Process for preparing low free toluene diisocyanate curing agent

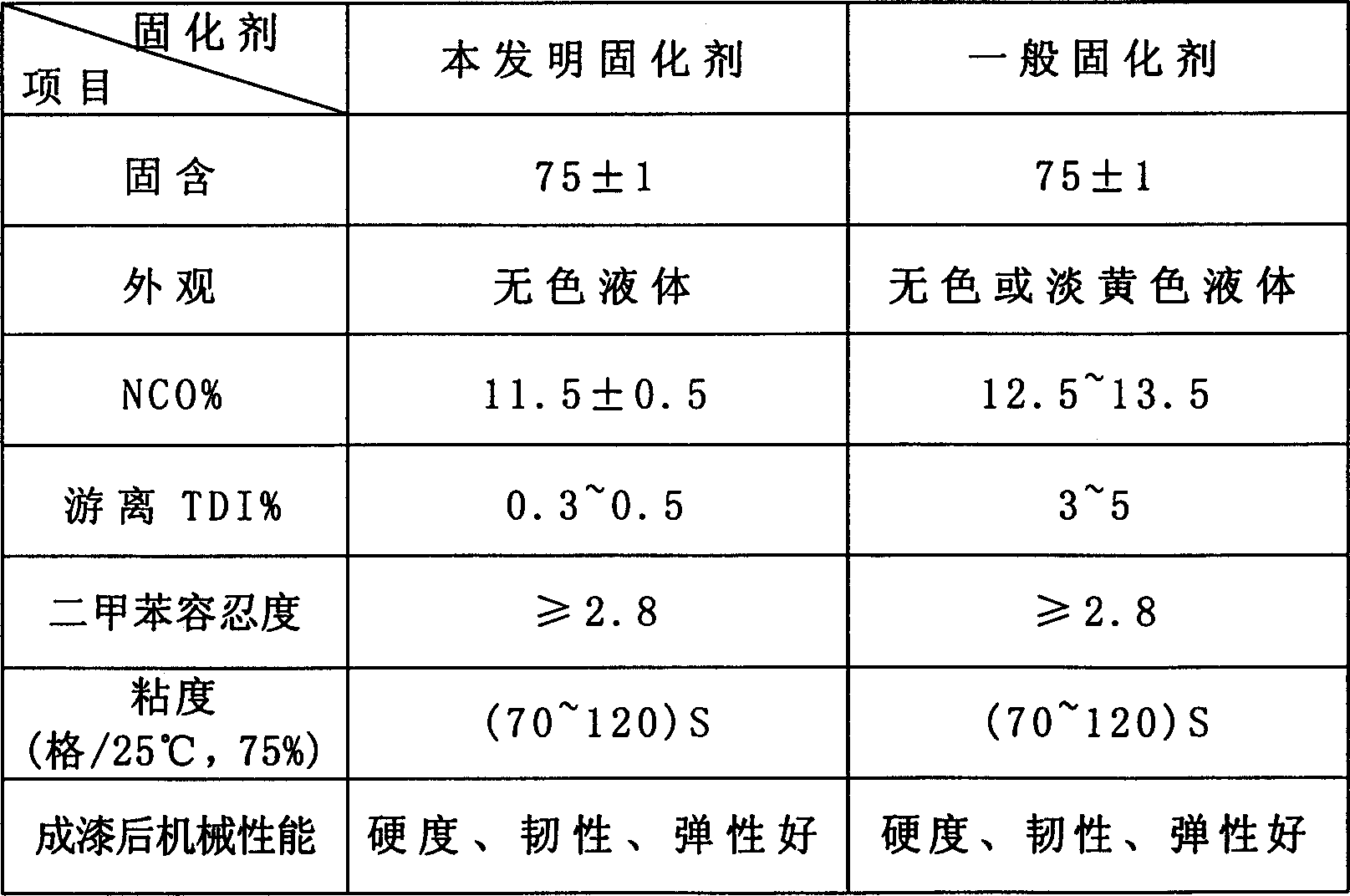

A technology of toluene diisocyanate and polyisocyanate, applied in the field of polyurethane curing agent preparation, can solve the problems of large loss of acetonitrile, dark color of curing agent, unsuitable for industrial production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

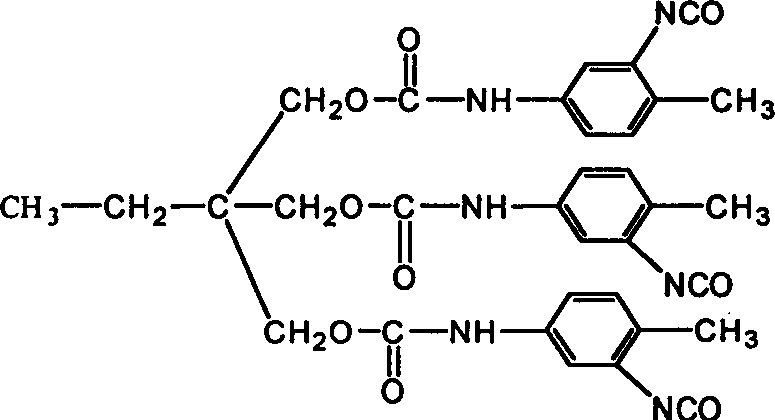

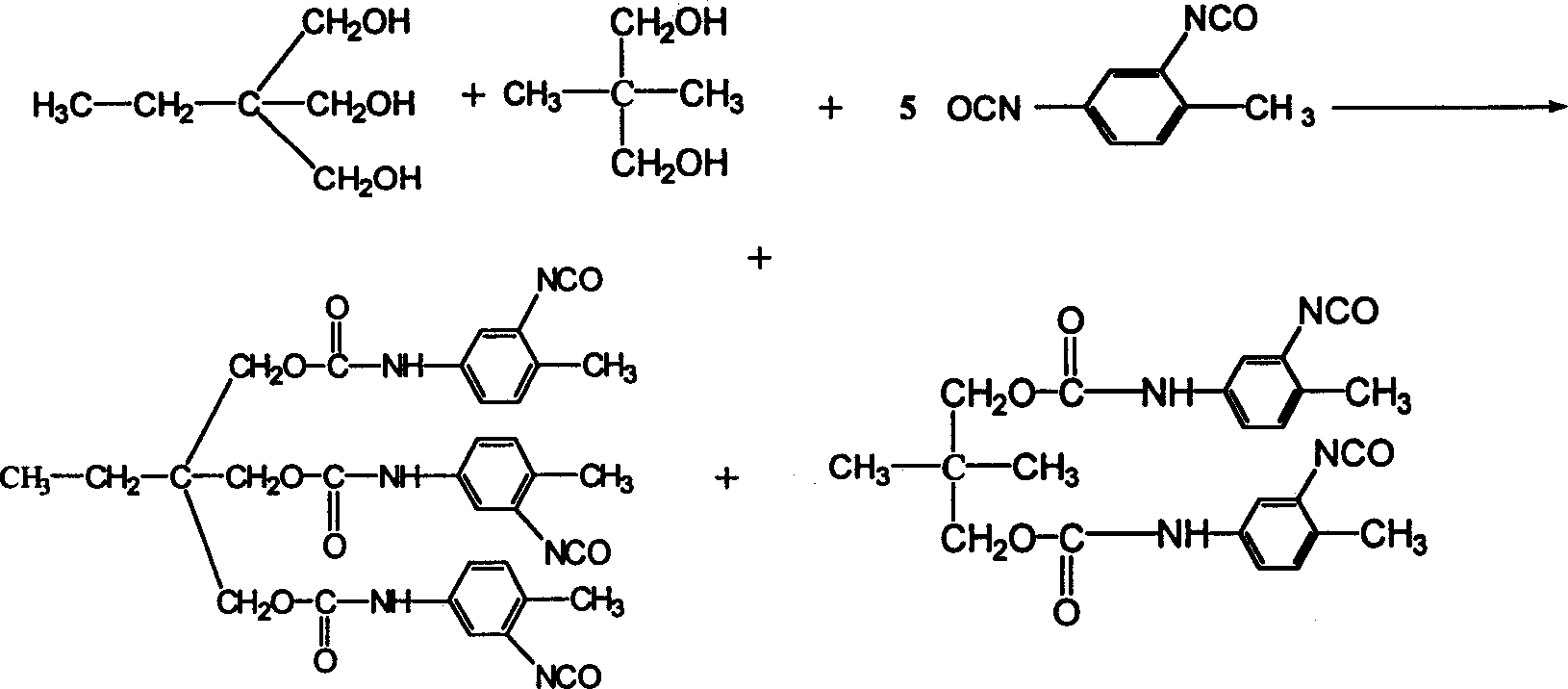

Method used

Image

Examples

Embodiment 1

[0026] Add 522g of toluene diisocyanate into a reactor equipped with a stirring device, a feeding port, a thermometer and a dry nitrogen protection device, then add 165.9g of dimethyl carboxylate, and add it in 6 batches after raising the temperature to 50°C A mixture of 91 g of trimethylolpropane and 50.5 g of neopentyl glycol was maintained at 70°C for 3.5 hours at intervals of 30 minutes.

[0027] When the weight percentage of free NCO groups is 15-16%, add polyisocyanate trimer catalyst lithium phenate 0.17g, react at 65°C for 3 hours, take a sample every 30 minutes to detect the free NCO Percentage by weight, the reaction continues until the NCO content drops to 14±0.5%, and then 0.08 g of polyisocyanate trimer inhibitor phosphoric acid is added to terminate the reaction.

[0028] Add 4147g of petroleum ether into the reactor in 5 times, after stirring for 15 minutes each time, let it stand for 5 minutes, pump the petroleum ether into the distillation still under vacuum, ...

Embodiment 2

[0039] Add 783g of toluene diisocyanate into a reactor equipped with a stirring device, a feeding port, a thermometer and a dry nitrogen protection device, then add 231.1g of γ-butyrolactone, and add 91g in 6 batches after raising the temperature to 50°C A mixture of trimethylolpropane and 50.5 g of neopentyl glycol, at 30 minute intervals, was then incubated at 70°C for 3.5 hours.

[0040] When measuring the weight percentage of free NCO groups to be 15-16%, add polyisocyanate trimer catalyst tin octoate 0.58g (0.05%), after reacting at 65°C for 3 hours, take a sample every 30 minutes Detect the weight percentage of free NCO, and the reaction continues until the NCO content drops to 14 ± 0.5%, and then 0.27 g of polyisocyanate trimer polymerization inhibitor benzoyl chloride is added to terminate the reaction.

[0041] Add 5778.1 g of cyclohexane into the reactor in 6 times, stir for 15 minutes each time, and then let stand for 5 minutes. Vacuumize the cyclohexane into the d...

Embodiment 3

[0052] Add 652.5g of toluene diisocyanate into a reactor equipped with a stirring device, a feeding port, a thermometer and a dry nitrogen protection device, then add 337g of dimethyl sulfoxide, and add 134g in 6 batches after raising the temperature to 50°C Trimethylolpropane, each interval is 30 minutes, and then incubated at 70°C for 3.0 hours.

[0053] When the weight percentage of free NCO groups is 15-16%, add polyisocyanate trimer catalyst lithium stearate 1.68g, react at 65°C for 2.5 hours, take a sample every 30 minutes The weight percentage of free NCO, the reaction continues until the NCO content drops to 14 ± 0.5%, after adding polyisocyanate trimer polymerization inhibitor diethylhexyl hydrogen phosphate 0.94g to terminate the reaction.

[0054] Add 5617.5 g of n-hexane into the reactor in 5 times, stir for 15 minutes each time, and let stand for 5 minutes. Vacuumize the n-hexane into the still, and separate the n-hexane from the free toluene diisocyanate through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com