Ionic waterborne curing agent based on bio-based pentamethylene diisocyanate and preparation method thereof

A technology of pentamethylene diisocyanate and water-based curing agent, applied in the field of ionic water-based curing agent and its preparation, can solve the problems of the influence of hydroxyl components on film formation, complicated production and preparation process, and large environmental pollution, and achieve curing Fast speed, easy to master operation process, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

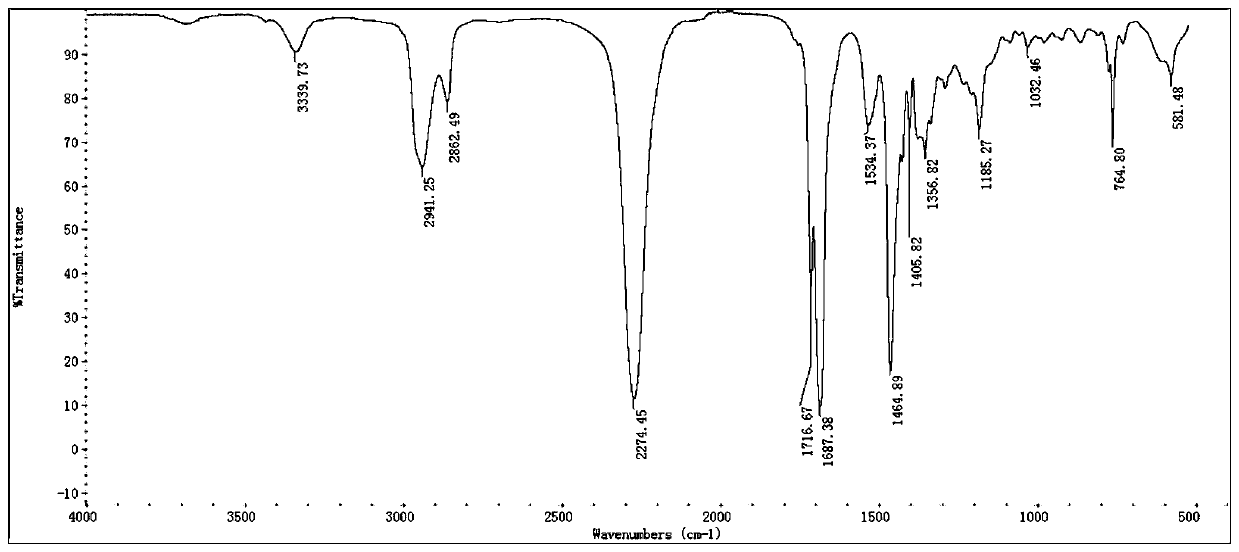

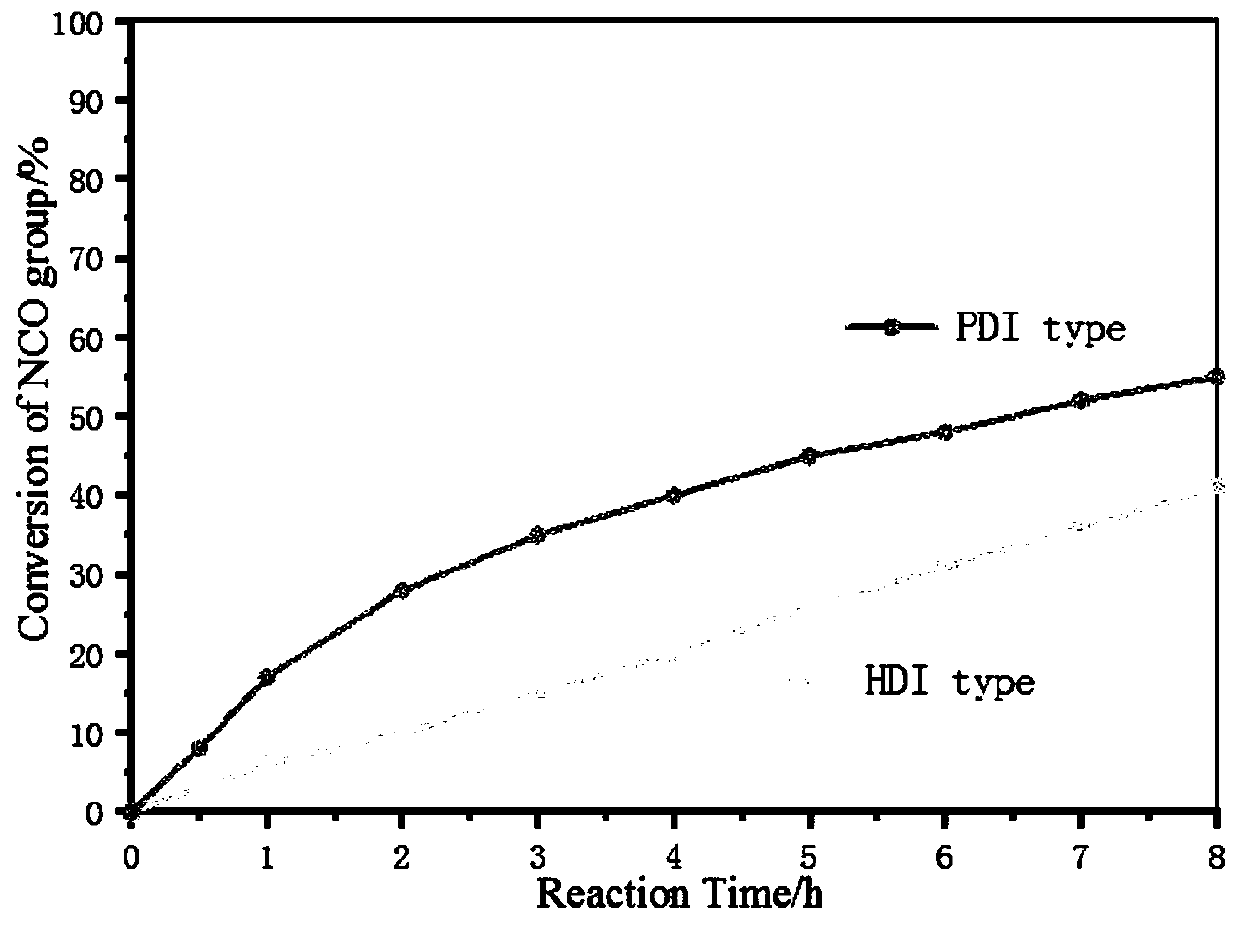

Method used

Image

Examples

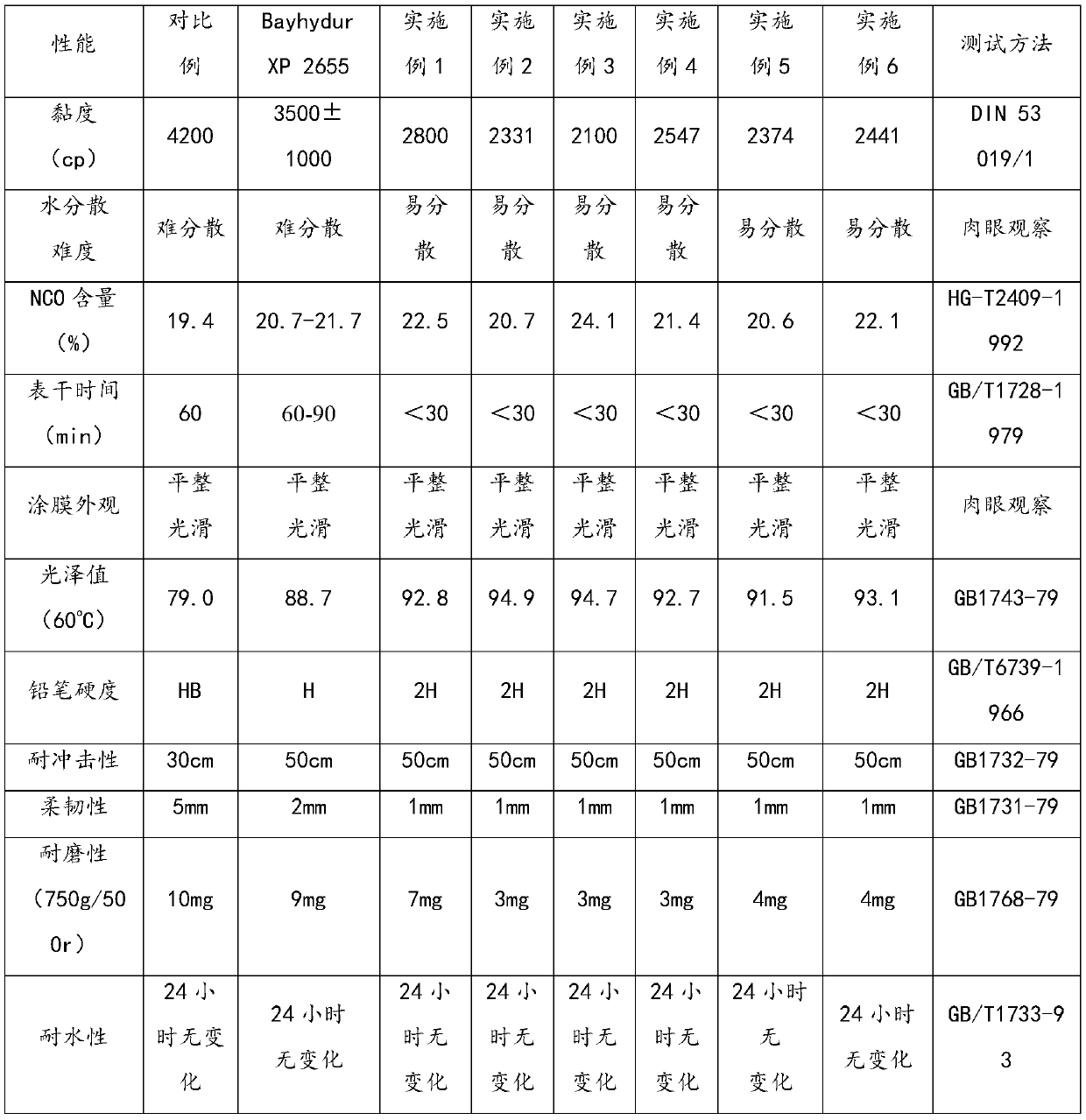

Embodiment 1

[0037] The preparation method of the ionic water-based curing agent based on bio-based pentamethylene diisocyanate of the present embodiment may further comprise the steps:

[0038] 1) The bio-based pentamethylene diisocyanate trimer is subjected to vacuum distillation with a rotary evaporator at a pressure of 20 mbar and a temperature of 170° C. to remove impurities and free monomers therein to obtain the impurity-removed Bio-based pentamethylene diisocyanate trimer;

[0039] 2) Add 120g of bio-based pentamethylene diisocyanate trimer, 5.8g of 2-cyclohexylaminoethanesulfonic acid, 2.58g of N,N-dimethyl Cyclohexylamine, then stirred and raised to 80°C under nitrogen atmosphere to fully react for 5 hours, and when the product in the bottle was clear and transparent, the temperature was lowered to 25°C, discharged, sampled and titrated to obtain the product.

[0040] The calculated -NCO content of the bio-based pentamethylene diisocyanate ionic water-based curing agent is 22.5%...

Embodiment 2

[0043] The preparation method of the ionic water-based curing agent based on bio-based pentamethylene diisocyanate of the present embodiment may further comprise the steps:

[0044] 1) The bio-based pentamethylene diisocyanate trimer is distilled under reduced pressure with a rotary evaporator at a pressure of 30 mbar and a temperature of 160° C. to remove impurities and free monomers therein to obtain the impurity-removed Bio-based pentamethylene diisocyanate trimer;

[0045] 2) Add 450g of bio-based pentamethylene diisocyanate trimer and 3.5g of dimethylcyclohexylamine after removing impurities in step 1) to the four-necked flask, and then add 6.3g of 3-cyclohexylaminopropyl During the reaction process, add sulfonic acid into the four-neck flask in batches, then stir and raise the temperature to 110°C for 6 hours in a nitrogen atmosphere to fully react.

[0046] The -NCO content of the bio-based pentamethylene diisocyanate-based ionic water-based curing agent obtained in th...

Embodiment 3

[0048] The preparation method of the ionic water-based curing agent based on bio-based pentamethylene diisocyanate of the present embodiment may further comprise the steps:

[0049] 1) The bio-based pentamethylene diisocyanate trimer (Mitsui Chemicals) was subjected to vacuum distillation with a rotary evaporator at a pressure of 25 mbar and a temperature of 170 ° C to remove impurities and free monomers therein, Obtain bio-based pentamethylene diisocyanate trimer after impurity removal;

[0050] 2) Add 200g of the bio-based pentamethylene diisocyanate trimer, 4.5g of sodium cyclamate, and 3.2g of o-toluidine to the four-necked flask after removing impurities in step 1), and then in a nitrogen atmosphere Under stirring, raise the temperature to 70°C and fully react for 7 hours. When the reactants in the bottle are clear and transparent, cool down to 30°C, discharge the material, take a sample for titration, and obtain the product.

[0051] The -NCO content of the bio-based pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com