Silicon nitride-based heating body and preparation process thereof

A preparation process and technology for a silicon nitride substrate are applied in the field of heating body components to achieve the effects of fast reaction, simple preparation process and material cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

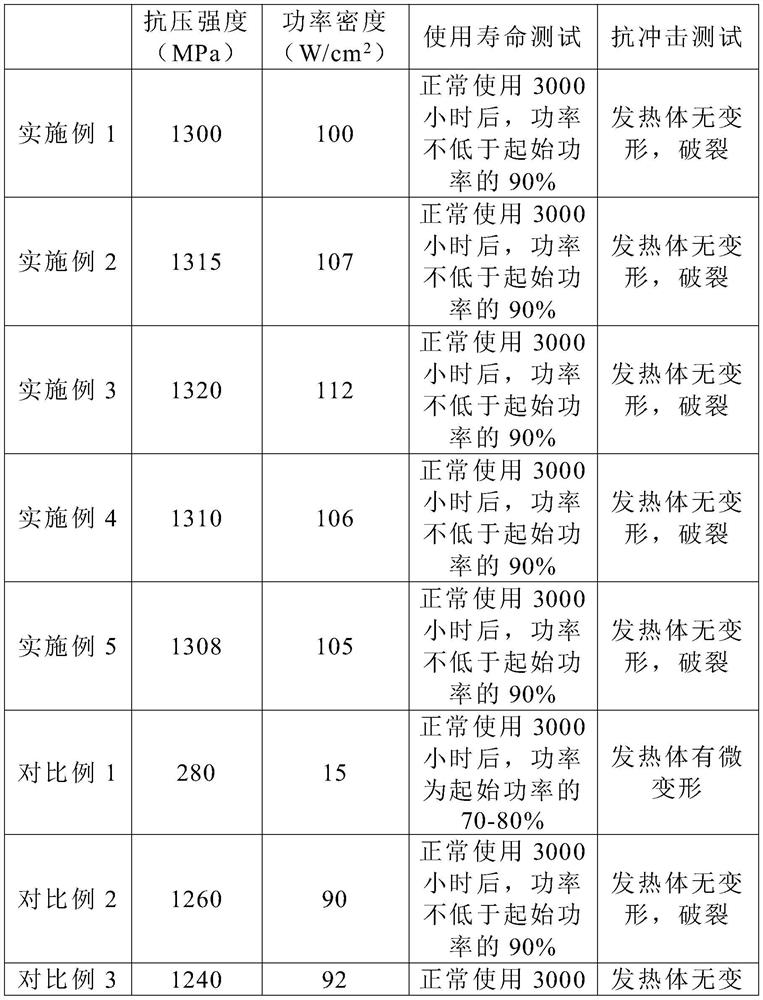

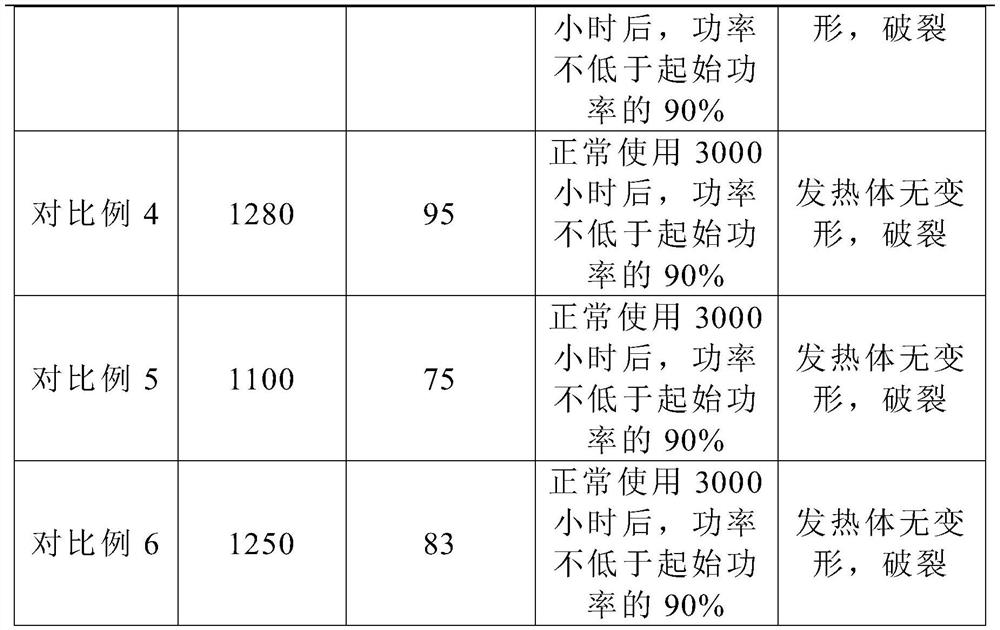

Examples

Embodiment 1

[0024] A heating body, which includes a silicon nitride substrate and a tin oxide film coated on the surface of the substrate, specifically prepared through the following steps:

[0025] S1. Cutting the silicon nitride substrate into a size with an outer diameter of 10 mm and a length of 80 mm, and then grinding and polishing to a surface roughness of Ra=1.2-1.6 μm;

[0026] S2. Place the pretreated silicon nitride substrate in a sintering furnace at 1100° C. for sintering in argon for 4 hours;

[0027] S3, prepare the reaction solution according to the following mass percentage: SnCl 4 .5H 2 O: 96.2%, SbCl 3 : 0.8%, CuO: 0.11%, MgO: 0.03%, FeO: 0.022%, HF: 0.024%, ethanol: 0.038%, the balance is deionized water and unavoidable impurities; pass the prepared reaction solution through 0.3MPa Air pressure atomization forms small droplets with an atomization volume of 200mL / m, and the small droplets are transferred to the surface of the silicon nitride substrate at a temperatur...

Embodiment 2

[0030] A heating body, which includes a silicon nitride substrate and a tin oxide film coated on the surface of the substrate, specifically prepared through the following steps:

[0031] S1. Cut the silicon nitride substrate into a size with an outer diameter of 12 mm and a length of 90 mm, and then polish and polish it to a surface roughness of Ra=1.2-1.6 μm;

[0032] S2. Place the pretreated silicon nitride substrate in a sintering furnace at 1150° C. for sintering in argon for 3 hours;

[0033] S3, prepare the reaction solution according to the following mass percentage: SnCl 4 .5H 2 O: 96.8%, SbCl 3 : 0.85%, CuO: 0.12%, MgO: 0.035%, FeO: 0.023%, HF: 0.028%, ethanol: 0.04%, the balance is deionized water and unavoidable impurities; pass the prepared reaction solution through 0.35MPa Air pressure atomization forms small droplets with an atomization volume of 220mL / m, and the small droplets are transferred to the surface of the silicon nitride substrate at a temperature of...

Embodiment 3

[0036] A heating body, which includes a silicon nitride substrate and a tin oxide film coated on the surface of the substrate, specifically prepared through the following steps:

[0037] S1. Cutting the silicon nitride substrate into a size with an outer diameter of 14 mm and a length of 100 mm, and then grinding and polishing to a surface roughness of Ra=1.2-1.6 μm;

[0038] S2. Place the pretreated silicon nitride substrate in a sintering furnace at 1200° C. for sintering in argon for 3 hours;

[0039] S3, prepare the reaction solution according to the following mass percentage: SnCl 4 .5H 2O: 97.5%, SbCl 3 : 0.9%, CuO: 0.14%, MgO: 0.04%, FeO: 0.025%, HF: 0.03%, ethanol: 0.042%, the balance is deionized water and unavoidable impurities; pass the prepared reaction solution through 0.4MPa Air pressure atomization forms small droplets with an atomization volume of 250mL / m, and the small droplets are transferred to the surface of the silicon nitride substrate at a temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com