A kind of highly water-resistant and hydrophilic polyisocyanate curing agent and its preparation method and application

A polyisocyanate and hydrophilic technology, applied in the field of polymers, can solve the problems of poor dispersion of the system, insufficient hydrophilic ability of the trimer, and influence on the gloss and fullness of the paint film, and achieve high NCO content and excellent water resistance. , low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

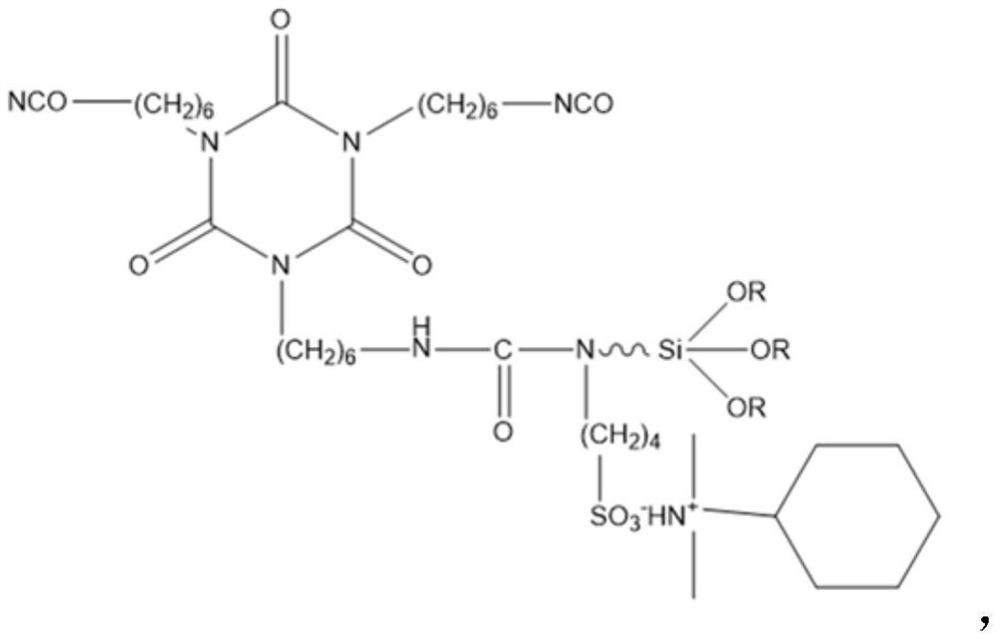

[0054] The structural formula of the highly water-resistant and hydrophilic polyisocyanate curing agent of the present embodiment is as follows:

[0055]

[0056] Wherein, R is selected from methyl, Represent-CH 2 CH 2 CH 2 -.

[0057] Its preparation method includes the following steps: under the protection of nitrogen, add 1kg of butane sultone into the reaction vessel, slowly add 1kg of silane coupling agent KH540 under stirring at 60°C, then continue stirring for 10min, add 98kg of HDI trimer , heat up to 100°C, slowly add N,N-dimethylcyclohexylamine dropwise under stirring for 100% neutralization, keep at 100°C and continue the reaction until the NCO content is 21wt%-22wt%, to obtain high water resistance and hydrophilic type Polyisocyanate curing agent.

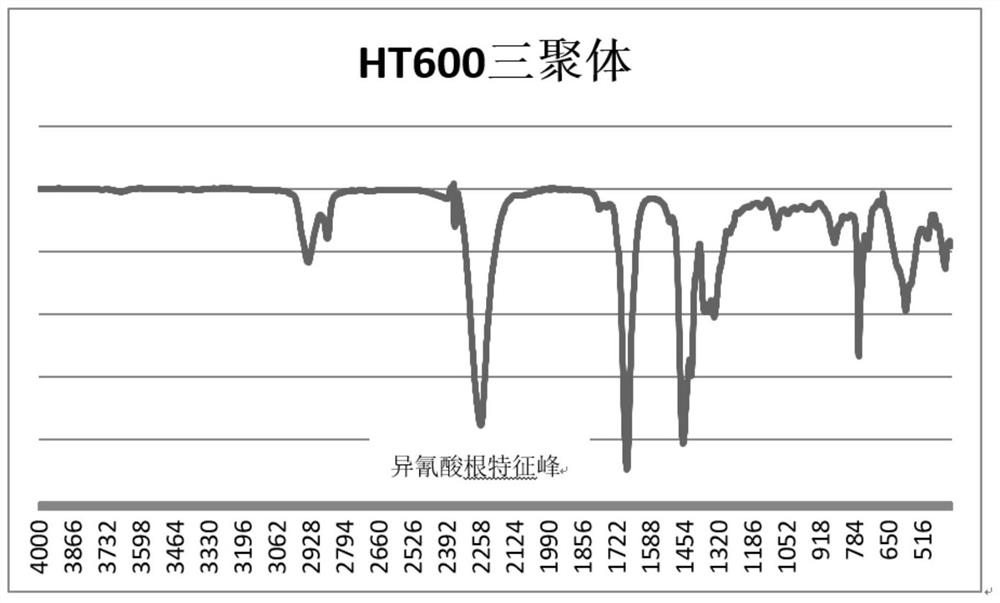

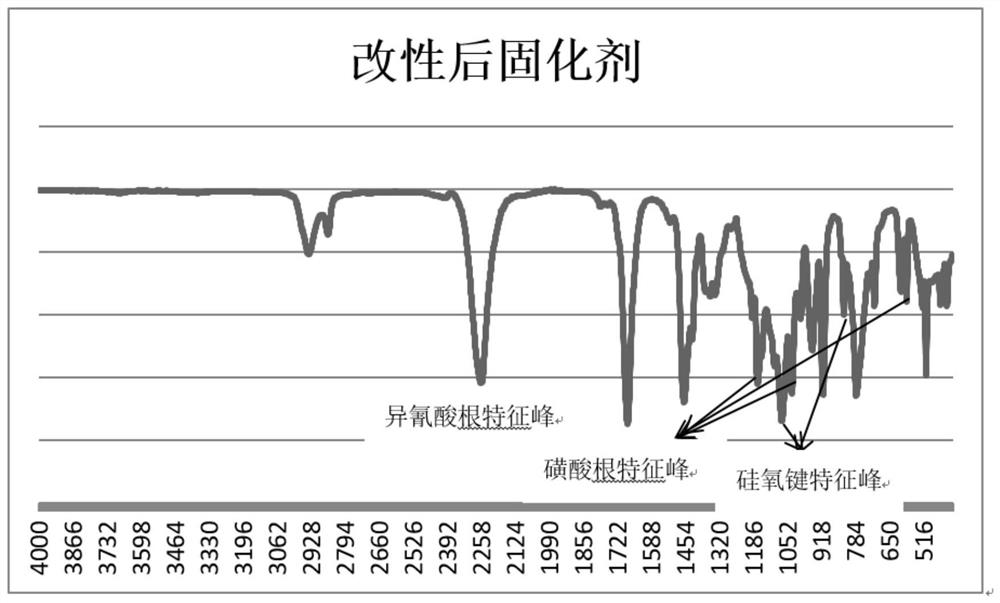

[0058] The IR spectrum of the HDI trimer is as follows figure 1 As shown, the IR spectrum of the highly water-resistant and hydrophilic polyisocyanate curing agent prepared in this embodiment is as follows: ...

Embodiment 2

[0061] The structural formula of the highly water-resistant and hydrophilic polyisocyanate curing agent of the present embodiment is as follows:

[0062]

[0063] Wherein, R is selected from ethyl, Represent-CH 2 CH 2 CH 2 -.

[0064] The difference between the preparation method of this example and Example 1 is that the silane coupling agent KH540 is replaced by KH550, and the rest of the raw materials and reaction conditions are the same as those of Example 1.

Embodiment 3-11

[0066] The difference between the preparation method of the highly water-resistant and hydrophilic polyisocyanate curing agent of Examples 3-11 and Example 1 is shown in Table 1.

[0067] The difference between the preparation method of table 1 embodiment 3-11 and embodiment 1

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com