Buffer sealing structure of one-time molding inflatable fabric

An inflatable fabric, cushioning and sealing technology, applied in fabrics, textiles, textiles and papermaking, etc., can solve the problem of rupture and failure at the junction of the air cavity and the sealing seam, and achieve the effect of easy stretching and large air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

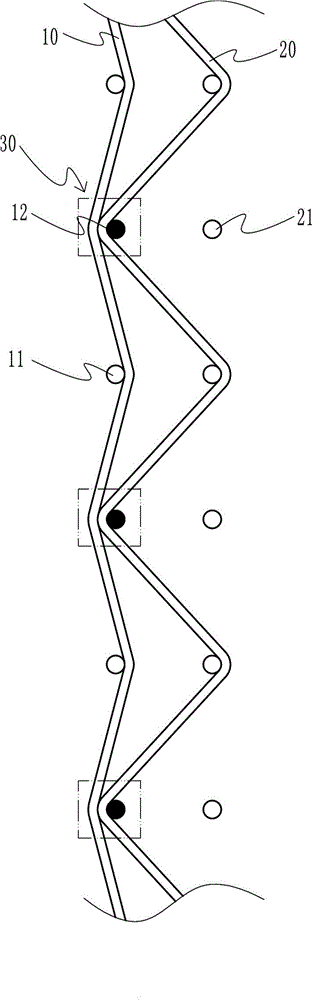

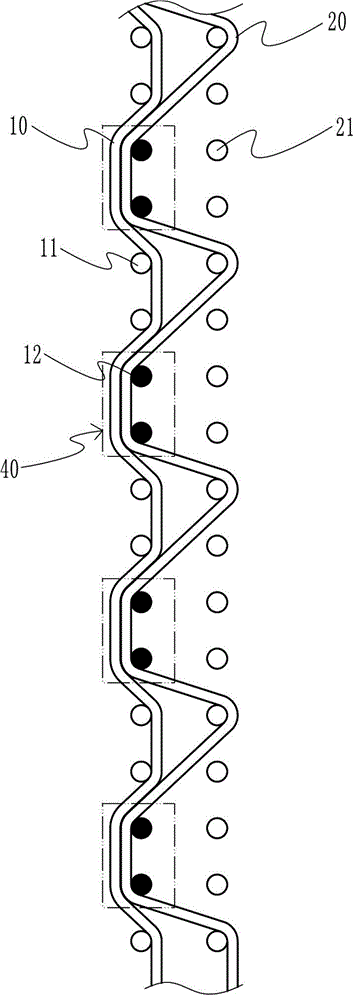

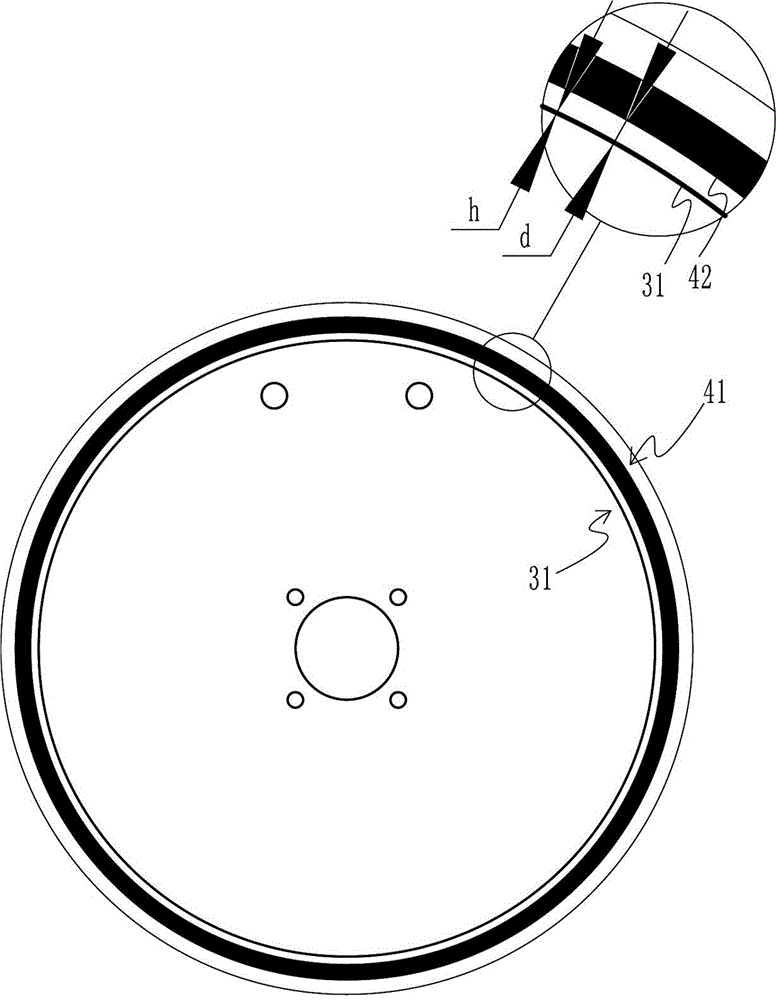

[0037] In this embodiment, 470 dtex nylon 66 yarn is used, and a high-speed air-jet loom equipped with a jacquard faucet is used to weave a one-time molding inflatable fabric with a warp density of 220 yarns / dm and a weft yarn density of 190 yarns / dm. like image 3 As shown, in this embodiment, multiple groups of single-thread knot seams 31 form a single-turn solid-line ring with a width h of 0.2 mm and a diameter of 680 mm. The inner side of the knotted seam 41, and the distance d from the innermost multi-threaded knotted seam is 2mm, so as to further prevent the excessive stretching of the single-threaded knotted seam. The performance indicators are shown in Table 1.

Embodiment 2

[0039] In this embodiment, 550 dtex polyester yarn is used, and a high-speed air-jet loom equipped with a jacquard faucet is used to weave a one-time molding inflatable fabric with a warp density of 220 threads / dm and a weft thread density of 170 threads / dm. In this embodiment, multiple sets of single-thread knot seams 31 form a single-turn solid-line ring with a width h of 0.4 mm and a diameter of 680 mm. Multi-turn multi-thread knot seams 41 constitute the sealing seam of this embodiment, and the single-thread knot seams 31 are in the multi-thread knot seams. 41, and the distance d from the innermost multi-thread knot seam is 2mm to further prevent the single-thread knot seam from being overstretched. The performance indicators are shown in Table 1.

[0040] Table I

[0041]

[0042] As can be seen from Table 1, the air permeability of the single-thread knotted seam of Embodiment 1 and Embodiment 2 all reaches 0.5L / dm 2 / min or more, it is enough to release the front pe...

Embodiment 3

[0045] like Figure 4 As shown, the difference of this embodiment is that the multiple groups of single-thread stitches 31 in this embodiment form a dotted line loop.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com