Repair coating for aerogel surface defects as well as preparation method and application of repair coating

An airgel and coating technology, applied in the direction of coating, etc., can solve problems such as easy pits and cracks, affect product service life, and reduce material mechanical properties, so as to reduce scrap rate, improve service life, and excellent matching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] According to some preferred embodiments, preferably, the preparation method of the phenolic resin solution includes: adding the phenolic resin into a solvent, stirring and dissolving, and then adding a curing agent, stirring and mixing to obtain the phenolic resin solution.

[0050] It should be noted that the selected phenolic resin of the present invention includes but not limited to commonly used phenolic resin, modified phenolic resin (boron phenolic, barium phenolic), molecular weight includes but not limited to 800~1500 (for example, can be 800,900 , 1000, 1100, 1200, 1300, 1400, 1500, etc.).

[0051] According to some preferred embodiments, the stirring speed is 50-1000rpm (for example, it can be 50rpm, 100rpm, 200rpm, 500rpm, 600rpm, 800rpm or 1000rpm), and the stirring time is 2-10h (for example, it can be 2h, 3h , 5h, 6h, 8h or 10h).

[0052] According to some preferred embodiments, the solvent is at least one selected from methanol, ethanol, isopropanol, ace...

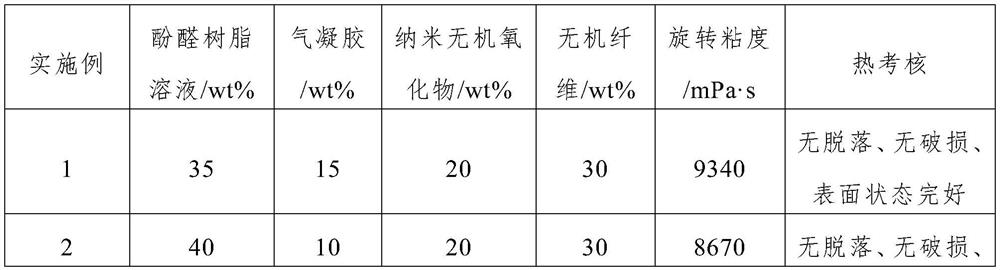

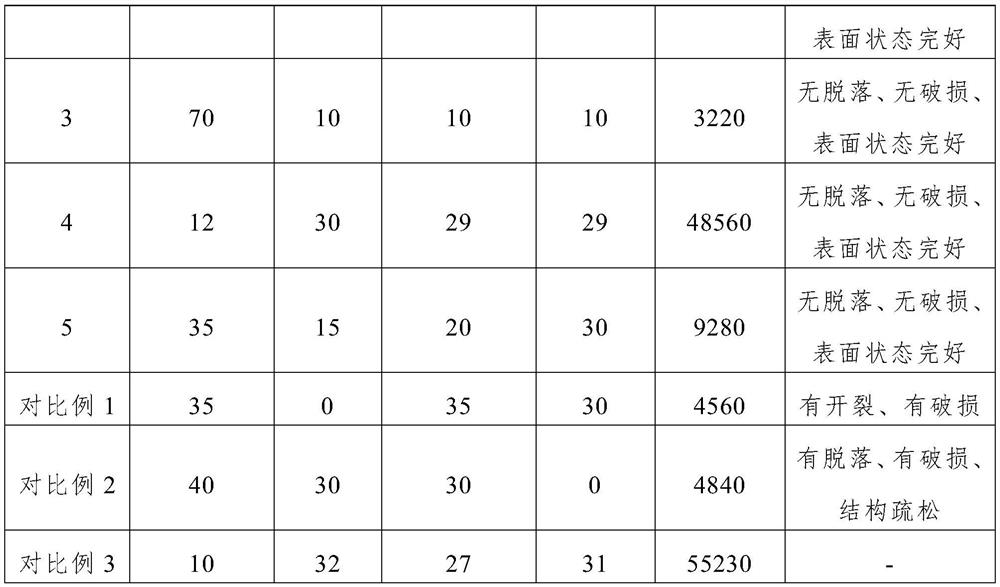

Embodiment 1

[0066] The mass fraction of each component in the repair paint is: 35% of phenolic resin solution, 15% of airgel, 20% of nanometer inorganic oxide and 30% of inorganic fiber;

[0067] Preparation:

[0068] (1) Add the phenolic resin to the solvent (acetone) and stir to dissolve, stir at a rotating speed of 250r / min for 3h to dissolve and disperse, then add a curing agent (aniline) to it, continue to stir at a rotating speed of 250r / min for 3h and mix evenly to obtain a phenolic resin solution;

[0069] The consumption of acetone accounts for 30% of the consumption of phenolic resin, and the consumption of aniline accounts for 0.8% of the consumption of phenolic resin;

[0070] (2) Airgel (phenolic airgel powder, particle size is 50nm), nano-inorganic oxide (SiO with a particle size of 30nm) according to the above proportioning ratio 2 powder) into the phenolic resin solution obtained in step (1), stirred and mixed at 350r / min for 0.5h, dispersed evenly, and then added inorga...

Embodiment 2

[0074] The mass fraction of each component in the repair coating is: 40% of phenolic resin solution, 10% of airgel, 20% of nanometer inorganic oxide and 30% of inorganic fiber;

[0075] Preparation:

[0076] (1) Add the phenolic resin to the solvent (isopropanol) and stir to dissolve, stir at a speed of 300r / min for 3h to dissolve and disperse, then add a curing agent (hexamethylenetetramine) to it, and continue to stir at a speed of 300r / min Mix evenly for 4.5 hours to obtain a phenolic resin solution;

[0077] The consumption of Virahol accounts for 40% of the consumption of phenolic resin, and the consumption of hexamethylenetetramine accounts for 1% of the consumption of phenolic resin;

[0078] (2) Airgel (phenolic airgel powder, particle diameter is 80nm), nano inorganic oxide (particle diameter is the Al of 30nm) according to the above proportioning ratio earlier 2 o 3 powder) into the phenolic resin solution obtained in step (1), stirred and mixed at 350r / min for 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com