Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Avoid crack failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

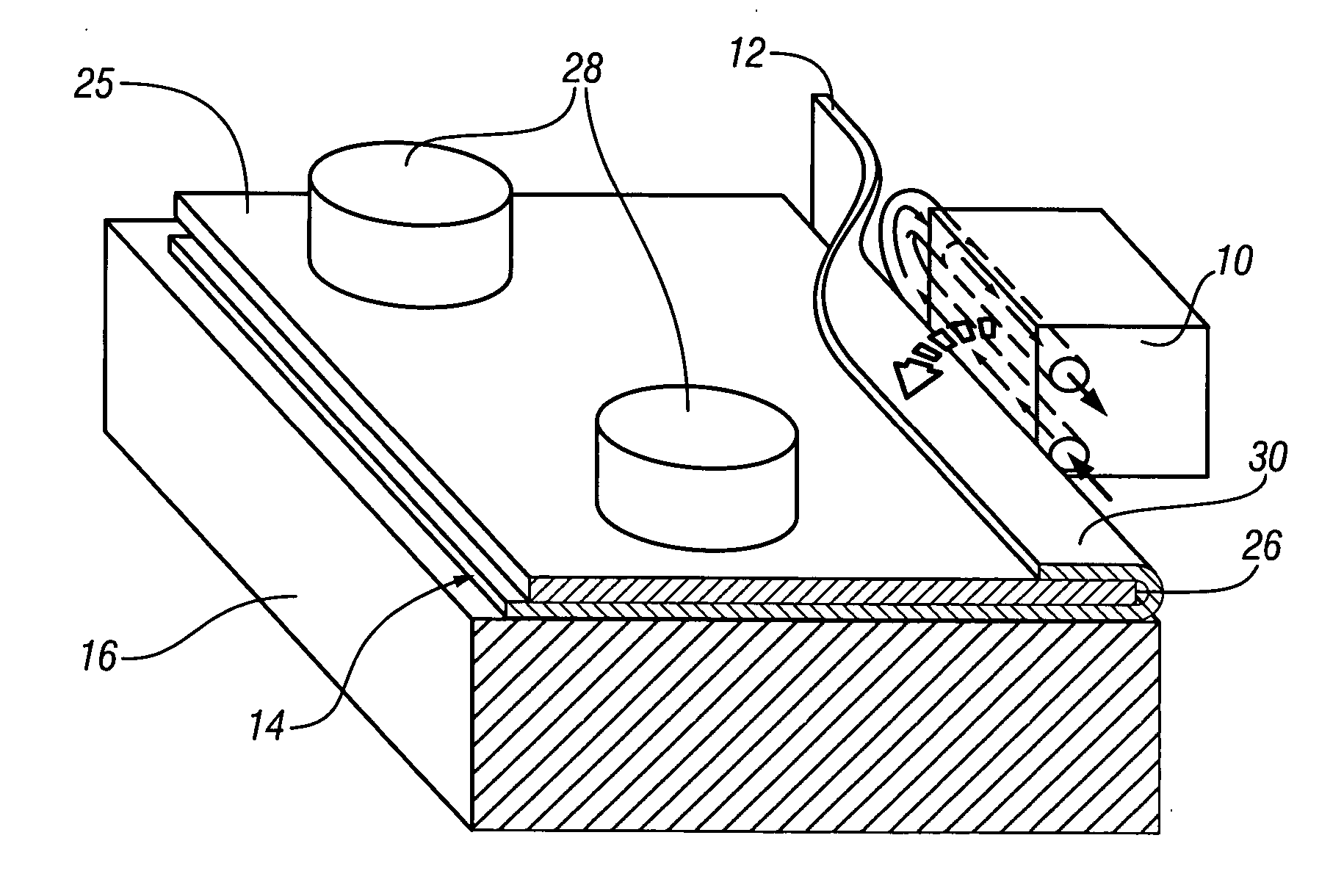

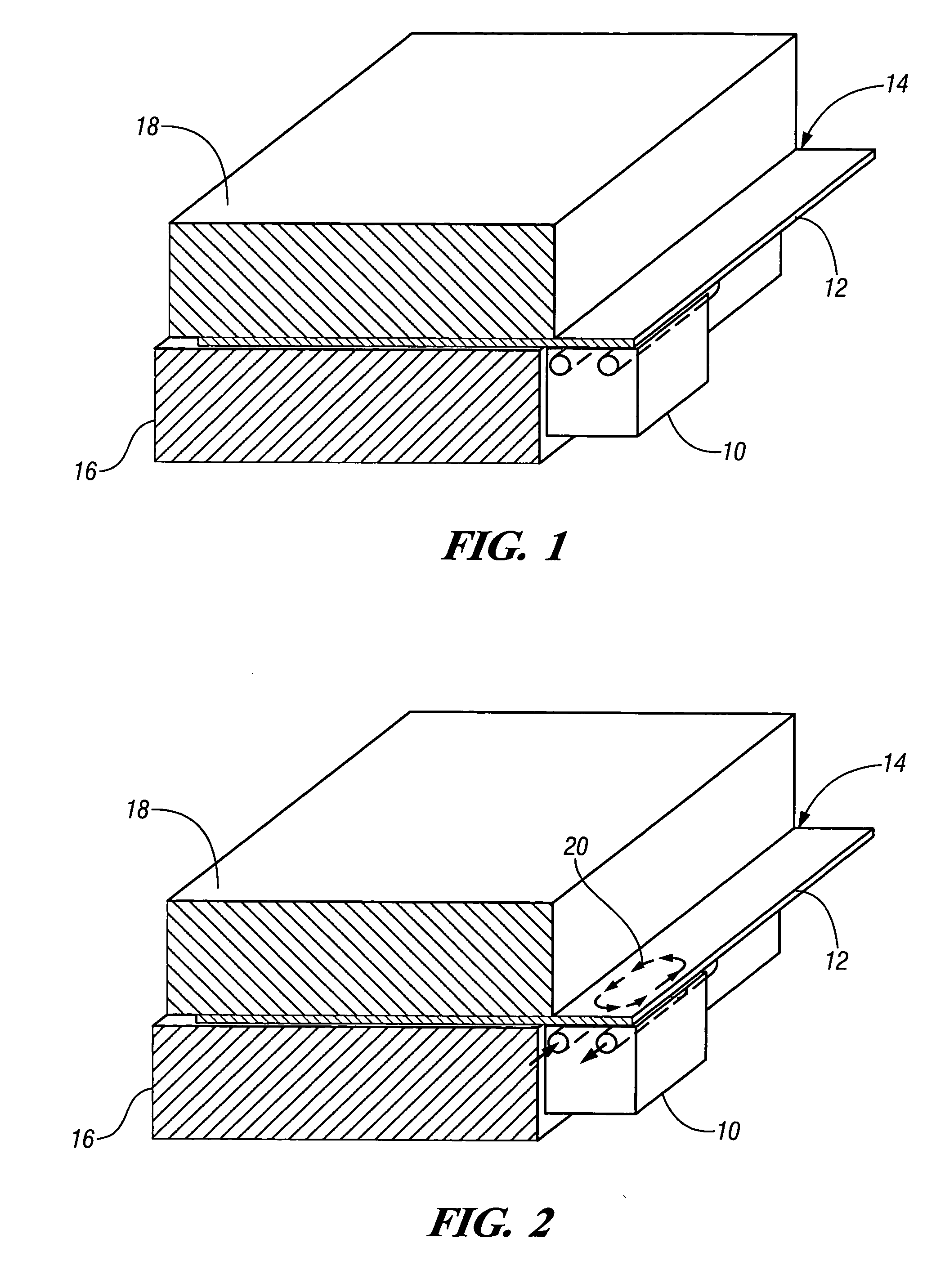

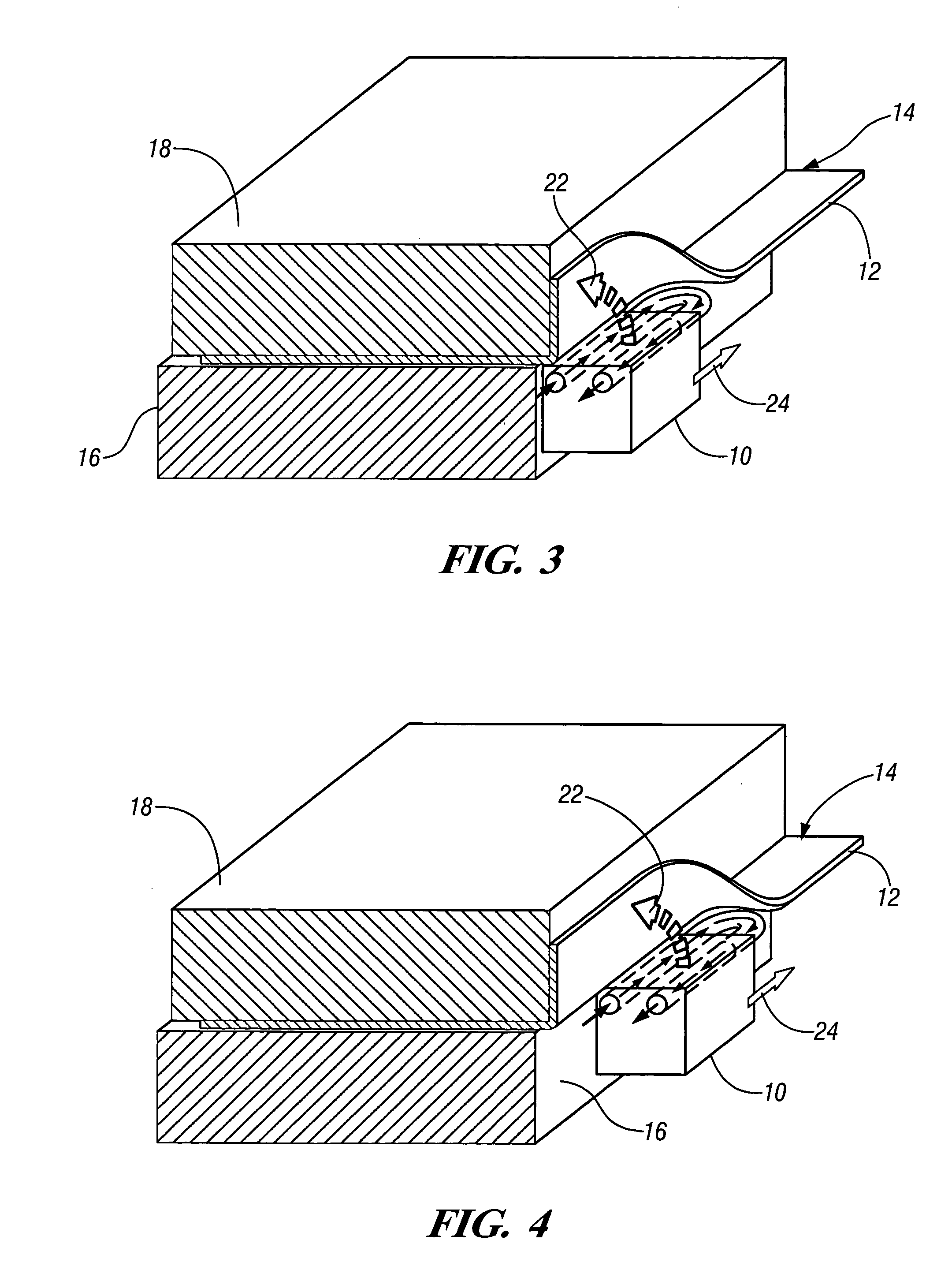

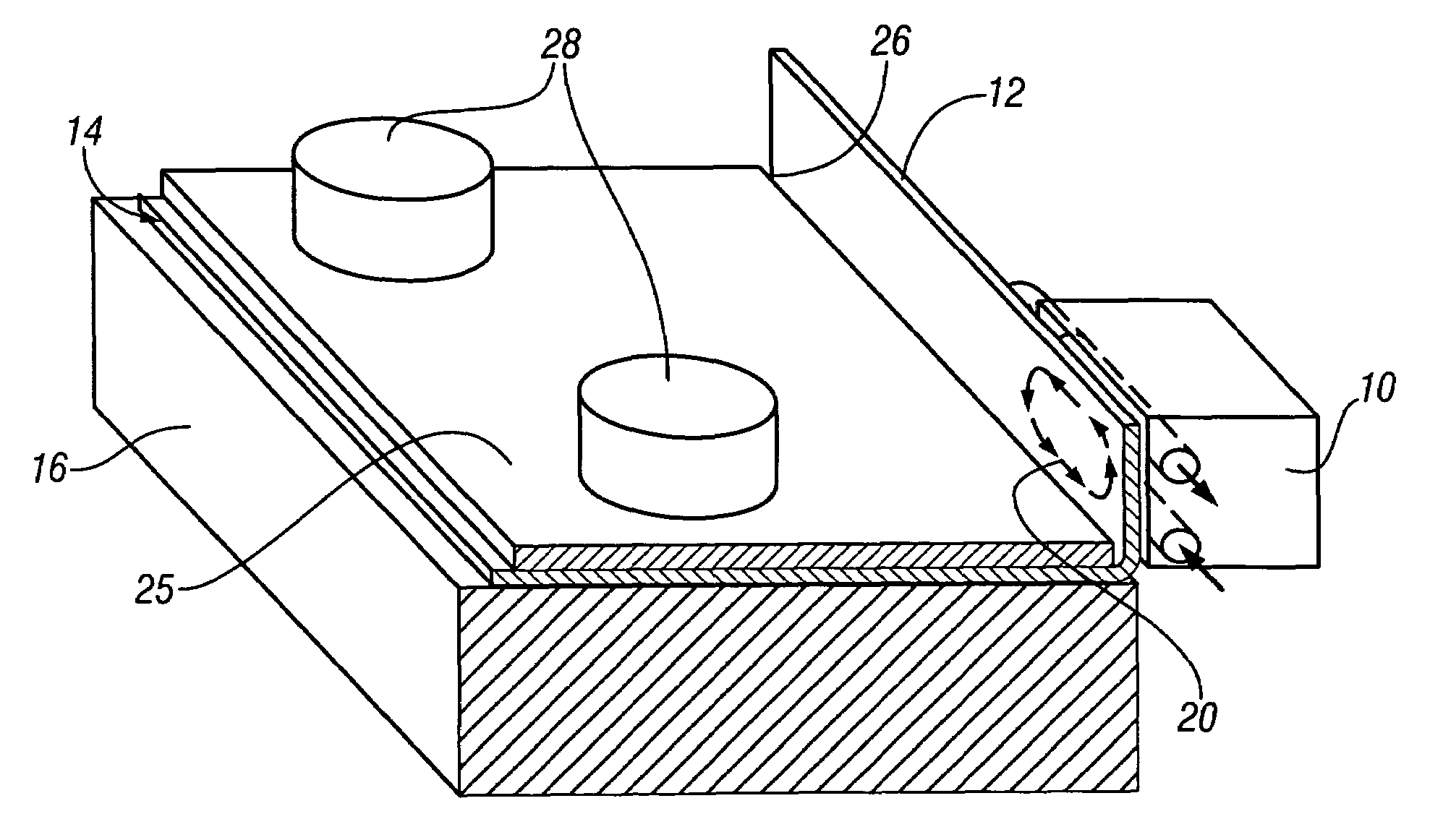

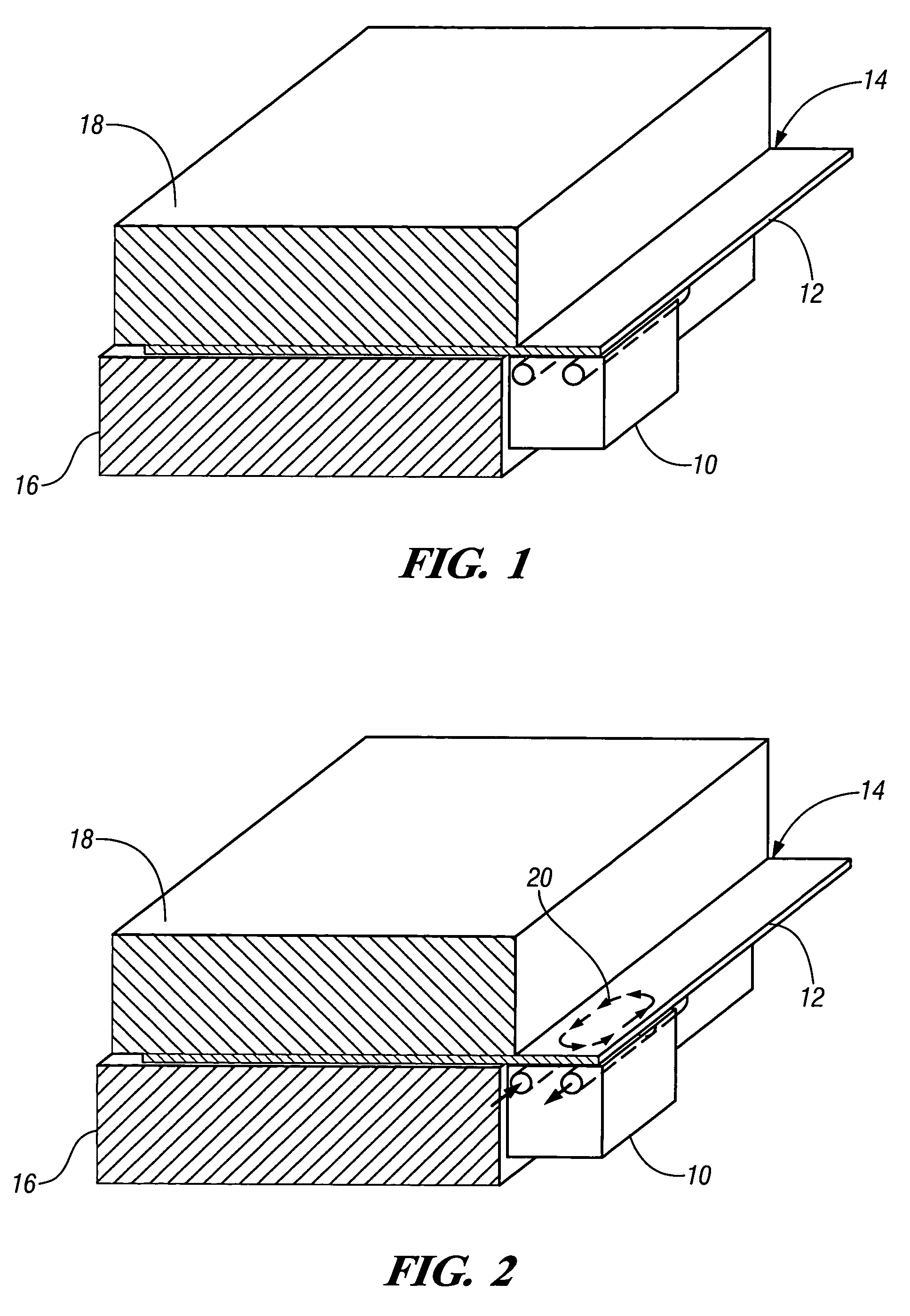

Electromagnetic flanging and hemming apparatus and method

InactiveUS20050229377A1Great bending plasticityAvoid crackingAutomatic control devicesAssembly machinesEngineeringFlanging

Apparatus and methods are disclosed for applying electromagnetic force (EMF) to flanging and hemming metal panels to form a hemmed panel assembly. First and second apparatus and method steps use a translating EMF coil to flange a sheet and to finish a hem by progressive non-planar bending. An alternate embodiment uses EMF hemming for difficult-to-hem portions of a flange and optionally precedes this with conventional hemming of straight hem portions.

Owner:RES IN MOTION LTD +1

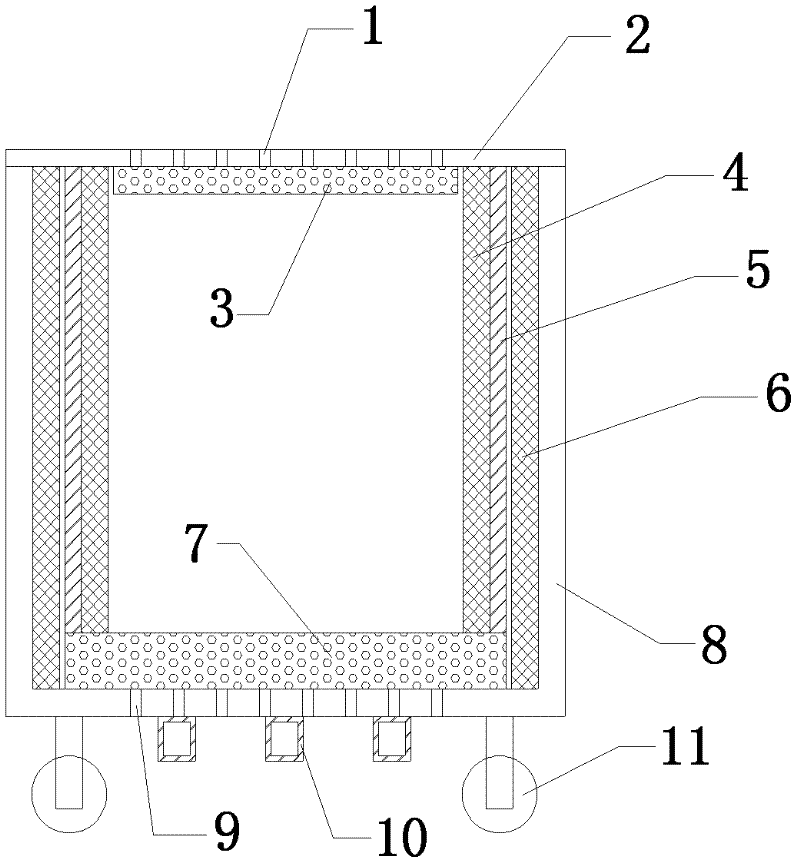

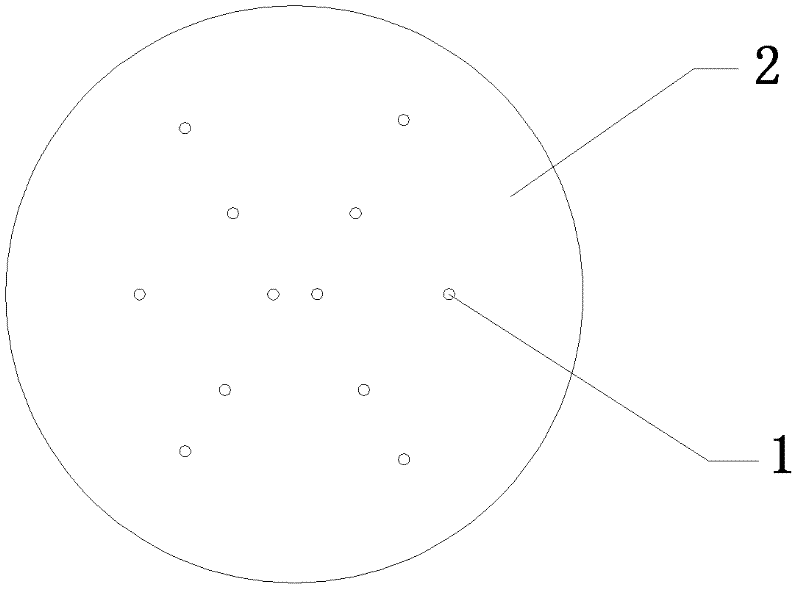

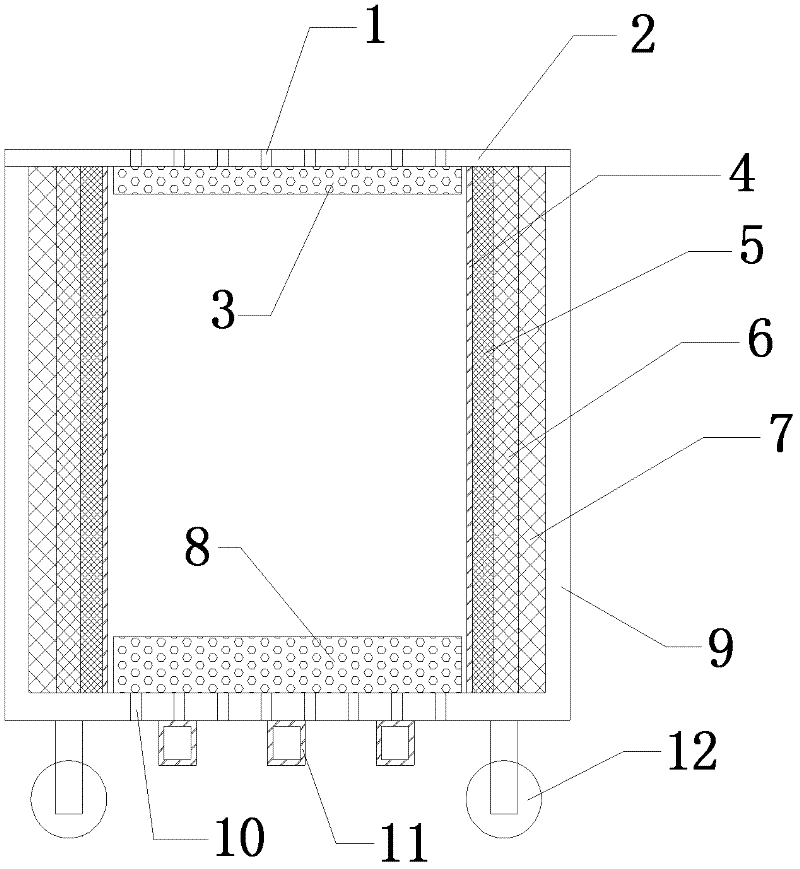

Pressure relief type explosion-proof tank

The invention discloses a pressure relief type explosion-proof tank, which comprises a tank body and a tank bottom, wherein a cover plate with cover plate pressure relief holes is arranged on the top of the tank body; the tank body consists of an inner cylinder and an outer cylinder; the outer cylinder consists of an outer cylinder wall and an outer cylinder buffer layer arranged in the outer cylinder wall; the tank bottom is provided with an outer cylinder wall bottom plate; a buffering base plate is arranged on the upper part of the outer cylinder wall bottom plate, on the inner side of the outer cylinder buffer layer and on the lower part of the inner cylinder; outer cylinder wall pressure relief holes are formed on the outer cylinder wall bottom plate; the inner cylinder consists of an inner cylinder wall and an inner cylinder buffer layer in the inner cylinder wall; a buffering lining plate is arranged on the lower part of the cover plate and on an inner side of the inner cylinder buffer layer; the buffering lining plate and the buffering base plate are made of porous foam metals; the inner cylinder buffer layer and the outer cylinder buffer layer are made of closed pore foam metals; and the thickness of the buffering base plate is greater than that of the buffering lining plate. By the explosion-proof tank, fragments produced through explosion can be prevented from flying out of the tank so as not to damage surrounding equipment and crowd, the internal pressure of the tank body can be reduced through pressure relief, and the safety performance of the explosion-proof tank is improved.

Owner:XI AN JIAOTONG UNIV

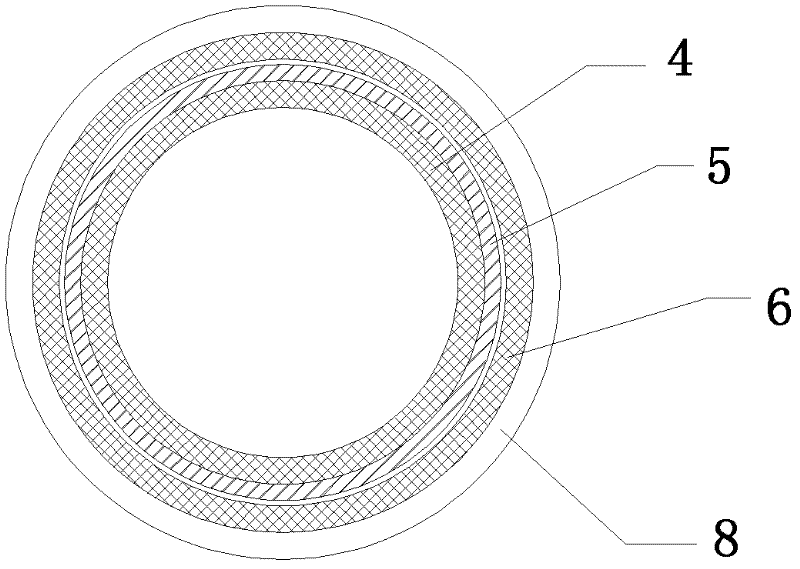

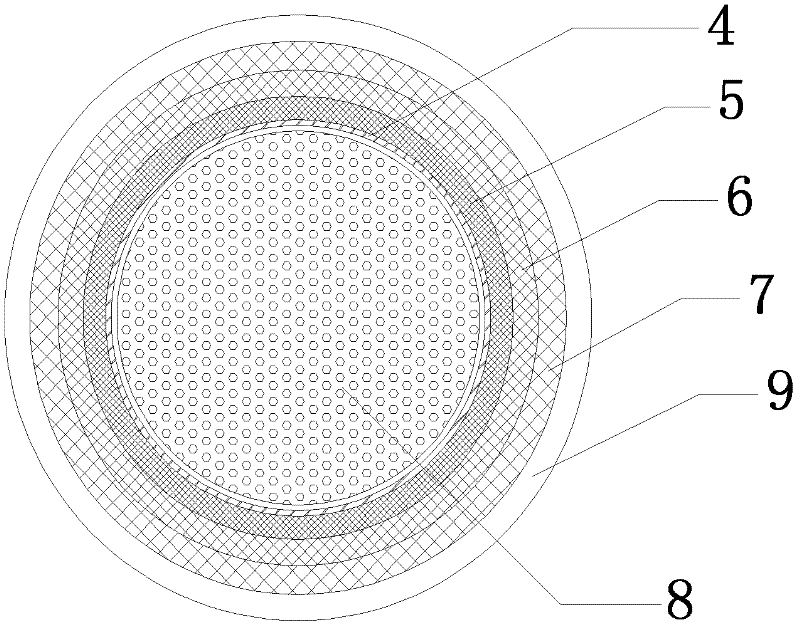

Gradient sandwiched anti-explosion pot

InactiveCN102538606AAvoid crack failureGood compression energy absorption performanceBlastingMetallic materialsMaterials science

The invention discloses a gradient sandwiched anti-explosion pot, comprising a pot body and a pot bottom, wherein the pot body is composed of an inner barrel, an inner buffer layer, a middle buffer layer, an outer buffer layer and an outer barrel; the inner buffer layer, the middle buffer layer and the outer buffer layer are made of closed cell foam metals and the density of the closed cell foam metal from the inner buffer layer, the middle buffer layer to the outer buffer layer is reduced gradually; a cover plate with a pressure relief hole is formed at the top of the pot body; the pot bottom is a bottom plate of the outer barrel; buffer base plates are installed on the upper part of the bottom plate of the outer barrel and the inner part of the inner barrel; a pressure relief hole is formed on the bottom plate of the outer barrel; buffer lining plates are installed at the lower part of the cover plate and the inner part of the inner barrel; the buffer lining plate and the buffer base plates are made of opening-hole foam metals; the thickness of the buffer base plate is more than that of the buffer lining plate; the thickness of the outer barrel is more than that of the inner barrel; the multilayer foam metal of which the density is reduced gradually from inside to outside is used as a sandwiched layer to improve the anti-explosion performance of the anti-explosion pot.

Owner:XI AN JIAOTONG UNIV

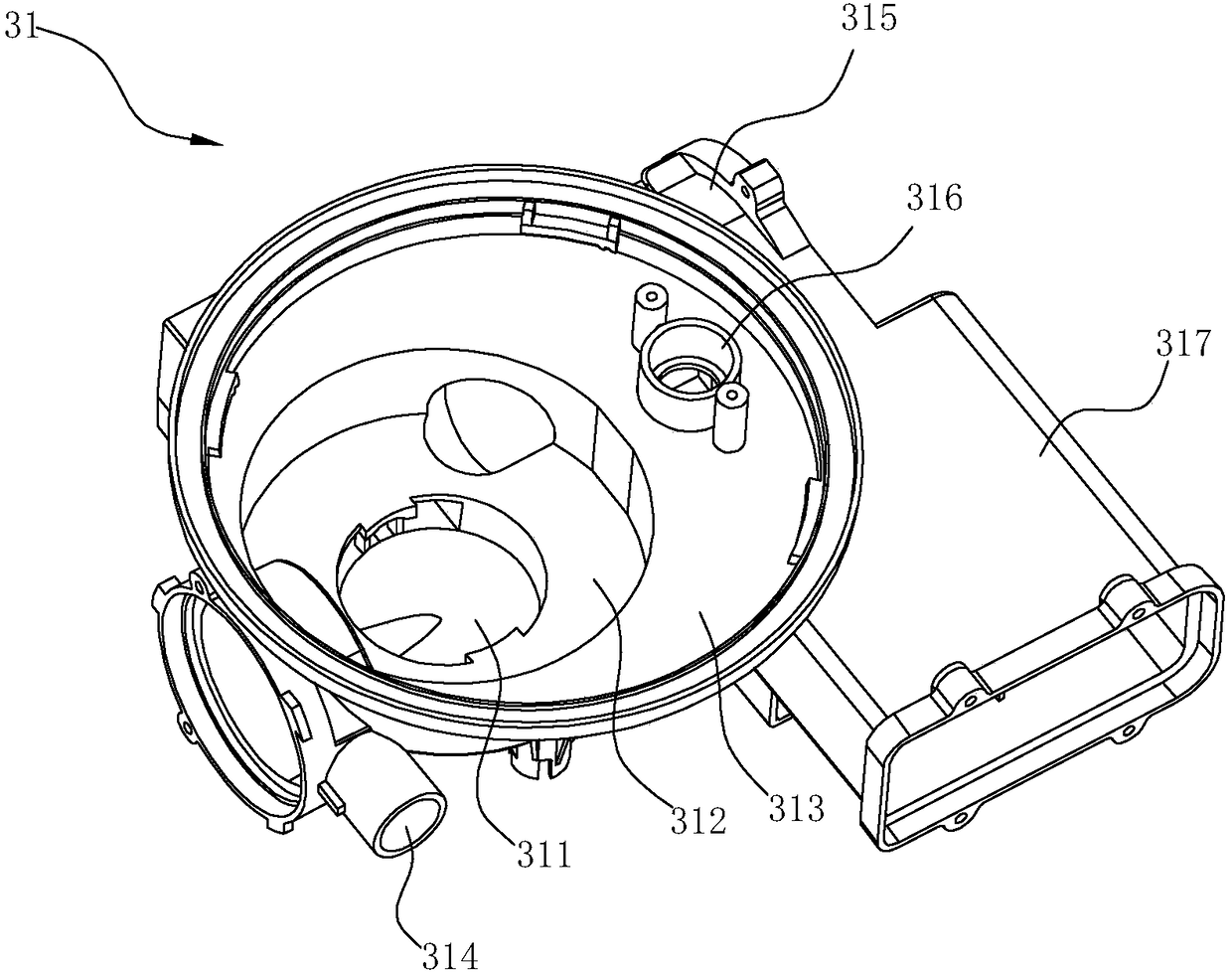

Method for improving reverse engineering accuracy of impeller part

ActiveCN103049596AImprove reverse engineering accuracyShorten the timeSpecial data processing applicationsImpellerPoint cloud

The invention provides a method for improving reverse engineering accuracy of an impeller part. The method includes: (A), selecting samples, (B), building a coordinate system of the samples; (C), scanning the samples into point cloud data Pa; (D), building a coordinate system on a three-coordinate measuring machine; (E) sequentially comparing parameters of dimension errors, strength and quality of a three-dimensional solid model with three data of the samples, and using the three-dimensional solid model nearest to the samples as the final model; and (F) exporting the three-dimensional solid model selected in the step (E), and exporting two-dimensional drawings. By means of the method, structure and dimension of impeller parts with high accuracy can be obtained under the condition that the samples cannot be damaged, the two-dimensional drawings of the impeller parts can be obtained for manufacturing and processing of products, the impeller profile error can be controlled to be lower than 0.08mm, and the errors of other dimensions can be controlled to be lower than 0.02mm. The impeller manufactured by the method is high in fidelity and can meet the using requirements.

Owner:SICHUAN AEROSPACE ZHONGTIAN POWER EQUIP CO LTD

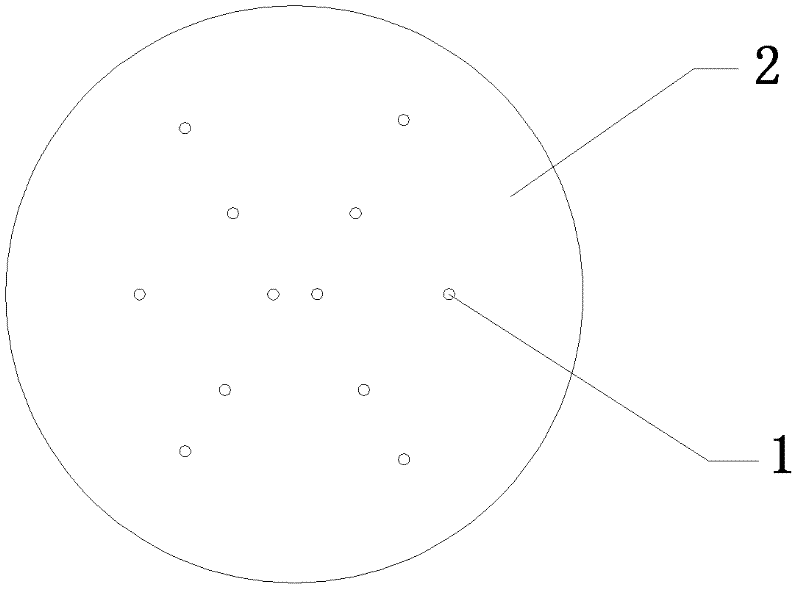

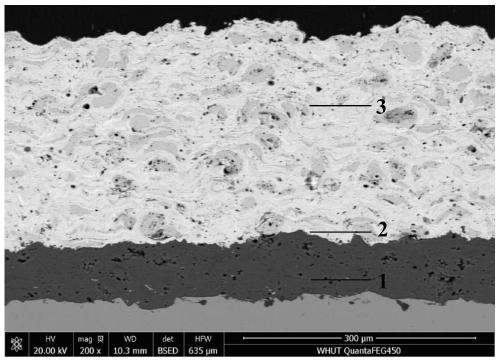

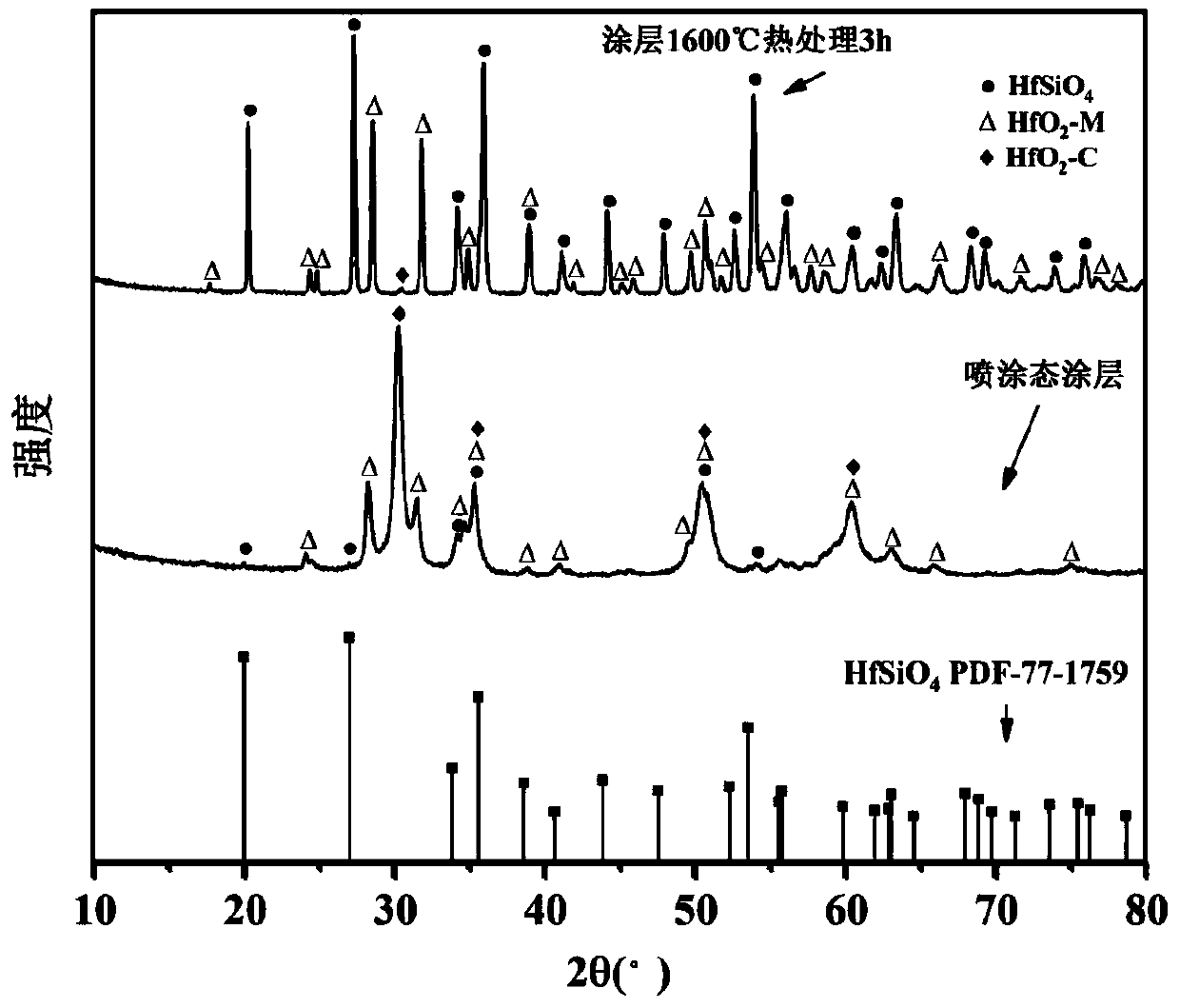

Hafnium silicate environment barrier coating for ceramic-based composite material matrix and preparation method thereof

The invention provides a hafnium silicate environment barrier coating for a ceramic-based composite material matrix and a preparation method thereof. The preparation method comprises the following steps: (1) mixing HfO2 and SiO2, carrying out wet mixing and ball milling on a ball mill, drying, grinding, sieving, sintering, and carrying out a high-temperature solid-phase reaction; (2) after the high-temperature solid-phase reaction is finished, adding deionized water for slurry preparation, then performing ball milling, and performing spray granulation to obtain an HfSiO4 powder material; (3) firstly spraying a Si layer on the surface of a ceramic-based composite matrix as a priming coat, and then spraying the HfSiO4 powder material on the surface of the priming coat as a surface layer to form a multi-layer coating; and (4) carrying out a heat treatment on the multi-layer coating to obtain the environmental barrier coating. Due to the added heat treatment, the crystallinity of the HfSiO4 surface layer is improved, the binding force of each layer of the coating is better, the stability is higher, and the water and oxygen resistance of the environment barrier coating is greatly improved. The provided preparation method is simple and easy to control, and is easy for industrial production and application.

Owner:WUHAN UNIV OF TECH

Electromagnetic flanging and hemming apparatus and method

InactiveUS7290318B2Avoid crack failureImprove plasticityAutomatic control devicesAssembly machinesElectromagnetic shieldingEngineering

Apparatus and methods are disclosed for applying electromagnetic force (EMF) to flanging and hemming metal panels to form a hemmed panel assembly. First and second apparatus and method steps use a translating EMF coil to flange a sheet and to finish a hem by progressive non-planar bending. An alternate embodiment uses EMF hemming for difficult-to-hem portions of a flange and optionally precedes this with conventional hemming of straight hem portions.

Owner:RES IN MOTION LTD +1

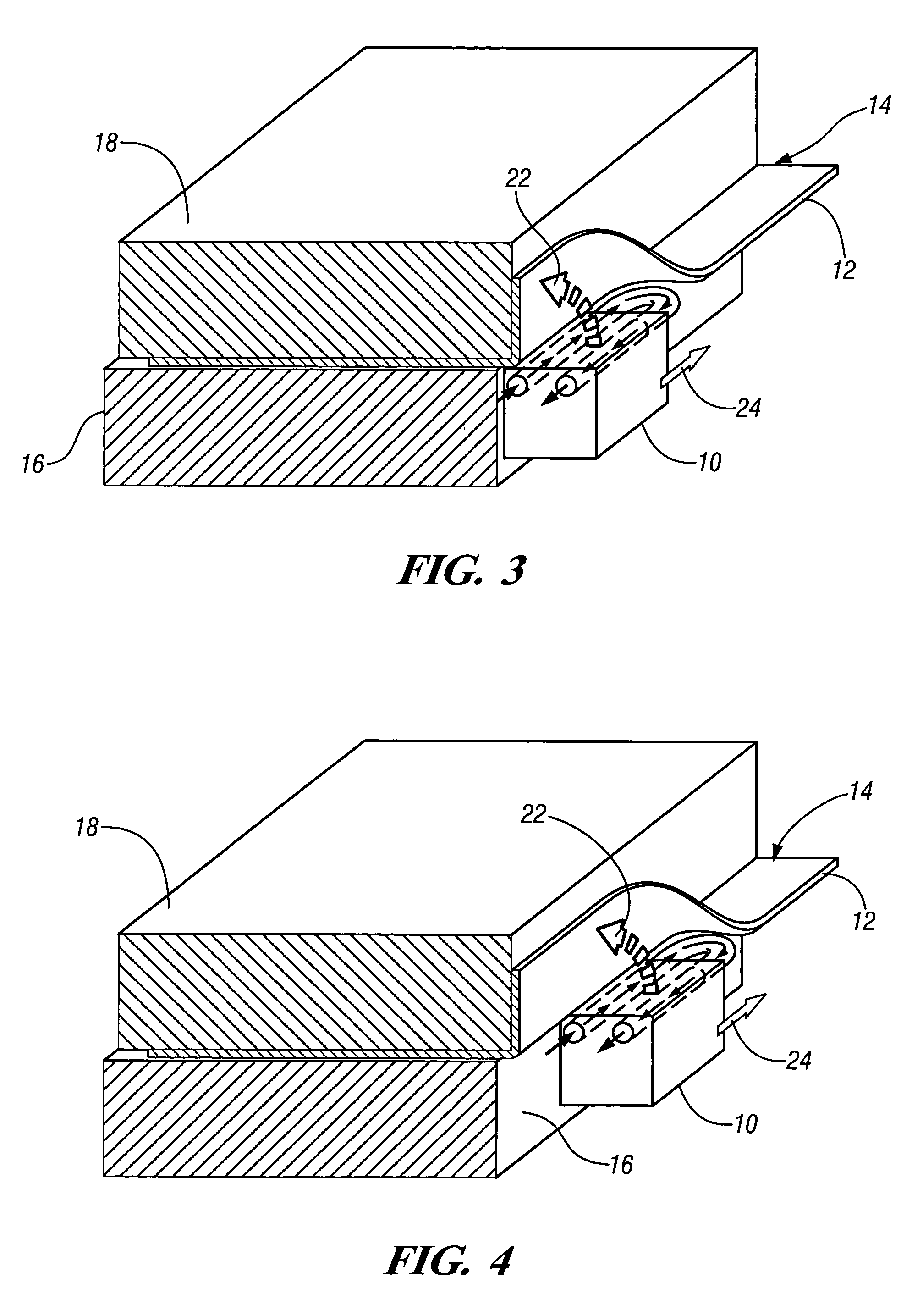

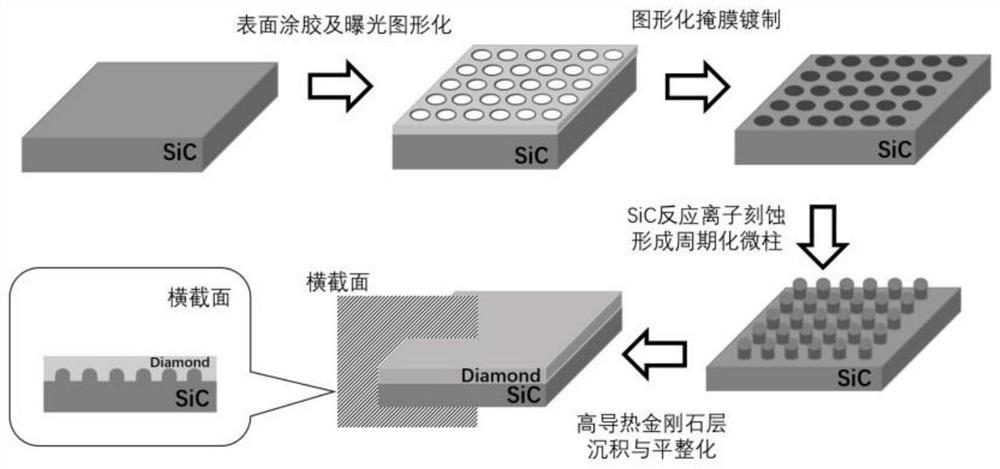

Preparation method of high-thermal-conductivity diamond reinforced silicon carbide substrate

ActiveCN113571409AImprove growth efficiencyIncrease contact areaSemiconductor/solid-state device manufacturingEvaporation (deposition)Semiconductor materials

The invention discloses a preparation method of a high-thermal-conductivity diamond enhanced silicon carbide (SiC) substrate, and belongs to the field of semiconductor material preparation. According to the invention, the method comprises the steps: patterning the carbon polar surface of SiC through gluing, photoetching and developing; performing electron beam evaporation or magnetron sputtering on a metal mask; after the photoresist is removed, performing reactive ion etching, mask removal and secondary ion etching on the SiC with the periodically arranged metal mask to obtain the micro-column array; growing a diamond layer through a microwave plasma chemical vapor deposition technology; after the diamond layer completely covers the micro-column and has a certain thickness, performing laser scanning leveling and subsequent precision polishing to obtain the high-thermal-conductivity diamond enhanced SiC substrate. The heat conduction efficiency is improved by increasing the effective contact interface area of diamond and SiC, and meanwhile, insufficient bonding force and local defect expansion of a single plane interface are effectively avoided. And a foundation is laid for obtaining SiC / Diamond and GaN / SiC / Diamond wafers for high power and high frequency by thinning a SiC silicon polar surface and depositing GaN on the surface of the SiC silicon polar surface at high temperature in the future.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for preparing super-high temperature anti-oxidation composite material

The invention discloses a method for preparing a super-high temperature anti-oxidation composite material and belongs to the technical field of aerospace materials. The method comprises the following steps: firstly, performing washing, combing, net overlapping and puncturing on a polyacrylonitrile pre-oxidized fiber in sequence so as to obtain a felt; further performing carbonization and activation with water steam so as to obtain a polyacrylonitrile-based activated carbon fiber felt; further performing electrochemical oxidation treatment, and mixing and soaking with ball-milling slurry consisting of aluminum nitride, boron nitride, absolute ethyl alcohol and organic silicon; further performing pre-sintering in the presence of argon, performing secondary soaking, and performing hot-pressing sintering molding in the presence of argon, thereby obtaining the super-high temperature anti-oxidation composite material. The product prepared by using the method is high in density and excellent in sintering erosion resistance and high-speed air flow impact resistance, is capable of meeting use requirements of high-temperature conditions of 2000 DEG C or greater, and has wide application prospects.

Owner:常州武城服饰有限公司

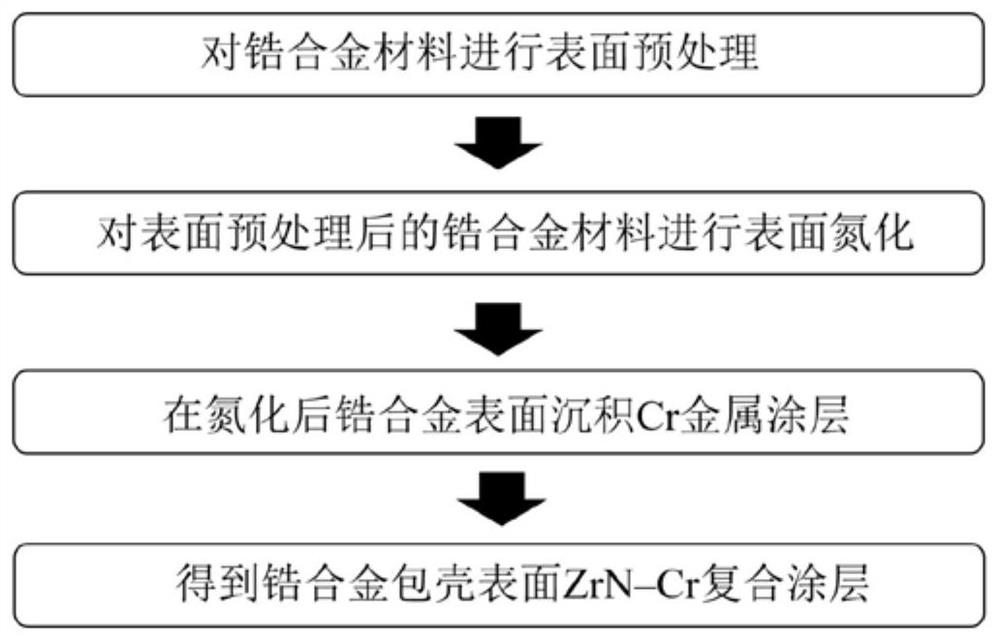

Coating for outer surface of zircalloy cladding tube and manufacturing method

PendingCN113293374AImprove corrosion resistanceImprove bindingOptical rangefindersNuclear energy generationThermal dilatationQuenching

The invention discloses a coating for the outer surface of a zircalloy cladding tube and a manufacturing method. According to the coating, a zircalloy cladding tube base body is sequentially coated with a ZrN transition layer and a Cr working layer; the thickness of the ZrN transition layer is 0.12 micron to 2 microns; and the main component of the Cr working layer is yttrium oxide doped stable zirconium oxide working layer. According to the method, mutual diffusion of elements between the Cr working layer and the zirconium alloy base body can be effectively inhibited, and mutual diffusion of the elements between the Cr working layer and the base body at high temperature is avoided; and under the quenching condition, the ZrN layer generates twin crystals under the stress effect, stress generated due to mismatching of thermal expansion coefficients between the coating and the base body can be effectively released, the binding force of the coating and the base body is enhanced, and cracking and failure of the coating are avoided.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

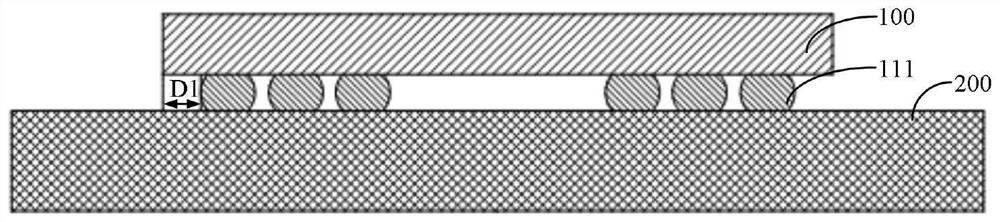

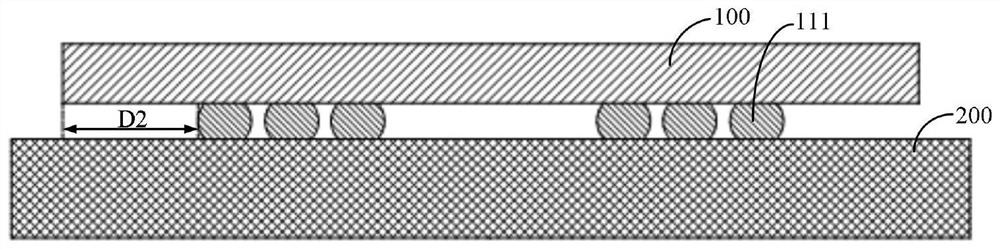

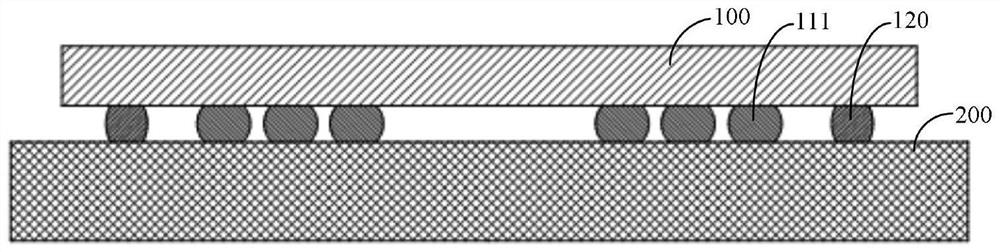

Flexible outer electrode of chip component and manufacturing method thereof

ActiveCN110838383AImprove efficiencyLow costConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersOrganic solventMacromolecule

The invention discloses a flexible outer electrode of a chip component and a manufacturing method thereof. The manufacturing method comprises the following steps of: mixing thermoplastic polymer spiral resin with silver powder, an organic solvent, a thickening agent and a dispersing agent to prepare flexible electrode slurry, coating the flexible electrode slurry on an extraction electrode part ofa chip component, drying and curing to prepare an outer electrode, and plating a metal layer to prepare the integral flexible outer electrode with weldability. The manufactured flexible outer electrode can effectively eliminate damage and cracking of a chip component body, an electrode and a welding spot of the chip component under bending, vibration or stress impact of a substrate, is remarkablein effect, free of pollution, low in cost, high in efficiency and easy to operate, and meets various chip component products.

Owner:SHENZHEN SUNLORD ELECTRONICS

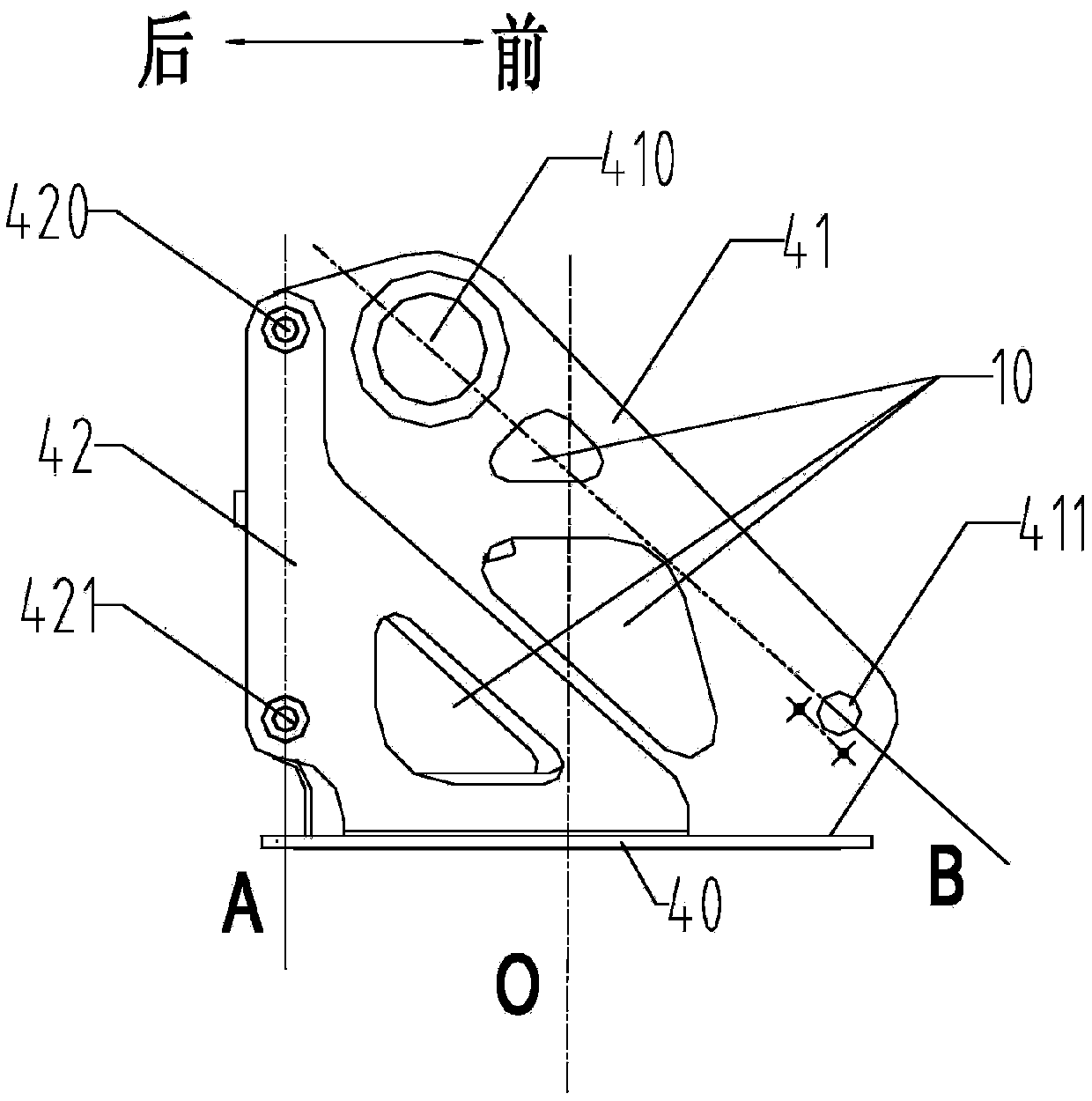

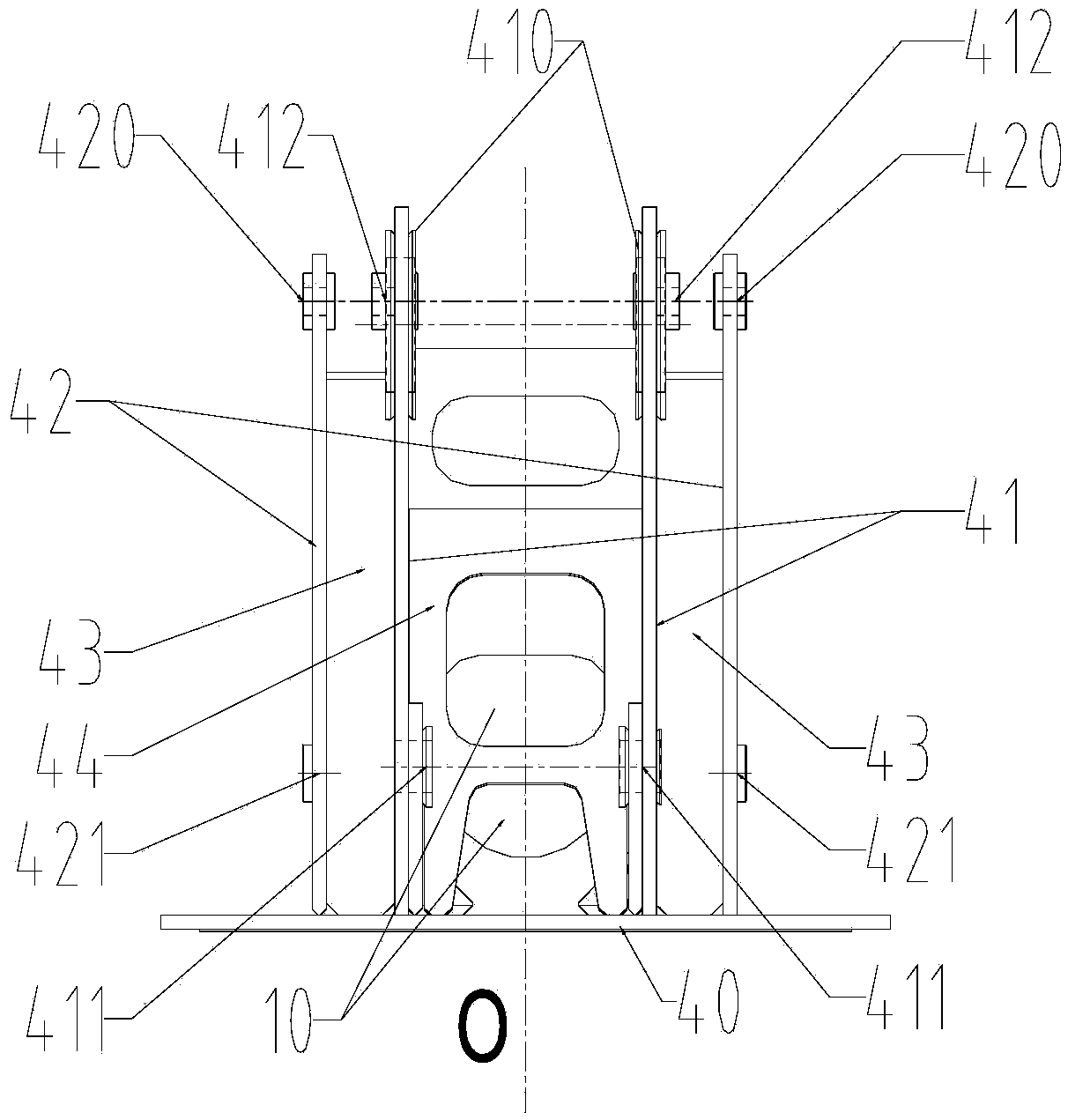

Rotary table and engineering machine

ActiveCN105366572AReduce local stress concentrationReduce tensionMechanical machines/dredgersCounterweightsStress concentrationEngineering

The invention discloses a rotary table and an engineering machine. The rotary table comprises a baseplate, a first vertical plate and a second vertical plate; the first vertical plate and the second vertical plate are mounted on the baseplate; a first pin shaft hole and a second pin shaft hole are formed in the first vertical plate; a third pin shaft hole and a fourth pin shaft hole are formed in the second vertical plate. A counter weight may be mounted on the rotary table, and therefore, the problem of stress concentration of the rotary table is eased, occurring of faults of bolt breakage and partial weld joint cracking is prevented and the safety performance is improved.

Owner:HUNAN SANY ROAD MACHINERY

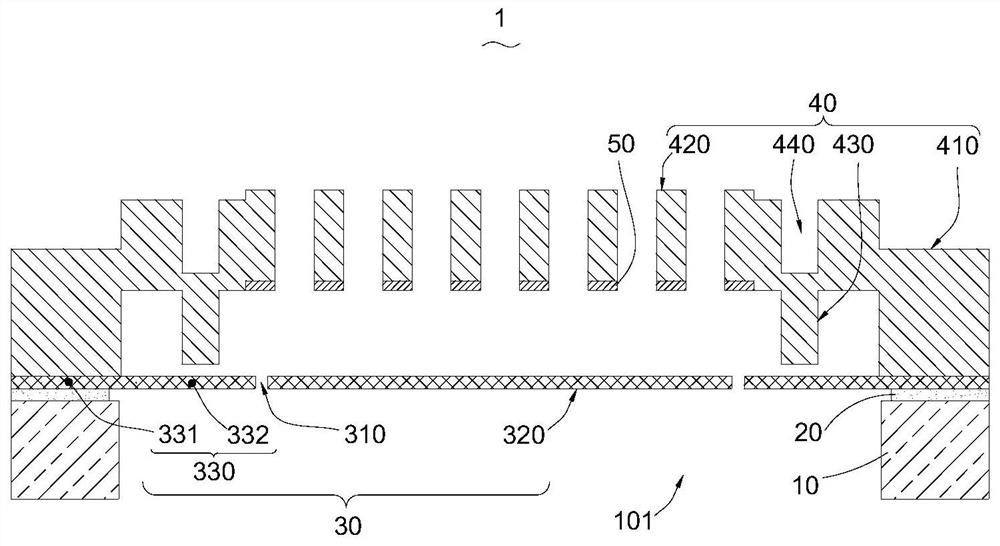

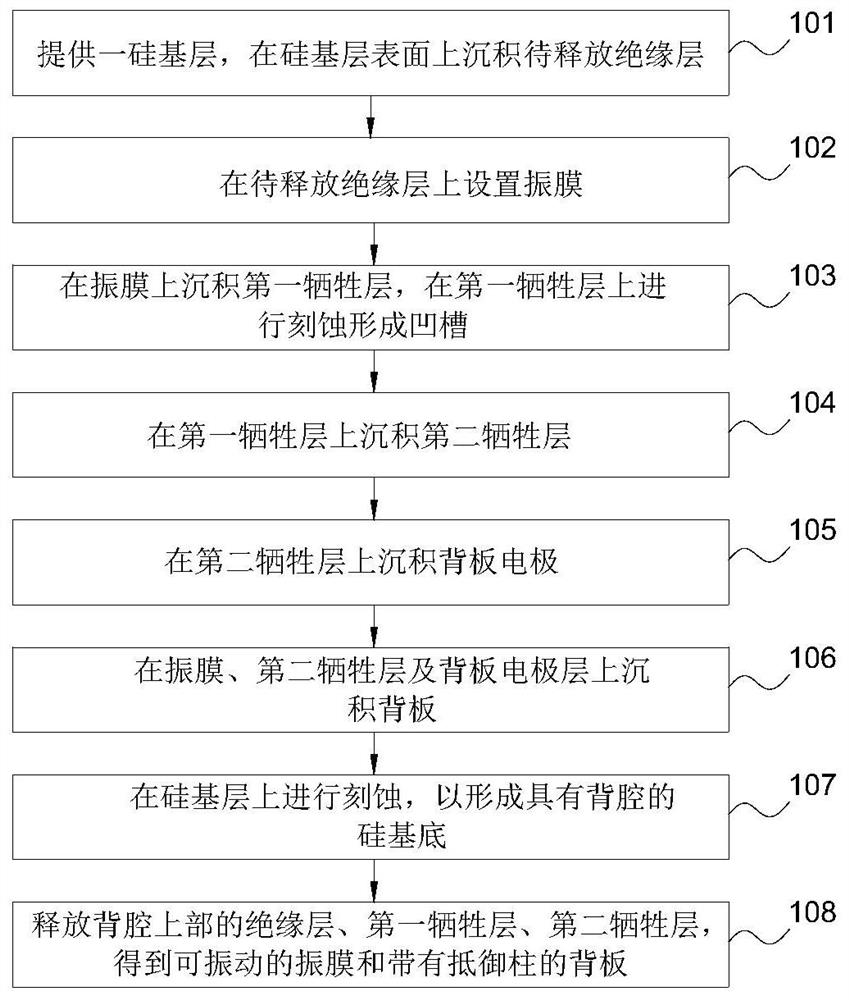

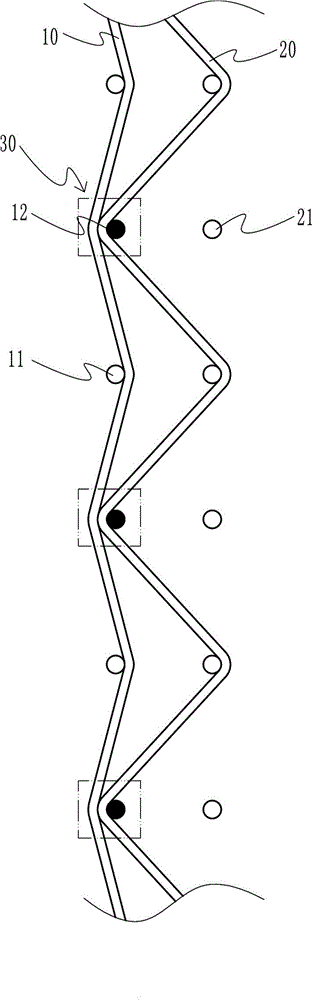

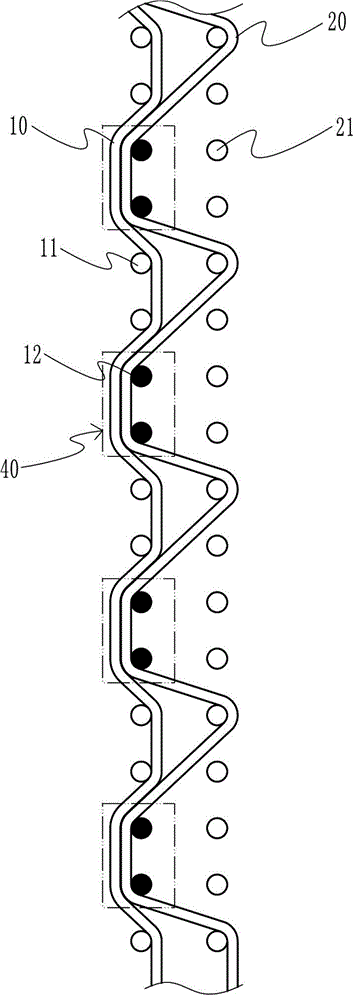

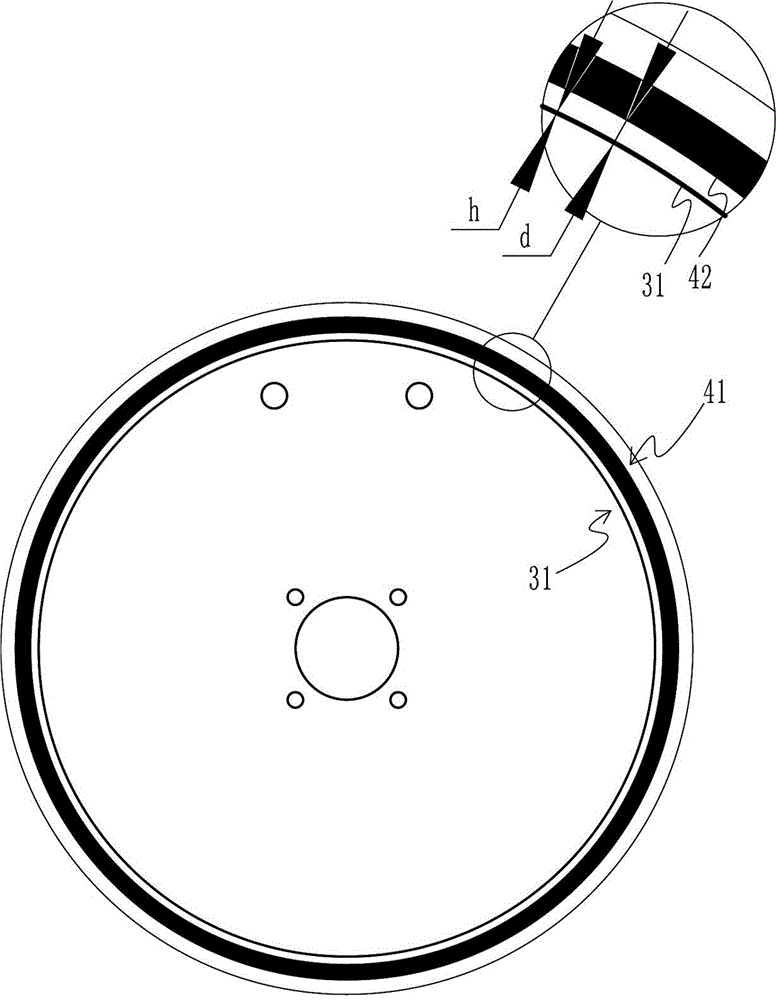

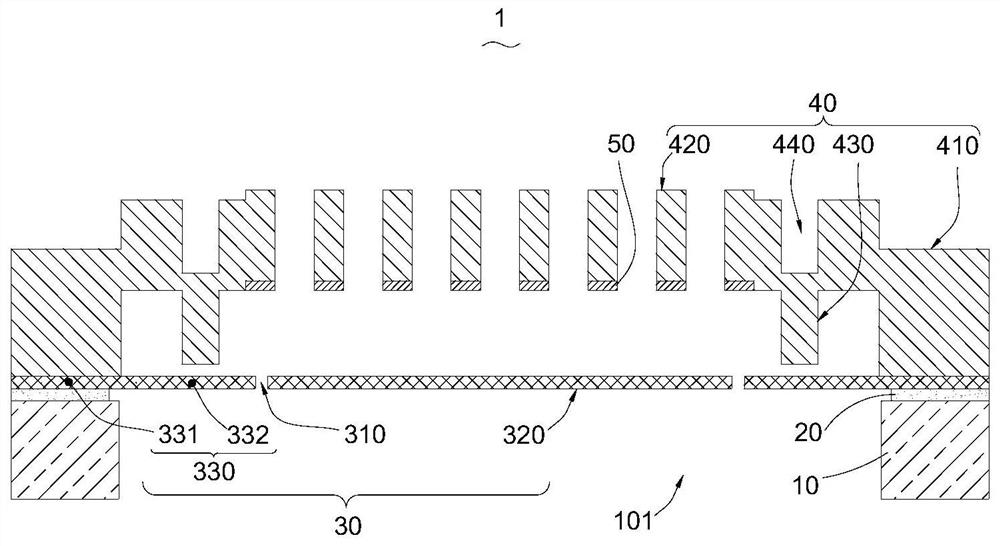

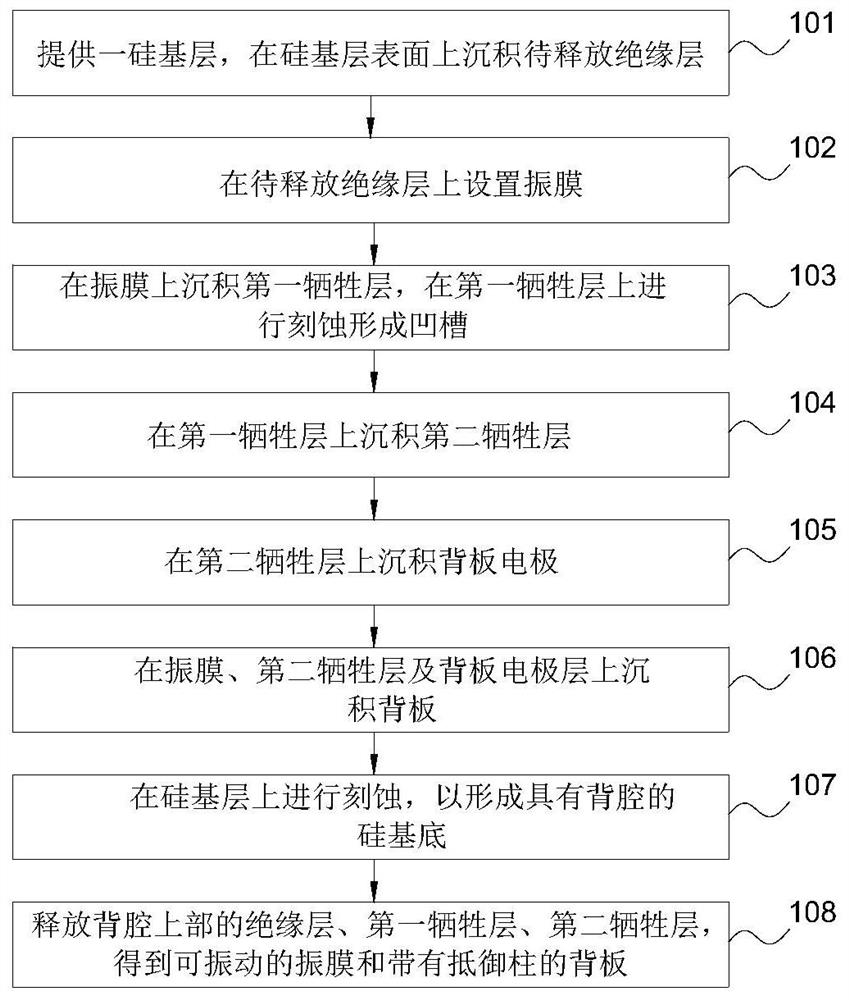

Silicon-based microphone and method for manufacturing same

ActiveCN112689229AAvoid deformationAvoid crack failureElectrostatic transducer microphonesPlane diaphragmsEngineeringMechanical engineering

The invention provides a silicon-based microphone, which comprises a silicon substrate with a back cavity, a vibrating diaphragm and a back plate, the vibrating diaphragm and the back plate are arranged above the silicon substrate, and the vibrating diaphragm comprises an inner vibrating diaphragm and an outer vibrating diaphragm which is positioned at the periphery of the inner vibrating diaphragm and is arranged at an interval with the inner vibrating diaphragm. The back plate comprises a back plate supporting body fixedly connected with the outer vibrating diaphragm, a back plate middle body supported by the back plate supporting body and located above the back cavity and a resisting column extending out from the back plate middle body towards the vibrating diaphragm, and when the vibrating diaphragm vibrates, the outer vibrating diaphragm can deform to abut against the resisting column. The silicon-based microphone provided by the invention has the advantage that the outer vibrating diaphragm is not easy to break under the action of large sound pressure.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

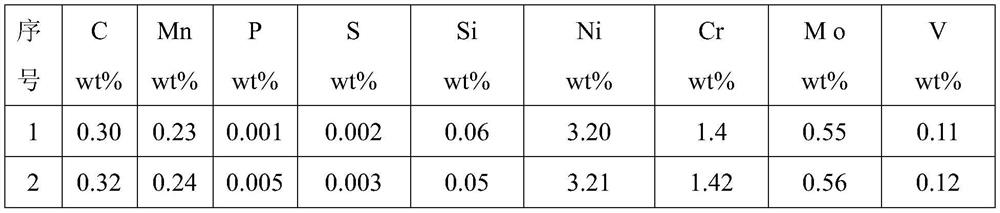

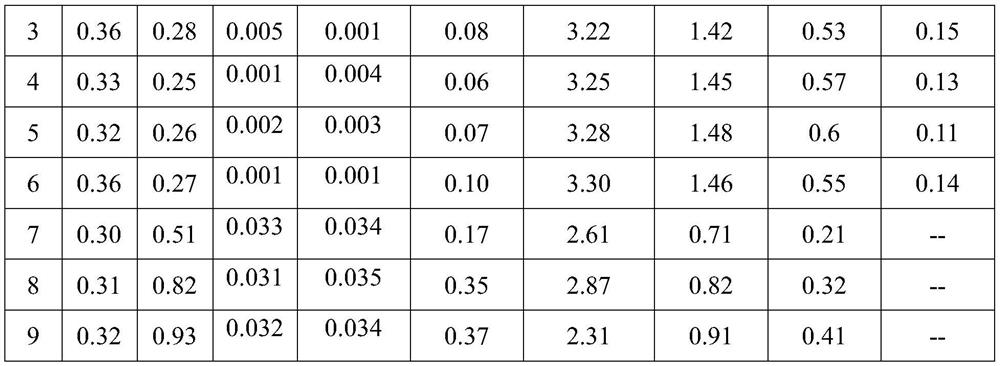

High-strength alloy structural steel for hydraulic cylinder of fracturing pump and preparation method thereof

The invention provides high-strength alloy structural steel for a hydraulic cylinder of a fracturing pump. The steel comprises the following chemical elements in percentage by weight: 0.30-0.36% of C,0.23-0.28% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.05-0.10% of Si, 3.20-3.30% of Ni, 1.40-1.50% of Cr, 0.55-0.60% of Mo, 0.11-0.15% of V, less than or equal to1.5 ppm of H, less than or equal to 112 ppm of O, less than or equal to 70-120 ppm of N and the balance Fe. Meanwhile, the invention further provides a preparation method of the structural steel, thestructural steel obtained through the preparation method is used for manufacturing a hydraulic cylinder of a fracturing pump, under the severe working condition of shale gas exploitation, the servicelife of the product can be prolonged, the use cost can be reduced, the quality is stable and reliable, unpredictable cracking failure and production accidents in the operation process are avoided, andthe requirements of oil-gas field deep well fracturing and shale gas exploitation are met.

Owner:江苏艾福泰克能源装备有限公司

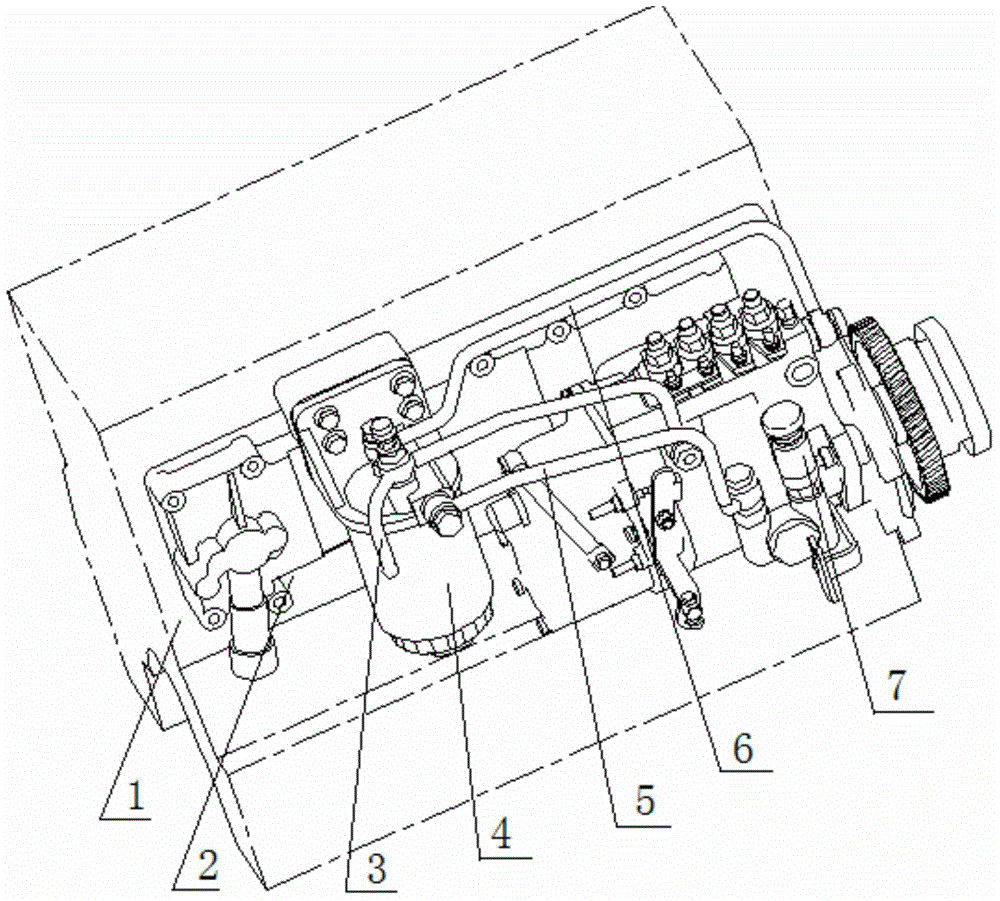

Centrally installed structure of diesel engine fuel filter

InactiveCN103953480AFlexible layoutIncrease contact areaMachines/enginesLiquid fuel feedersJoint surfaceInjection pump

The invention discloses a centrally installed structure of a diesel engine fuel filter. The technical scheme is as follows: an engine oil cooler is fixedly arranged at the side of a diesel engine cylinder body, and an engine oil cooler cover is cast with a flange surface for installing the fuel filter; the fuel filter with a mounting flange is fixedly arranged on an outer cover of the engine oil cooler. An oil return pipe assembly of the fuel filter and an oil inlet pipe assembly of the fuel filter are respectively connected with an injection pump. The injection pump is positioned at the front end of the diesel engine, and one end of an injection pump oil inlet pipe is connected with the fuel filter; the other end of the injection pump oil inlet pipe is connected with the injection pump. With the structure, the control flexible axle of a vehicle is conveniently arranged, and meanwhile, the length of a fuel pipeline is shortened by about one third. Because the fuel filter is directly arranged on the engine oil cooler cover without a cantilever beam, the contact areas of two joint surfaces are large, the vibration amplitude is small, the shaking problem of the fuel filter is significantly improved, and the centrally installed structure is suitable for assembly systems of a plurality of diesel engine fuel filters.

Owner:东风朝阳朝柴动力有限公司

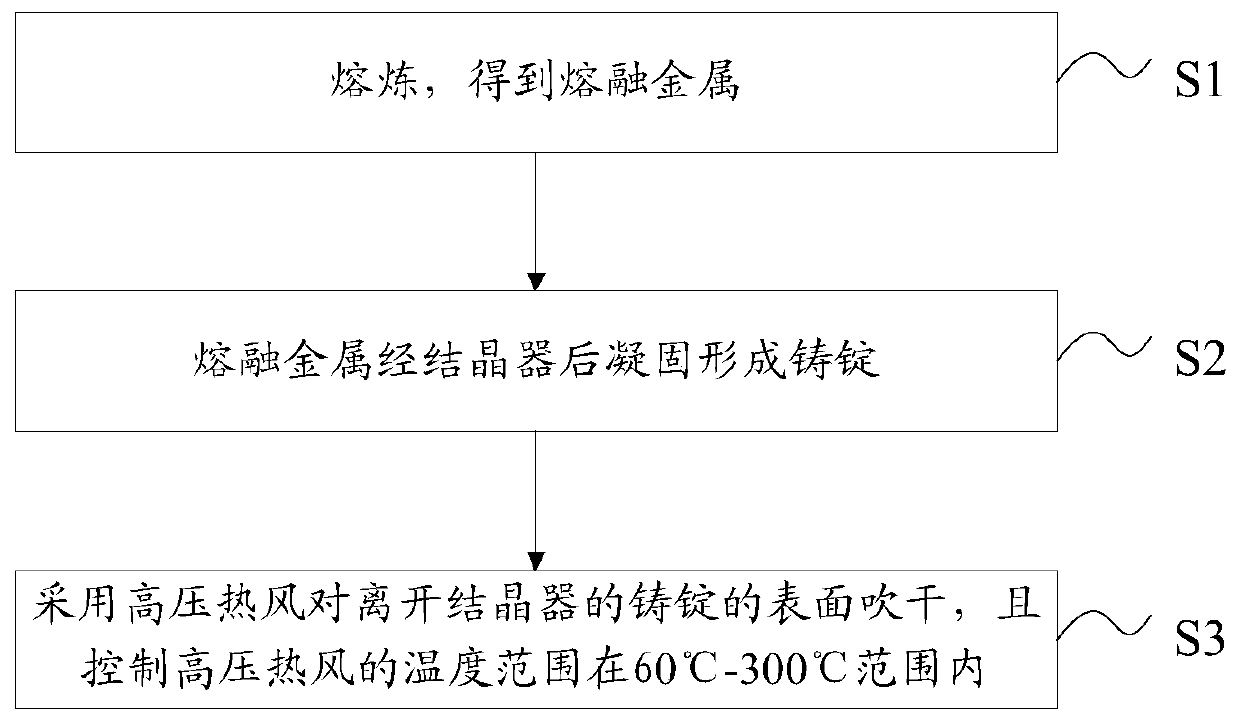

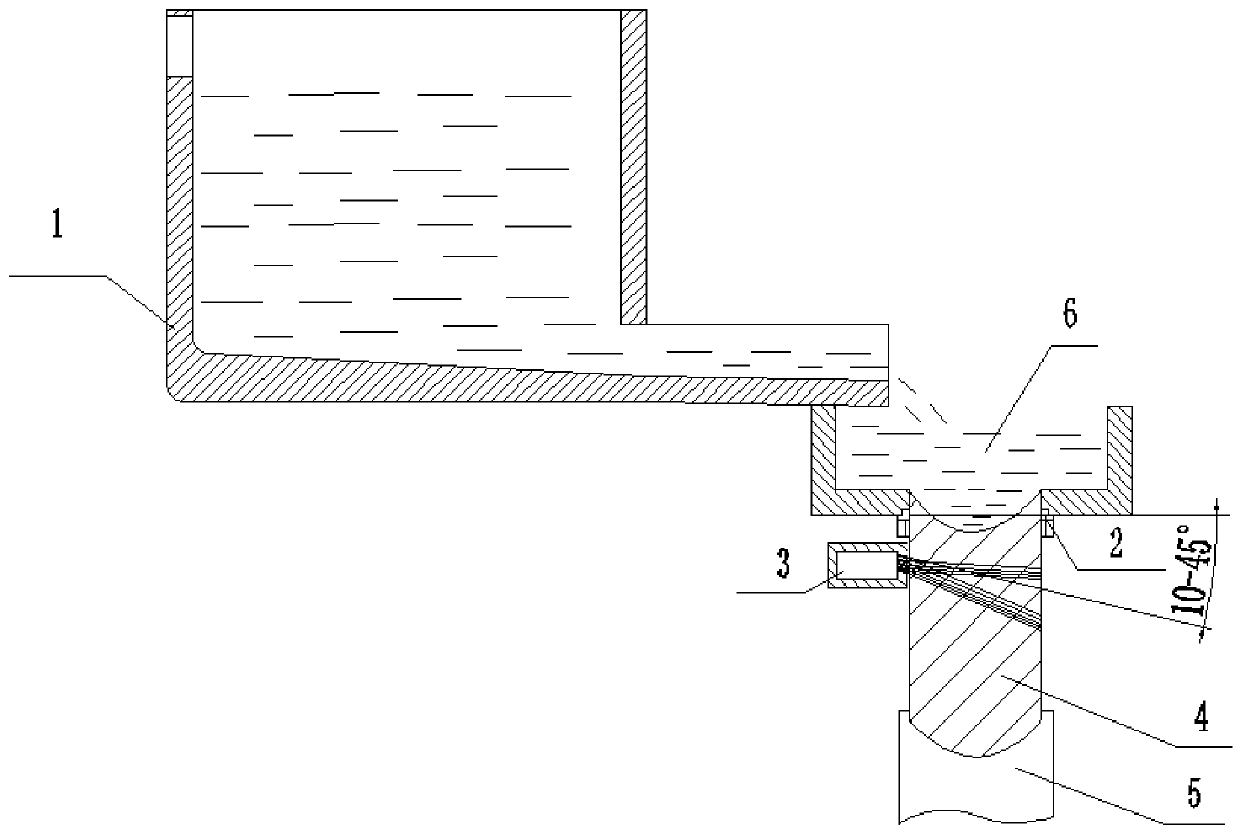

Casting process and casting system

The invention discloses a casting process. The casting process comprises steps of smelting to obtain molten metal; solidifying the molten metal through a crystallizer to form a cast ingot; adopting high-pressure hot air to blow-dry a surface of the cast ingot leaving the crystallizer, and controlling a temperature range of the high-pressure hot air within the range of 60-300 DEG C. The invention further discloses a casting system which comprises a smelting device used for obtaining the molten metal, the crystallizer used for solidifying the molten metal into the cast ingot, and a high-pressureair heater arranged at an outlet of the cast ingot of the crystallizer, wherein the temperature of hot air outputted by the high-pressure air heater ranges from 60-300 DEG C. By applying the castingprocess and the casting system, the water on the surface of the cast ingot is blow-dried by adopting the high-pressure hot air, and the high-pressure hot air cannot be damaged due to contact abrasionwith the cast ingot, so reliability is higher, and cast ingot cracking failure caused by water residue on the surface of the cast ingot is effectively avoided.

Owner:SOUTHWEST ALUMINUM GRP

Abrasion-resistant scratch-proof coating and preparation method thereof

The invention discloses abrasion-resistant scratch-proof coating and a preparation method thereof. The coating is prepared from the following components in parts by weight: 100-120 parts of a film forming agent, 30-50 parts of filler, 25-45 parts of a diluting agent, 1-5 parts of a defoaming agent and 30-50 parts of a curing agent, wherein the filler is mixture of SiC and sodium benzenesulfonate coated polymer. The coating has the characteristics of large hardness, abrasion resistance, scratch resistance, strong adhesion and the like, has the hardness to be over 6H and adhesion to be zero grade, and can avoid the problems of coating cracking, peeling, falling and the like, and improve the coating construction performance, so that the technical problems of poor filler dispersibility, low hardness of coating, easily scratched coating and poor adhesion can be solved. The preparation method is simple and easily controllable in operation, can easily realize industrial production, and has anexcellent application prospect.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

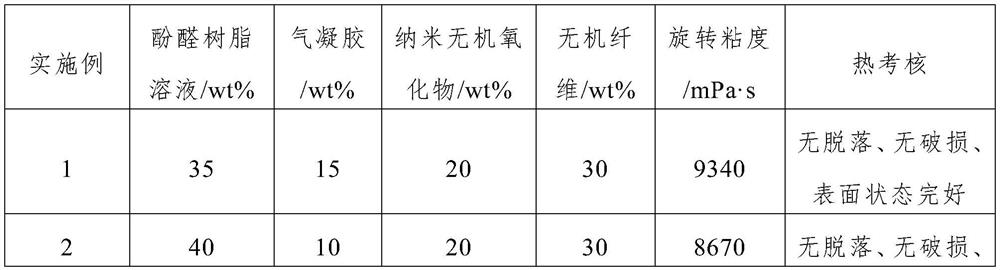

Repair coating for aerogel surface defects as well as preparation method and application of repair coating

The invention provides an aerogel surface defect repairing coating as well as a preparation method and application thereof, the repairing coating is applied to a to-be-repaired surface of a phenolic aerogel material, and the repairing coating comprises the following components in percentage by mass: 10-70% of a phenolic resin solution, 10-30% of aerogel, 10-30% of nano inorganic oxide and 10-30% of inorganic fiber. The repair coating provided by the invention can be used for repairing defects of phenolic aerogel materials, is simple to operate, has excellent matching property with the phenolic aerogel materials, and has excellent maintainability and ablation resistance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Glass-flake mastic resin special for flue gas desulfurization

InactiveCN108410327AImprove flexibilityAvoid product cracking and failureAnti-corrosive paintsEpoxy resin coatingsPliabilityChemistry

The invention discloses glass-flake mastic resin special for flue gas desulfurization and belongs to the technical field of chemical coating. The glass-flake mastic resin comprises matrix resin, modified glass flakes, modified sepiolite, a coupling agent, a defoaming agent and an accelerant, wherein the matrix resin is formed by phenolic aldehyde epoxy type vinyl ester resin and modified unsaturated polyester resin. A preparation method of the glass-flake mastic resin includes: mixing the matrix resin and the modified sepiolite, shearing and dispersing to obtain a dispersed material, adding the dispersed material, the modified glass flakes, the coupling agent, the defoaming agent and the accelerant into a kneading machine, kneading, and performing vacuum defoaming, discharging and packaging to obtain the glass-flake mastic resin special for flue gas desulfurization. The prepared glass-flake mastic resin is excellent in toughness, thermal shock resistance and corrosion resistance.

Owner:江苏新亿源环保科技有限公司

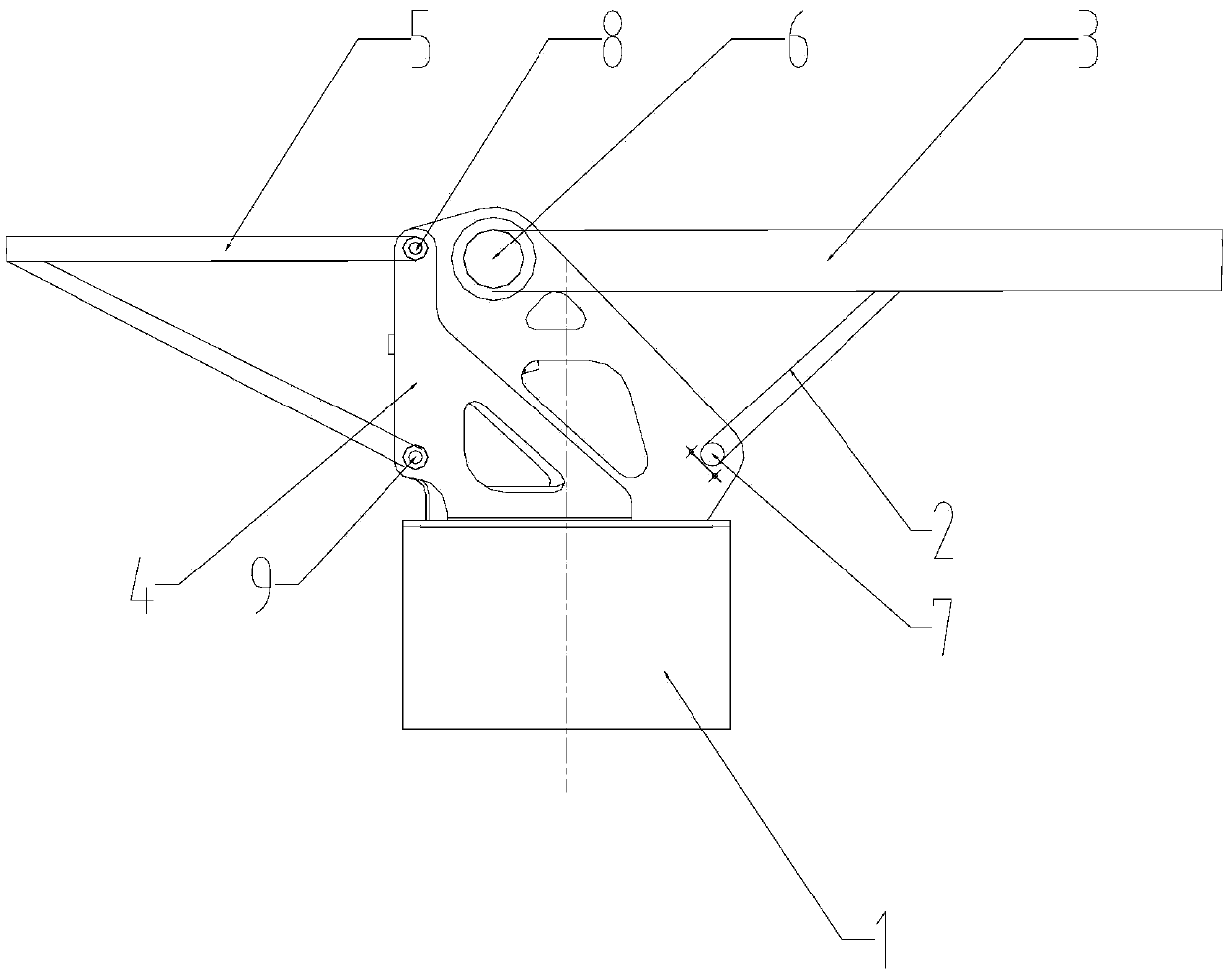

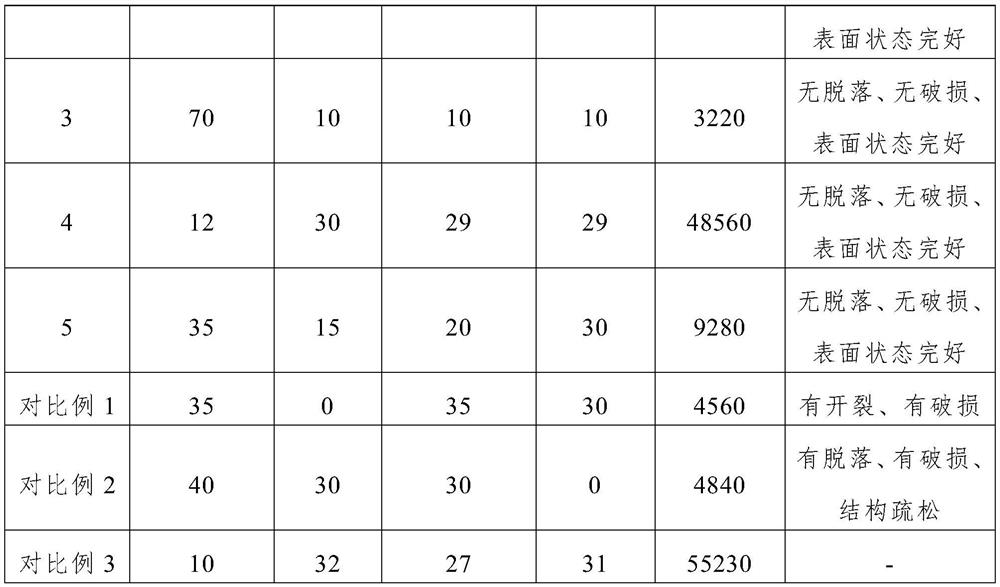

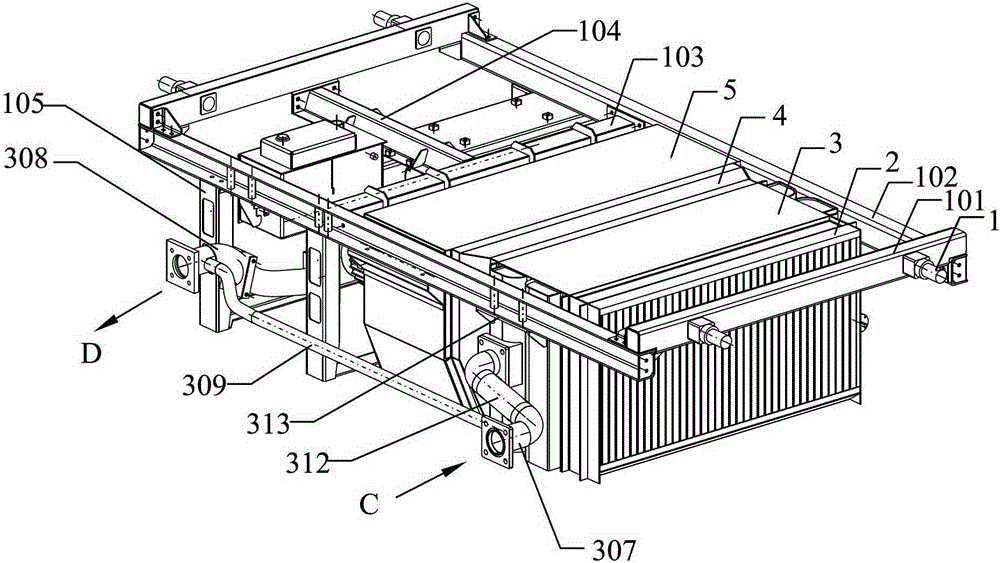

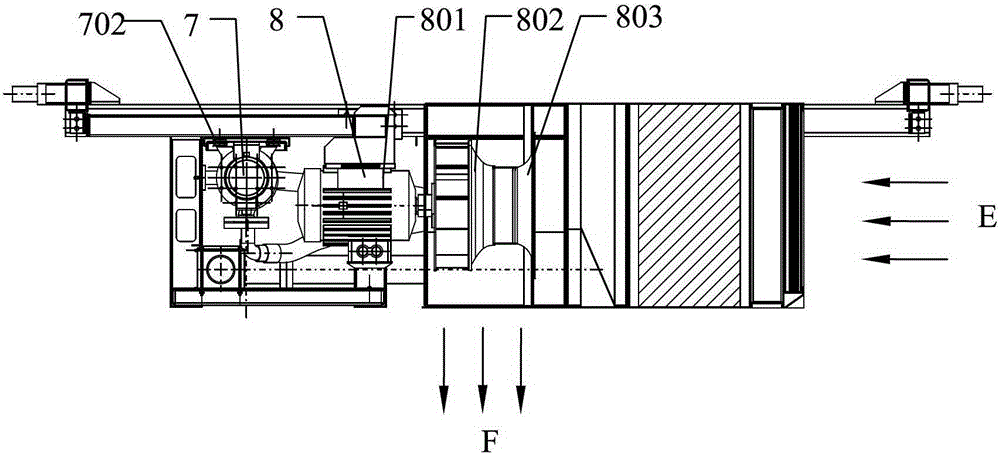

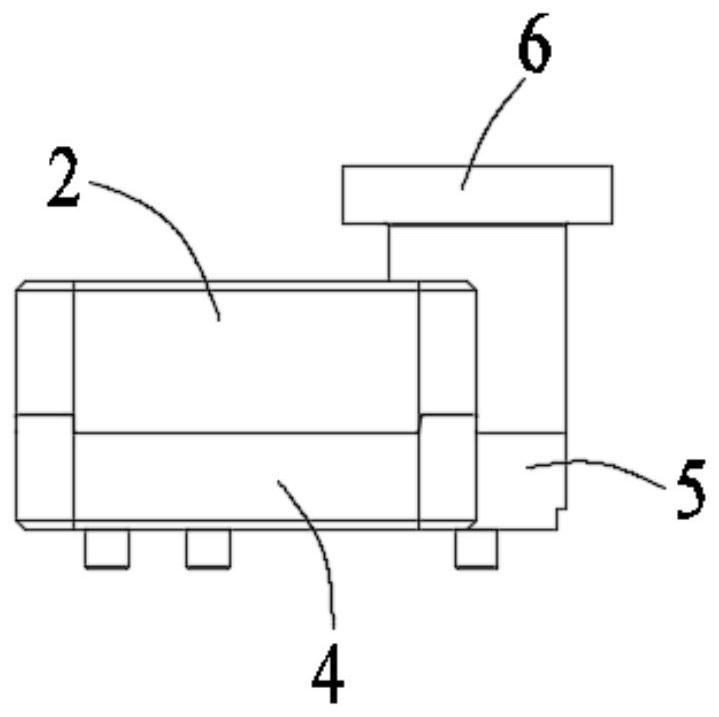

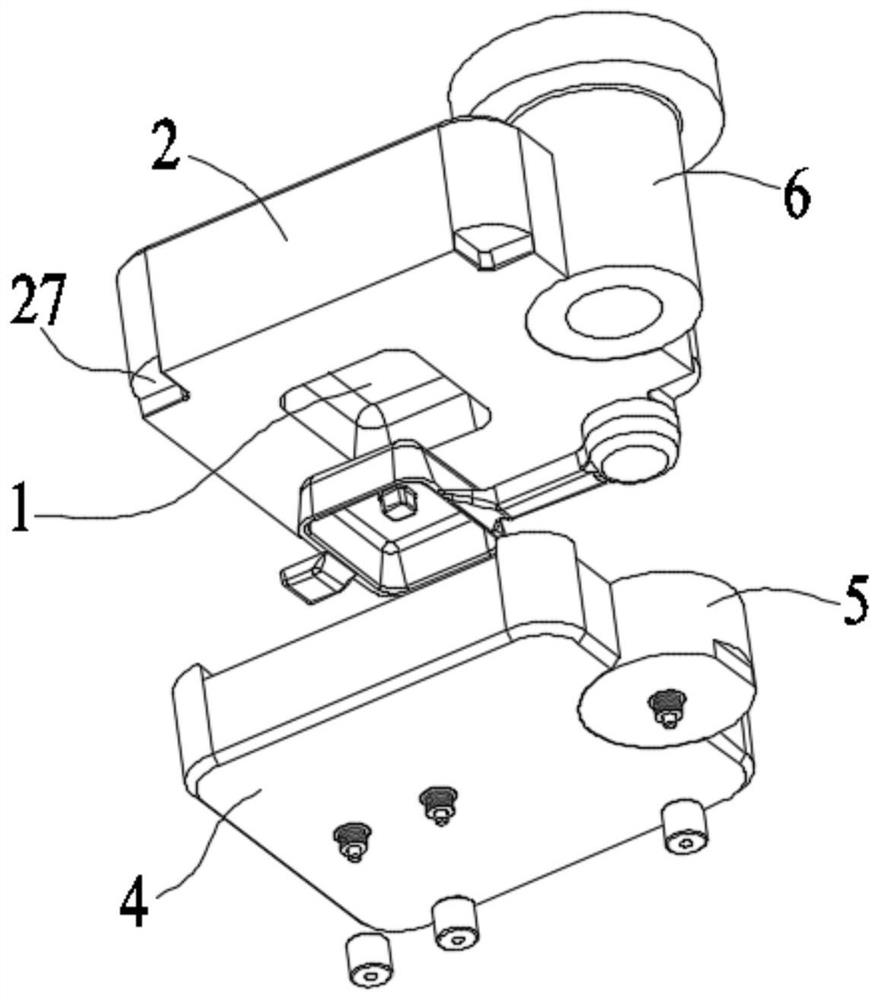

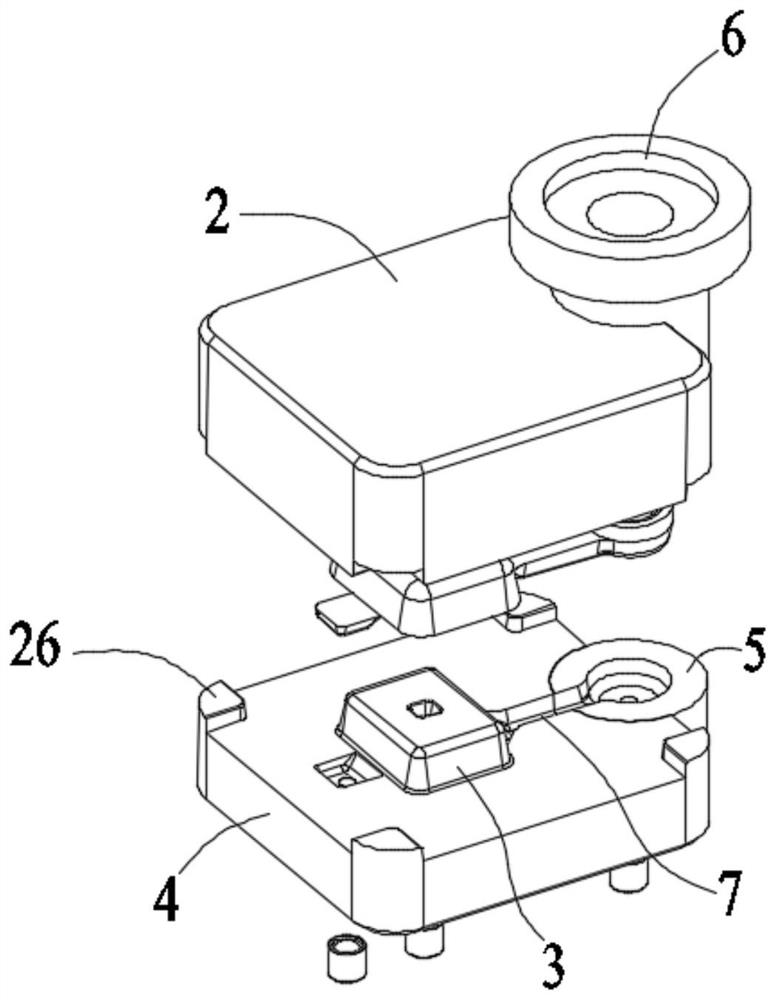

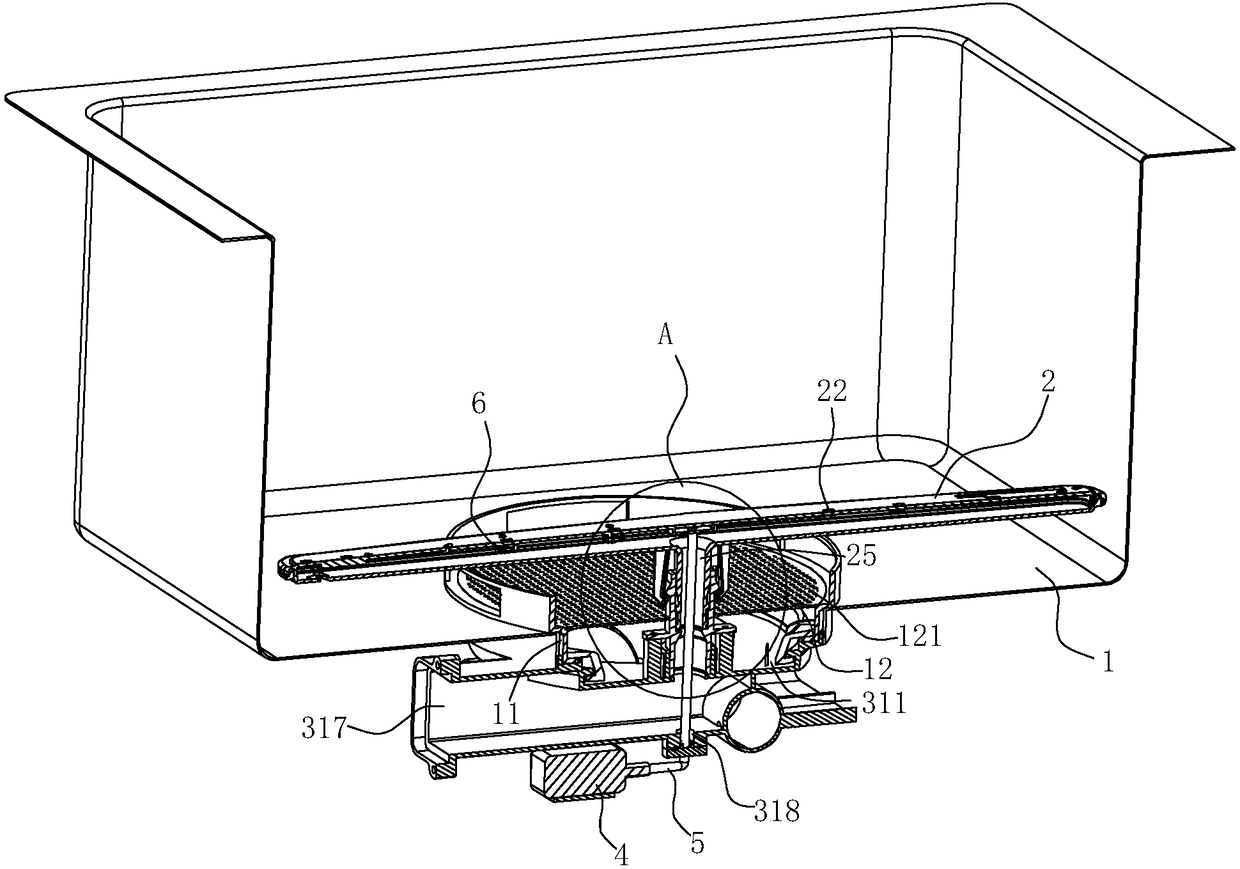

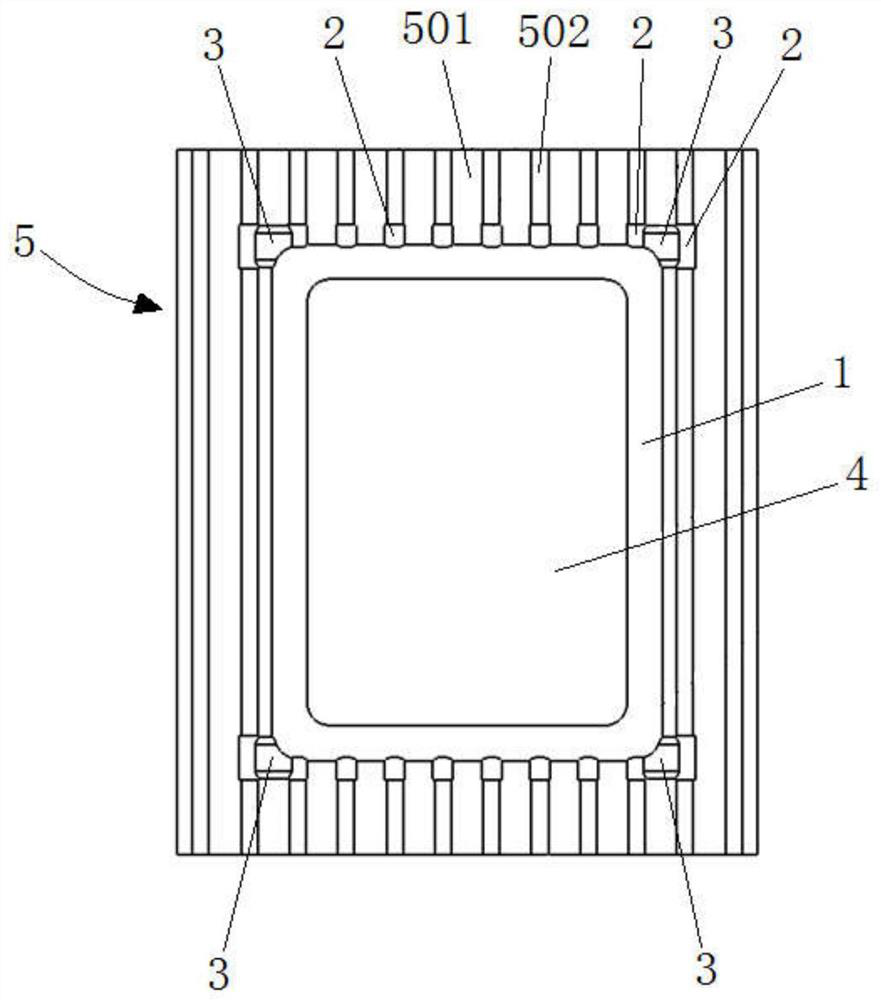

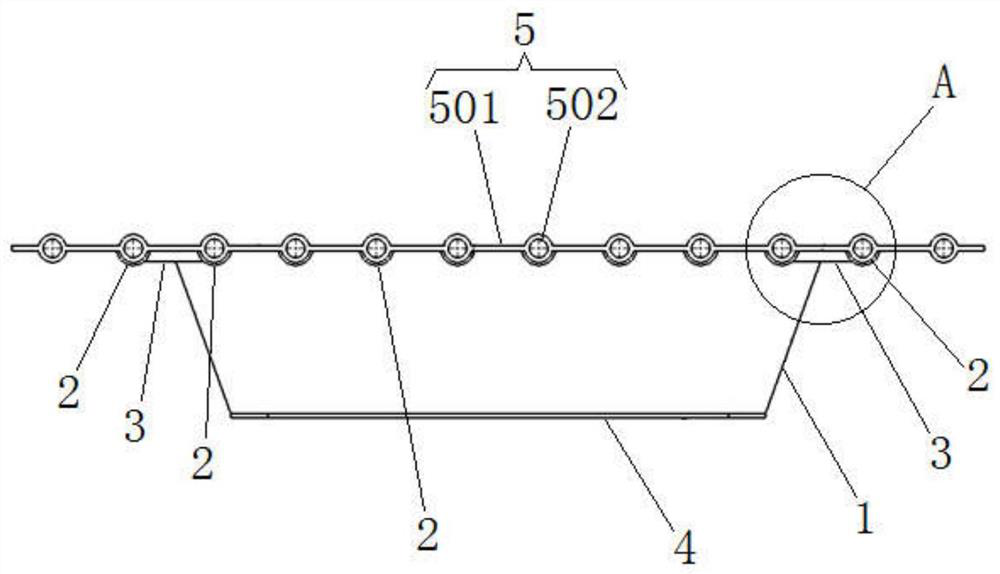

Cooling unit for traction system

ActiveCN103253277BChange connection methodAvoid crack failureLocomotivesExpansion tankTraction system

A cooling unit for a traction system comprises a bearing and supporting framework (1), an air filtering apparatus (2), a radiator (3), an air guide cylinder (4), a fan box body (5), an expansion water tank (6), a water pump (7), and a fan group (7), as well as a water system pipeline, an oil system pipeline, a pressure sensor and a temperature sensor, a wire junction box (10), an electric rapid connector (9) and another part. The water system pipeline and the oil system pipeline communicate with the radiator (3), and the pressure sensor and the temperature sensor are disposed on the pipelines. An integral matched design method is used on the cooling unit; a traction transformer cooling unit and a traction converter cooling unit are integrated into one unit, and on the premise of simultaneously meeting heat radiation requirements of the traction transformer and the traction converter, the cooling unit for a traction system brings a small size, a light weight, low in noise, a compact structure, high reliability, convenient mounting, and low maintenance and repair work load.

Owner:CRRC DALIAN INST CO LTD

Forming device for metal parts

The invention discloses a forming device for metal parts, which comprises an upper mold with a cavity, a lower mold with a core, a shunt cone connected to one end of the lower mold, and a gate sleeve connected with the shunt cone. The upper opening of the sleeve is connected to the die-casting machine, the lower end of the gate sleeve is connected to the shunt cone, and the upper surface of the lower mold is located between the core and the shunt cone. A first runner groove is provided. It communicates with the gap formed between the cavity and the core. A third cap body is fixedly connected to the lower surface of the shunt cone, the lower end of the third movable column is embedded in the third cap body, and a third elastic component is sleeved in the third cap body. The third movable column is located between the lower surface of the third flange portion and the third cap body. The present invention can monitor the pressure of the die-casting liquid entering the shunt cone through the deformation amount of the elastic component, thereby avoiding the problem of mold cracking and failure caused by excessive pressure of the die-casting liquid entering the mold, and prolonging the service life of the mold.

Owner:苏州圣美特压铸科技有限公司

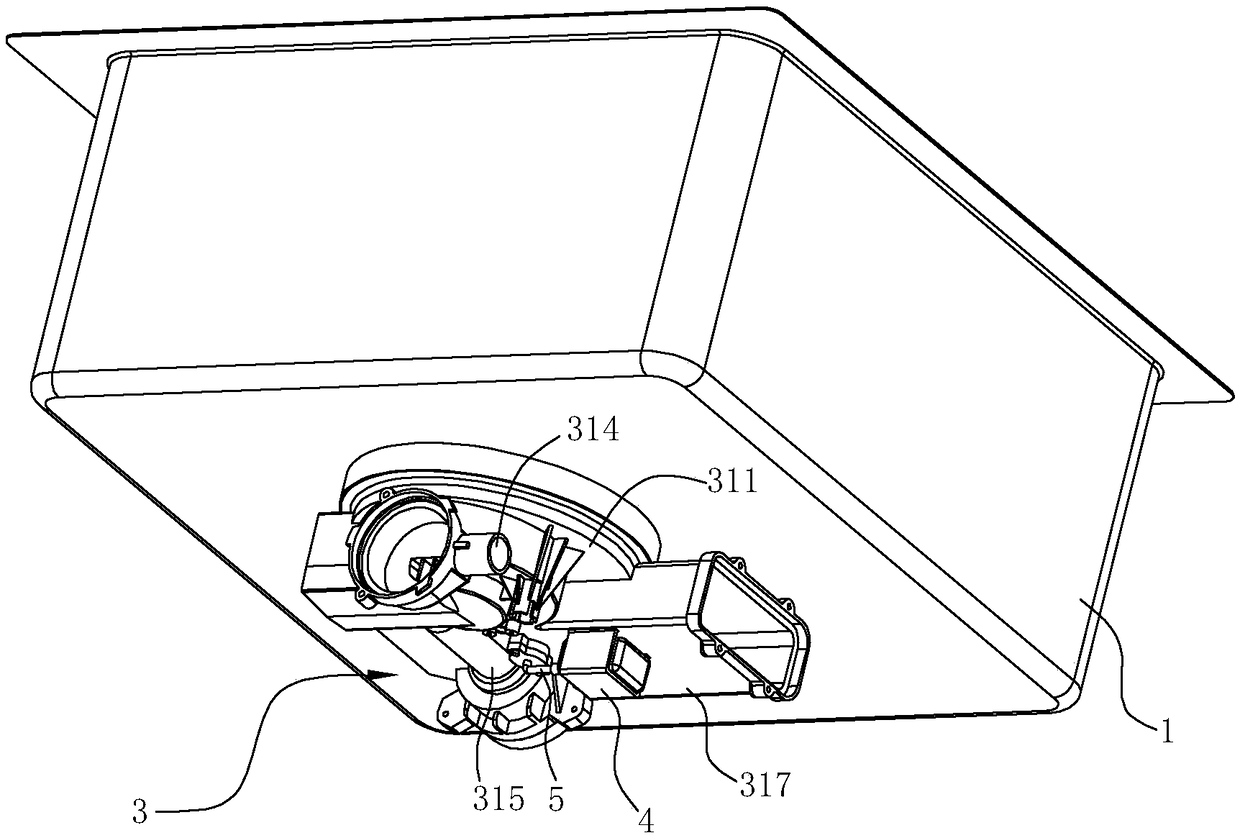

Circuit board and circuit module

PendingCN114823591AGuaranteed structural reliabilityGuaranteed compactnessSemiconductor/solid-state device detailsSolid-state devicesPhysicsChipset

The invention provides a circuit board and a circuit module, the circuit board is used for bearing a packaging chip, the circuit board comprises a substrate, the substrate is provided with a chip bearing area corresponding to the packaging chip, and the chip bearing area comprises a first sub-area corresponding to an electric contact area of the packaging chip and a second sub-area located at the periphery of the first sub-area; the supporting structure is located in the second sub-area and arranged on the surface of the substrate. When the packaging chip is assembled on the circuit board, the periphery of the electric contact area of the packaging chip can be supported through the supporting structure, so that the corner position of the packaging chip is prevented from cracking and losing efficacy due to pressure, and the structural reliability of the packaging chip is ensured. As the supporting structure is arranged on the circuit board, the effective area of the packaged chip is not occupied, the compactness of devices in the packaged chip is ensured, the integration level of the packaged chip is improved, static electricity is not accumulated on the packaged chip, the structure on the packaged chip is prevented from being damaged due to static electricity release, and the reliability of the packaged chip is ensured.

Owner:CHANGXIN MEMORY TECH INC

A micron-based al 2 o 3 Composite aluminum-based brazing wire and preparation method thereof

ActiveCN109304558BEasy to integrateIncrease in sizeWelding/cutting media/materialsSoldering mediaAl powderMetallurgy

The invention discloses a composite aluminum-based brazing wire based on micron Al2O3 and a preparation method thereof. The composite aluminum-based brazing wire comprises the following chemical ingredients in parts by weight: 75.24-82.92 parts of Al, 9-11 parts of Si, 3-6 parts of Cu, 5-7 parts of Zn, 0.01-0.1 part of a microelement Mg, 0.01-0.06 part of a microelement Sr, 0.01-0.1 part of microelement rare earth Ce and 0.05-0.5 part of micron Al2O3. The preparation method comprises the following steps: embedding the micron Al2O3 particles onto the surfaces of pure aluminium powder particlesto form an aluminium-embedded micron Al2O3 particle pile; after that, preparing a solder alloy high-temperature melt; adding the aluminium-embedded micron Al2O3 particle pile into the solder melt by means of mechanical stirring; and uniformly dispersing the micron Al2O3 particles released after the aluminium powder particles are molten to obtain the composite aluminum-based brazing wire. The preparation method is easy to operate and implement; the micron Al2O3 particles of the composite aluminum-based brazing wire prepared by the preparation method are uniformly distributed in an aluminium-based solder matrix to play a dispersion strengthening role; and the defects that a soldered joint has high probability of fracture and is low in bearing capability are avoided.

Owner:GUILIN UNIV OF AEROSPACE TECH

Washing machine

PendingCN109394123AAvoid Bubble Burst FailuresGood cleaning effectTableware washing/rinsing machinesEngineeringAir bubble

The invention relates to a washing machine. The washing machine comprises a tank, a spraying arm and a power assembly, wherein the spraying arm is arranged in the tank, and the power assembly is connected below the spraying arm. The washing machine further comprises an air pump and an air guide pipe, wherein the air pump is arranged at the outer side of the tank, the air inlet end of the air guidepipe is connected with the air pump, the output end of the air guide pipe extends into the spraying arm, an air collecting cavity connected with the output end of the air guide pipe is arranged in the spraying arm, and air guide channels extending towards the direction of water outlet holes of the spraying arm are formed in the air collecting cavity. For the washing machine, the guide channels can guide the added air, so that the added air is rapidly sprayed out from the water outlet holes after generating a cavitation effect with a water flow and generating air bubbles in the water flow, then the cracking failure of the air bubbles caused by the excessively long conveying flow of the water flow is avoided, when the water flow mixed with the air bubbles is sprayed to bowls and dishes, theair bubbles in the water flow crack after contacting the bowls and dishes and generate a relatively large impact force, so that the stubborn dirt on the bowls and dishes or vegetables and fruits is scattered, and then a very good washing effect is achieved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

A preparation method of high thermal conductivity diamond-reinforced silicon carbide substrate

ActiveCN113571409BImprove growth efficiencyIncrease contact areaSemiconductor/solid-state device manufacturingEvaporation (deposition)Carbide silicon

The invention discloses a method for preparing a high thermal conductivity diamond reinforced silicon carbide (SiC) substrate, which belongs to the field of semiconductor material preparation. In the present invention, patterning is realized on the carbon polar surface of SiC through glue coating, photolithography and development. This is followed by electron beam evaporation or magnetron sputtering of the metal mask. After removing the photoresist, the SiC with periodically arranged metal masks is subjected to reactive ion etching, mask removal, and secondary ion etching to obtain a microcolumn array. The diamond layer is then grown by microwave plasma chemical vapor deposition technique. After the diamond layer completely covers the micropillars and has a certain thickness, laser scanning planarization and subsequent precision polishing are used to obtain a diamond-reinforced SiC substrate with high thermal conductivity. By increasing the effective contact interface area between diamond and SiC, the heat conduction efficiency is improved, and at the same time, the insufficient bonding force of the single-plane interface and the expansion of local defects are effectively avoided. It lays the foundation for obtaining high-power, high-frequency SiC / Diamond and GaN / SiC / Diamond wafers for future SiC silicon polar face thinning and high-temperature deposition of GaN on the surface.

Owner:UNIV OF SCI & TECH BEIJING +1

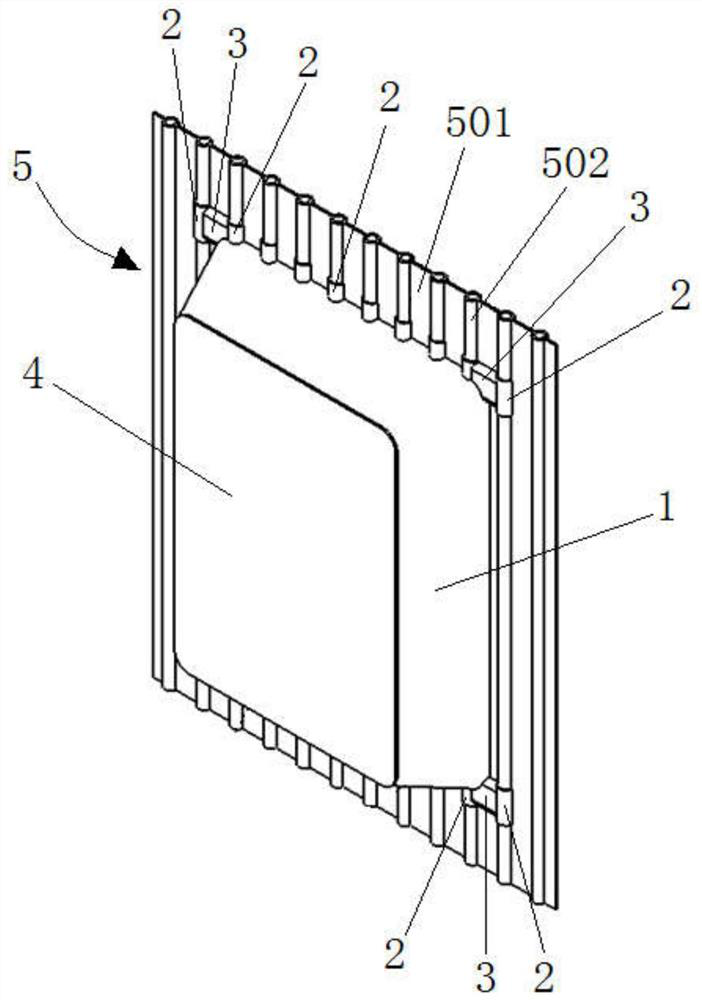

Manhole door sealing box and tower-type supercritical boiler

PendingCN113719819AAvoid crack failureIncrease the bearing areaBoiler drums/headersBoiler water tubesSupercritical steam generatorTower

The invention relates to a manhole door sealing box and a tower-type supercritical boiler. The manhole door sealing box comprises a sealing box body, a plurality of protective tiles and a plurality of corner protectors, each protective tile covers the outer side of each water-cooled wall tube in a water-cooled wall, each corner protector is connected between two adjacent protective tiles, each protective tile is located at a position opposite to the edge of the sealing box body, the corner protectors are located at the positions opposite to the vertex angles of the sealing box body respectively, the edge of the sealing box body is connected with the protective tiles and fins in the water-cooled wall respectively in a sealed mode, and the vertex angles of the sealing box body are connected with the corresponding corner protectors respectively in a sealed mode. According to the manhole door sealing box, the technical problem that due to the arrangement of the manhole door sealing box, local stress on the connecting position of the sealing box and the water cooling wall is concentrated, and the water cooling wall is damaged is solved.

Owner:北京华科同和科技有限公司

Buffer sealing structure of one-time molding inflatable fabric

The invention relates to the field of one-piece-woven fabrics, in particular to a buffering seal structure of a one-piece-woven fabric. The buffering seal structure is applicable to automobile air bags. Due to the fact that seal seams of the one-piece-woven fabrics are uniform and firm and difficult for impact airflow to break through, weak portions at junctions of an air cavity and the seal seams always become breakthrough ports for impact airflows so as to result in breakage and failure. Single-thread seams are additionally arranged inside the junctions of the air cavity and the seal seams (multi-thread seams); on the one hand, weaving points of the single-thread seams are larger in elastic tensile deformation to absorb certain energy and buffer the impact airflows; on the other hand, leading peaks (airflow portions largest in impact force) of the impact airflows can be leaked and released through the single-thread seams to greatly cut off impact energy, so that breakage and failure can be avoided. Therefore, the buffering seal structure of the one-piece-woven fabric has the advantages of capability of buffering the impact airflows and effectiveness in sealing.

Owner:HMT XIAMEN NEW TECHN MATERIALS

Silicon-based microphone and manufacturing method thereof

ActiveCN112689229BAvoid deformationAvoid crack failureElectrostatic transducer microphonesPlane diaphragmsVibrating membraneEngineering

The present invention provides a silicon-based microphone, comprising a silicon substrate with a cavity back, a diaphragm and a back plate arranged above the silicon substrate, the diaphragm includes an inner diaphragm and an outer periphery of the inner diaphragm and is connected to the The outer diaphragm with the inner diaphragm arranged at intervals is characterized in that the back plate includes a back plate support fixedly connected to the outer diaphragm, a back plate supported by the back plate support and located above the back cavity The plate intermediate body and the resisting column extending from the back plate intermediate body toward the diaphragm, when the diaphragm vibrates, the outer diaphragm can be deformed to interfere with the resisting post. The silicon-based microphone of the invention has the advantage that the outer diaphragm is not easily broken under the action of loud pressure.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD

Tractor frame and traveling wheel system

ActiveCN108327794AImprove enduranceImprove reliabilityUnderstructuresEndless track vehiclesStructural engineeringTractor

The invention relates to the technical field of tractors, in particular to a tractor frame and a traveling wheel system. The tractor frame comprises a front supporting cross beam and a rear supportingcross beam which are disposed opposite to each other. Side supporting longitudinal beams are fixed between the left end of the front supporting cross beam and the left end of the rear supporting cross beam and between the right end of the front supporting cross beam and the right end of the rear supporting cross beam. The intermediate portion of the front supporting cross beam is arched upwards,and the intermediate portion of the rear supporting cross beam is arched upwards. The side supporting longitudinal beams include main supporting beams, front oblique beams and rear oblique beams, wherein the main supporting beams extend forwards and backwards in a linear mode, the front oblique beams extending obliquely forwards and downwards are fixed to the front ends of the main supporting beams and used for mounting tensioning wheels, and the rear oblique beams extending obliquely backwards and downwards are fixed to the rear ends of the main supporting beams and used for mounting fixed wheels. The structure is more stable, an operator is more comfortable to use, and the operation is more cheerful.

Owner:XINGGUANG AGRI MACHINERY

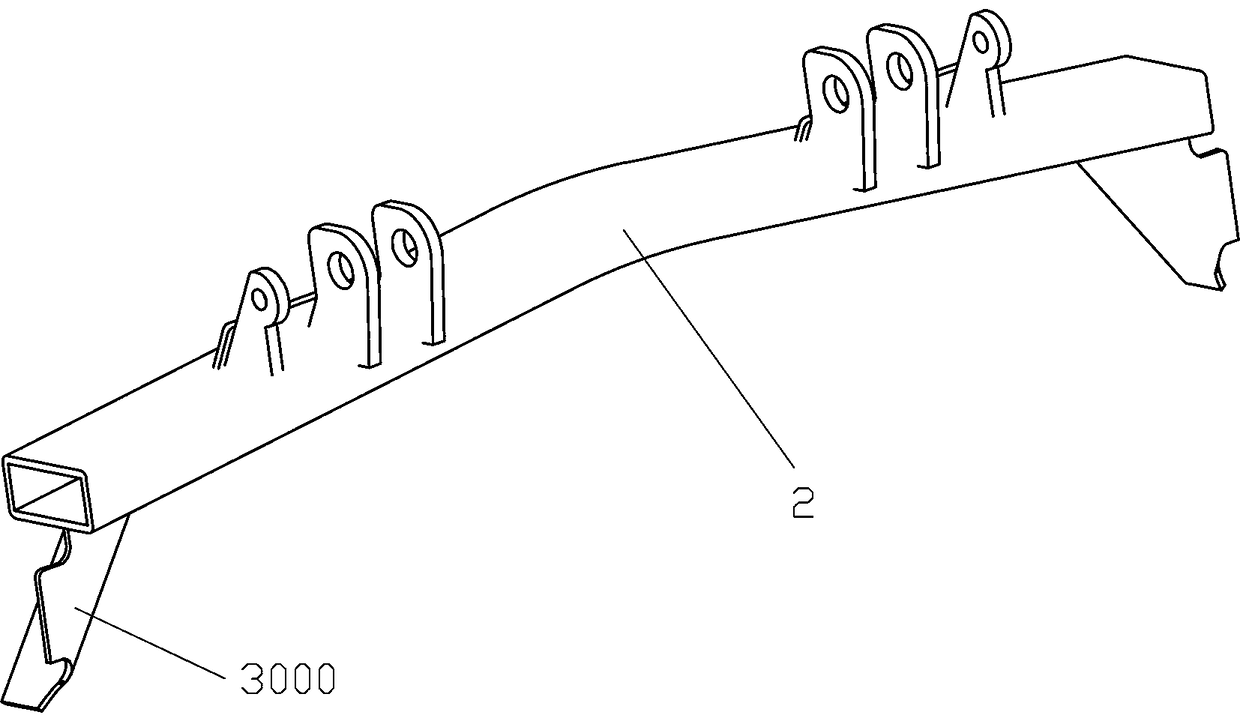

Automobile front anti-collision beam system

ActiveCN112172720AIntegrity guaranteedRetention of Dispersion IntegrityBumpersEnergy absorptionEngineering

An automobile front anti-collision beam system comprises a front anti-collision beam, two energy absorption boxes and elastic connecting assemblies for connecting the front anti-collision beam and theenergy absorption boxes; the two ends of one side of the front anti-collision cross beam are each provided with a plurality of connecting protruding blocks, and first connecting holes are formed in the middles of the connecting protruding blocks; an opening is formed in one end of each energy absorption box, protruding parts are formed on the upper portion and the lower portion of each opening, and second connecting holes are formed in the protruding parts; the elastic connecting assemblies are located at the openings, and each elastic connecting assembly comprises an elastic connecting sheet, two first connecting pins and a second connecting pin; two ends of the inner concave surface of each elastic connecting sheet are respectively connected with a first connecting hook ring, and the middle part of the outer convex surface of each elastic connecting sheet is connected with a second connecting hook ring; the first connecting pins penetrates through the first connecting hook rings andthe first connecting holes of the connecting lugs; and the second connecting pins penetrate through the second connecting hook rings and the second connecting holes of the energy absorption boxes. Reversible elastic deformation can be generated during light collision, the elastic connecting assemblies are convenient to replace during repairing, and the maintenance cost is reduced; during medium-high speed collision, peak stress can be effectively decomposed, joint cracking and failure are avoided, and the integrity of a force dispersion transmission system is maintained.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

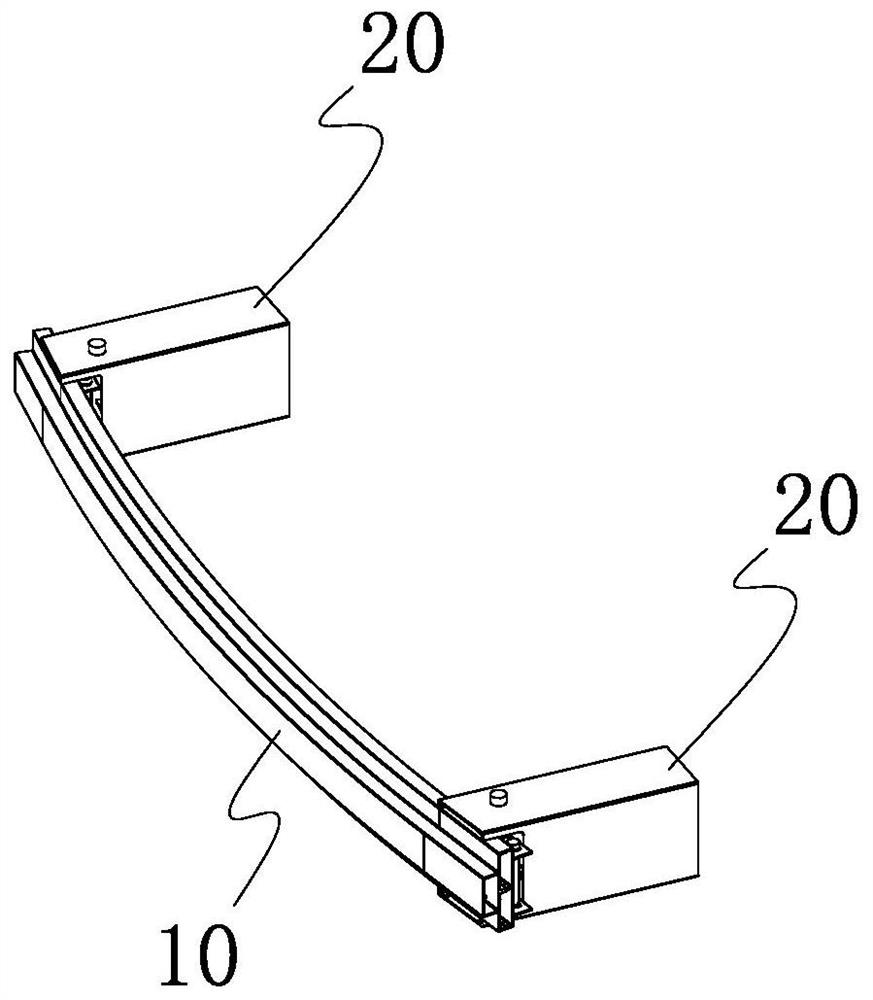

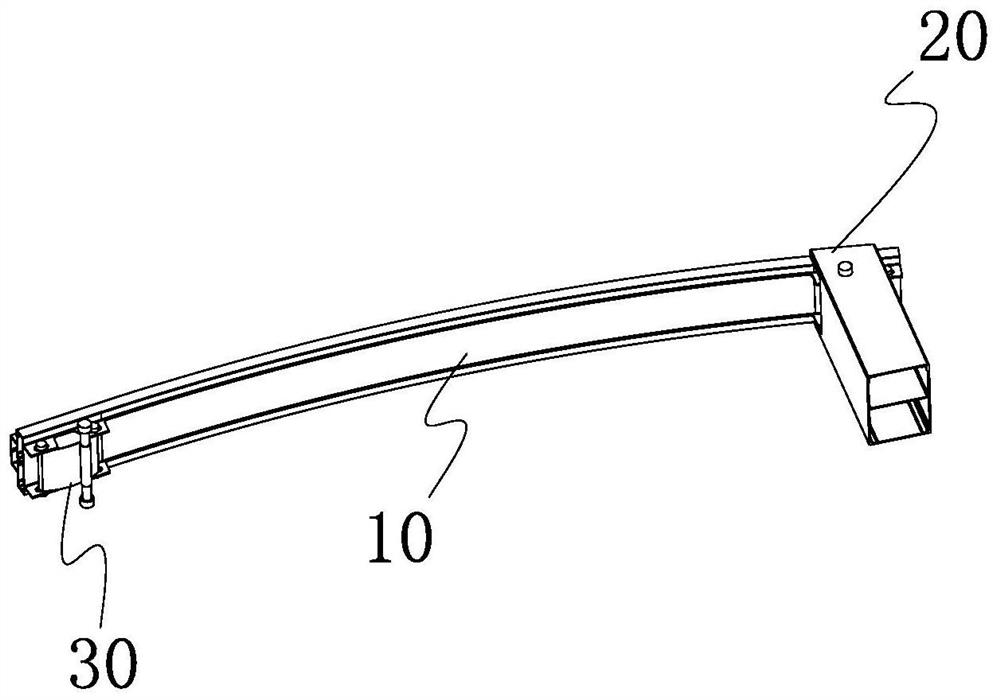

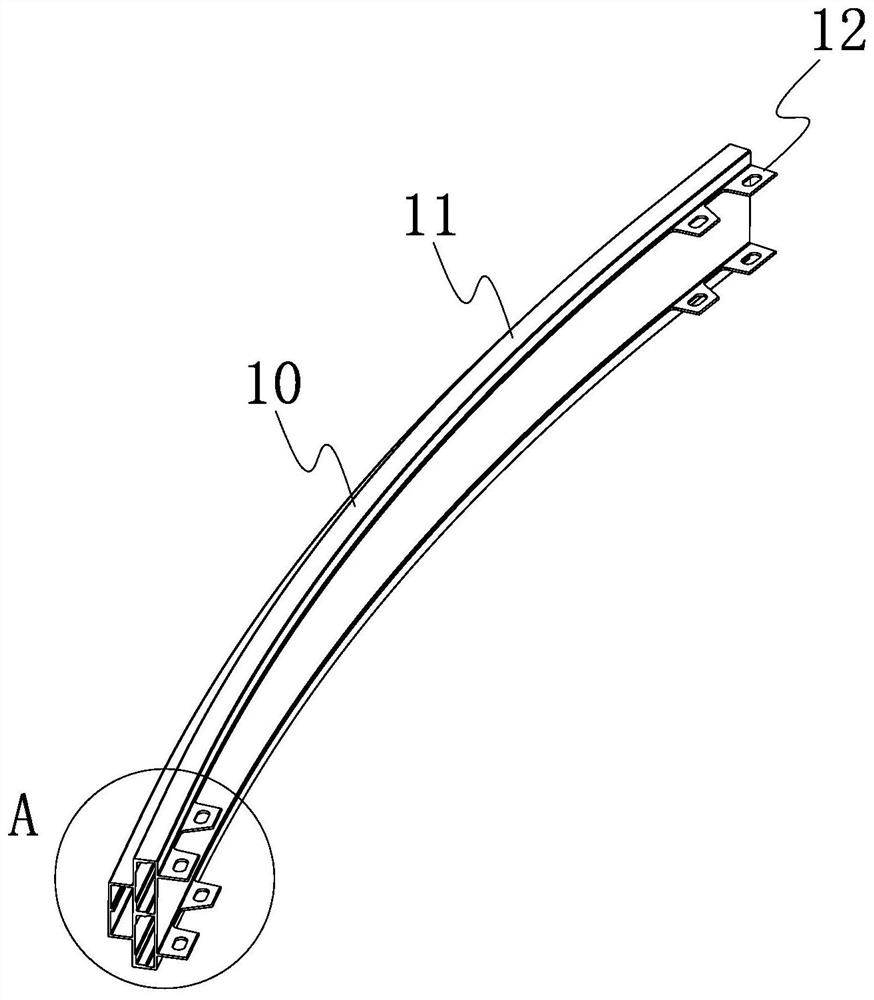

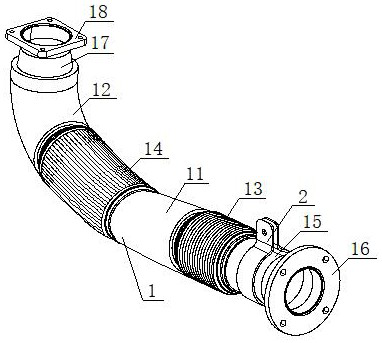

Heat preservation exhaust pipe structure

InactiveCN111764992AMeet layout needsAvoid Fracture FailureExhaust apparatusSilencing apparatusThermodynamicsStraight tube

The invention discloses a heat preservation exhaust pipe structure. The heat preservation exhaust pipe structure is of an L-shaped structure and comprises a first heat preservation pipe section, a second heat preservation pipe section, a longitudinal high-frequency steel wire line pipe section and a transverse high-frequency steel wire line pipe section, wherein the first heat preservation pipe section and the longitudinal high-frequency steel wire line pipe section are each of a straight pipe structure, one end of the longitudinal high-frequency steel wire line pipe section is connected withan engine exhaust manifold, and the other end of the longitudinal high-frequency steel wire line pipe section is connected with one end of the transverse high-frequency steel wire line pipe section through the first heat preservation pipe section; and the second heat preservation pipe section and the transverse high-frequency steel wire line pipe section are each of an arc-shaped tubular structure, and the two ends of the second heat preservation pipe section are connected with the other end of the transverse high-frequency steel wire line pipe section and an air inlet of a silencer correspondingly. According to the design, the arrangement requirement of the exhaust pipe is met, and the exhaust pipe is prevented from being broken and losing efficacy due to high-frequency vibration.

Owner:DONGFENG AUTOMOBILE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com