Graphene anticorrosive paint and preparation method thereof

A technology of anti-corrosion coatings and graphene, applied in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., to achieve the effects of repairing void defects, enhancing compactness, and enhancing anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a kind of preparation method of graphene anticorrosion coating, comprises following preparation steps:

[0041] S1: dissolving cellulose ether and potassium silicate in water respectively to form a mixed solution, then adding graphene to the above mixed solution, and stirring evenly to obtain a graphene mixed solution;

[0042] S2: Dissolve water-based polyurethane resin and water-based epoxy resin in water, add wetting and dispersing agent, filler, γ-glycidyl etheroxypropyl trimethoxysilane in sequence while stirring, and stir evenly to form a resin mixture;

[0043] S3: Stir and disperse the graphene mixed solution, hydrophobic silica material, defoamer, and film-forming aid in sequence for 20-40 minutes, and let stand for 10-20 minutes to obtain the graphene anti-corrosion coating.

[0044] Compared with the prior art, the present invention has the following beneficial effects:

[0045] 1. The present invention uses cellulose ethe...

Embodiment 1

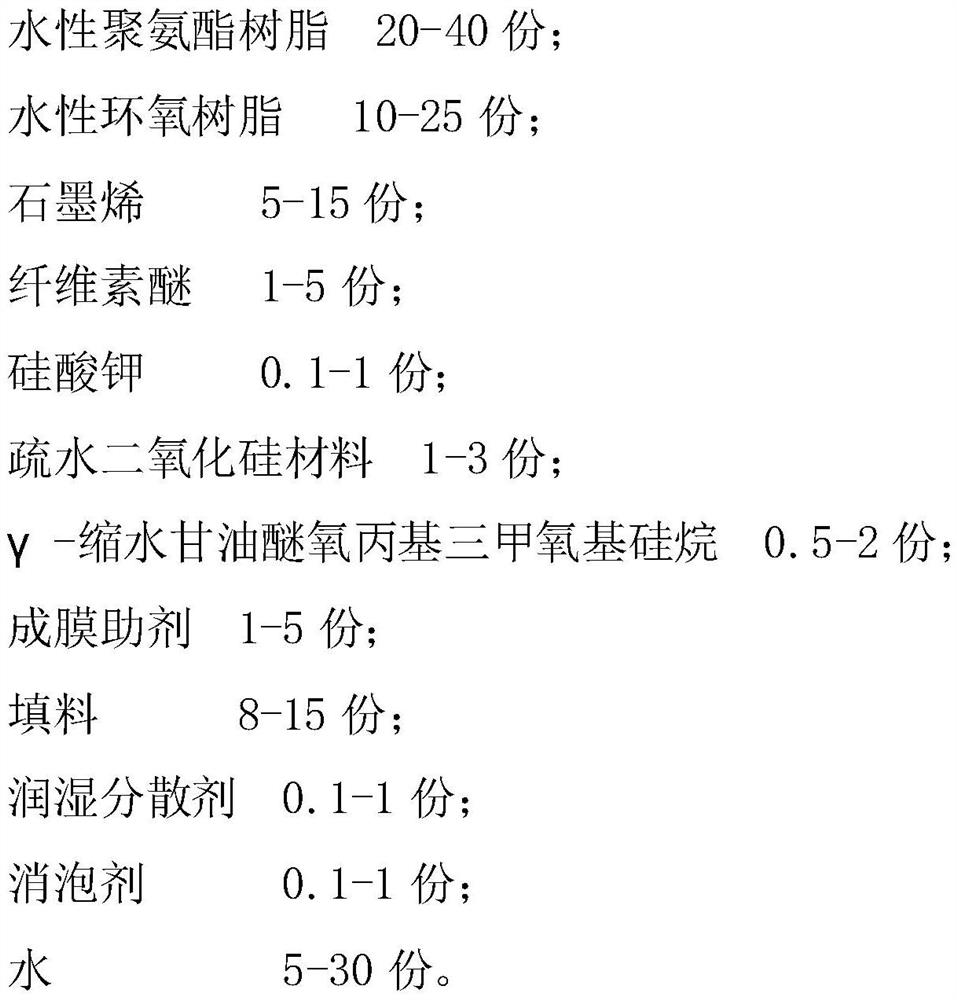

[0049] A kind of graphene anticorrosion paint, comprises the component of following parts by weight:

[0050] 20 parts of water-based polyurethane resin; 10 parts of water-based epoxy resin; 5 parts of graphene; 1 part of cellulose ether; 0.1 part of potassium silicate; 1 part of hydrophobic silica material; 0.5 parts; 1 part of coalescent; 8 parts of filler; 0.1 part of wetting and dispersing agent; 0.1 part of defoamer; 5 parts of water.

[0051] The graphene anti-corrosion coating is prepared through the following steps:

[0052] S1: dissolving cellulose ether and potassium silicate in water respectively to form a mixed solution, then adding graphene to the above mixed solution, and stirring evenly to obtain a graphene mixed solution;

[0053] S2: Dissolve water-based polyurethane resin and water-based epoxy resin in water, add wetting and dispersing agent, filler, γ-glycidyl etheroxypropyl trimethoxysilane in sequence while stirring, and stir evenly to form a resin mixtur...

Embodiment 2

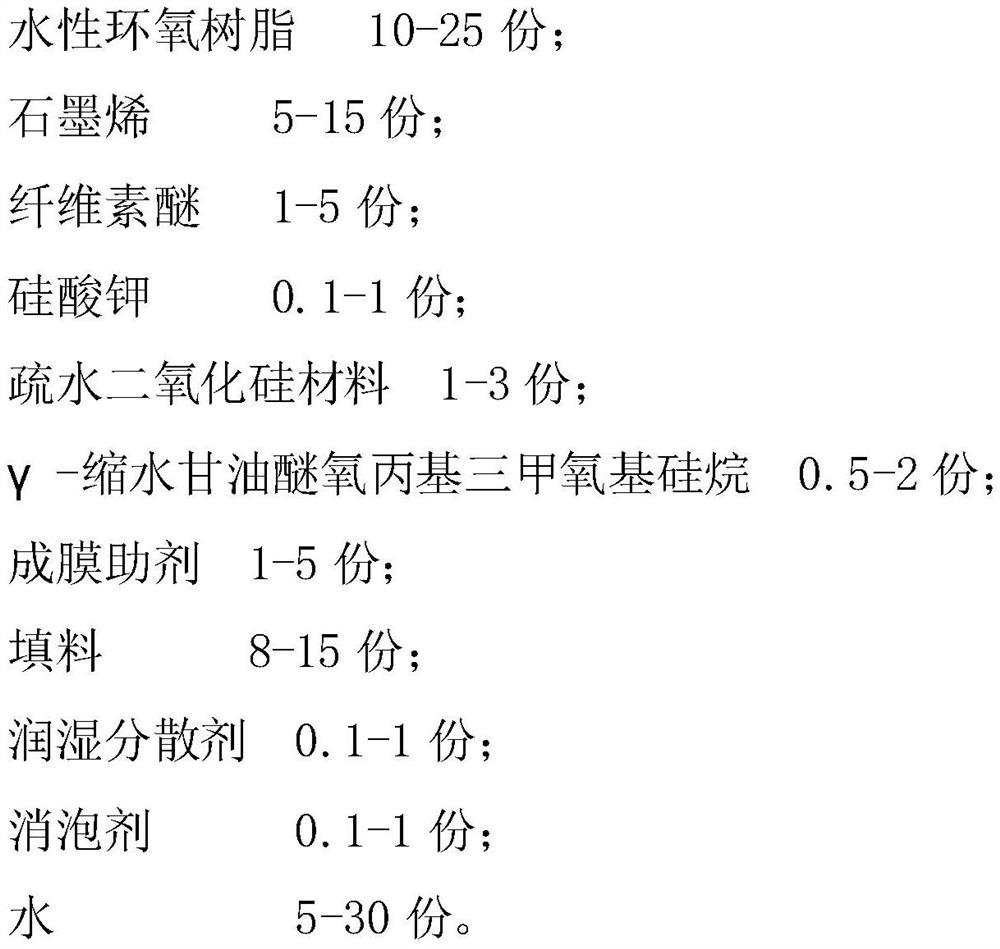

[0057] Different from embodiment 1, the graphene anticorrosion coating of embodiment 2 comprises the component of following weight portion:

[0058] 30 parts of water-based polyurethane resin; 18 parts of water-based epoxy resin; 10 parts of graphene; 3 parts of cellulose ether; 0.5 parts of potassium silicate; 2 parts of hydrophobic silica material; γ-glycidyl etheroxypropyl trimethoxysilane 1 part; 3 parts of coalescent; 13 parts of filler; 0.5 part of wetting and dispersing agent; 0.5 part of defoamer; 15 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com