Preparation method for inducing titanium or titanium alloy surface chemical conversion film by virtue of electric coupling

A technology of chemical conversion and surface chemistry, applied in the coating process of metal materials, etc., can solve the problems of easy generation of sediment, long reaction time, exposed substrate, etc., and achieve improved industrial application range, excellent electrochemical performance, and improved cell adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Use deionized water to mix phosphoric acid 15ml / L, nitric acid 30ml / L, zinc oxide 25g / L, and different types of accelerators 7g / L in order to prepare a chemical conversion solution and adjust the pH value of the solution to 2.7.

[0033] (2) The titanium alloy substrate is sequentially ground, activated, and surface adjusted.

[0034] (3) The titanium alloy substrate obtained through step (2) is directly contacted with the magnesium alloy to form a magnesium alloy-titanium alloy coupling system, wherein the titanium alloy substrate with a higher self-corrosion potential is the cathode, and the magnesium alloy with a lower self-corrosion potential It is an anode, and the area ratio of the cathode and the anode is 1:1, and the chemical conversion solution obtained in step (1) is left standing at room temperature for 1 min.

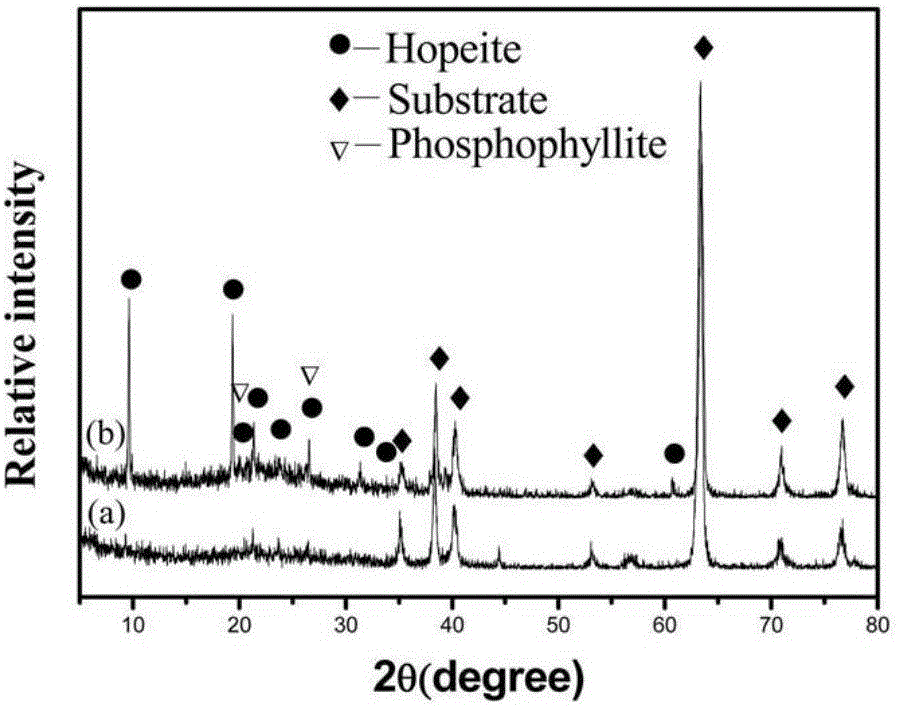

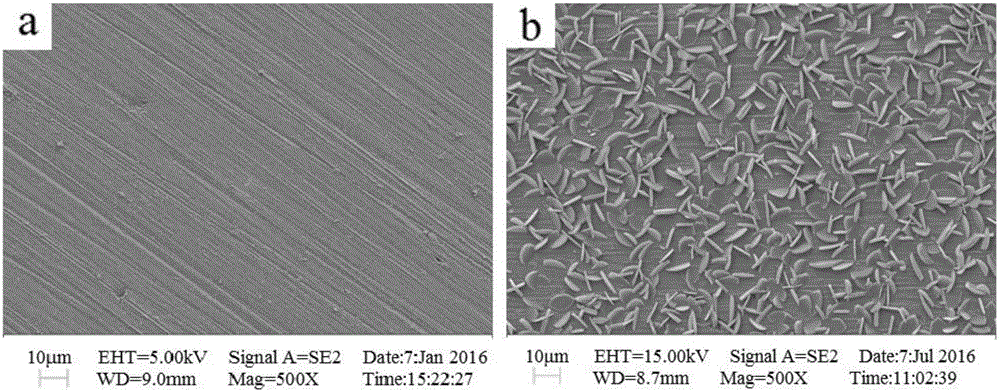

[0035] (4) The product obtained in step (3) is fully washed with running water and deionized water, and dried at normal temperature to obtain a c...

Embodiment 2

[0038] (1) Use deionized water to mix phosphoric acid 20ml / L, nitric acid 25ml / L, zinc oxide 30g / L, and different types of accelerators 5g / L in order to prepare a chemical conversion solution and adjust the pH value of the solution to 2.5.

[0039] (2) The titanium alloy substrate is sequentially ground, activated, and surface adjusted.

[0040] (3) Connect the titanium alloy substrate obtained through step (2) with the magnesium alloy wire to form a magnesium alloy-titanium alloy coupling system, wherein the titanium alloy substrate with a higher self-corrosion potential is the cathode, and the magnesium alloy with a lower self-corrosion potential It is an anode, and the area ratio of the cathode and the anode is 1:2, and the chemical conversion base solution obtained in step (1) is left standing at room temperature for 5 minutes for conversion.

[0041] (4) The product obtained in step (3) is fully washed with running water and deionized water, and dried at normal temperatur...

Embodiment 3

[0044] (1) Use deionized water to mix phosphoric acid 15ml / L, nitric acid 35ml / L, zinc oxide 35g / L, and different types of accelerators 10g / L in order to prepare a chemical conversion solution and adjust the pH value of the solution to 3.0.

[0045] (2) The titanium alloy substrate is sequentially ground, activated, and surface adjusted.

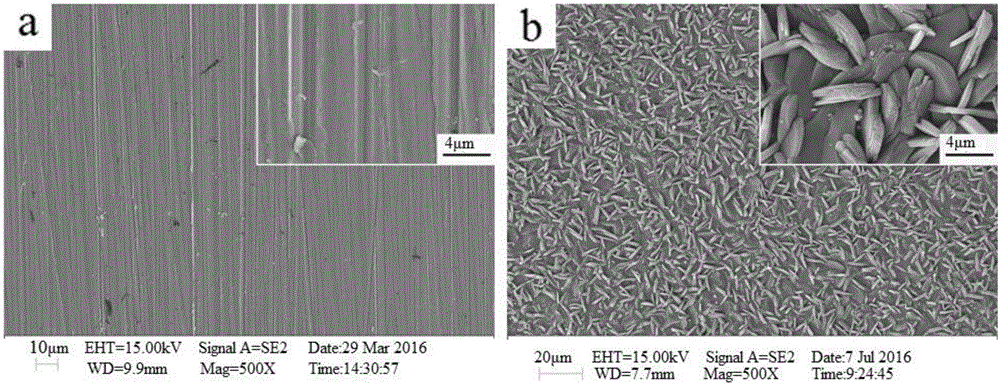

[0046] (3) The titanium alloy substrate obtained through step (2) is directly contacted with pure iron to form a pure iron-titanium alloy coupling system, wherein the titanium alloy substrate with a higher self-corrosion potential is the cathode, and the pure iron with a lower self-corrosion potential It is an anode, and the area ratio of the cathode and the anode is 1:1, and the chemical transformation base solution obtained in step (1) is left to transform at room temperature for 10 minutes.

[0047] (4) The product obtained in step (3) is fully washed with running water and deionized water, and dried at normal temperature to obtain a chem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com