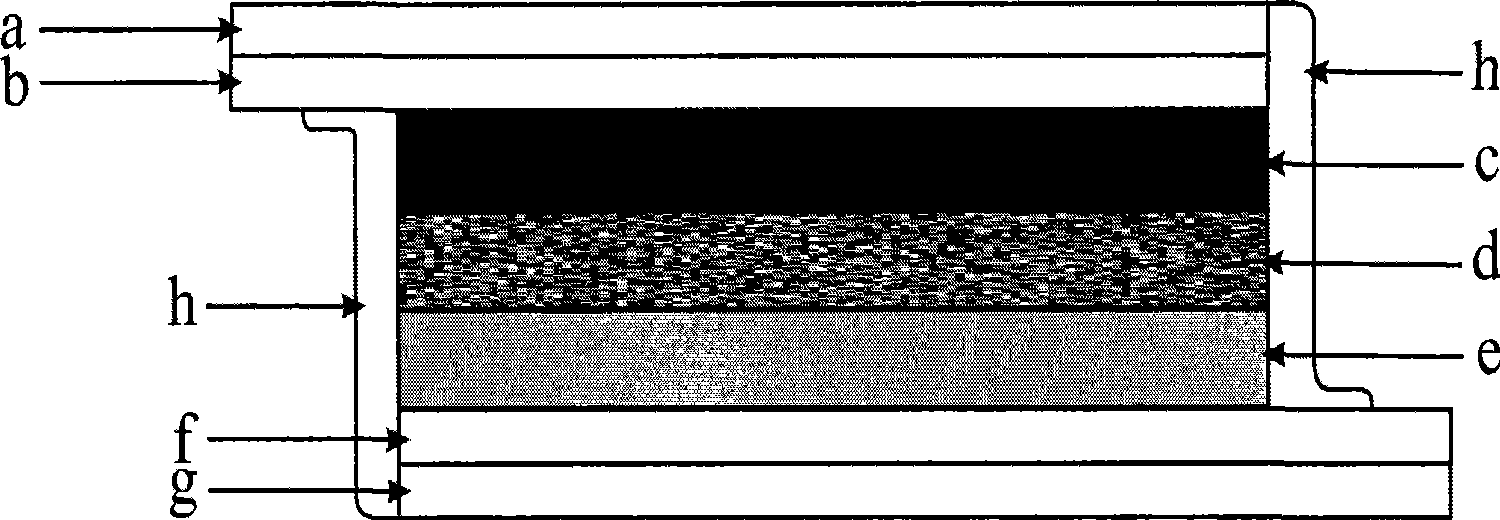

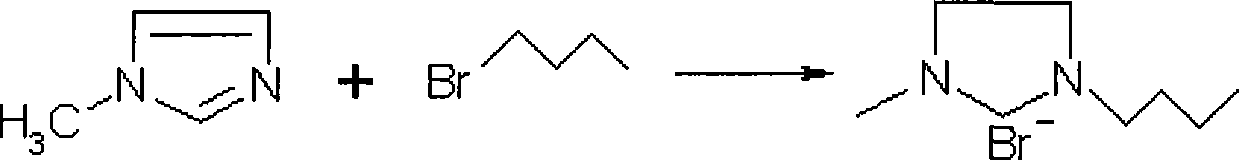

InactiveCN101445723AFlat surfaceFast film formation rateTenebresent compositionsElectrochromismMetal

The invention provides a novel nano-composite electrochromic material, comprising a metal nano-material layer and an inorganic chromic material layer which covers the metal nano-material layer; wherein, the metal nano-material layer is a nano-Ag film layer; the inorganic chromic material layer is a WO3 layer, a TiO2 layer or the combination of the WO3 layer and the TiO2 layer. The invention also provides an electrochromic device and a preparation method for the nano-composite electrochromic material. The composite electrochromic material has excellent electrochromic performance.

Owner:EAST CHINA NORMAL UNIVERSITY

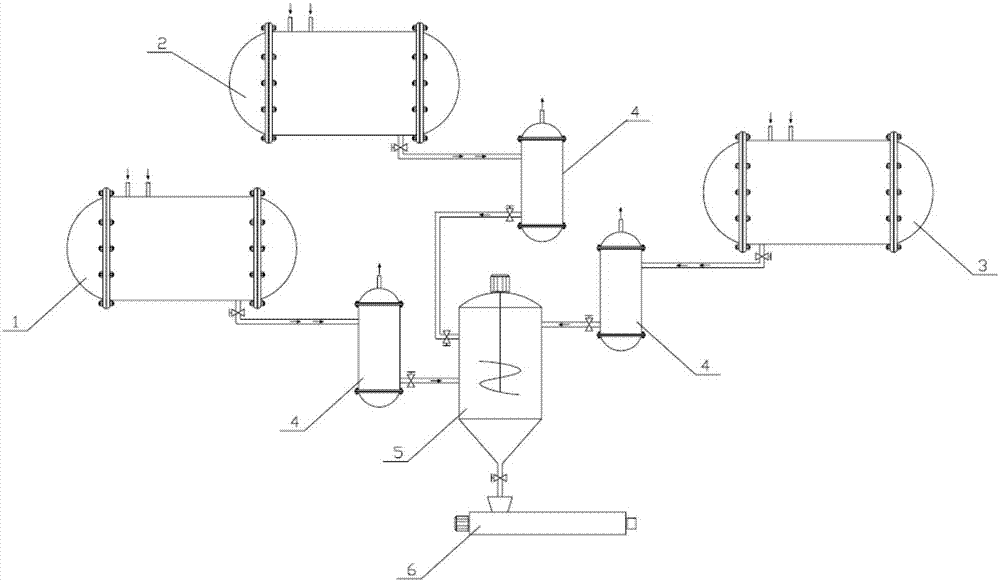

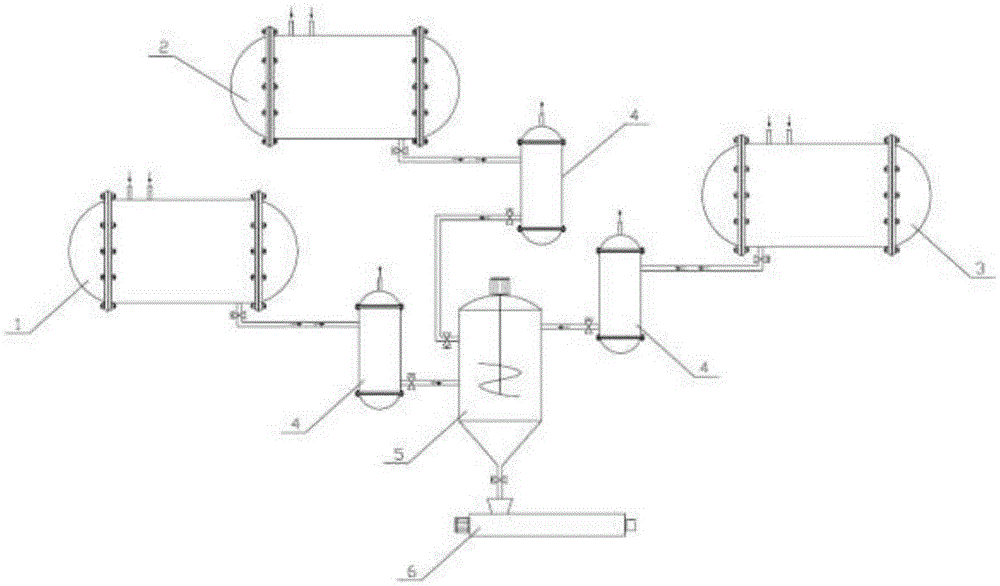

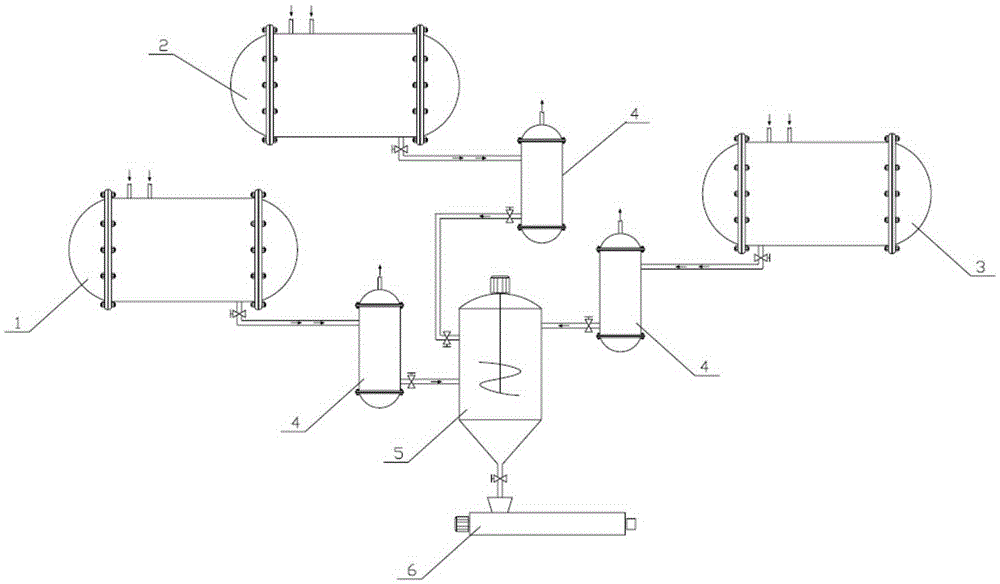

Film plating device and method for preparing TCO (Transparent Conducting Oxide) glass online by floating method

The invention discloses a method for preparing TCO (Transparent Conducting Oxide) glass online by a floating method and a special film plating device. The film plating device is characterized in that a film plating reactor is a rectangular structure comprising double channels for inputting gas and double channels for discharging gas; the film plating device is fixed above a floating-method glass production line and the lower part of the film plating device is located in a temperature region of 630-650 DEG C in a floating-method glass tin groove; the film plating reactor is further internally provided with six rectangular oil cooling circulating cavities and two air discharging cavities; a mixing cavity is arranged between two side wall plates of a central line and the width of the mixing cavity is 100-200mm; and an aerosol guiding channel is arranged and the width of the aerosol guiding channel is 10-30mm. The method comprises the following steps: (1) preparing a base film; and (2) mixing a tin source, a fluorine source doping agent, a stabilizing agent and a catalyst precursor in the film plating reactor to form a TCO film layer. The method and the film plating device disclosed by the invention have the advantages of small investment, low cost, operability and easiness for maintenance; the uniformity of the TCO film layer is good, the wear resistance, the conductivity and the visible light transmittance are high; and the industrial production is easy to realize.

Owner:QINHUANGDAO GLASS IND RES & DESIGN INST

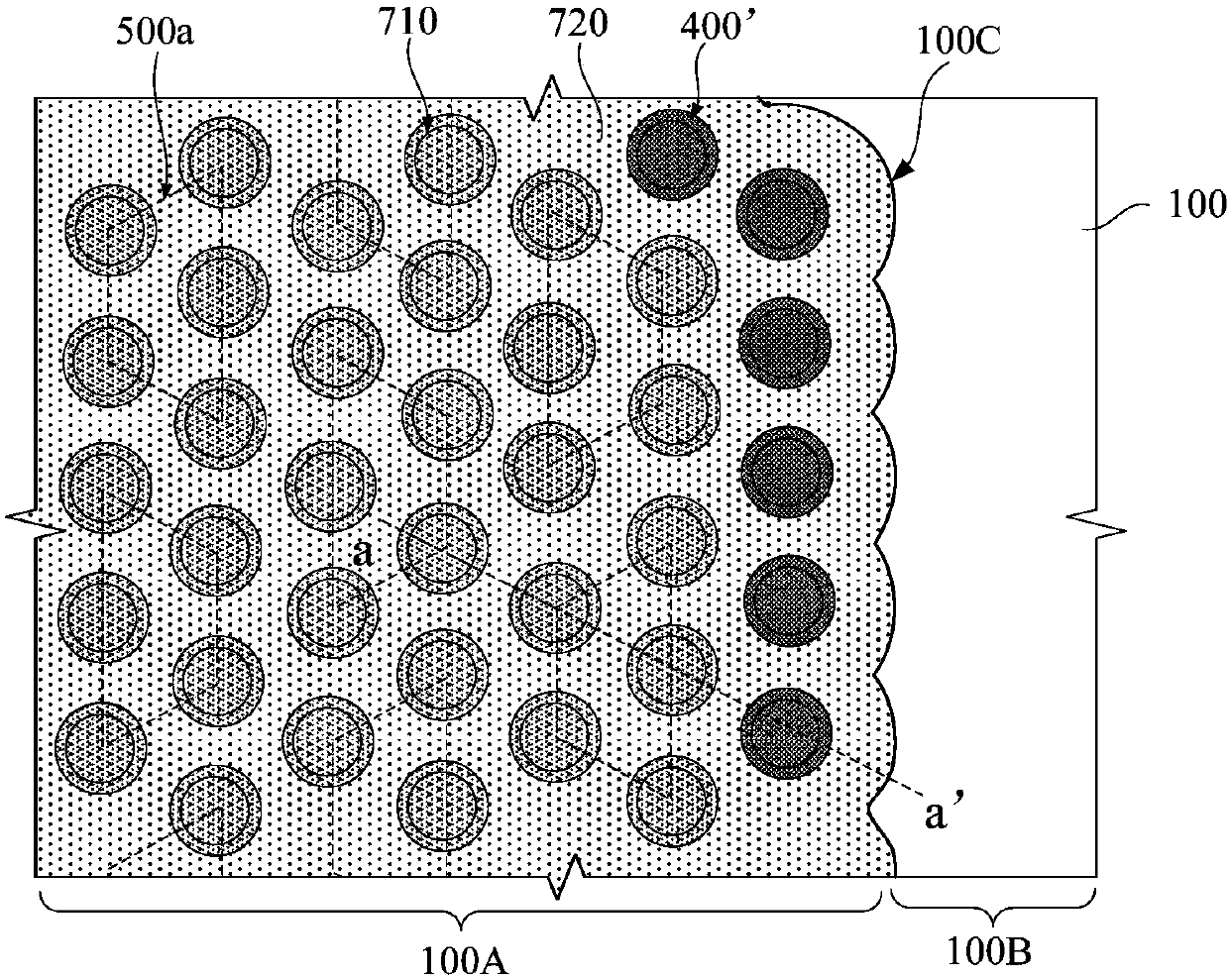

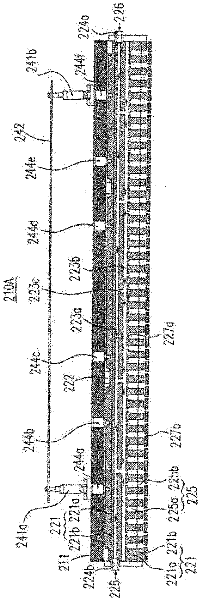

Container array, formation method thereof and semiconductor device

PendingCN107706206AIncrease capacitanceEasy accessSolid-state devicesSemiconductor devicesCapacitanceDevice material

The invention provides a container array, a formation method thereof and a semiconductor device. In the container array, a penetrating hole in an electrode group pattern layer communicates with a cylindrical internal part and a cylindrical external part of a cylindrical structure of a lower electrode, the projection of a linear boundary of the penetrating hole in a height direction penetrates through at least one top port of the lower electrode, thus, the area size, corresponding to the penetrating hole, of the top port of the lower electrode still cannot be effected even displacement deviation exists in the penetrating hole in an extension direction of the linear boundary, and a complete capacitance dielectric layer and an upper electrode can be enabled to be formed on an inner surface and an outer surface of the lower electrode. Moreover, the opening size of the penetrating hole is relatively large, so that the corresponding etching rate and the film formation rate are also favorablyimproved during etching an etching process and a film formation process via the penetrating hole.

Owner:CHANGXIN MEMORY TECH INC

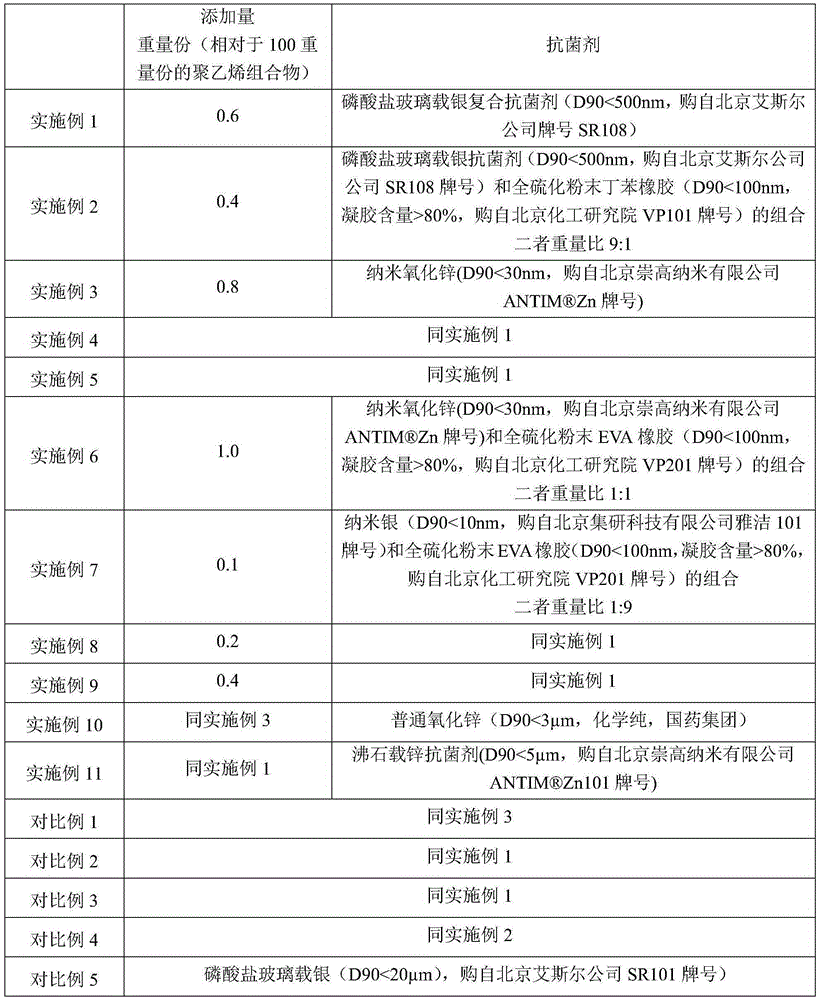

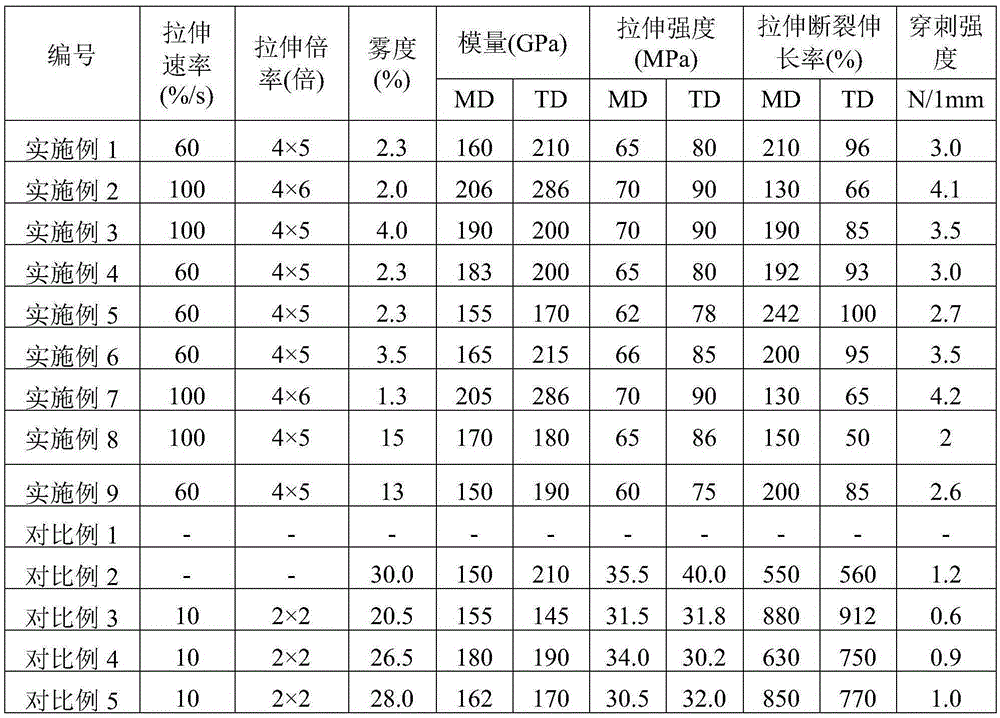

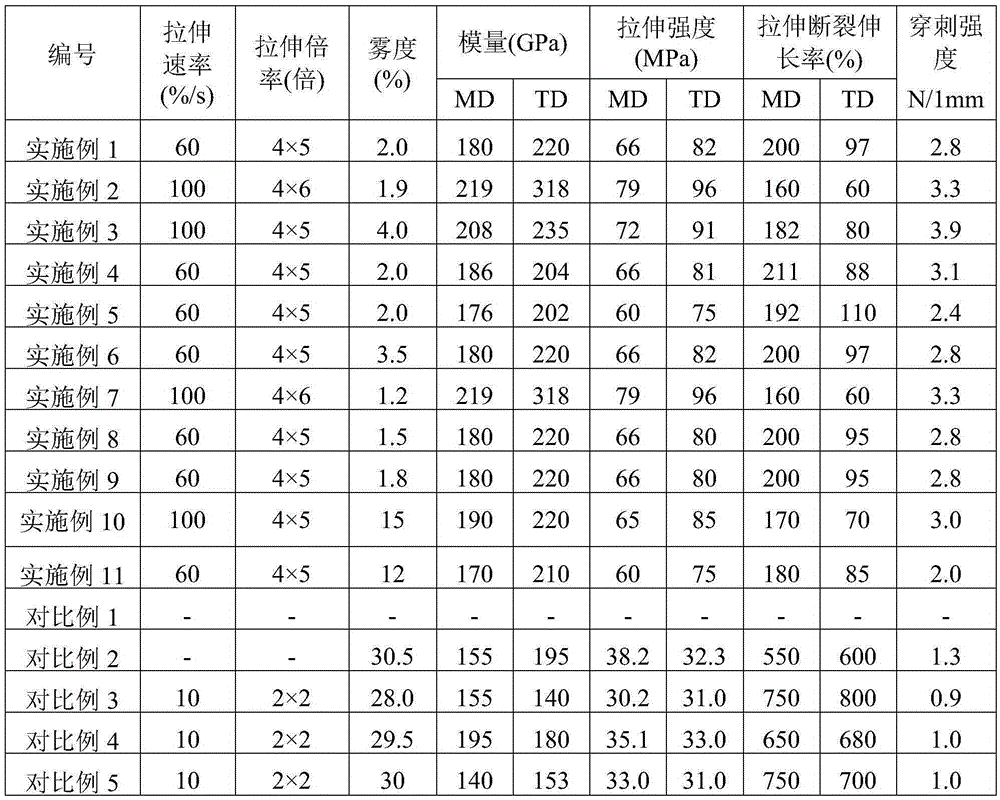

Polyethylene film and preparation method thereof

ActiveCN107312229AHigh standardIncrease the stretch ratioSynthetic resin layered productsFlat articlesLinear low-density polyethylenePolymer science

The present invention relates to the field of polymers, and provides a polyethylene film and a preparation method thereof. The polyethylene film comprises a polyethylene core layer and a polyethylene surface layer attached to at least one side surface of the polyethylene core layer, wherein the polyethylene core layer is formed from a first polyethylene composition containing a component A, a component B and a component C, the polyethylene surface layer is formed from a second polyethylene composition containing a component D, the components A, B, C and D respectively are ethylene / alpha olefin copolymerized linear low density polyethylene, the melt indexes of the components A, B, C and D at a temperature of 190 DEG C and a load of 2.16 kg respectively are 0.01-3.5 g / 10 min, 3.6-9.9 g / 10 min, 10-80 g / 10 min and 0.5-50 g / 10 min, and the densities of the components A, B, C and D respectively are 0.915-0.936 g / cm<3>, 0.915-0.930 g / cm<3>, 0.915-0.930 g / cm<3> and 0.880-0.910 g / cm<3>. The polyethylene film of the present invention has advantages of excellent mechanical property, excellent optical property, excellent heat sealing strength, and great industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

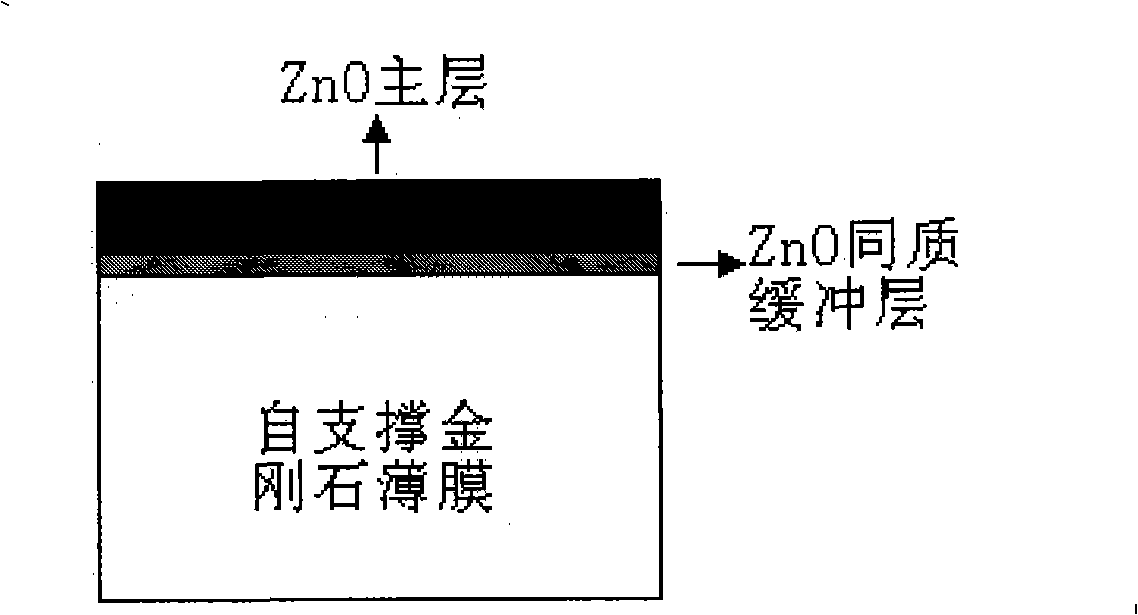

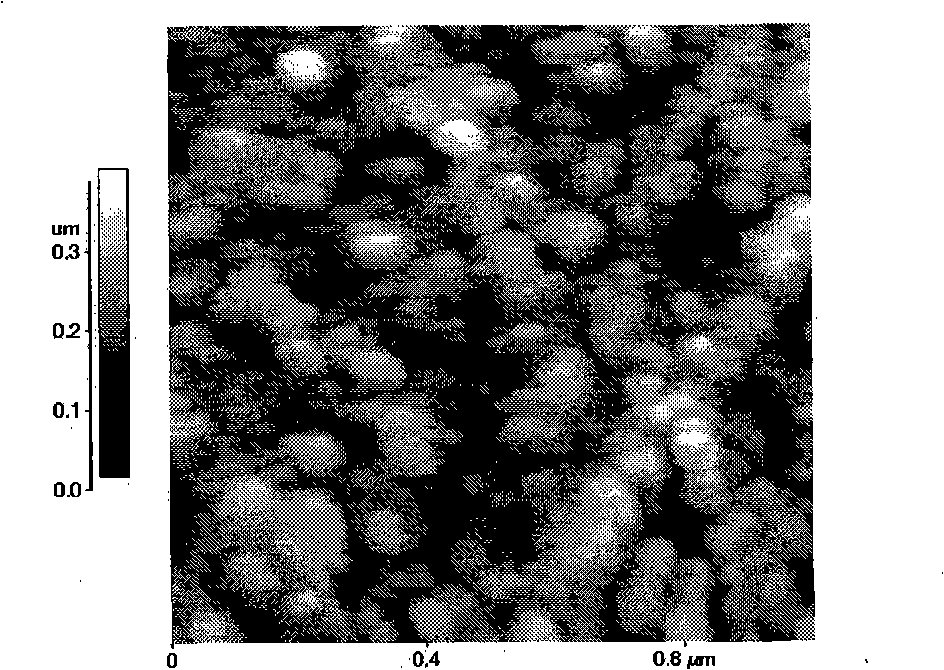

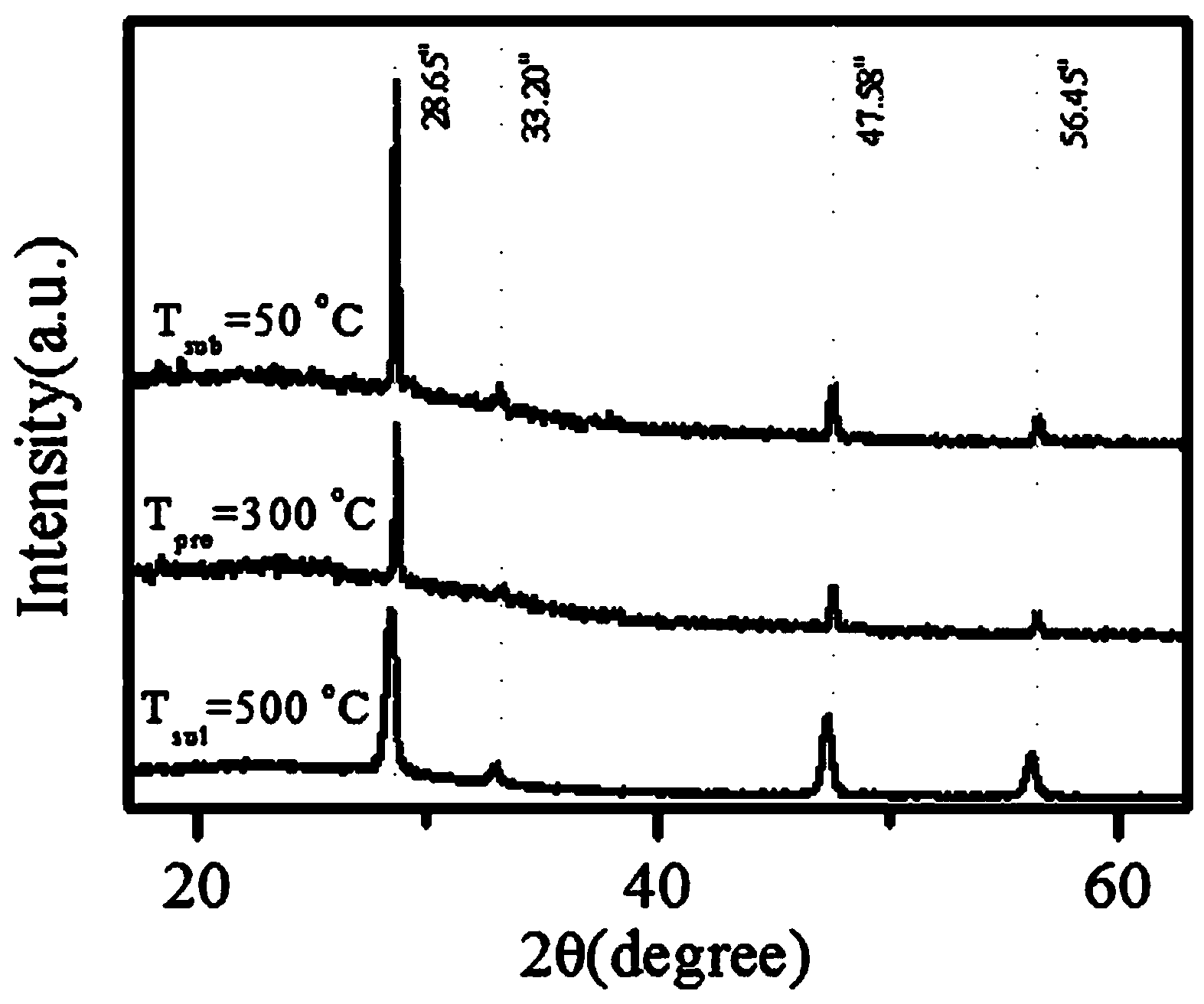

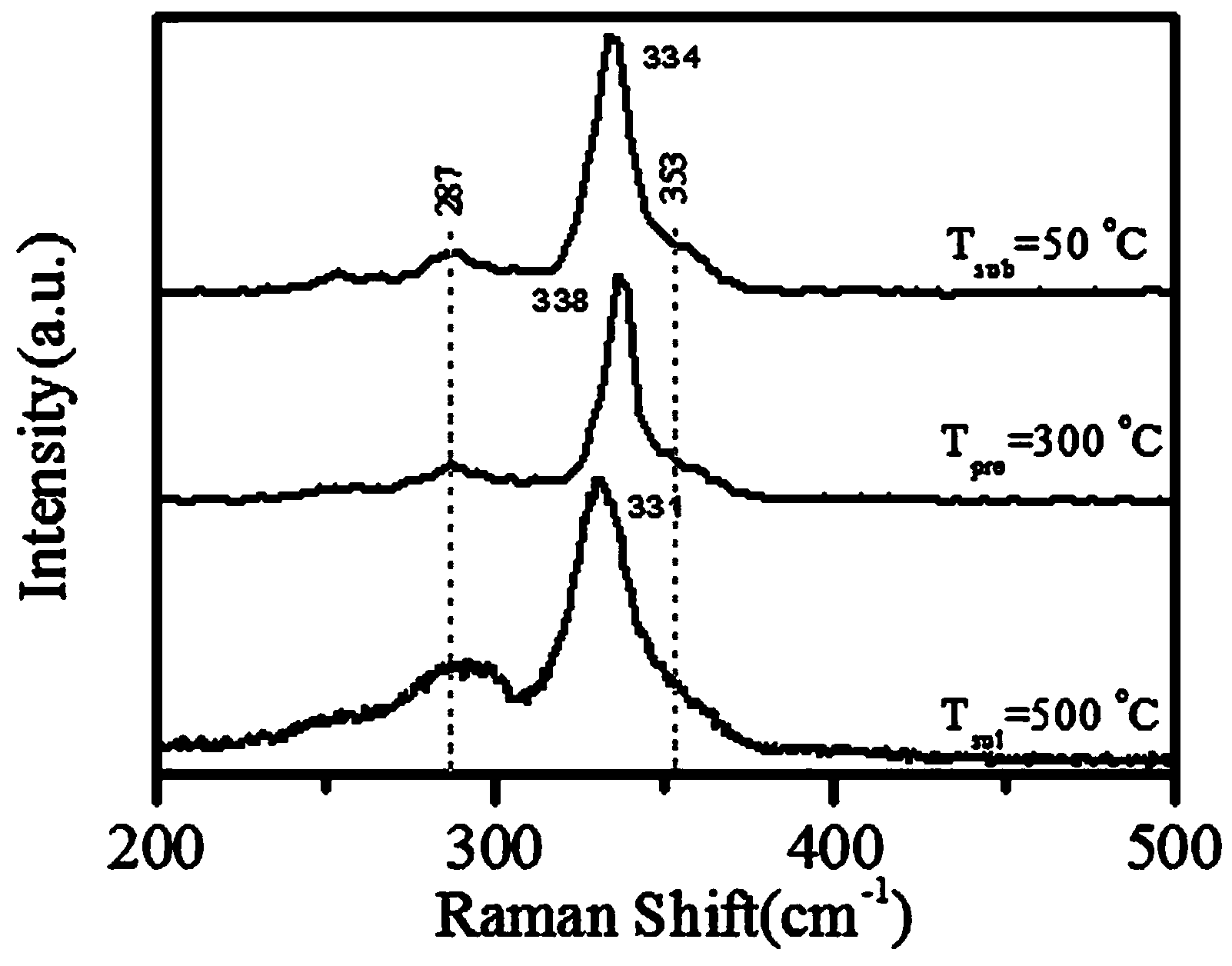

Method for preparing high quality ZnO film using cushioning layer

InactiveCN101323971ASolve Thickness ProblemsHigh crystallinityPolycrystalline material growthFrom chemically reactive gasesGas phaseDirect current magnetron sputtering

The invention relates to a method that prepares a high-quality ZnO film by utilizing a buffer layer, which comprises following main steps: a silicon substrate is preprocessed and placed into a reaction chamber of a hot filament chemical vapor depositing device as a deposited substrate; nucleation and growth of a diamond film are implemented in mixed reaction gases of hydrogen and acetone, and the silicon substrate is soaked and rusted in a mixed solution of HNO3 and HF, thus forming the self-supporting diamond film; the ZnO film is prepared on the self-supporting diamond film by the direct current magnetron sputtering method, the ZnO buffer layer is firstly sputtered and deposited in Ar and O2, and then a ZnO main layer is deposited. The method that prepares the high-quality ZnO film has simplified techniques and low cost and is favor for promoting large-scale application of high-quality ZnO film devices. The produced ZnO film has small crystal grain size, high crystal quality and low surface roughness.

Owner:SHANGHAI UNIV

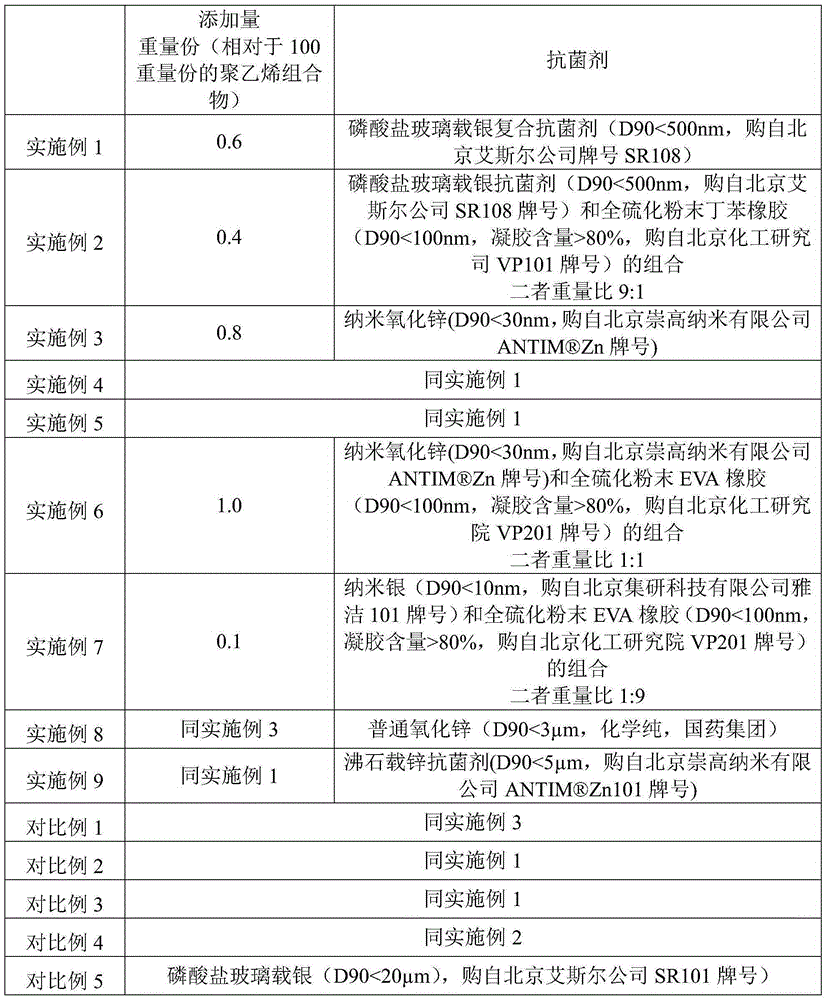

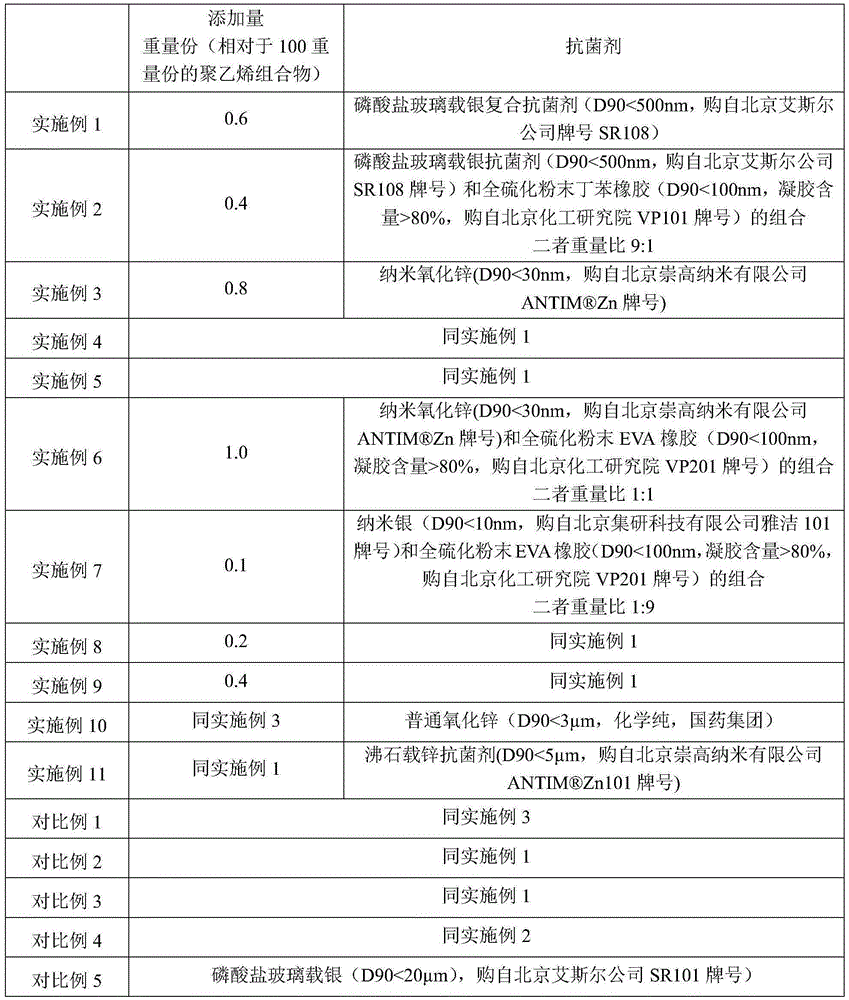

Antibacterial composition and film thereof

InactiveCN106674701AHigh standardAdapt to economic needsSynthetic resin layered productsLinear low-density polyethylenePolymer science

The present invention relates to an antibacterial composition, which contains a polyethylene composition and an antibacterial agent, wherein the polyethylene composition contains a component A, a component C and an optional component B, the component A is ethylene / alpha olefin copolymerized linear low density polyethylene and has a melt index MIA of 0.01-3.5 g / 10 min, the component B is ethylene / alpha olefin copolymerized linear low density polyethylene and has a melt index MIB of 3.6-9.9 g / 10 min, and the component C is ethylene / alpha olefin copolymerized linear low density polyethylene and has a melt index MIC of 10-80 g / 10 min. The present invention further provides a film, which comprises at least a layer of a polyethylene layer formed from the antibacterial composition. According to the present invention, the film achieves good antibacterial property while has advantages of high elongation ratio and high film-forming rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

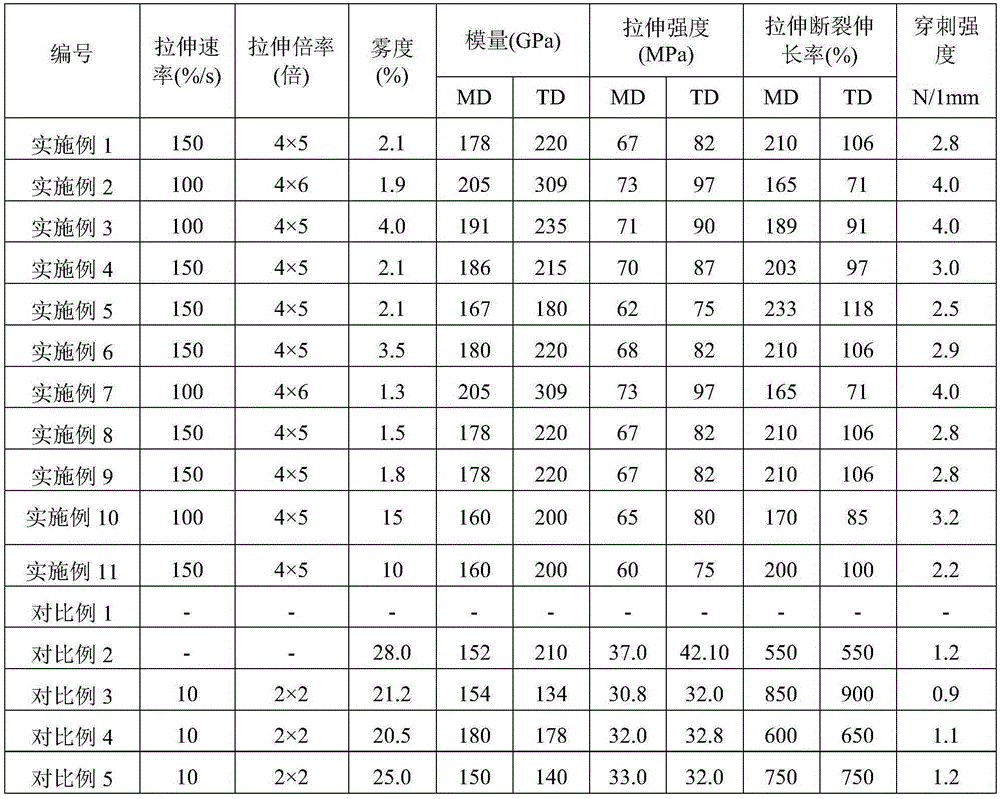

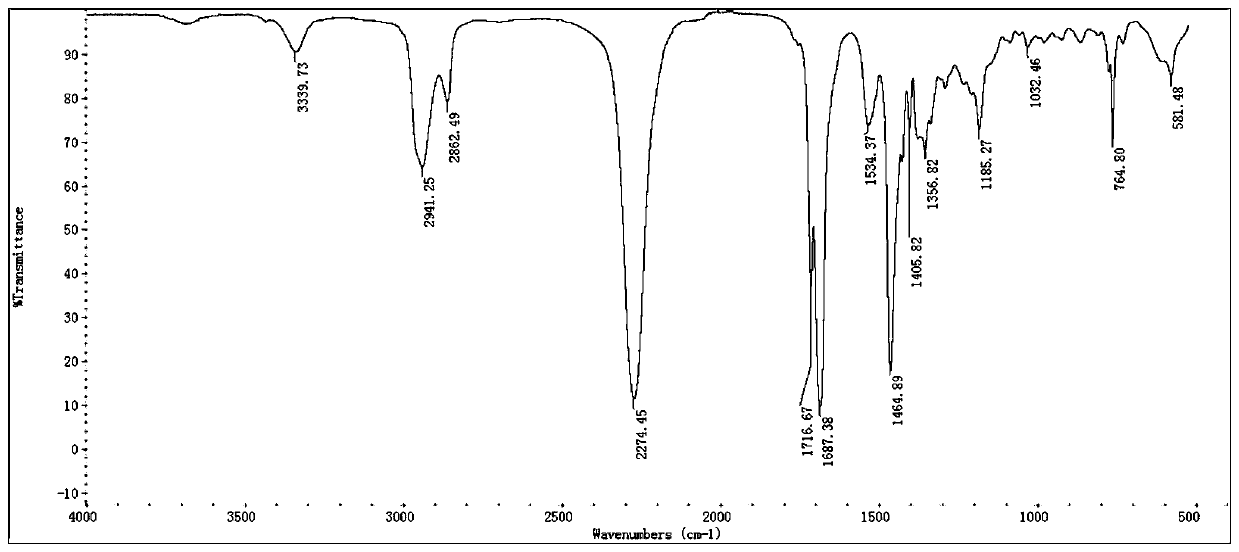

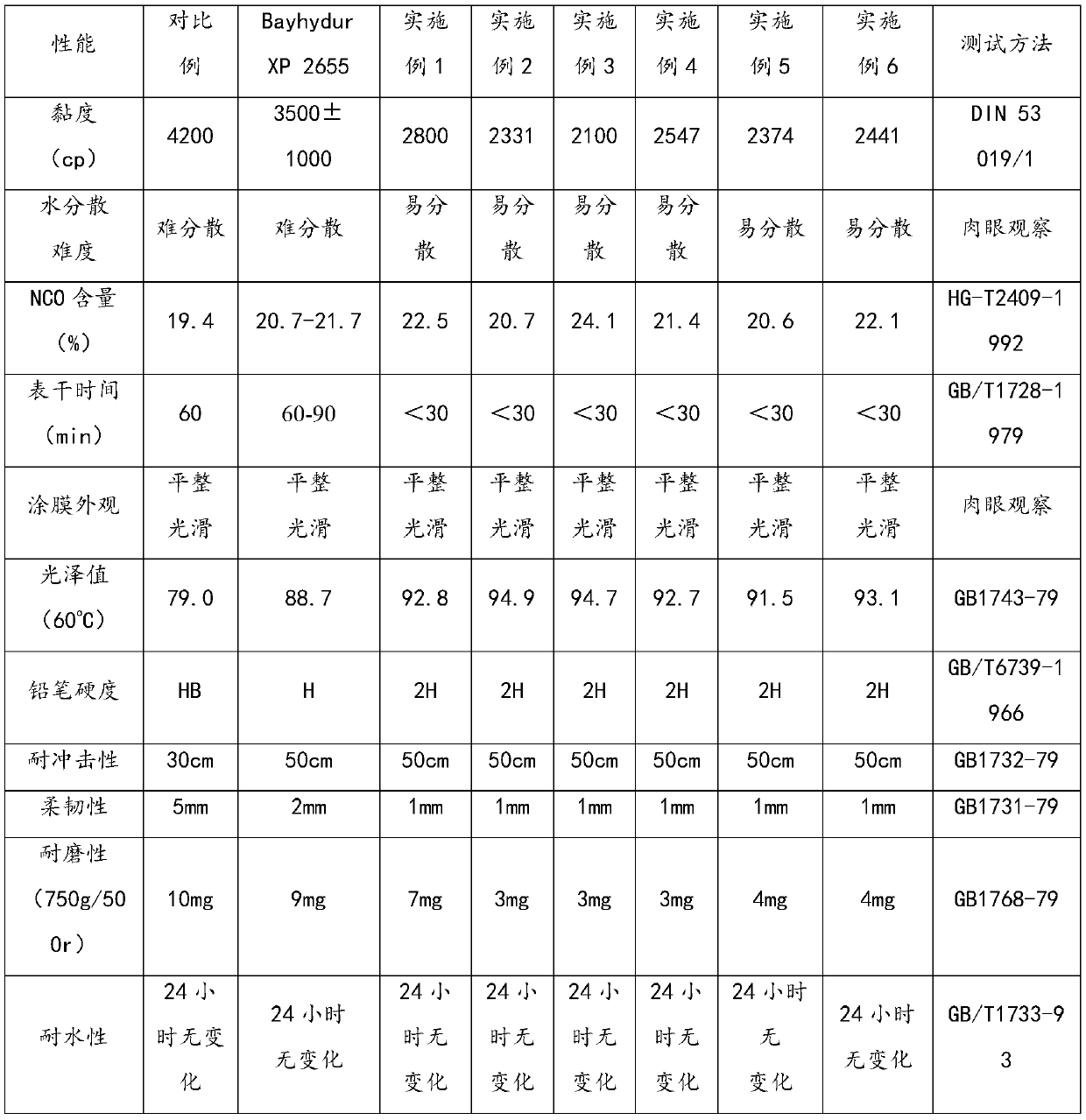

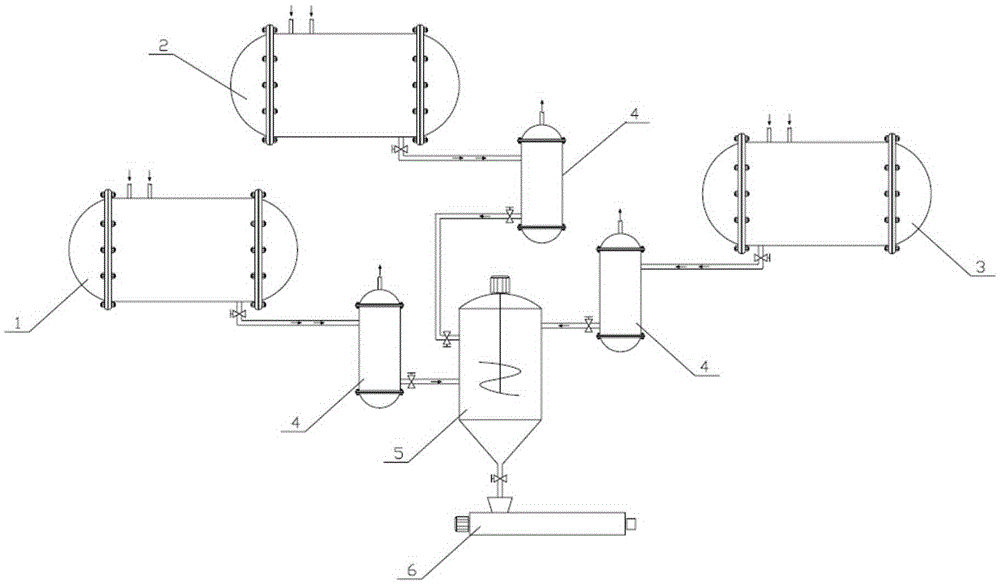

Ionic waterborne curing agent based on bio-based pentamethylene diisocyanate and preparation method thereof

The invention relates to the technical field of curing agents, specifically to an ionic waterborne curing agent based on bio-based pentamethylene diisocyanate and a preparation method thereof. The preparation method for the ionic waterborne curing agent based on the bio-based pentamethylene diisocyanate provided by the invention comprises the following steps: mixing an impurity-removed bio-based pentamethylene diisocyanate trimer, a sulfamic acid substance and organic amine, then carrying out heating to 60 DEG C to 110 DEG C under the protection of nitrogen, carrying out a reaction for 3 to 7hours, and when a product is transparent, carrying out cooling to 25 DEG C to 40 DEG C. The preparation method provided by the invention has the following advantages: the process of synthesis is simple; the flow of operation is easy to be mastered; the raw material namely the bio-based pentamethylene diisocyanate trimer has a clean source and is free of pollution to the environment; and through addition of a small amount of sulfonate and the organic amine, the ionic waterborne curing agent with a solid content of 100%, an NCO content of up to 22.3%, low viscosity and rapid curing rate can be obtained.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Antibacterial composition and thin film thereof

The invention relates to an antibacterial composition. The antibacterial composition contains a polyethylene composition and an antibacterial agent, wherein the polyethylene composition contains a component A, a component C and an optional component B; the component A is linear low-density polyethylene copolymerized with ethylene / alpha olefins, and the melt index MIA is 0.01-3.5 g / 10 min; the component B is linear low-density polyethylene copolymerized with ethylene / alpha olefins, and the melt index MIB is 3.6-14.9 g / 10 min; the component C is linear low-density polyethylene copolymerized with ethylene / alpha olefins, and the melt index MIC is 15-150 g / l0 min. The invention further provides a thin film; the thin film at least comprises a polyethylene layer formed by the antibacterial composition. The thin film provided by the invention has the advantages of being large in draft ratio and high in film forming rate while obtaining better antibacterial property.

Owner:CHINA PETROLEUM & CHEM CORP +1

Symmetric magnetron sputtering process and application of diamond-like carbon coating thereof

InactiveCN108330459AIncrease ionization rateIncrease profitVacuum evaporation coatingSputtering coatingCarbon ionDiamond-like carbon

The invention discloses a symmetric magnetron sputtering process and application of a diamond-like carbon coating thereof. Due to the electron gathering effect in the discharging process of symmetricmagnetron sputtering cathodes opposite in direction, the ionization rate of sputtered carbon particles is increased, the high-energy carbon particles overflow from a gap between the symmetric cathodesand is subjected to doping of metal atoms of a magnetron sputtering metal target so that the diamond-like carbon coating can be formed, and due to the symmetric magnetron sputtering process, the target material utilizing rate can be increased, and the ionization rate of sputtered particles is also greatly increased; and the diamond-like carbon coating is composed of a metal base layer, a gradientcomposite layer and a metal-doped diamond-like carbon coating, and in the deposition process of the diamond-like carbon coating, the diamond-like carbon coating in certain gradient and with stable doping proportion can be obtained by adjusting the power of the magnetron sputtering metal target. Due to the process, high energy ionized carbon ions can be obtained, and the compact and fine diamond-like carbon coating can be formed easily.

Owner:WENZHOU POLYTECHNIC

Production technology of vacuum coating antique copper

InactiveCN103741110AImprove qualityHigh surface finishVacuum evaporation coatingSputtering coatingComposite filmHigh energy

The invention relates to a metal surface treatment technology, and particularly relates to a production technology of vacuum coating antique copper. The technology comprises the following steps: carrying out magnetron sputtering on a work-piece of which the substrate surface is cleaned or coating red copper / brass through plating by a multi-arc ion plating method; carrying out chemical agent black coating on the work-piece coated with the red copper / brass, so as to obtain a black surface film; carrying out manual or mechanical drawing treatment on a copper film on the surface of the work-piece; exposing a part of bottom red copper or brass film, so as to form archaistic stripes; and coating the surface of the work-piece with an organic coating or carrying out fingerprint resistant treatment and then baking at 100-150 DEG C for 20-30 minutes, thus finally obtaining the antique copper product of the vacuum coating composite film. By adopting the production technology, the problems of heavy metal ion pollution and high energy and material consumption existing in the traditional antique copper production technology are solved, the surface smoothness of the film and the binding force of the film are improved, production of the high-quality and pollution-free antique copper decorating film product is achieved, and the antique copper and green bronze products have good surface texture and visual effect.

Owner:遵化市超越钛金设备有限公司

Liquid bandage used in field

InactiveCN105797200AReasonable formulaPlay an antibacterial and hemostatic effectBandagesAntibiosisCellulose acetate

The invention discloses a liquid bandage used in field. The liquid bandage used in field comprises chitosan, cellulose acetate, bullfrog antibacterial peptide, polyvinyl alcohol, polyvinylpyrrolidone, ovalbumin and glycerin. A preparation method of the field liquid bandage comprises dissolving the bullfrog antibacterial peptide in a protein solution with content of 6% to obtain a chitosan-acetic acid solution with content of 2%, taking polyvinyl alcohol and polyvinylpyrrolidone, uniformly stirring the polyvinyl alcohol and polyvinylpyrrolidone, dissolving the mixture in injection water according to a W / V ratio of 1.0-1.5: 100 to obtain a solution, dissolving cellulose acetate in a solvent, carrying out magnetic stirring to obtain a uniform solution, blending the above solutions, dropwisely adding a glycerinum solution into the mixed solutions and adjusting pH to 5.5-6.8 so that the liquid bandage is obtained. The liquid bandage used in field has a reasonable formula. The bullfrog antibacterial peptide has effects of antibiosis, haemostasis and ovalbumin crosslinking reaction promotion and improves a film forming rate. Cellulose acetate is a film forming material and a good slow release material and improves bullfrog antibacterial peptide use effects.

Owner:TIANJIN PHARMACN MEDICAL TECH

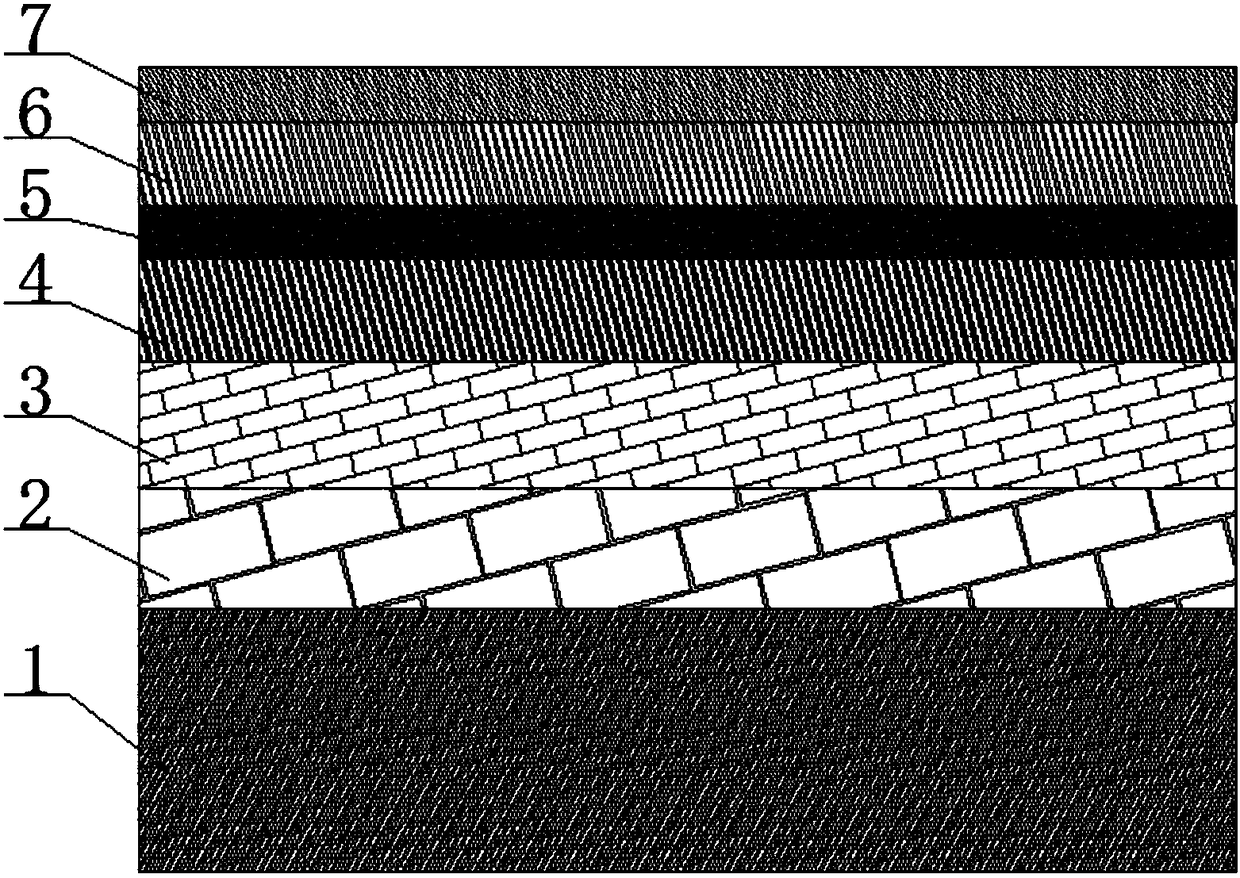

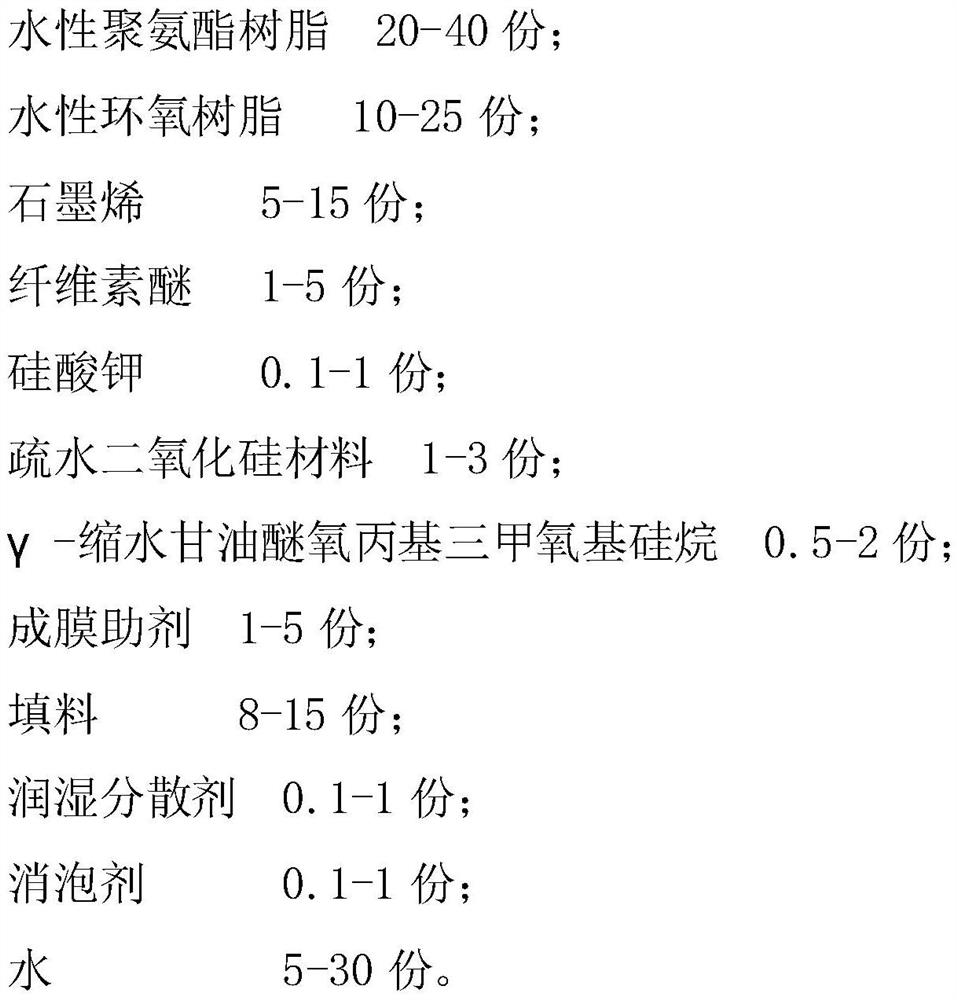

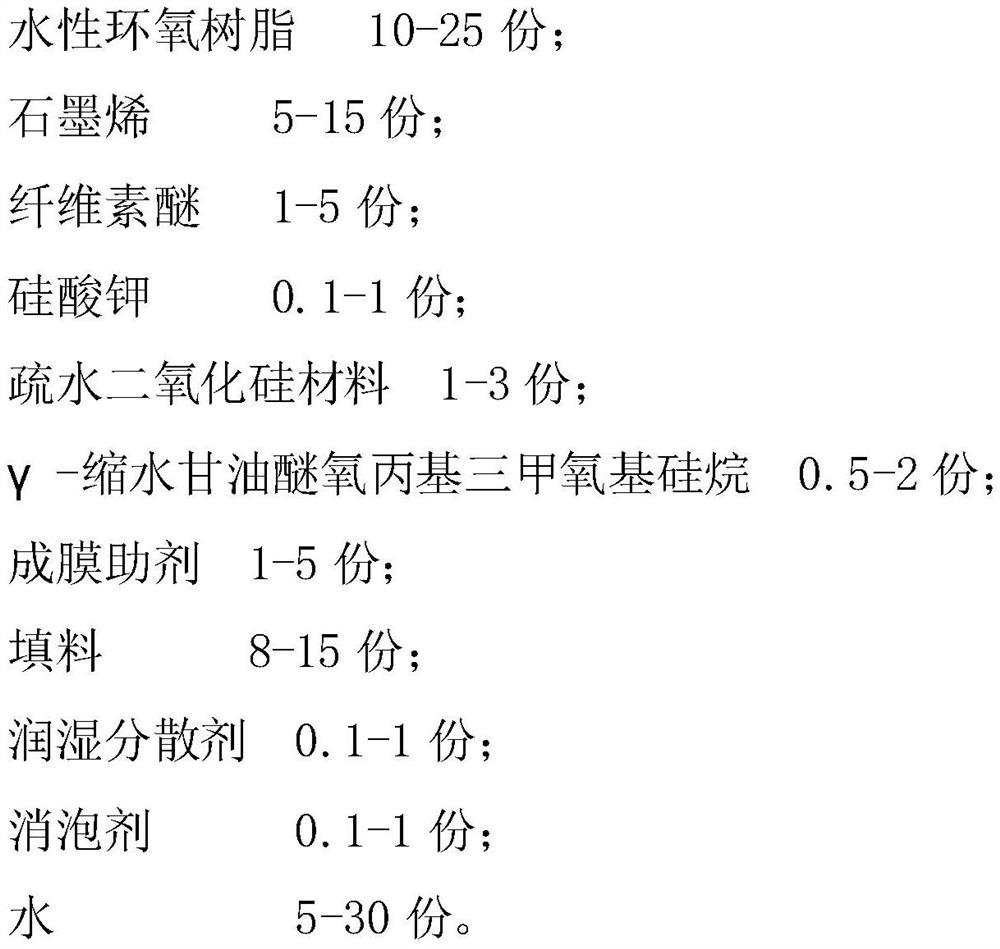

Graphene anticorrosive paint and preparation method thereof

InactiveCN111647342AGood dispersionImprove shielding effectAnti-corrosive paintsPolyurea/polyurethane coatingsCelluloseSilicic acid

The invention relates to a graphene anticorrosive coating and a preparation method thereof. The graphene anticorrosive coating comprises the following components: waterborne polyurethane resin; an aqueous epoxy resin; graphene; a cellulose ether; potassium silicate; a hydrophobic silica material; gamma-glycidoxypropyltrimethoxysilane; a coalescing agent; a filler; a wetting dispersant; a defoamerand water. According to the invention, the cellulose ether, the potassium silicate and other substances are mixed; the dispersity of the graphene can be effectively improved; by dispersing the graphene into the water-based resin, interface bonding strength is enhanced, the void defect of the coating material is repaired, the compactness of the coating material is substantially enhanced, the shielding effect on a corrosion medium is improved, the corrosion resistance is enhanced, and the gamma-glycidoxypropyltrimethoxysilane is added so as to improve the physical properties and the water resistance of the water-based coating material and the water-based adhesive system, and improve the storage stability and the mechanical property.

Owner:广东烯创科技有限公司

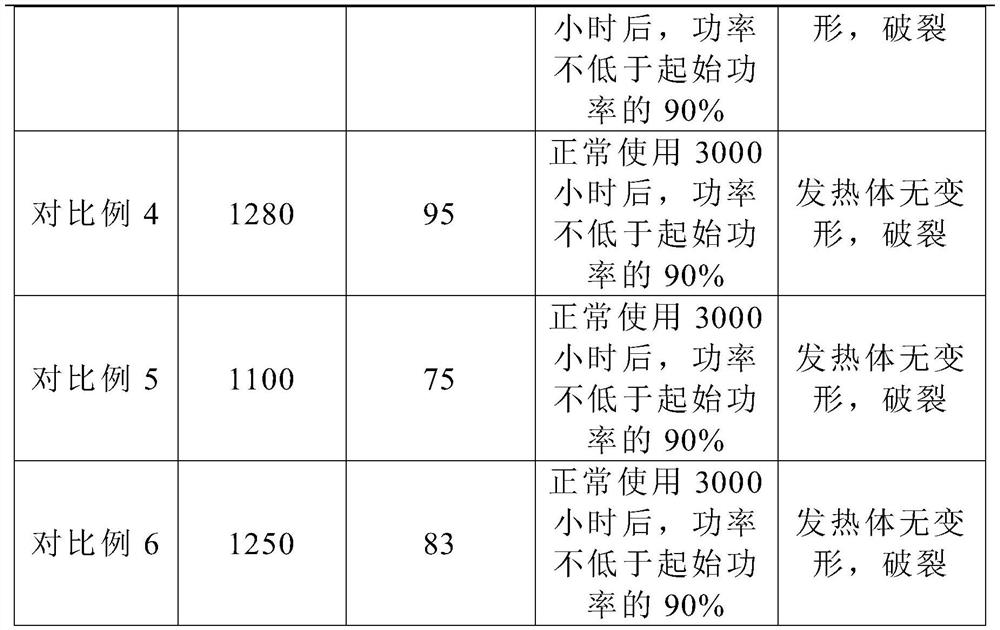

Pottery agent and pottery liquid preparation method and pottery process

ActiveCN108754471AImprove corrosion resistanceImprove rust resistanceMetallic material coating processesAcid washingPotassium

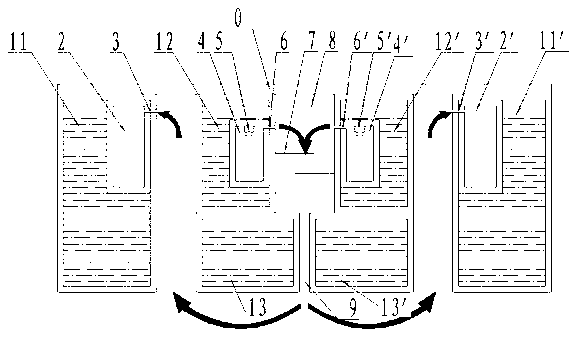

The invention relates to pretreatment before metal coating, discloses a pottery agent, a preparation method thereof and a pottery process, and solves the problem of fast easy re-rusting time caused byweak corrosion resistance of pottery films obtained by a traditional pottery process. The pottery agent comprises the following components in parts by mass: 5-10 parts of sodium hexafluorozirconate,3-5 parts of potassium fluotitanate, 5-10 parts of silane coupling agent, 5-8 parts of tartaric acid, 62-77 parts of de-ionized water, and 10-15 parts of nanometer silicon powder. Water and an adjusting agent are added in the pottery agent for dilution to prepare pottery liquid; metal workpieces are conveyed by a conveying lifting frame to move through a phosphorus-free cleaning chamber, a first ultrasonic cleaning tank and a first water washing tank in sequence for cleaning and degreasing, are derusted and cleaned by an acid washing tank, a second water washing tank and a second ultrasonic cleaning tank, and enter a first pottery pool with the pottery liquid for pottery to form pottery films on the surfaces; and the obtained pottery films improve the corrosion resistance, and achieve excellent rust resistance.

Owner:厦门力九化工有限公司

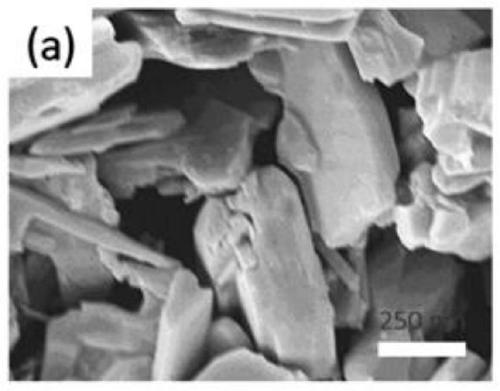

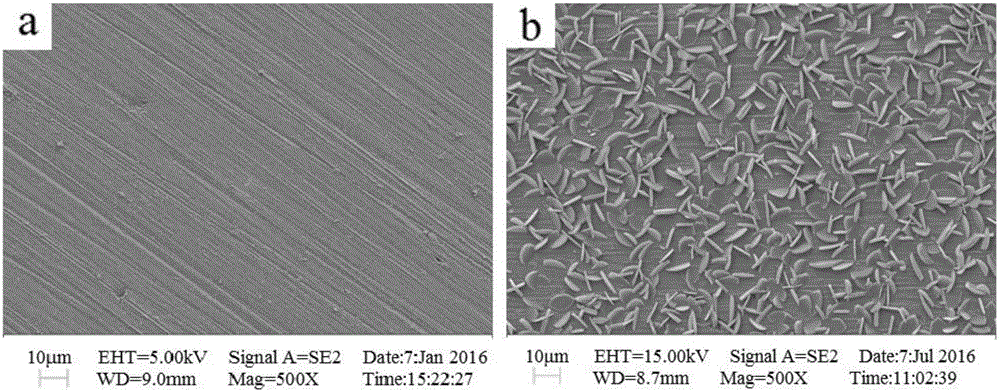

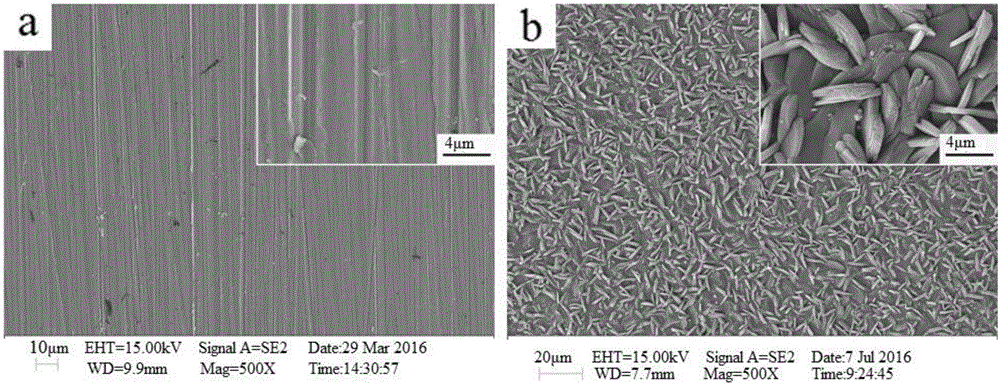

Preparation method of Al/NiO flaky aluminothermic agent

ActiveCN109678630AUniform surface distributionIncrease contact areaVacuum evaporation coatingSputtering coatingSputteringComposite film

A preparation method of an Al / NiO flaky aluminothermic agent comprises the following steps: providing a flaky peelable metal substrate; preparing hydrothermal synthesis reaction liquid; performing a hydrothermal synthesis reaction to obtain a precursor on the substrate; calcinating the precursor to form an NiO flaky layer on the substrate; finally, forming a nanometer aluminum film on the NiO flaky layer through magnetron sputtering so as to obtain a flaky Al / NiO nanometer energetic composite film. The aluminothermic agent is convenient to store and carry, low in production cost, environmentally friendly and excellent in combustion heat release performance.

Owner:CHONGQING UNIV

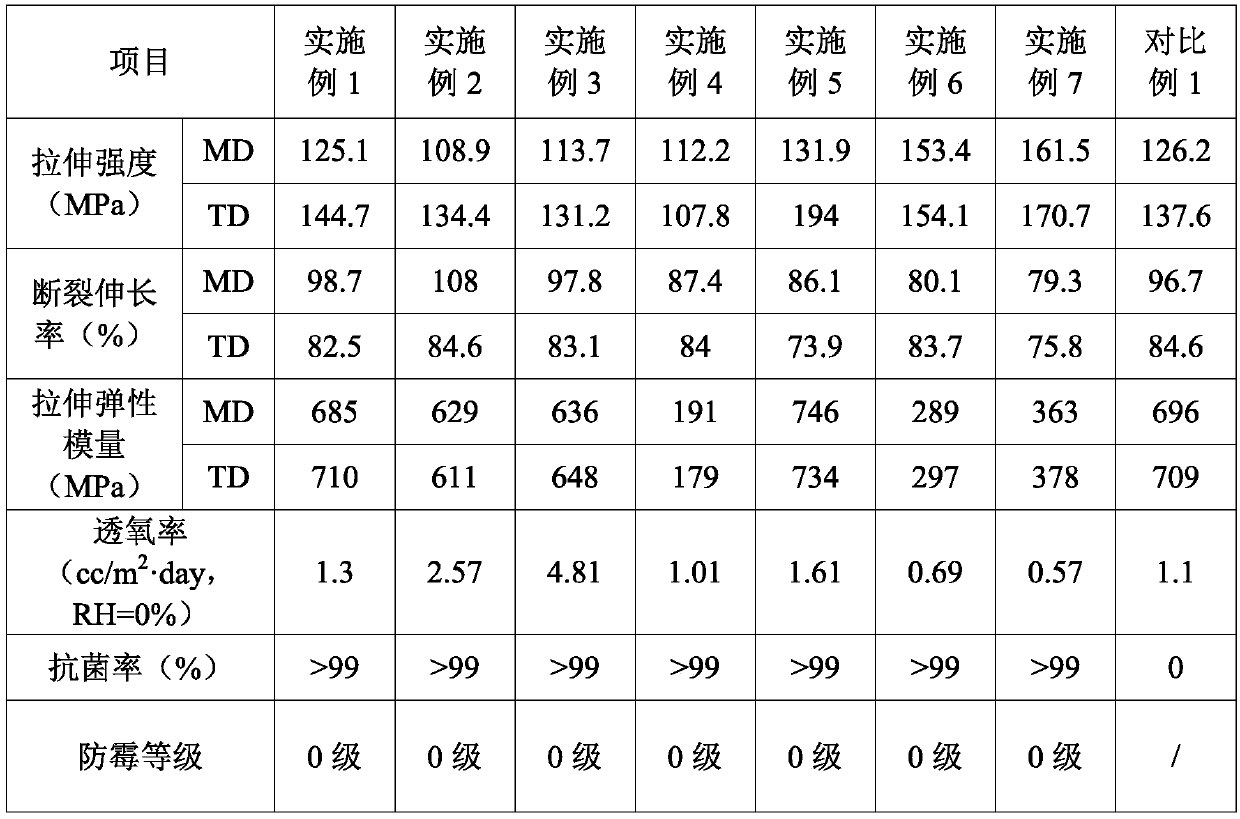

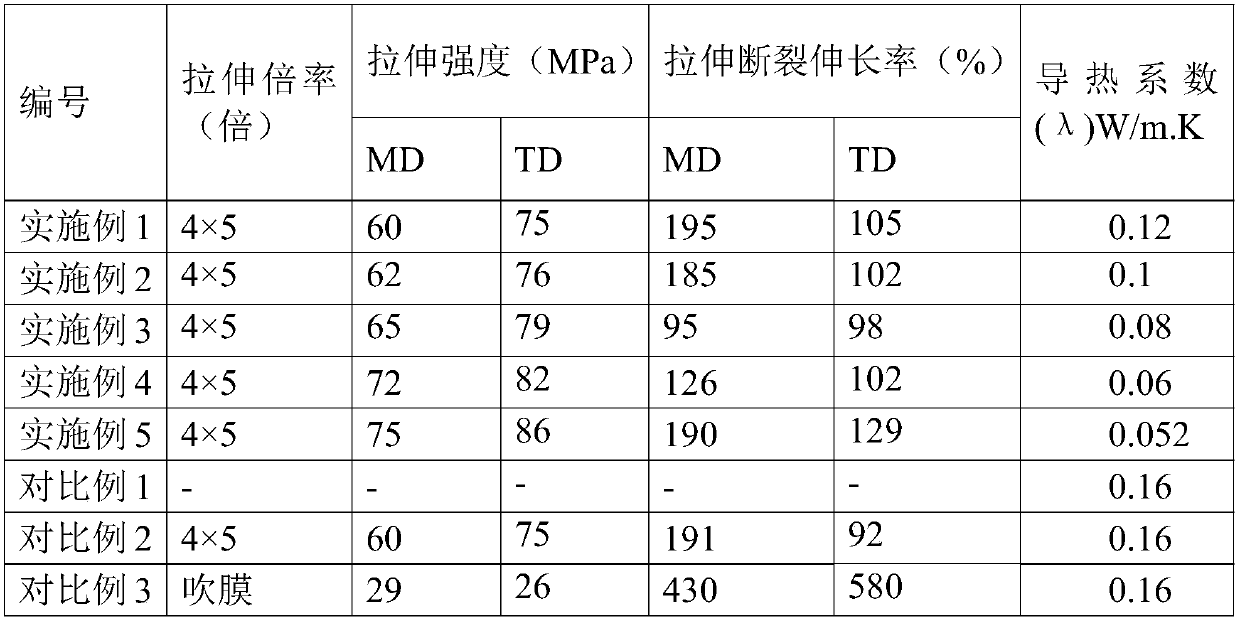

Antibacterial mildew-proof polyvinyl alcohol composition, biaxially oriented polyvinyl alcohol film and preparation method thereof

ActiveCN111087727AHigh tensile strengthImprove barrier propertiesSynthetic resin layered productsPolymer sciencePolyvinyl alcohol

The invention belongs to the field of polyvinyl alcohol film materials, and discloses an antibacterial mildew-proof polyvinyl alcohol composition, a biaxially oriented polyvinyl alcohol film and a preparation method thereof. The antibacterial mildew-proof polyvinyl alcohol composition contains polyvinyl alcohol, a plasticizer, a guanidine salt composite antibacterial agent, a mildew-proof agent and an auxiliary agent, wherein based on 100 parts by weight of polyvinyl alcohol, the content of the plasticizer is 10 to 30 parts by weight, the content of the guanidine salt composite antibacterial agent is 0.05 to 1.5 parts by weight, the content of the mildew-proof agent is 0.05 to 5.0 parts by weight, and the content of the auxiliary agent is 0.05 to 10 parts by weight. The polyvinyl alcohol film prepared by the invention has high tensile strength and barrier property, and also has good antibacterial and mildew-proof properties.

Owner:CHINA PETROLEUM & CHEM CORP +1

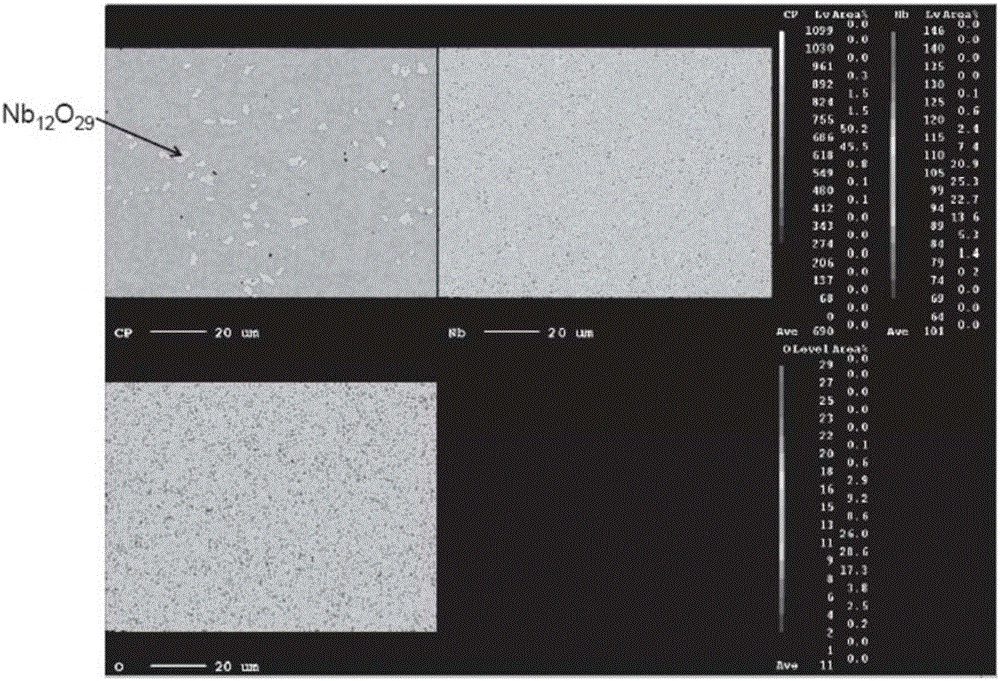

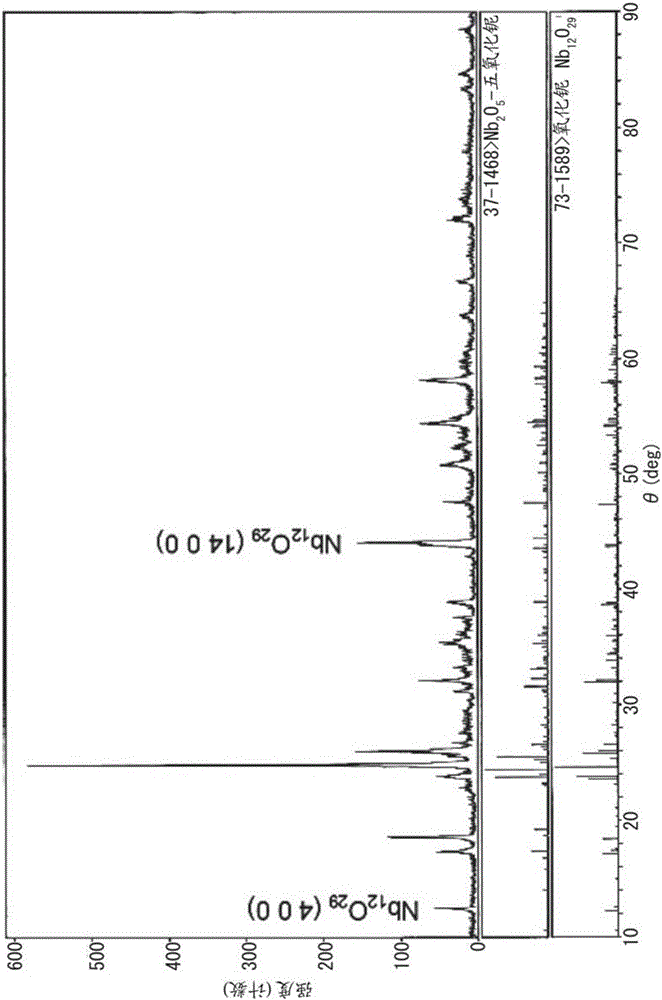

Niobium oxide sputtering target, production method therefor, and niobium oxide film

InactiveCN105074046AStable sputteringLower target specific resistanceVacuum evaporation coatingSputtering coatingSputteringMetallurgy

The present invention provides a niobium oxide sputtering target that enables direct current (DC) sputtering, and a production method. This niobium oxide sputtering target is characterized by being a niobium oxide sintered body and in that the specific resistance thereof is 0.001-0.05 Ω⋅cm over the entire area of the sintered body in the thickness direction.

Owner:MITSUBISHI MATERIALS CORP

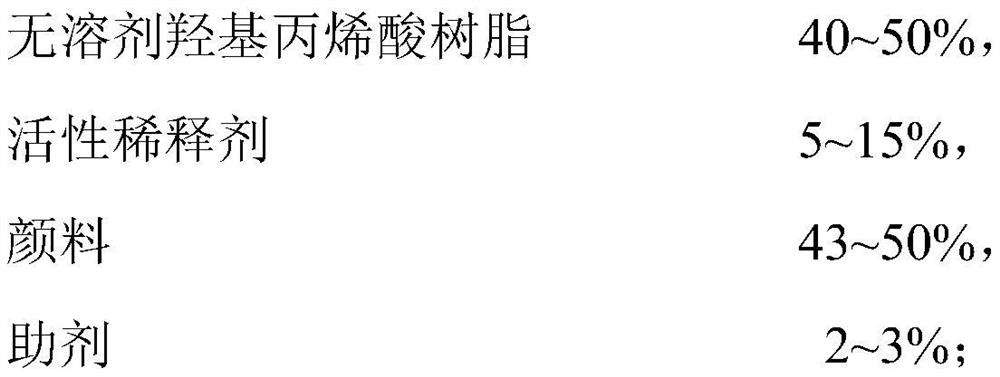

Solvent-free polyurethane coating and preparation method thereof

InactiveCN112029398AGood film formingGood coating performancePolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention provides a solvent-free polyurethane coating, which comprises a first component and a second component, and is prepared from the following components in percentage by weight based on thetotal weight of the first component being 100 percent: 40 to 50 percent of a solvent-free hydroxyl acrylic resin, 5 to 15 percent of an active diluent, 43 to 50 percent of a pigment and 2 to 3 percent of an auxiliary agent, and the second component comprises an isocyanate curing agent. The solvent-free polyurethane coating is a two-component solvent-free polyurethane coating, the solvent-free strong-base acrylic resin and the reactive diluent cooperate with the isocyanate curing agent to achieve the film forming effect, the film forming speed is increased, the coating effect of the coating isimproved, the zero VOC content is achieved, and the specified film forming thickness can be achieved through one-time coating in a severe corrosion environment; the performance is excellent.

Owner:珠海展辰新材料股份有限公司

Preparation method of nickel-iron-copper-molybdenum alloy target material

ActiveCN113265627AGrain size growthSmall and uniform grain sizeVacuum evaporation coatingSputtering coatingIngotCopper

The invention discloses a preparation method of a nickel-iron-copper-molybdenum alloy target material. The preparation method of the nickel-iron-copper-molybdenum alloy target material comprises the following steps that (1) raw materials Mo and raw materials Ni are added into a smelting furnace, suspension smelting is carried out in a vacuum environment, and an alloy ingot A is obtained after cooling; (2) raw materials Fe and raw materials Cu are added into the smelting furnace containing the alloy ingot A in the step (1), smelting treatment continues to be conducted in the vacuum environment, and an alloy ingot B is obtained after cooling; (3) the alloy ingot B is refined for three times in the vacuum environment, and the melt of the alloy ingot B is cast after the third refining to obtain a cast ingot; and (4) the cast ingot obtained in the step (3) is rolled, and the nickel-iron-copper-molybdenum alloy target material is obtained. According to the preparation method, a nickel-molybdenum alloy is firstly smelted, then the raw materials Fe and Cu are added to be smelted again, and then three times of homogenizing refining are combined, so that the uniformity of components of the nickel-iron-copper-molybdenum alloy target material is guaranteed to a large extent, and the target material has the performance of high resistivity, high relative density and high magnetic permeability.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

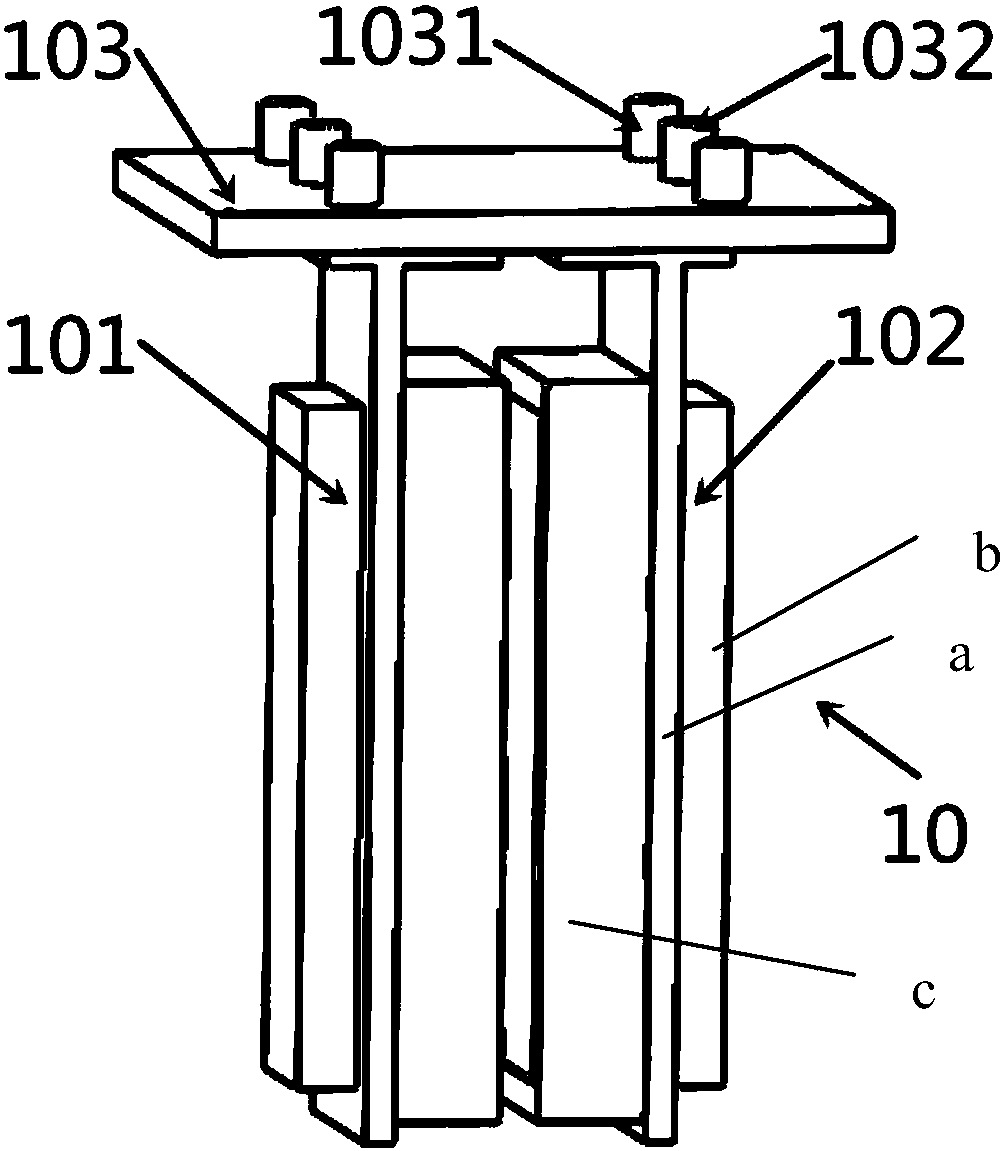

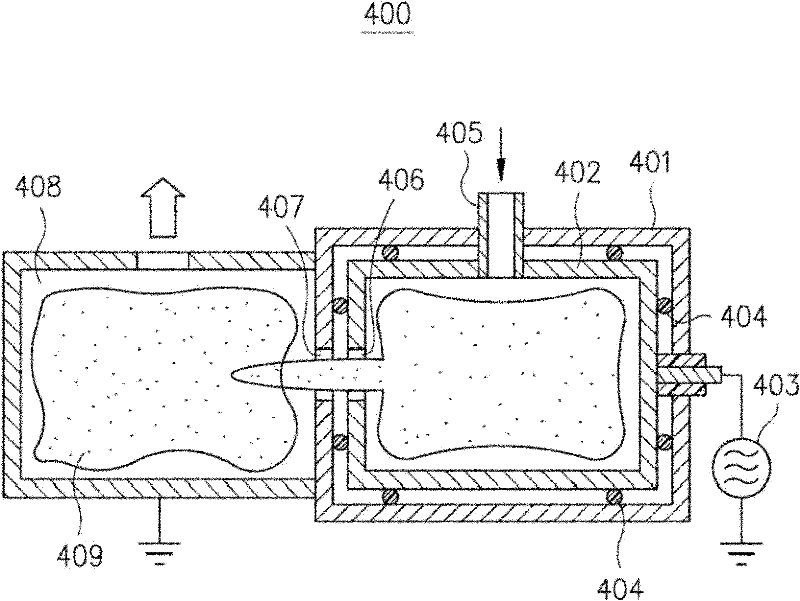

Plasma processing apparatus

ActiveCN102477547AImprove uniformityIncrease dissociationElectric discharge tubesChemical vapor deposition coatingHigh densityPlasma diffusion

A plasma processing apparatus is disclosed, which includes: a cathode module comprising a plurality of first channels which generate plasma; an anode having a chamber which contains the cathode and having at least one plasma outlet corresponding to the first channels; an electrode connected to a high-frequency electrical power and the cathode; and a plurality of second channels penetrating through the anode; wherein each first channel and each second channel are disposed alternately. A first gas is introduced into the first channels ionized under high frequency electrical power. In the first channels, the free electrons collided brings high density of plasma. The generated plasma is expelled through the plasma outlet to form a plasma diffusion region. A second gas is introduced into the plasma diffusion region through the second channels to take part in the reaction of plasma.

Owner:IND TECH RES INST

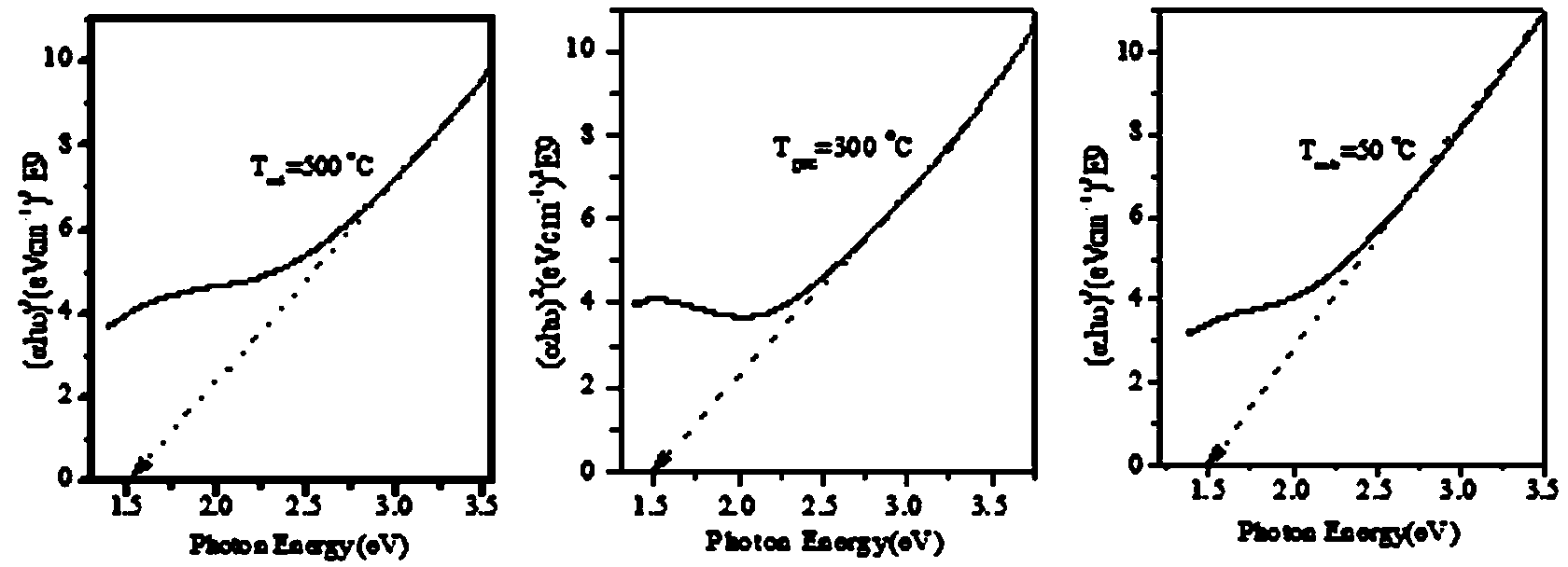

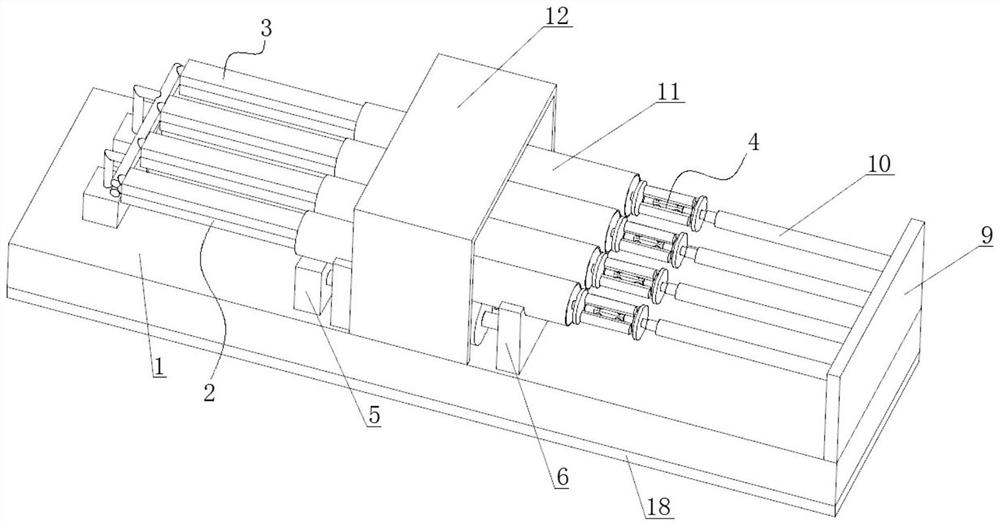

Preparation method of high-quality copper-zinc-tin sulphur semiconductor film

InactiveCN104278238AQuality improvementHigh purityFinal product manufactureVacuum evaporation coatingVulcanizationEvaporation

The invention discloses a preparation method of a high-quality copper-zinc-tin sulphur semiconductor film. The method comprises the following steps: through a vacuum heating evaporation mode, sequentially placing high-purity copper, zinc and tin, which are respectively put in different tungsten boats or molybdenum boats on a substrate which is heated to 20-200 DEG C, so as to obtain a metal film precursor; and then obtaining a high-quality copper-zinc-tin sulphur film by vulcanizing the metal film precursor. Adhesion of a precursor metal layer on the substrate and chemical combination among three elements are affected by changing the temperature of the substrate, so that the vulcanization efficiency is increased, and preparation of the high-quality copper-zinc-tin sulphur semiconductor film is achieved. The equipment disclosed by the invention is relatively simple, and easy to operate; the prepared film is high in purity, good in quality, high in film-forming rate, and high in efficiency; and the problems that impurities are formed at the vulcanization stage in the prior art to cause influence on film quality, long vulcanization time and high vulcanization temperature are solved.

Owner:WUYI UNIV

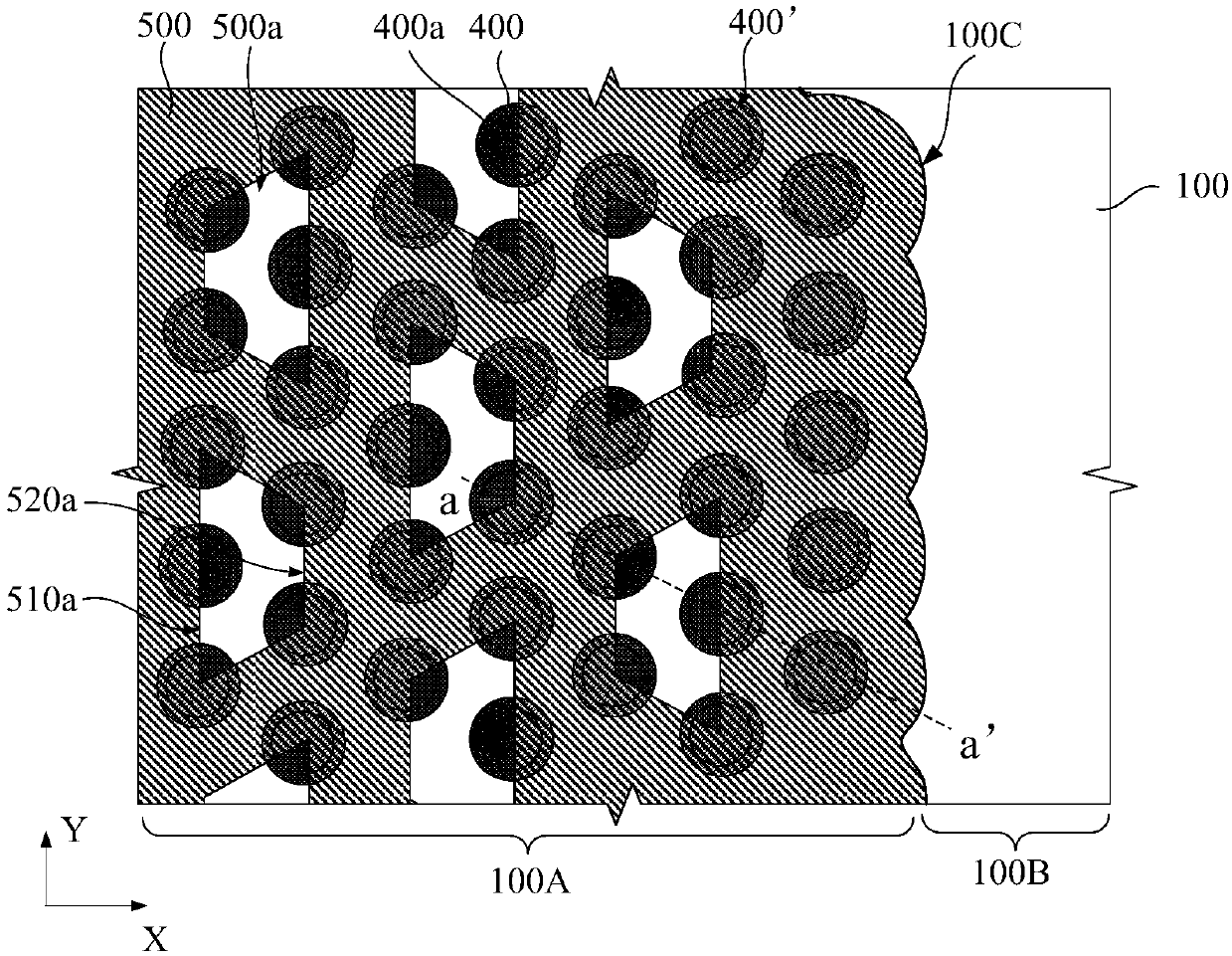

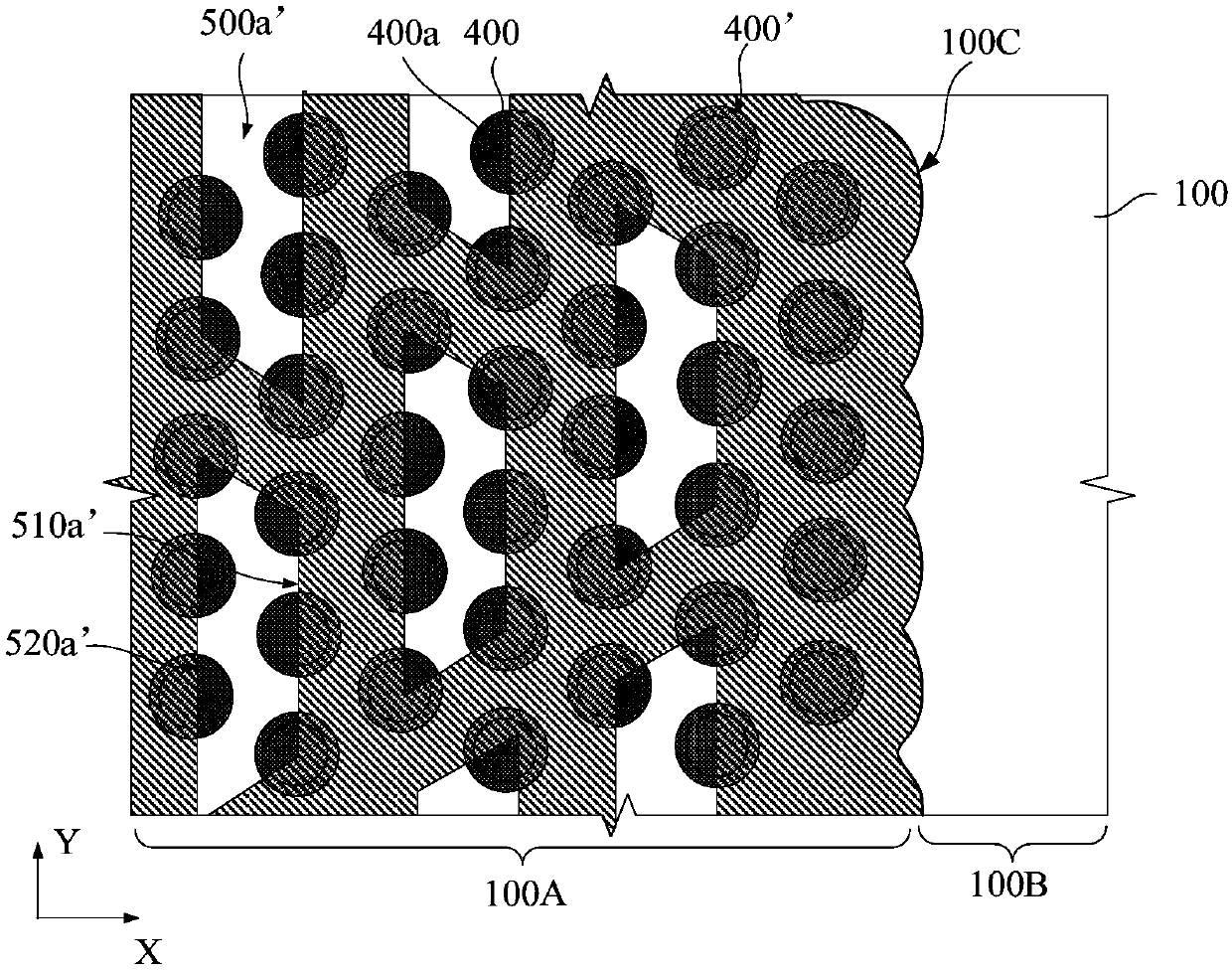

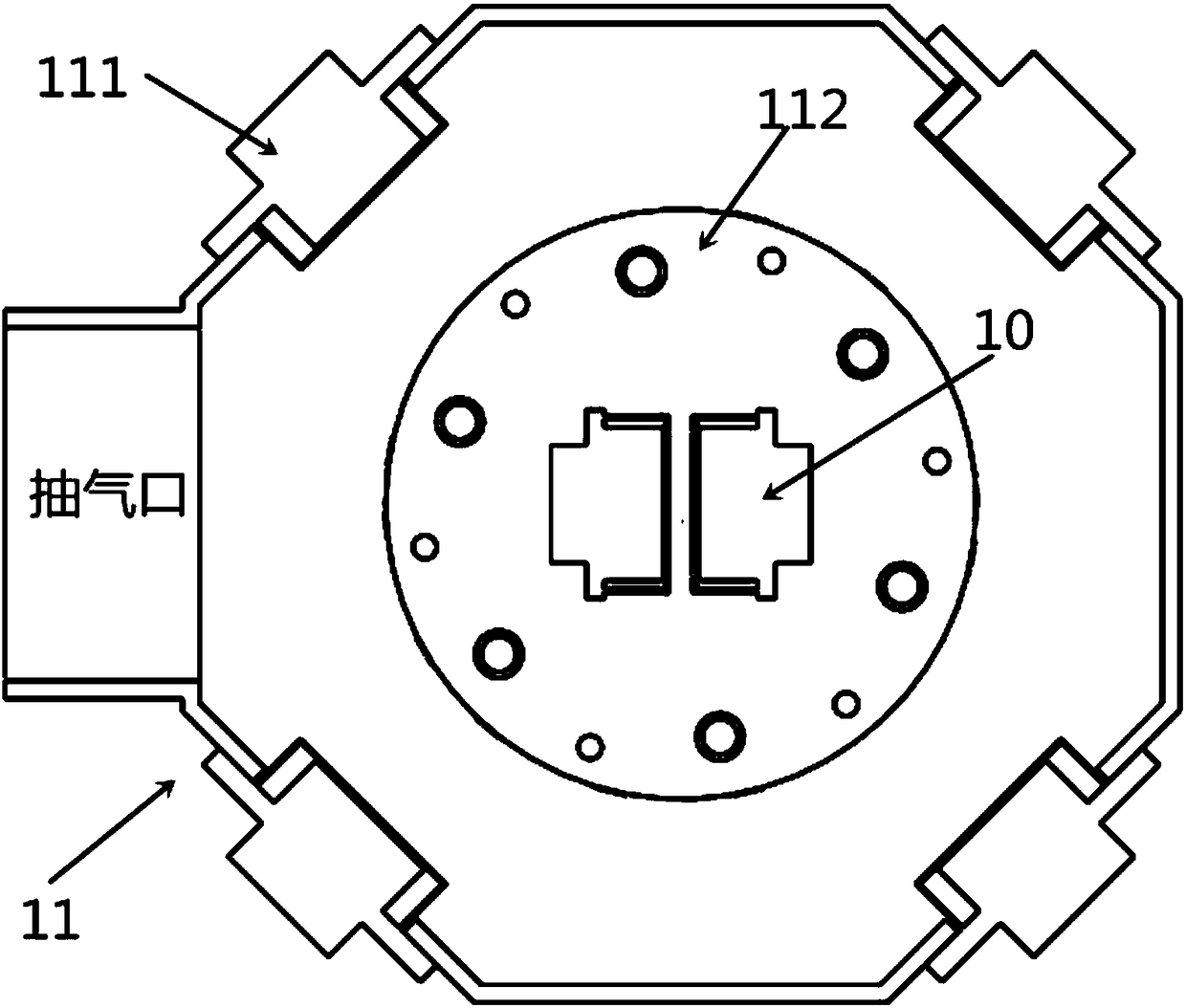

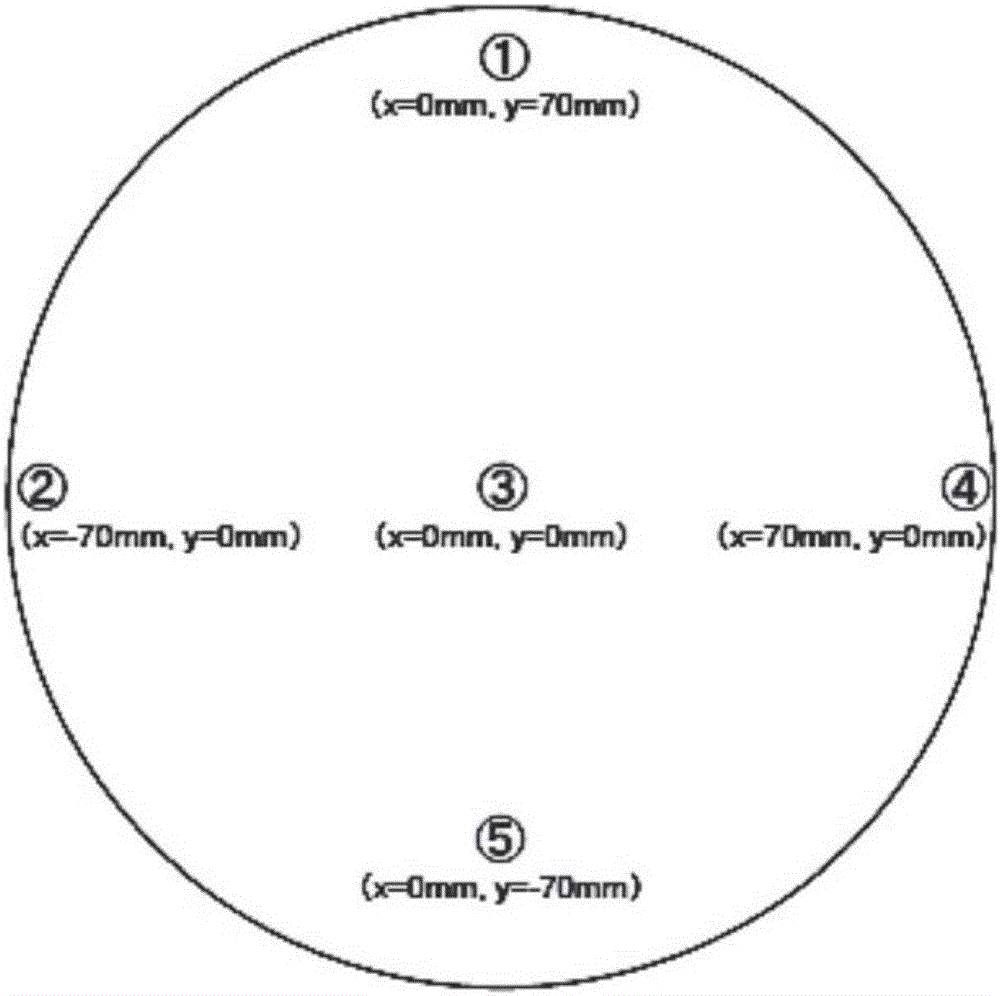

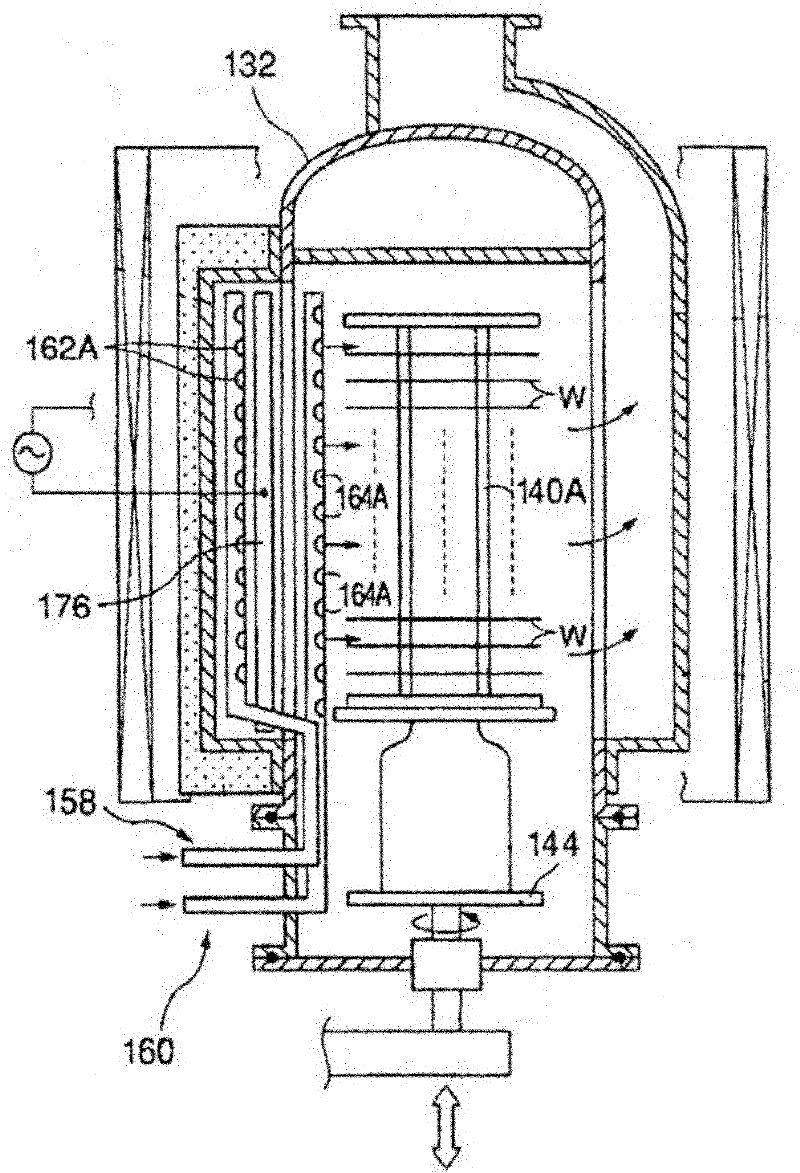

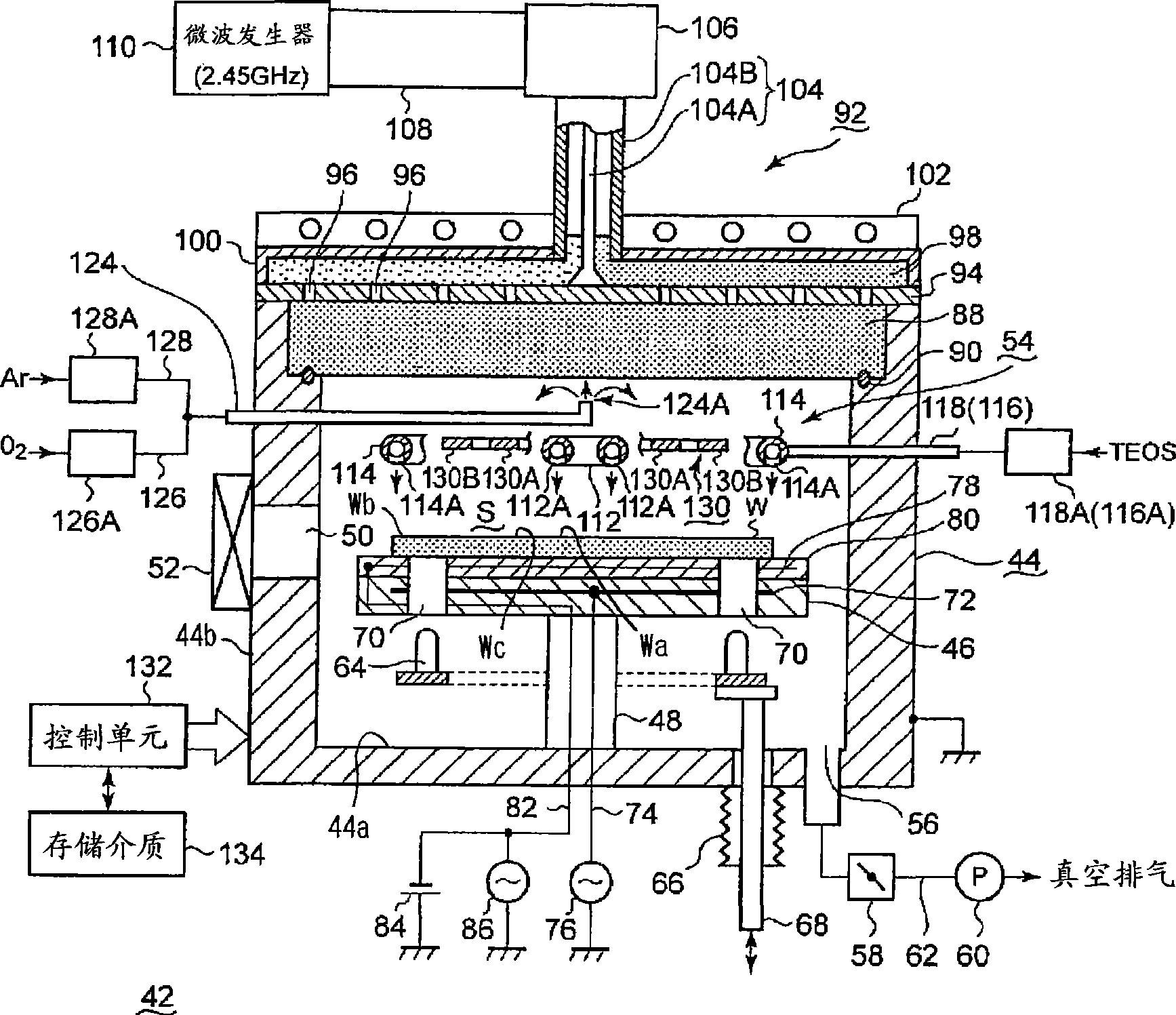

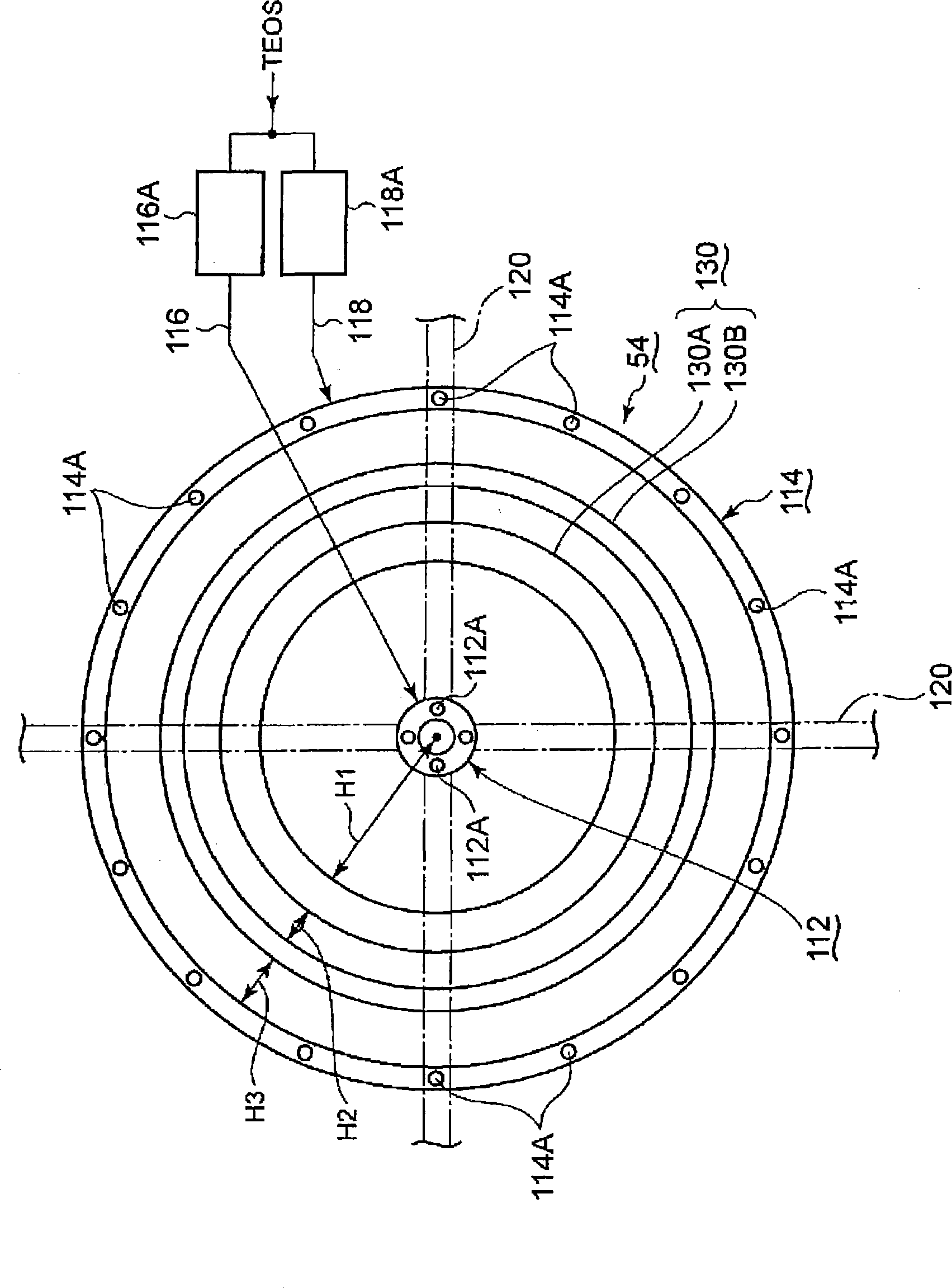

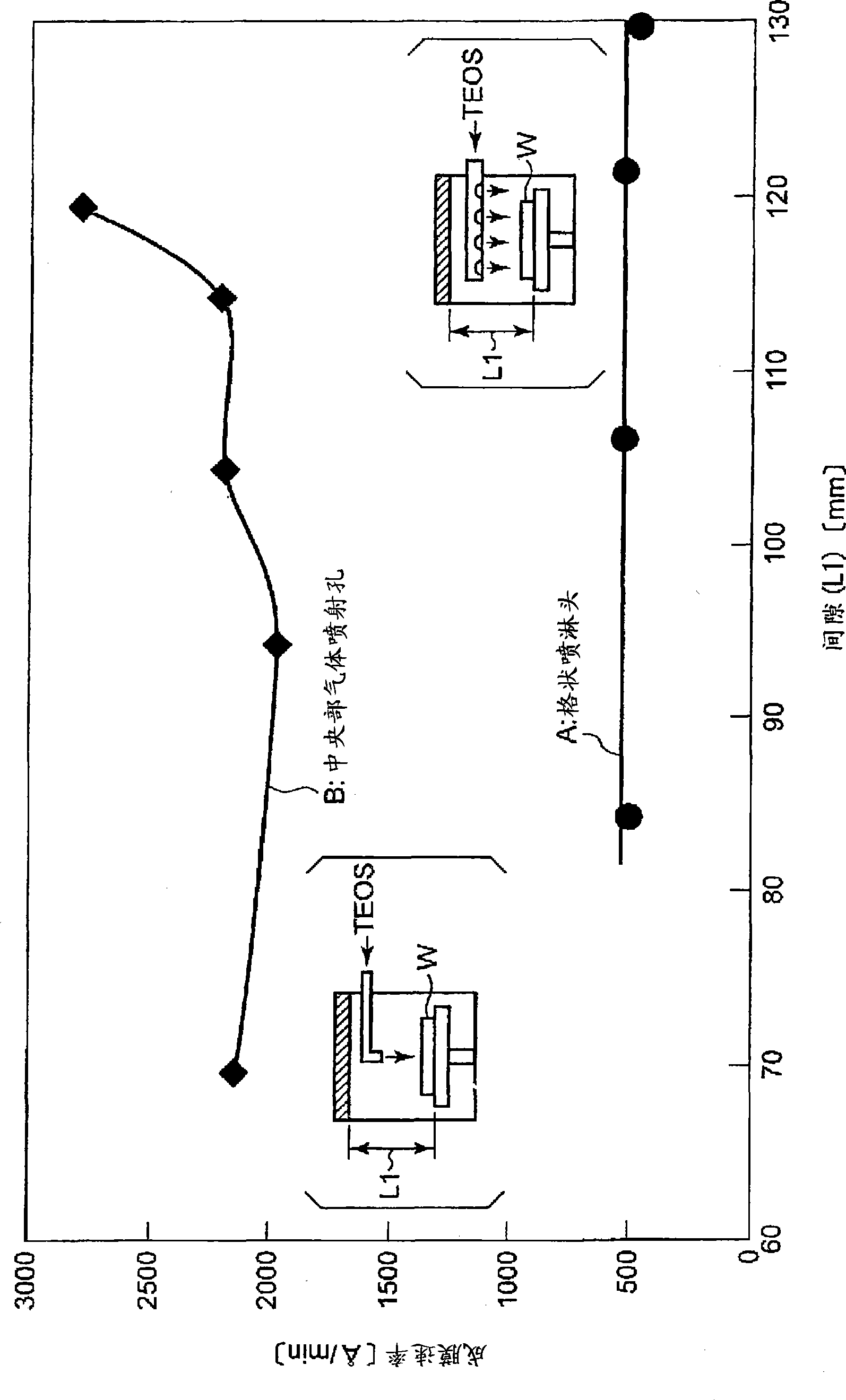

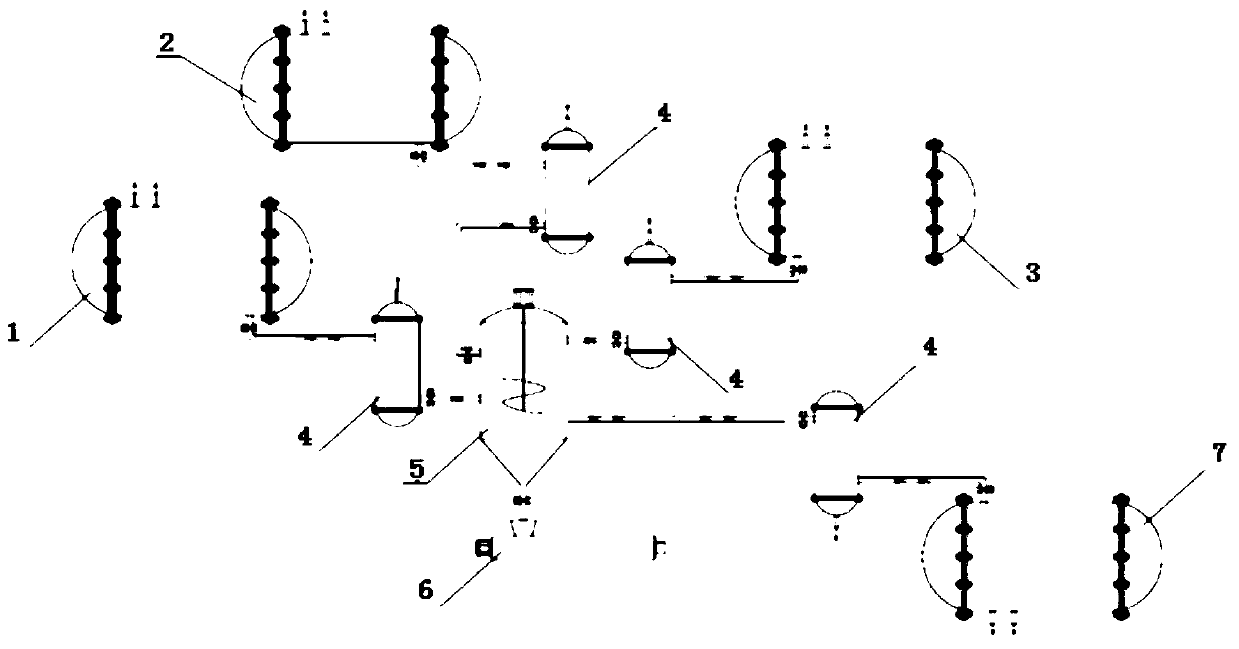

Plasma filming apparatus, and plasma filming method

InactiveCN101523573AReduce electron densitySmall footprintElectric discharge tubesSemiconductor/solid-state device manufacturingIn planeMicrowave

Provided is a plasma filming apparatus, which can keep high not only a filming rate but also an in-plane homogeneity of a film thickness. The plasma filming apparatus comprises a treating container (44) made evacuative, a placing bed (46) for placing a treatment object (W) thereon, a ceiling plate (88) mounted in the ceiling and made of a dielectric material for transmitting microwaves, gas introducing means (54) for introducing a treating gas containing a filming raw gas and a support gas, and microwave introducing means (92) having a plain antenna member disposed on the ceiling side for introducing the microwaves. The introducing means includes central gas injection holes (112A) for the raw gas positioned above the central portion of the treatment object, and a plurality of peripheral gas injection holes (114A) for the raw gas arrayed above the peripheral portion of the treatment object and along the peripheral direction of the same. Above the treatment object and between the central gas injection holes (112A) and the peripheral gas injection holes (114A), there are disposed plasma shielding portions (130) for shielding the plasma along the peripheral direction.

Owner:TOKYO ELECTRON LTD

Antibacterial composition and film thereof

ActiveCN106674702AHigh standardAdapt to economic needsSynthetic resin layered productsAntimicrobialLinear low-density polyethylene

The invention relates to an antibacterial composition. The antibacterial composition comprises a polyethylene composition and an antibacterial agent, wherein the polyethylene composition contains a component A and a component C, and selectively contains a component B; the component A is ethylene / alpha olefin copolymerized linear low-density polyethylene and the melt index MIA is 0.01 to 2 g / 10min; the component B is ethylene / alpha olefin copolymerized linear low-density polyethylene and the melt index MIB is 2.1 to 14.9 g / 10min; and the component C is ethylene / alpha olefin copolymerized linear low-density polyethylene and the melt index MIC is 15 to 150 g / 10min. The invention also provides a film. The film at least comprises a polyethylene layer formed by the antibacterial composition. The film provided by the invention achieves high antibacterial property and has the advantages of large stretching ratio and high film-forming speed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyethylene composition and film thereof

ActiveCN111100363AIncrease the stretch ratioFast film formation ratePolymer sciencePolyethylene glycol

The invention relates to the field of polyethylene materials, and discloses a polyethylene composition, which is characterized by comprising a component A, a component B, a component C, a component Dand a component E, wherein under the conditions that the temperature is 190 DEG C and the load is 2.16 kg, the MIA of the component A is 0.01 g / 10 min to 3.5 g / 10 min, and the rho A is 0.880 g / cm < 3> to 0.936 g / cm < 3 >; the MIB of the component B is 3.6 g / 10 min to 9.9 g / 10 min, and the rho B is 0.910 g / cm < 3 > to 0.930 g / cm < 3 >; the MIC of the component C is 16 g / 10 min to 80 g / 10 min, andthe rhoC is 0.880 g / cm < 3 > to 0.930 g / cm < 3 >; the MID of the component D is 10 to 15g / 10min, and the rho D is 0.880 to 0.930 g / cm < 3 >; and the component E is obtained by performing twin-screw extrusion granulation on an ethylene-octene copolymer, polyethylene glycol and an aerogel. When a polyethylene film is prepared from the polyethylene composition prepared by matching the component A, the component B, the component C, the component D and the component E with specific melt indexes and densities by adopting a flat film stretching method, the polyethylene film has the advantages of highstretching ratio, high film forming rate, high mechanical strength and excellent barrier property, and has great industrial application prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Waterborne polyurethane resin emulsion and preparation method thereof

PendingCN114075322AUniform chain structureGood membrane mechanical propertiesPolyesterPolymer science

The invention belongs to the technical field of polymer synthesis, and particularly relates to a waterborne polyurethane emulsion and a preparation method thereof. The water-based polyurethane-containing emulsion is prepared from the following raw materials in parts by weight: 50-80 parts of mixed polyol which is composed of polyester and polyether polyol in a weight ratio of 0.3-0.7, 10-40 parts of isocyanate, 1-3 parts of a hydrophilic chain extender, 1-6 parts of a first-type alcohol chain extender, 1-6 parts of a second-type chain extender, 0.01-0.05 part of a catalyst and 1-3 parts of a salt-forming agent. The waterborne polyurethane emulsion with a solid content of 30-45% is prepared by adjusting the weight ratio of the polyester to the polyether polyol in the polyol while the excellent mechanical property and chemical property of the polyurethane resin are not influenced; and the emulsion not only has good stability, but also has higher tensile strength and excellent film-forming property, so the waterborne polyurethane emulsion can be widely applied to the fields of coatings, printing ink, adhesives and life health products.

Owner:SHANGHAI MINGBANG RUBBER PROD

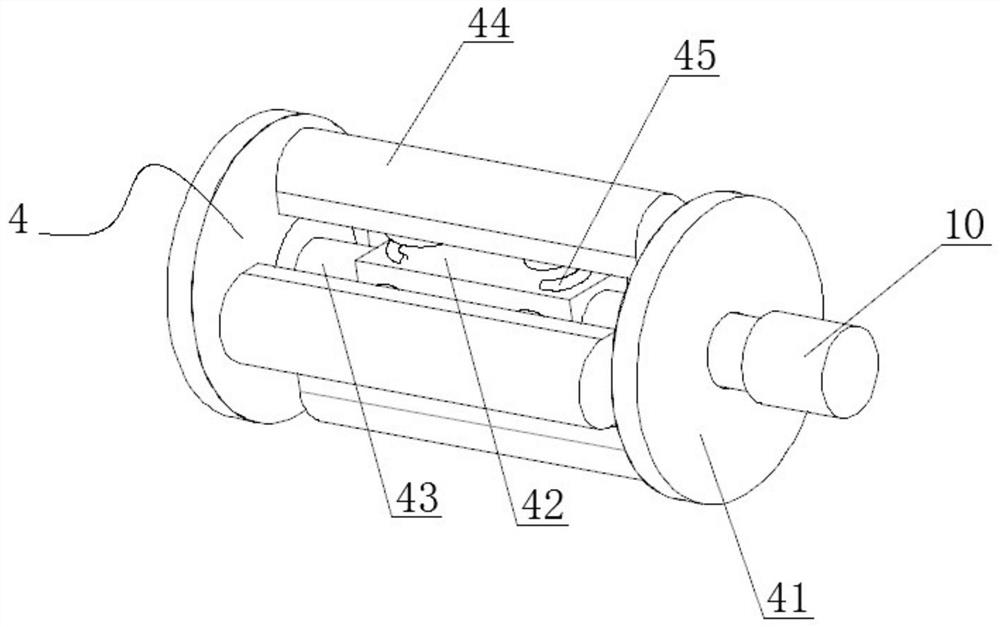

Solar heat collecting tube

InactiveCN102384599AFast film formation rateImprove high temperature stabilitySolar heat devicesSolar thermal energy generationNiobiumOxygen

The invention discloses a solar heat collecting tube, belonging to the field of solar energy utilization. A light absorption layer is composed of complete oxidized aluminum oxide and partial oxidized other elements; and the heat collecting tube is prepared by a co-sputtering method in the reaction in the argon and oxide atmosphere, wherein a target is a metal aluminum target for depositing complete oxidized aluminum oxide, and another target is used for depositing partial oxidized other metal, and the materials comprise chromium, molybdenum, tungsten, titanium, zirconium, vanadium, niobium, tantalum, ferrum, cobalt, nickel and alloy thereof. According to the invention, the technology process is simple and reliable, the obtained light absorption film layer has great high-temperature-resistant capability and high efficiency, and the solar heat collecting tube is suitable for production applications in a large scale.

Owner:李德杰

Hardware spraying machine with polishing and rust removing functions and using method

InactiveCN112642632ASolve the problem of easy residues affecting the health of usersSolve physical healthGrinding carriagesGrinding drivesElectric machineryWater pipe

The invention discloses a hardware spraying machine with polishing and rust removing functions and a using method, and belongs to the technical field of spraying devices. The hardware spraying machine comprises a workbench, a vertical plate is fixedly connected to the upper surface of the workbench, four air cylinders are fixedly connected to the left side face of the vertical plate, and a rust removing mechanism is installed at the telescopic end of each air cylinder; and a spraying mechanism and an air drying mechanism are installed on the upper surface of the workbench. According to the machine, by arranging the rust removing mechanisms, a rotary disc, a motor, a first rotary shaft, the air cylinders and a gear, the motor drives the first rotary shaft and the rotary disc to rotate so as to drive a hardware water pipe body to rotate, circular tables are rotated to adjust the positions of the two circular tables, the circular tables push rust removing blocks to move away from a square barrel to proper positions, the telescopic ends of the air cylinders stretch and retract, therefore, the rust removing mechanisms are driven to move left and right in the hardware water pipe body to remove rust on the inner wall of the hardware water pipe body, and the rust on the inner wall of the hardware water pipe body is removed in a physical rust removal mode.

Owner:东阳市君泽钓具有限公司

Film curing method of concrete wall column

InactiveCN109680973AHigh water retentionReduce lossBuilding material handlingCasting moldMaterials science

The invention relates to a film curing method of a concrete wall column. The film curing method is characterized by comprising the following steps of (1) casting concrete into casting molds of walls and columns, and removing a formwork after final setting of concrete; when the formwork is removed, preparing film curing liquid; (2) mixing the raw materials of the film curing liquid according to a ratio, loading into a spray pot, and enabling the spray pot to spray to the surfaces of the walls and columns; (3) in the spraying process in step (2), the spraying manner of a column body is to sprayfrom the lower part of the column body to the upper part of the column body, after spraying to the top end of the column body, spray from an unsprayed position of the lower part of the column body tothe upper part of the column body until the film curing liquid completely covers all the surfaces of the column body, wherein the spraying is performed along the direction parallel with the axis direction of the column body. The film curing method has the advantages that the defects of the prior art are overcome; the structural design is reasonable and novel.

Owner:青建集团股份公司

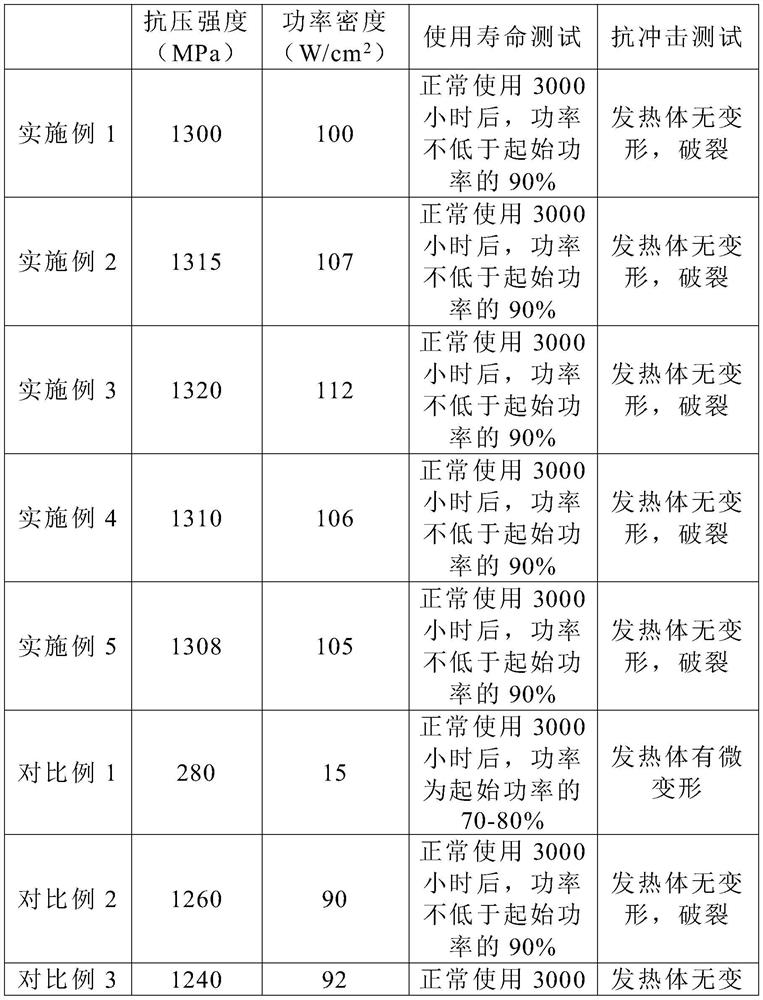

Silicon nitride-based heating body and preparation process thereof

The invention relates to the technical field of heating body components, in particular to a silicon nitride-based heating body and a preparation process thereof. The preparation method of the heating body comprises the following steps of S1, carrying out cutting, grinding and polishing pretreatment on a silicon nitride substrate, S2, placing the pretreated silicon nitride substrate in a sintering furnace to be sintered in an inert atmosphere, S3, atomizing the reaction liquid through air pressure to form small liquid drops, transferring the small liquid drops to the surface of a preheated silicon nitride substrate through carrier gas, and performing thermal decomposition to form a tin oxide film to coat the surface of the substrate, and S4, carrying out heat treatment on the silicon nitride substrate coated with the tin oxide film to obtain the heating body. According to the silicon nitride-based heating body, the compressive strength reaches up to 1300 MPa, the bearable power density reaches up to 100 W / cm<2> and is far higher than that of a traditional heating body based on a quartz tube, the heating body is fast in reaction and small in size, the material cost is saved, and the heating efficiency is improved.

Owner:宁波云川环保科技有限公司

Preparation method of tungsten sulfide target material

ActiveCN108585868AHigh densityFast film formation rateVacuum evaporation coatingSputtering coatingMaterials preparationInstability

The invention relates to a preparation method of a tungsten sulfide target material, and belongs to the technical field of non-metallic target materials. Vacuum hot-pressing sintering is adopted for preparation. The method comprises the following steps of tungsten sulfide pretreatment, wherein tungsten sulfide is mixed with molybdenum disulfide powder and carbon dust to be uniform, and a mixture is obtained for use; vacuum hot-pressing sintering, wherein the mixture obtained in step 1 is loaded into a mold, the mold with the mixture is placed in a sintering furnace for sintering, the sinteringtemperature is controlled to be 1,300-1,550 DEG C, the sintering pressure is controlled to be 25-38 MPa, the temperature and pressure are kept for 2-5 h, after sintering is completed, the temperatureis lowered to range from 810 DEG C to 850 DEG C, the pressure is released, when the temperature is lowered to be 150 DEG C or below, the material is taken out of the furnace, and a rough blank is obtained; finish machining, wherein the rough blank obtained in step 2 is subjected to cutting and plane grinding, and the tungsten sulfide target material is obtained. Accordingly, the method is simple,easy to implement, safe and free of pollution, and fills in the blank of tungsten sulfide target material preparation, and the prepared tungsten sulfide target material is high in density and good instability.

Owner:河北东同光电科技有限公司

Preparation method for inducing titanium or titanium alloy surface chemical conversion film by virtue of electric coupling

ActiveCN106521466ARaise the pHGrain refinementMetallic material coating processesTitanium alloyMechanical property

The invention discloses a preparation method for inducing a titanium and titanium alloy surface chemical conversion film by virtue of electric coupling. The method comprises the following steps: coupling a pre-treated titanium and titanium alloy matrix with metals with relatively low corrosion potentials, wherein the titanium and titanium alloy matrix with a high self-corrosion potential is a cathode, and a magnesium alloy, pure iron and 35CrMnSi with low self-corrosion potentials are an anode; connecting the cathode with the anode in a manner of direct contact and conductive wire connection, and then placing the cathode and the anode in a chemical conversion solution; and carrying out chemical conversion at the room temperature to obtain the titanium and titanium alloy surface chemical conversion film. According to the method disclosed by the invention, the reaction can be completed at the room temperature, and the obtained film layer are fine and compact in grains, excellent in electrochemical performance, low in cost, high in film-forming speed and easy to operate. A titanium-based chemical conversion film with more excellent surface structure and mechanical property can be obtained through changing different coupling systems and cathode-anode area ratios.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com