Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Tripropylene glycol methyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

TRIPROPYLENE GLYCOL METHYL ETHER is a colorless liquid with a mild odor. (USCG, 1999)

Zinc base liquid composite heat stabilizer and preparation method of zinc base liquid composite heat stabilizer

The invention discloses a zinc base liquid composite heat stabilizer and a preparation method of the zinc base liquid composite heat stabilizer. The heat stabilizer is formed by the following raw materials according to mass ratio: 40-60 parts of barium fatty acid, 10-18 parts of zinc fatty acid, 10-35 parts of phosphite ester, 2-7 parts of beta-diketone, 1-10 parts of anti oxidizers and 10-20 parts of solvent, wherein barium in the barium fatty acid accounts for 10-15 percent in mass fraction, zinc in the zinc fatty acid accounts for 8-12 percent in mass fraction, and one of diethylene glycolmonobutylether, butyl cellosolve, dipropylene glycol methyl ether, tripropylene glycol methyl ether, white oil or coal oil is used as the solvent; the zinc base liquid composite heat stabilizer can effectively delay zinc burning phenomenon in a system, the PVC (polyvinyl chloride) thermal stabilization is improved, auxiliaries and PVC resin selected in the system have more approximate refractive indexes, a prepared PVC product has good transparent performance and good anti-precipitation property.

Owner:ZHEJIANG HIMPTON NEW MATERIAL

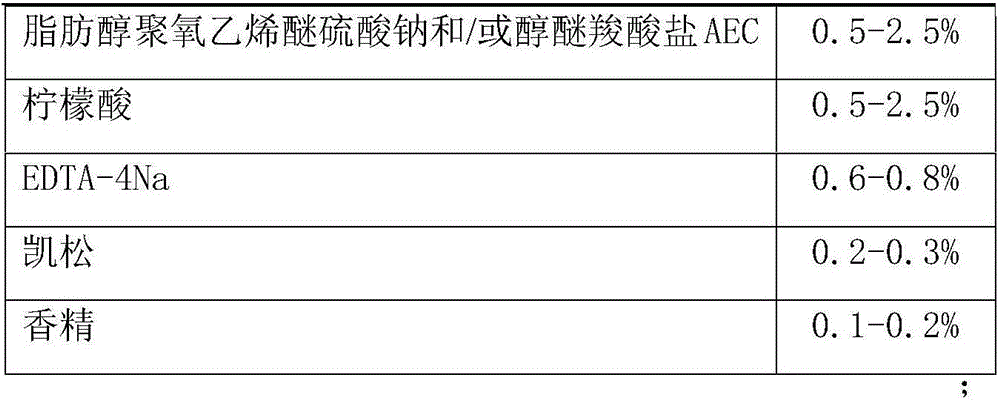

Printed wiring board cleaning agent and use method thereof

InactiveCN103627539AReduce liquidityLow viscosityNon-ionic surface-active compoundsDetergent compounding agentsCoconut diethanolamideDipropylene glycol

A printed wiring board cleaning agent comprises the following components in parts by weight: 20-60 parts of a dispersing agent, 1-5 parts of FMEE, 1-6 parts of coconut diethanolamide, 0.1-2.5 parts of sodium dodecyl sulfate, 0.5-10 parts of a washing assistant and 20-500 parts of deionized water, wherein the dispersing agent is one or more of isopropyl alcohol, dipropylene glycol or tripropylene glycol; the washing assistant comprises sodium carbonate and sodium silicate in the weight ratio of 0.5:1-4:1. According to the cleaning agent, the sodium carbonate and the sodium silicate are added simultaneously to be used as the washing assistant, so that a better cleaning function for a printed wiring board is achieved in comparison with the addition of other washing assistants or a washing assistant with only the sodium carbonate or the sodium silicate, and the primary welding and secondary welding qualification rate and the gold thread tensile force testing qualification rate of the printed wiring board are improved. Particularly, when the sodium carbonate and the sodium silicate are in the rate of 1:1, the cleaning performance of the washing assistant is best.

Owner:深圳市华大电路科技有限公司

Environment-friendly constant-temperature hole sealing agent for aluminum and aluminum alloy and hole sealing technique thereof

ActiveCN107805837AImprove stabilityImprove permeabilitySurface reaction electrolytic coatingEnvironmental resistanceAccelerant

The invention provides an environment-friendly constant-temperature hole sealing agent for aluminum and an aluminum alloy. The environment-friendly constant-temperature hole sealing agent comprises the following components of, by total weight, 3%-15% of magnesium acetate, 0%-10% of cobaltous acetate, 5%-15% of tripropylene glycol methyl ether, 5%-15% of surfactants, 0%-10% of dust inhibiting agents, 0%-8% of accelerants, 0.5%-10% of pH buffer agents, 0%-10% of corrosion inhibitors and the balance deionized water. The environment-friendly constant-temperature hole sealing agent is good in stability and permeation effect; a hole sealing film is dense and can completely seal gaps on the surface of a workpiece; the hole sealing condition requirement is low, after hole sealing, the surface of the workpiece is flat, bright and free of discoloring, powder forming is avoided, oil fouling resistance and fingerprint resistance are achieved, and the strength, hardness and corrosion resistance ofthe workpiece are improved; the environment-friendly constant-temperature hole sealing agent does not contain elements of nickel, fluorine, chromium and the like and is safe and environmentally friendly, pollution to the operation environment is avoided, and damage to health of a human body is avoided; and the cost is low, energy consumption is less, and the environment-friendly constant-temperature hole sealing agent is suitable for being produced industrially on a large scale.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

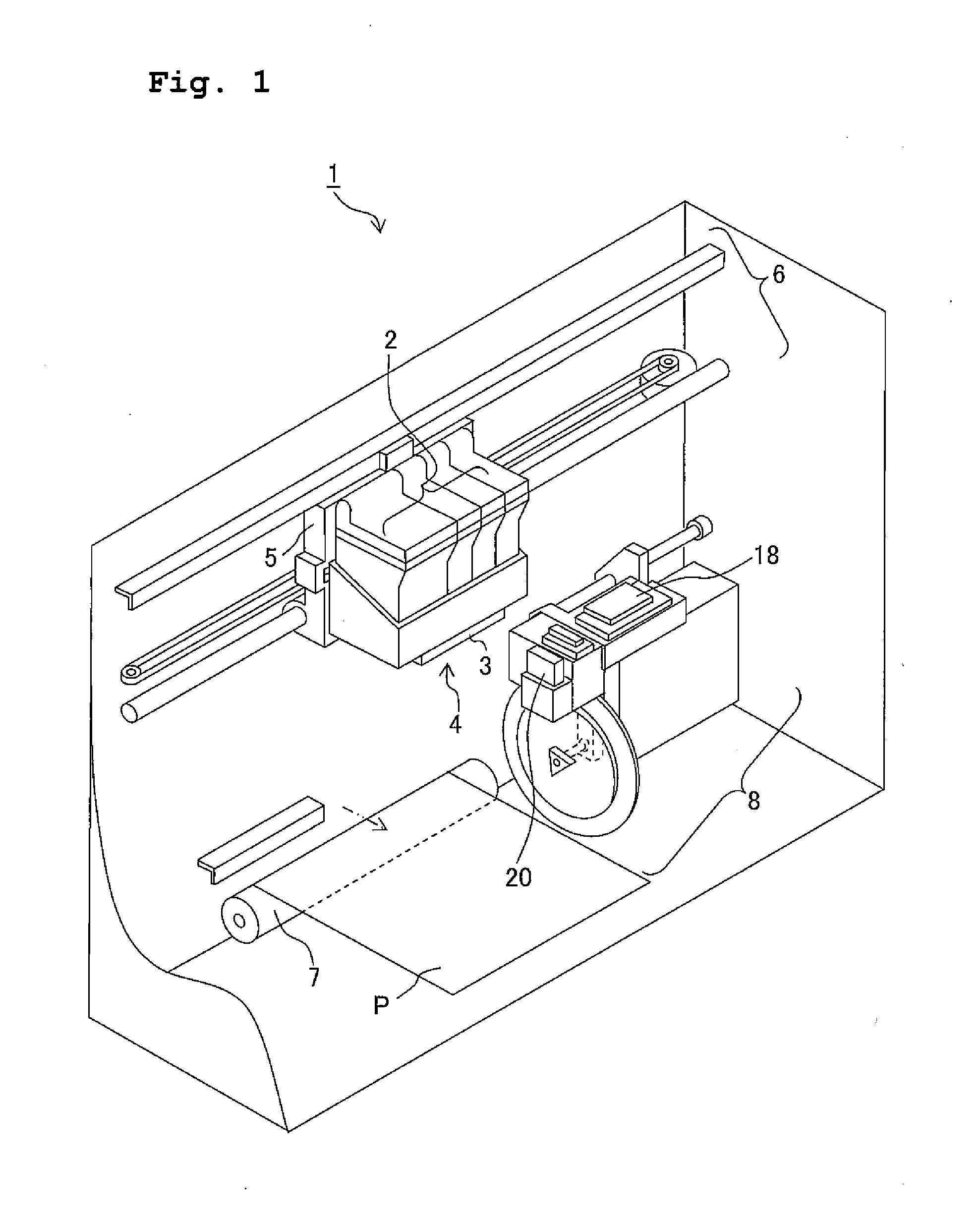

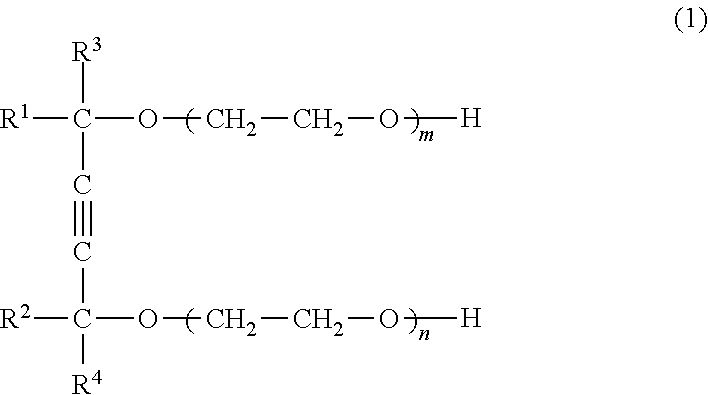

Water-Based Ink for Ink-Jet Recording, Water-Based Ink Set for Ink-Jet Recording, Ink Cartridge, and Ink-Jet Recording Method

ActiveUS20140292901A1Suppress any bleedingExcellent in vaporization characteristicInksPrintingSurface-active agentsAcetylenediol

A water-based ink for ink-jet recording includes a pigment; water; an acetylene glycol-based surfactant contained by 0.1% by weight to 0.3% by weight in the water-based ink; tripropylene glycol methyl ether contained by 2.5% by weight to 4.5% by weight in the water-based ink; and tripropylene glycol n-butyl ether contained by 0.5% by weight to 1.5% by weight in the water-based ink.

Owner:BROTHER KOGYO KK

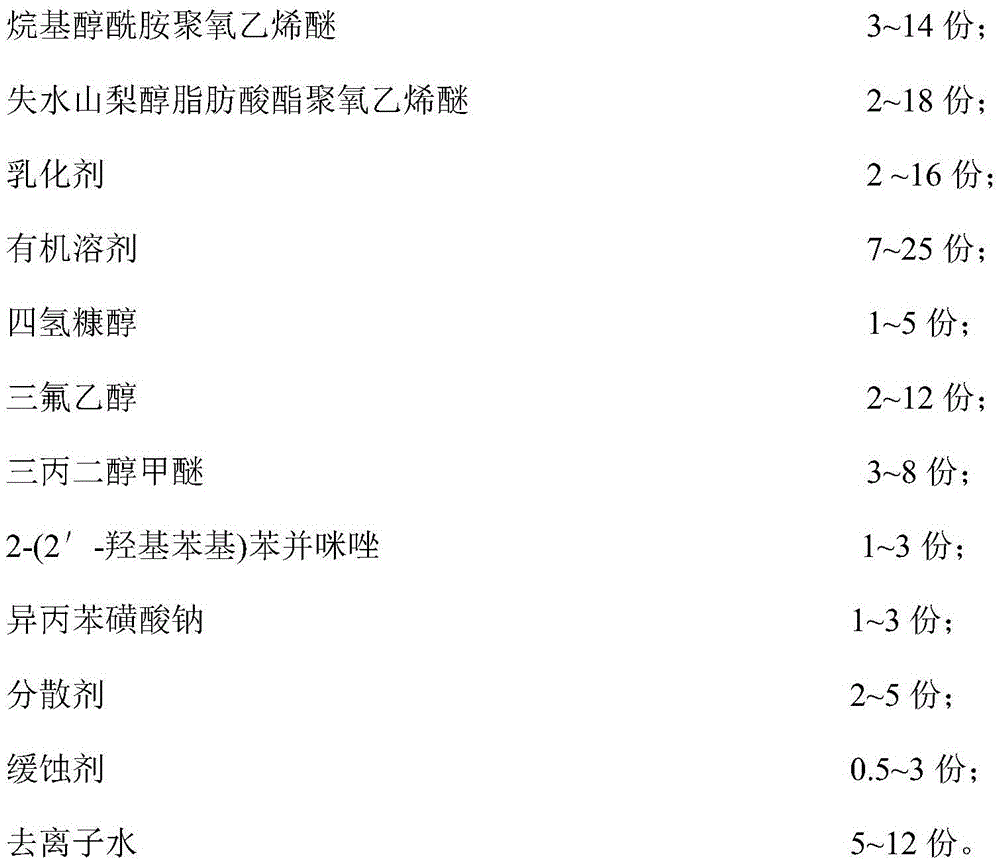

Water-based LED (light emitting diode) chip cleaning agent

InactiveCN105542990ANo generationReduce harmOrganic detergent compounding agentsSurface-active detergent compositionsWater basedCleansing Agents

The invention discloses a water-based LED (light emitting diode) chip cleaning agent, prepared from the following components of alkylolamide polyoxyethylene ether, polyoxyethylene sorbitan fatty acid ester, an emulsifier, an organic solvent, tetrahydrofurfuryl alcohol, trifluoroethanol, tripropylene glycol monomethyl ether, 2-(2'-hydroxylphenyl)benzoimidazole, sodium cumenesulfonate, a dispersant, a corrosion inhibitor and deionized water. The cleaning agent provided by the invention has the advantages that the effects of high cleaning efficiency, strong detergency, good safety performance, freeness from environmental pollution, energy saving and low washing cost are achieved; an LED is not damaged in a washing process; a protective film can be formed on the surface of a chip through the cleaning agent, so that air is isolated, and the chip is prevented from being corroded by moisture and other molecules in the air, therefore the effect of oxidation resistance is achieved, and a next production process is conveniently performed.

Owner:SUZHOU JIAYIDA ELECTRICAL APPLIANCES

LED chip cleaning solution

InactiveCN106085622AImprove cleaning efficiencyImprove decontamination abilityInorganic/elemental detergent compounding agentsNon-ionic surface-active compounds4-MethoxyphenolCleansing Agents

The invention discloses an LED chip cleaning solution. The LED chip cleaning solution comprises the following raw materials by mass: 10 to 15 parts of alkylolamide polyoxyethylene ether, 10 to 15 parts of sorbitan fatty acid ester polyoxyethylene ether, 5 to 8 parts of benzotriazol, 3 to 4 parts of citric acid, 1 to 2 parts of glycerin, 1 to 2 parts of ethanol, 5 to 8 parts of polyoxyethylene ether, 5 to 8 parts of hydrogen peroxide, 2 to 4 parts of ammonium hydroxide, 6 to 10 parts of 1,3-dioxolane, 6 to 8 parts of t-butyl-4-methoxyphenol and 4 to 5 parts of tripropylene glycol methyl ether. The LED chip cleaning solution is high in cleaning efficiency, strong in detergency, good in safety performance, free of pollution to environment, reduced in consumption of energy and low in washing cost; and in the process of washing, the cleaning solution causing no damage to LEDs can form a protection film on the chip, isolate air, prevent water and other molecules in the atmosphere from corroding the chip, resist oxidation and facilitates subsequent operations.

Owner:ANHUI FUN OPTOELECTRONICS TECH

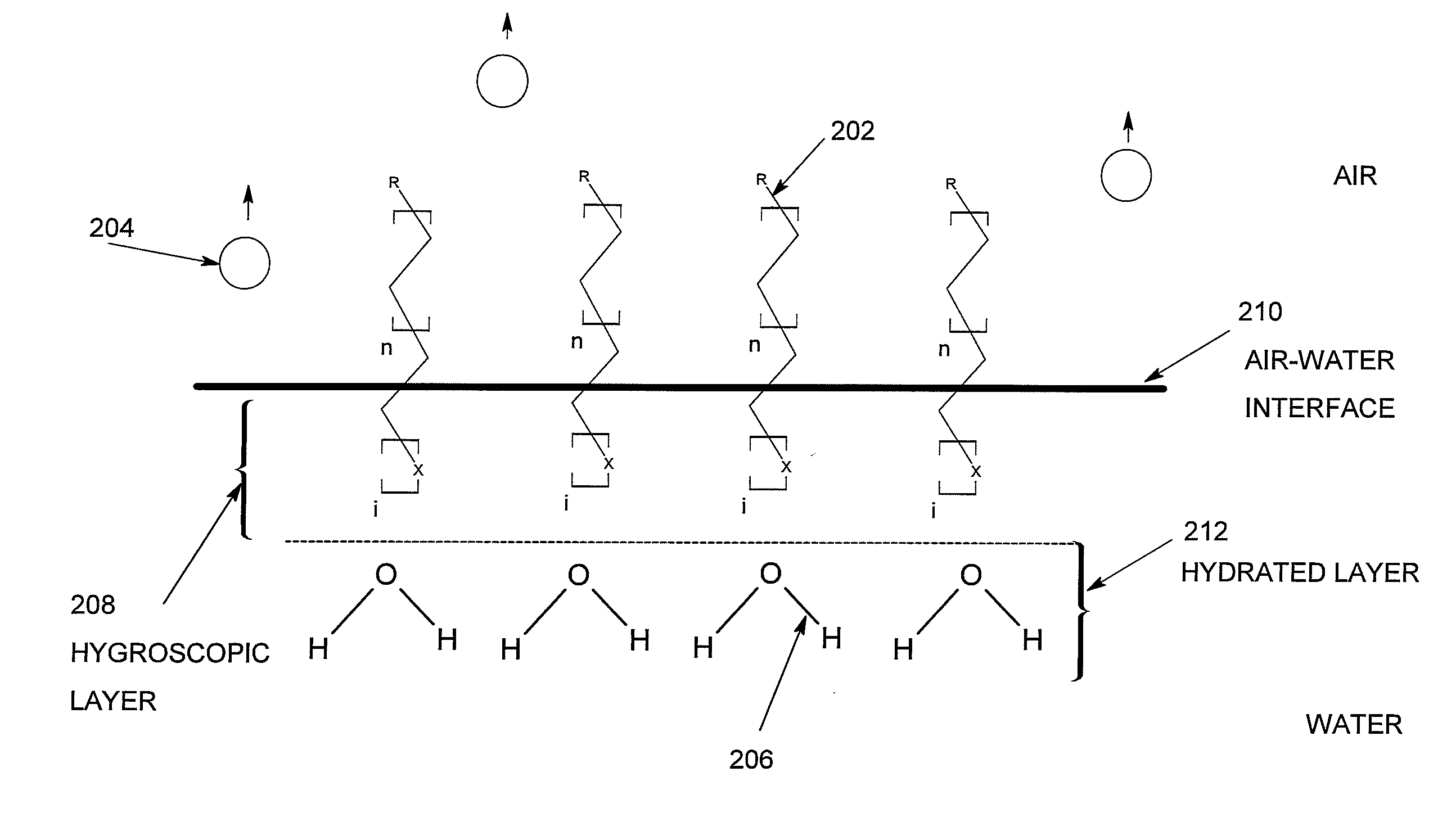

Fast-Drying Ink Composition

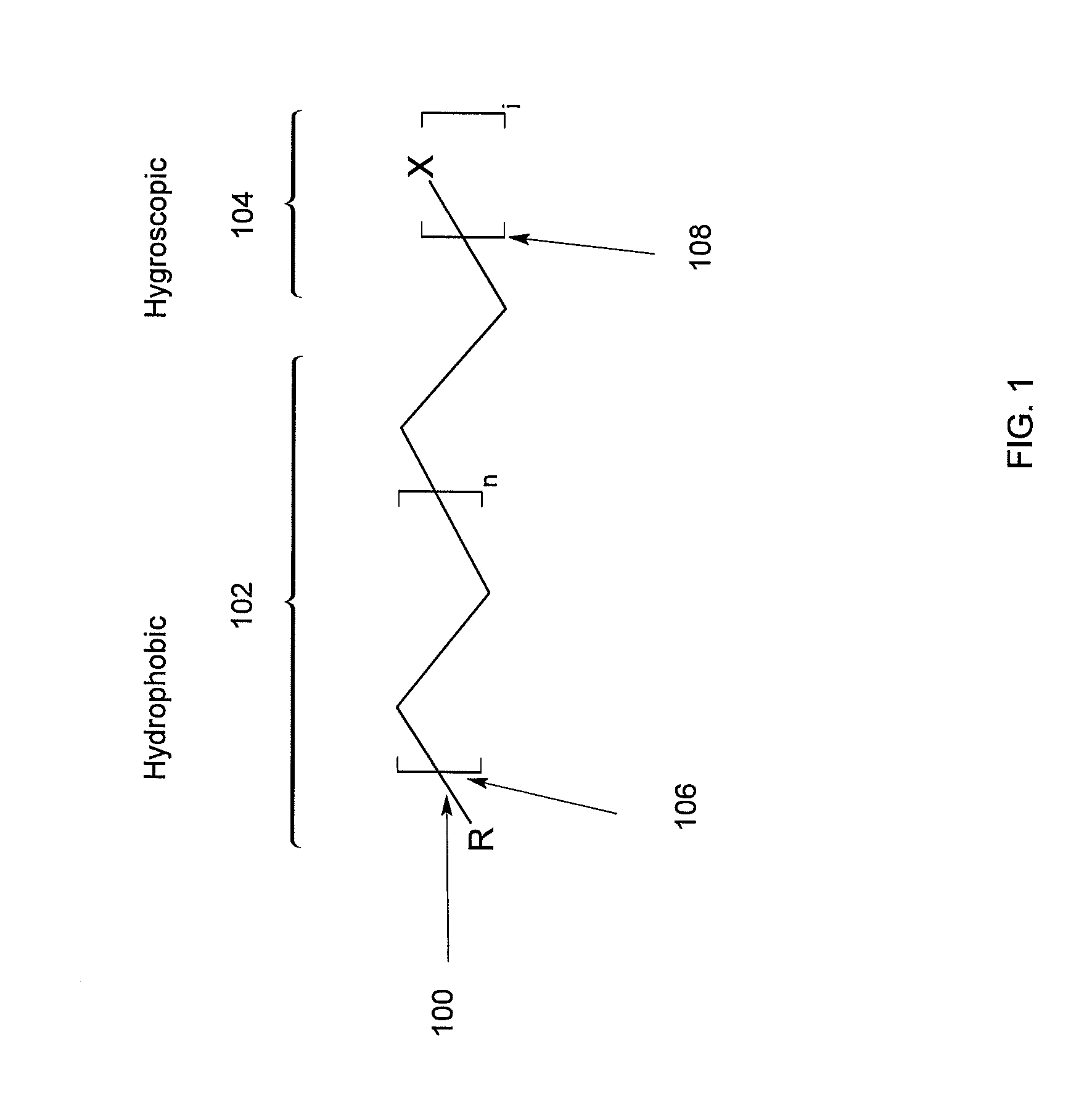

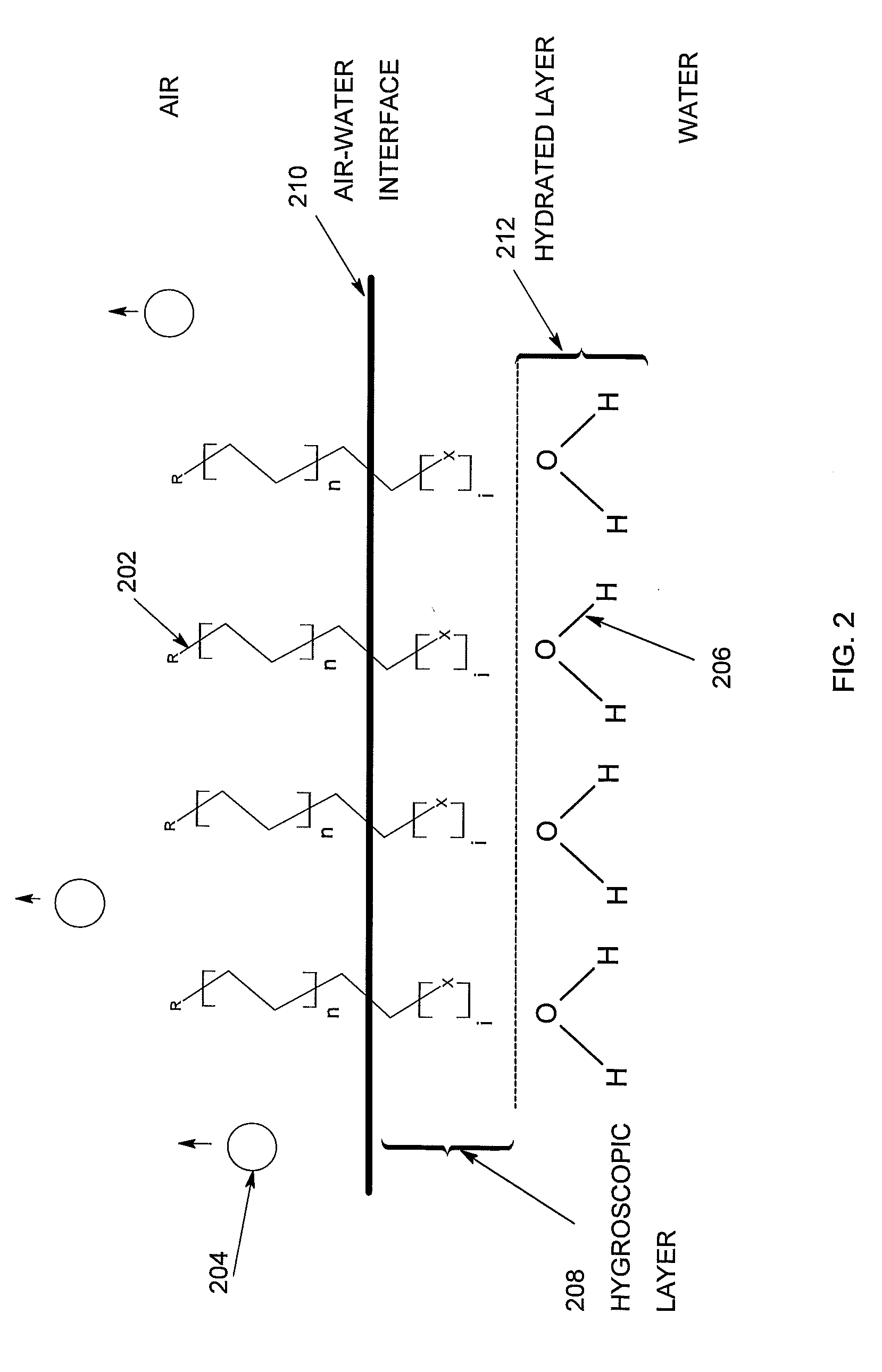

A fast-drying ink composition comprising water, a fast-drying solvent mixture including a hydrophilic co-solvent having low enthalpy of evaporation, a surface-active humectant, and a colorant. The hydrophilic co-solvent may be selected from the group consisting of propylene glycol n-propyl ether, tripropylene glycol methyl ether, and dipropylene glycol methyl ether. The surface-active humectant may comprise a hydrophobic end having a repeating unit “n” ranging from 1 to 36 and selected from the group consisting of alkane-based (CH2)n, fluoro-based (CF2)n, and silicone-based (SiO)n, and a hygroscopic end having a repeating unit “i” ranging from 2 to 8 and selected from the group consisting of a hydroxyl group, an amine group, a carboxyl group and an ester group.

Owner:BUI LOC +4

Kitchen oil stain cleaning agent and preparation method thereof

InactiveCN106479737AEasy to cleanStrong Dissolving Cleansing ActionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium metasilicateCleansing Agents

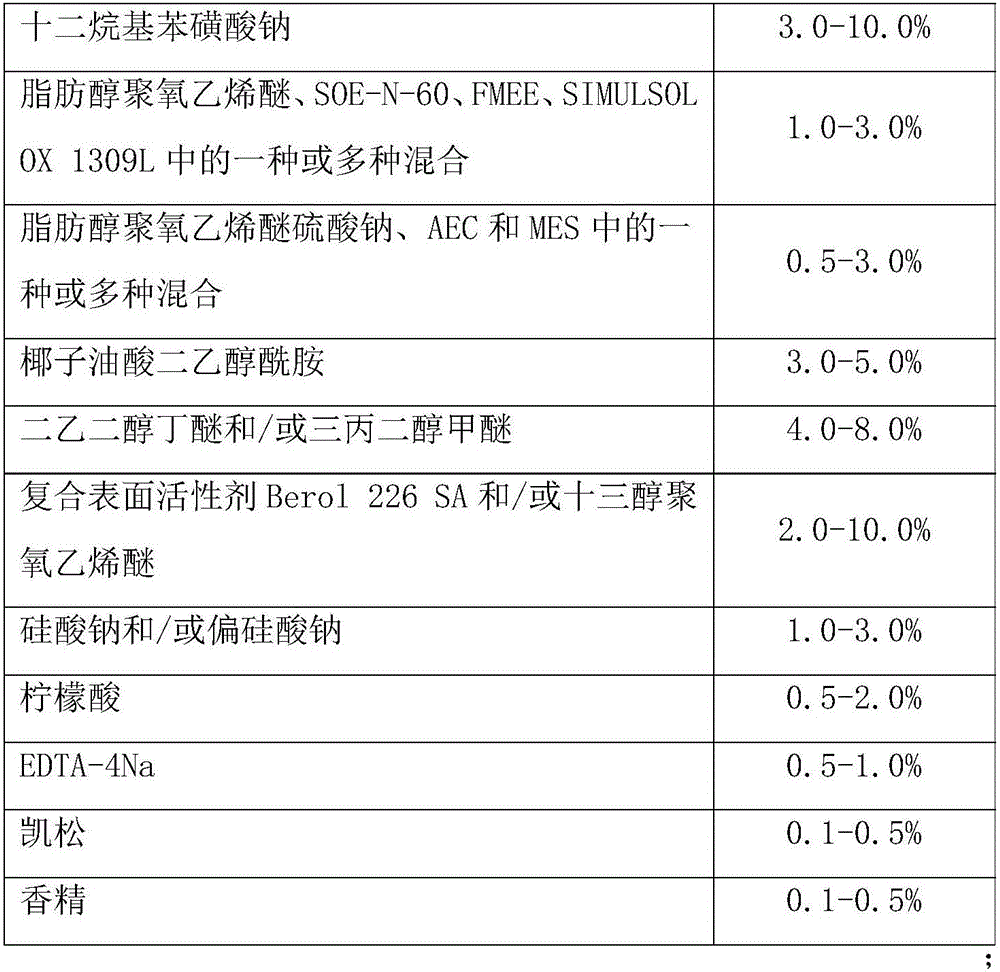

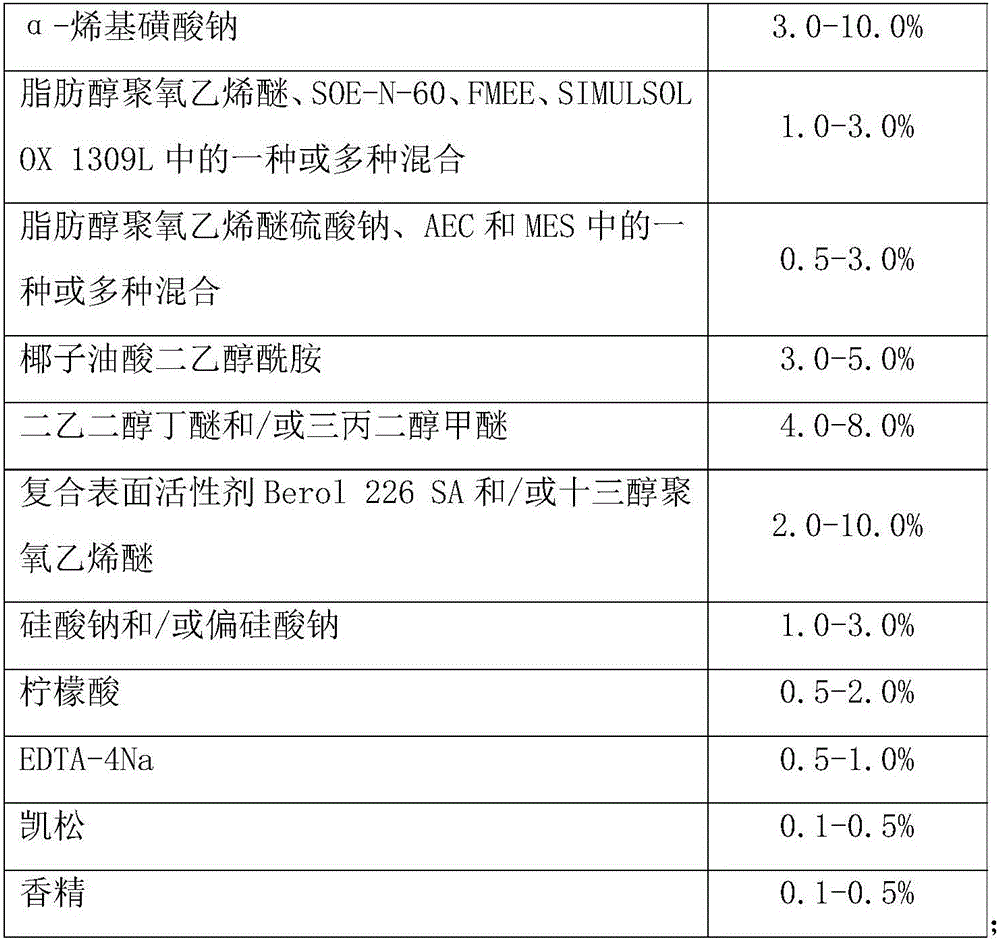

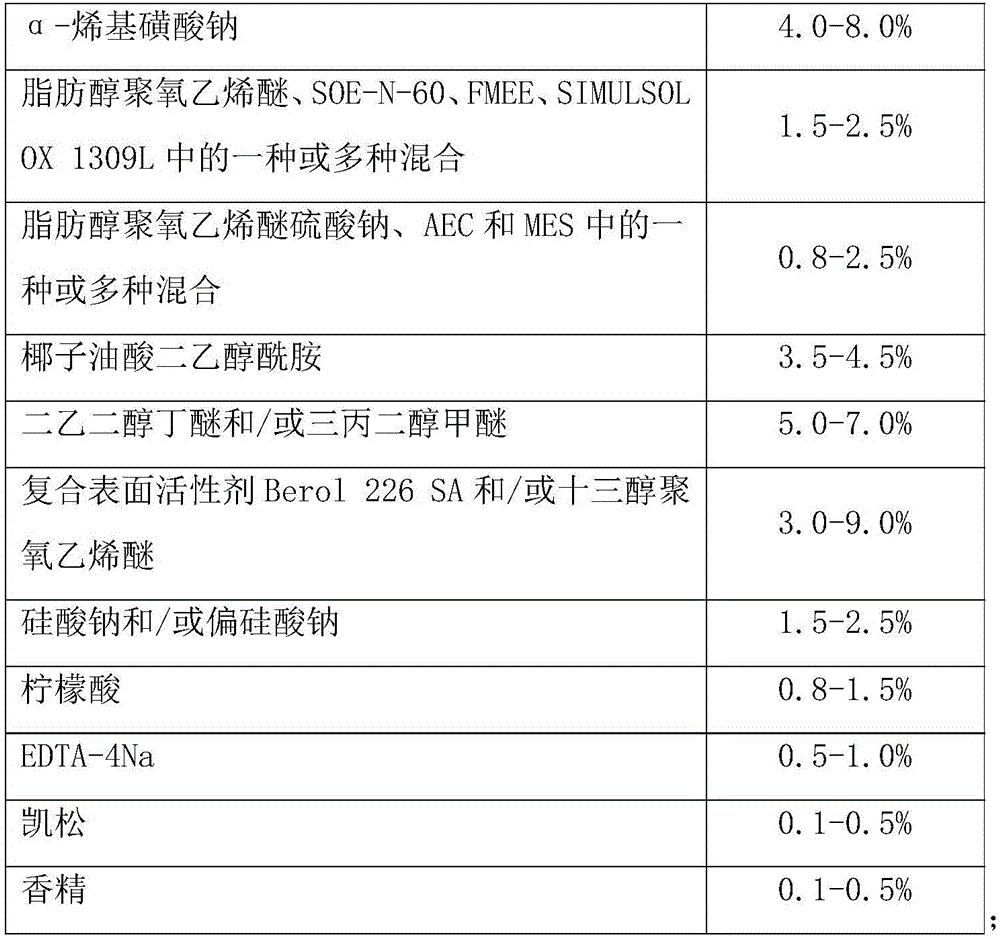

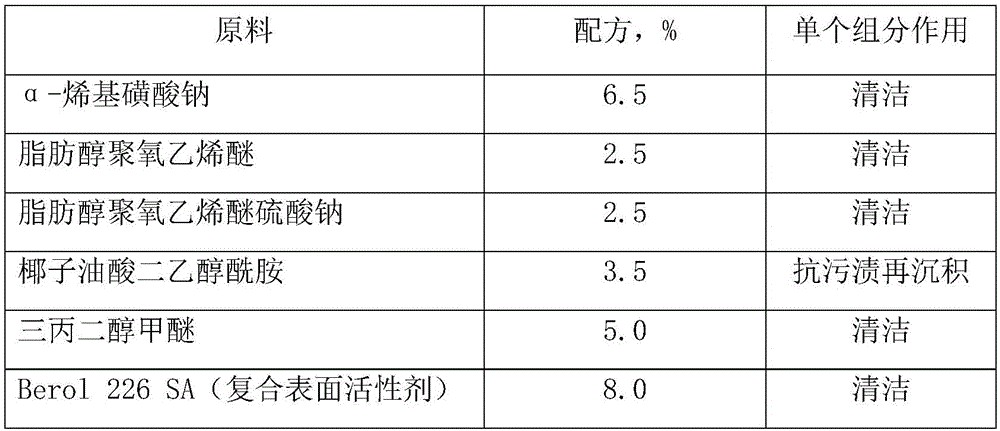

The invention relates to a kitchen oil stain cleaning agent and a preparation method thereof. The preparation method of the kitchen oil stain cleaning agent comprises the following steps: firstly, adding water into a batching tank, starting stirring, mixing one or more of sodium dodecyl benzene sulfonate, fatty alcohol-polyoxyethylene ether, SOE-N-60, FMEE and SIMULSOL OX 1309L, mixing one or more of polyoxyethylene fatty alcohol sodium sulfate, AEC and MES, adding coconut oil diethanoamine, diethylene glycol butyl ether and / or tripropylene glycol monomethyl ether, a composite surfactant Berol 226 SA and / or tridecanol polyoxyethylene ether, sodium silicate and / or sodium metasilicate, and EDTA-4 Na into the batching tank, stirring evenly, then adjusting the pH value with citric acid, adding Kathon and an essence, stirring evenly, then settling for 24 hours, and filtering. Under a condition without dismantling and washing, all kinds of oil stains are quickly permeated, softened and dissolved into liquids. The stubborn oil stains can be removed with easy wiping, and the oil stains automatically drop into an oil cup.

Owner:长兴净安环保科技有限公司

Antifreezing glass cleaning liquid

InactiveCN104342293AImprove low temperature resistanceImprove performanceInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSalicylic acidGlycerol

The invention provides antifreezing glass cleaning liquid prepared from the following raw materials in parts by weight: 6-10 parts of ethylenediamine tetramethylenephosphonic acid sodium, 3-8 parts of tripropylene glycol monomethyl ether, 5-9 parts of monoethanolamine, 6-8 parts of glycerindiacetate, 5-9 parts of coconut oil fatty acid, 4-8 parts of salicylic acid, 5-8 parts of urea, 7-9 parts of sodium hydroxide, 5-10 parts of silicone emulsion, 2-6 parts of saponin glue, 7-11 parts of propylene glycol, 6-8 parts of kudzu glue, 3-6 parts of silicon dioxide, 1-5 parts of wax and 30 parts of water. The antifreezing glass cleaning liquid has the beneficial effects of being used normally at a low temperature and having good low-temperature resistance, a good antifreezing effect and excellent performance.

Owner:QINGDAO KELIKE INFORMATION TECH

Efficient kitchen greasy dirt cleaning agent and preparation method thereof

InactiveCN106479719AEasy to cleanStrong Dissolving Cleansing ActionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsDiethylene glycol monobutyl etherSodium metasilicate

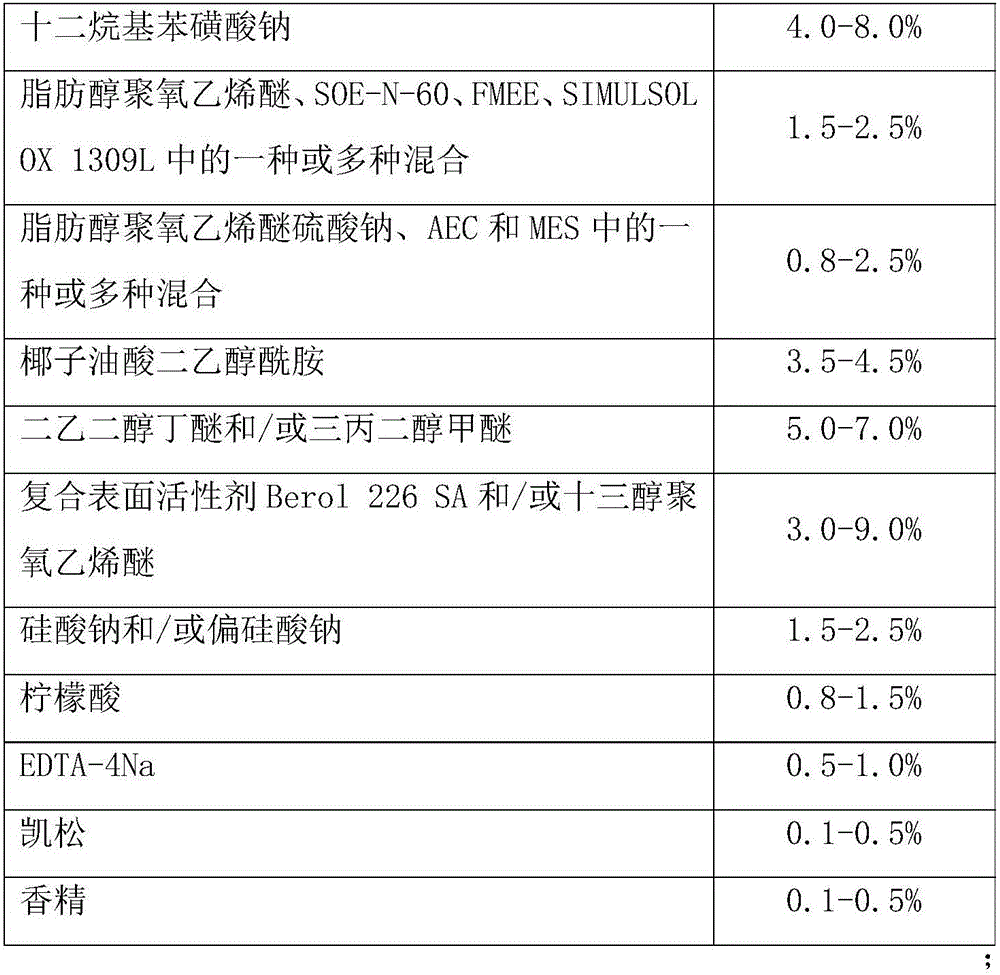

The invention relates to an efficient kitchen greasy dirt cleaning agent and a preparation method thereof. The preparation method of the efficient kitchen greasy dirt cleaning agent includes the following steps that water is added into a mixing tank, stirring is started, one or more of alpha-olefin sulfonate, fatty alcohol-polyoxyethylene ether, SOE-N-60, FMEE and SIMULSOL OX 1309L are mixed, one or more of ethoxylated lauryl alcohol sulfates, AEC and MES are mixed, coconut oil diethanoamine condensate, diethylene glycol monobutyl ether and / or tripropylene glycol monomethyl ether, composite surfactant Berol 226 SA and / or alcohol ethoxylates, sodium silicate and / or sodium metasilicate and EDTA-4Na are added into the mixing tank, the materials are evenly stirred, citric acid is used for adjusting the pH value, Kathon and essence are added, the materials are evenly stirred and settle for 24 h, and then filtering is conducted. Various kinds of greasy dirt quickly permeates, softens and is dissolved into liquid without detaching kitchen appliances for cleaning, stubborn greasy dirt can be removed without wiping with effort, and the greasy dirt automatically drops into a grease cup.

Owner:长兴净安环保科技有限公司

Down jacket dry-cleaning agent and preparation method thereof

InactiveCN106635466ADoes not affect warmth retentionEfficient removalNon-ionic surface-active compoundsOrganic detergent compounding agentsFiltrationCleansing Agents

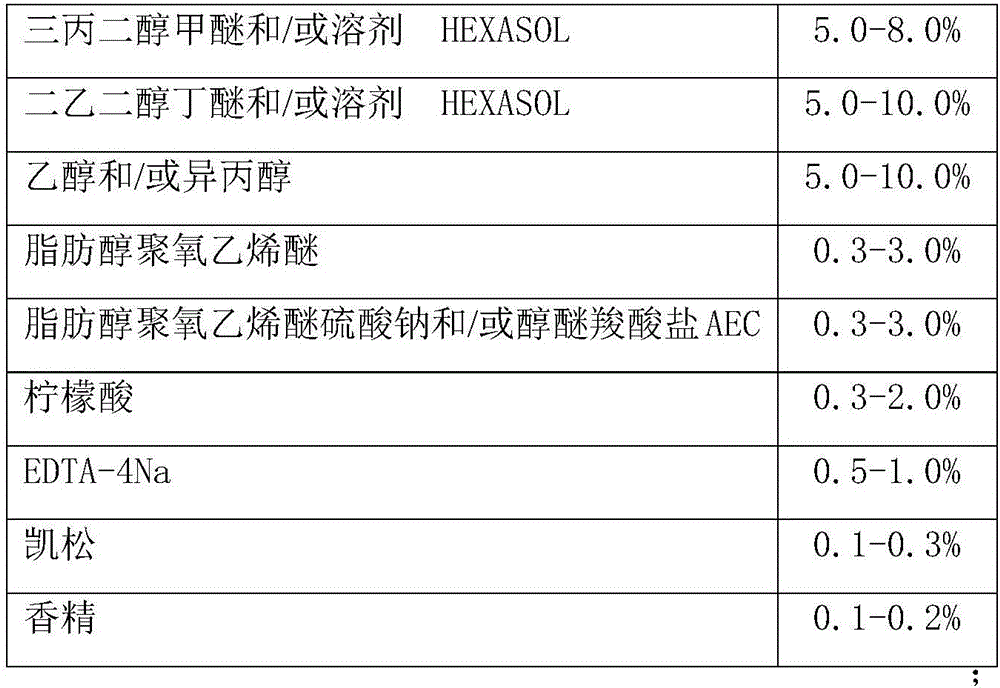

The invention relates to a down jacket dry-cleaning agent and a preparation method thereof. The preparation method of the down jacket dry-cleaning agent comprises the following steps that water is firstly added to a burdening tank, stirring begins, propylene glycol monomethyl ether and / or a solvent HEXASOL, butyl cellosolve and / or a solvent HEXASOL, ethanol and / or isopropyl alcohol, EDTA-4Na, fatty alcohol-polyoxyethylene ether sodium sulfate and / or alcohol ether carboxylate AEC and fatty alcohol polyoxyethylene ether are added into the burdening tank, a pH value is regulated with citric acid to a prescribed range, essence and Caisson are finally added, and settlement is performed for 24 hours and filtration is performed after even stirring. The down jacket dry-cleaning agent is specially used for local cleaning of a down jacket, contains multiple dry-cleaning solvents and is good in cleaning effect, free of water washing and quick to dry.

Owner:长兴净安环保科技有限公司

Novel marble cleaning agent

InactiveCN105018237AEasy to cleanEffective protectionOrganic detergent compounding agentsSurface-active detergent compositionsGluconic acidCleansing Agents

The invention discloses a novel marble cleaning agent, which comprises the following components by mass percentage: 12-20% of sodium gluconate, 2-5% of propylene glycol monomethyl ether or tripropylene glycol monomethyl ether, 5-10% of sodium dodecyl sulfate, 10-20% of calcium carbonate, 10-20% of starch, 1-3% of surfactant, 1-3% of thickening agent, 3-5% of salt, 2-4% of deionized water and 5-10% of citric acid, wherein the content of propylene glycol monomethyl ether and the content of tripropylene glycol monomethyl ether are same, and content of sodium dodecyl sulfate is 50-70%. Through the above mode, the novel marble cleaning agent has better cleaning effect by adding the raw materials such as citric acid and sodium dodecyl sulfate with appropriate proportion, and the marble surface can be effectively protected.

Owner:SUZHOU YONGCHUANGDA ELECTRONICS

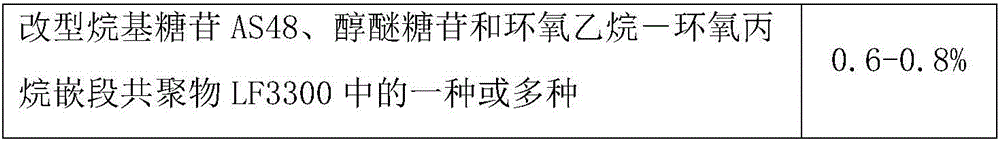

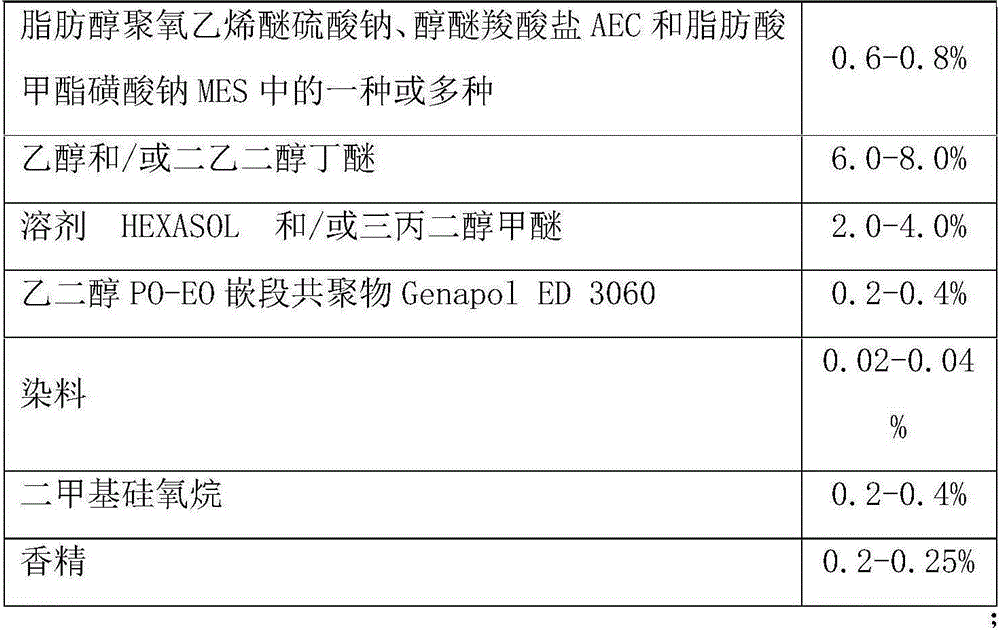

Antifogging water-ripple-proof glass cleaning agent and preparation method thereof

InactiveCN106479725AGood cleaning and anti-fog abilityNon-ionic surface-active compoundsOrganic detergent compounding agentsSucroseCleansing Agents

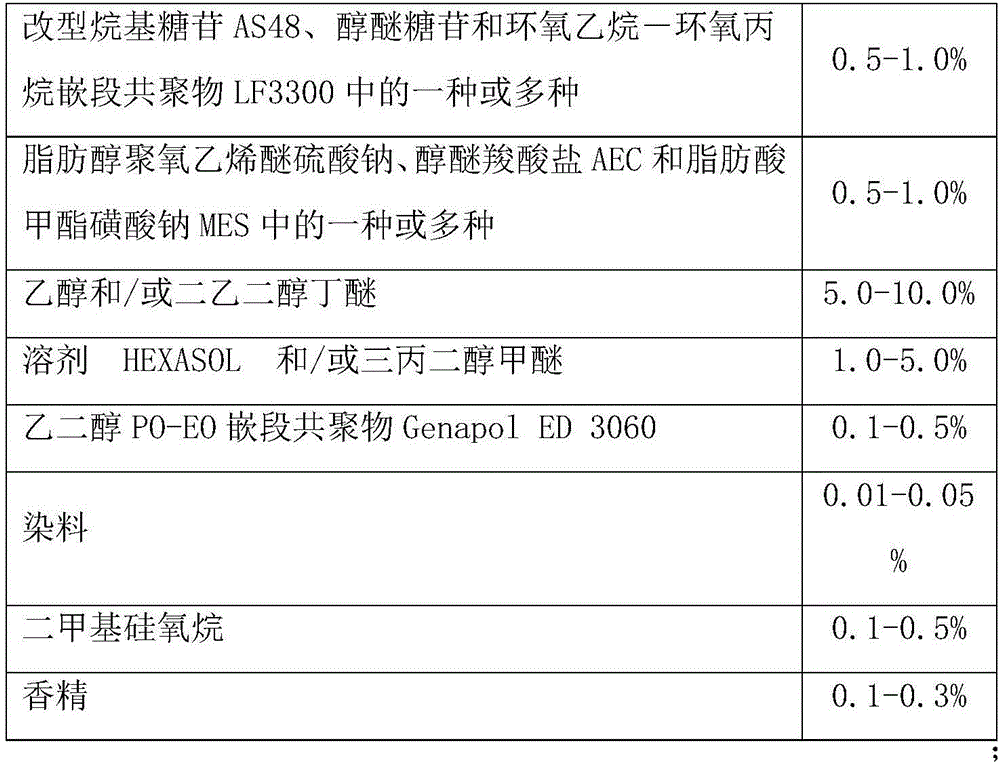

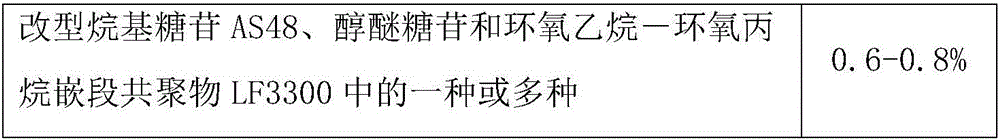

The invention relates to an antifogging water-ripple-proof glass cleaning agent and a preparation method thereof. The preparation method of the antifogging water-ripple-proof glass cleaning agent comprises the following steps: adding water into a material-mixing tank and performing stirring; adding one or more of modified alkyl glycoside AS48, alkyl ethoxy polyglycosides and an ethylene oxide-propylene oxide block copolymer LF3300, one or more of sodium alcohol ether sulphate, alcohol ether carboxylate AEC and sodium fatty acid methyl ester sulfonate MES, ethanol and / or diethylene glycol butyl ether, a solvent HEXASOL and / or tripropylene glycol monomethyl ether, sucrose ester, dimethyl siloxane, an essence, and a dye into the material-mixing tank; performing uniform stirring; and performing filtering after sedimentation for 24 hours. The antifogging water-ripple-proof glass cleaning agent has the advantages of good cleaning and antifogging abilities, and meets the requirements of industry standards QB / T 4086.

Owner:长兴净安环保科技有限公司

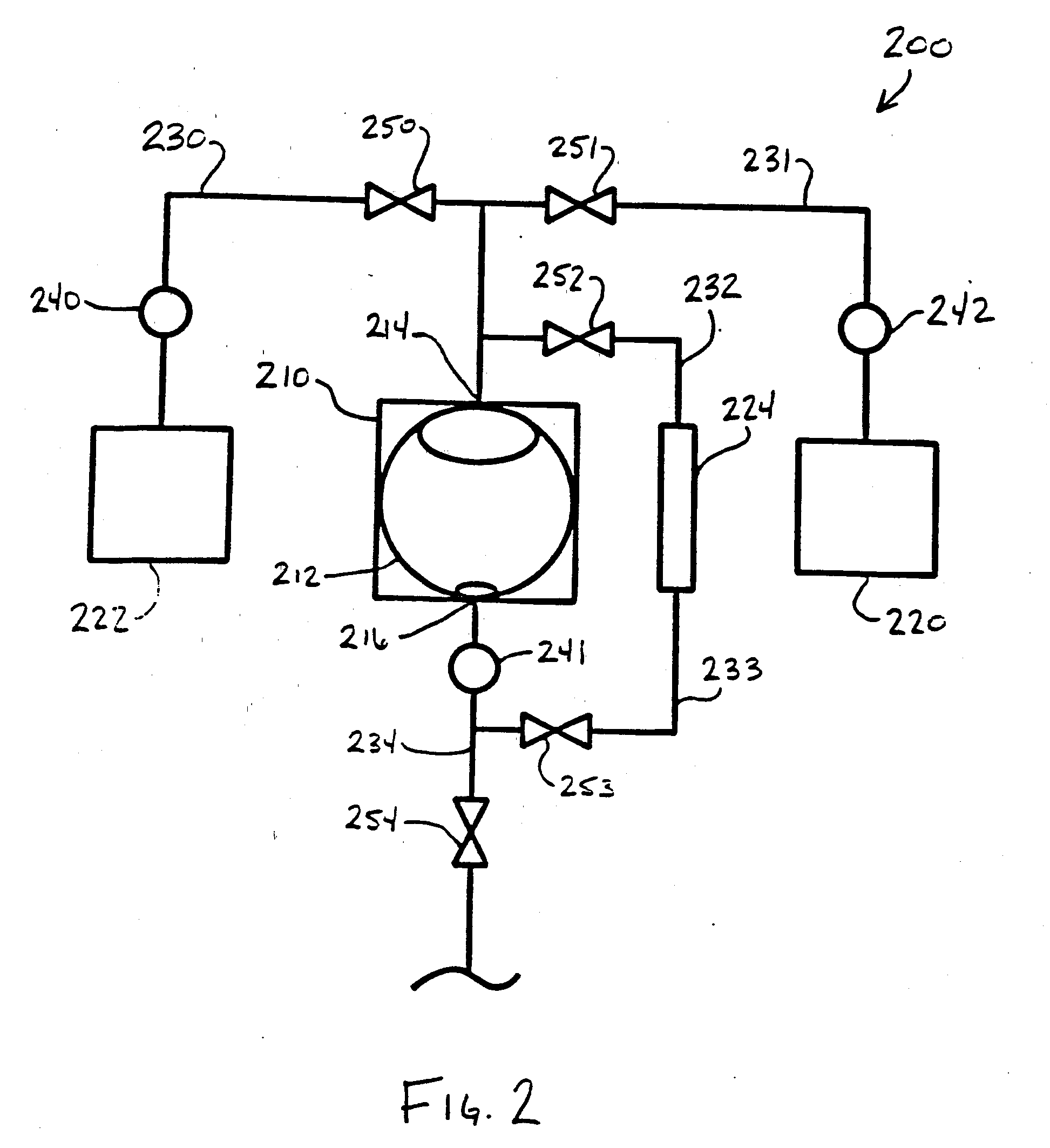

Cleaning system utilizing an organic and a pressurized fluid solvent

InactiveUS20070017036A1Efficient removalLess regulationDry-cleaning apparatusDry-cleaning apparatus for textilesSolubilitySolvent free

A cleaning system that utilizes an organic cleaning solvent and pressurized fluid solvent is disclosed. The system has no conventional evaporative hot air drying cycle. Instead, the system utilizes the solubility of the organic solvent in pressurized fluid solvent as well as the physical properties of pressurized fluid solvent. After an organic solvent cleaning cycle, the solvent is extracted from the textiles at high speed in a rotating drum in the same way conventional solvents are extracted from textiles in conventional evaporative hot air dry cleaning machines. Instead of proceeding to a conventional drying cycle, the extracted textiles are then immersed in pressurized fluid solvent to extract the residual organic solvent from the textiles. This is possible because the organic solvent is soluble in pressurized fluid solvent. After the textiles are immersed in pressurized fluid solvent, pressurized fluid solvent is pumped from the drum. Finally, the drum is de-pressurized to atmospheric pressure to evaporate any remaining pressurized fluid solvent, yielding clean, solvent free textiles. The organic solvent is preferably dipropylene glycol n-butyl ether, tripropylene glycol n-butyl ether or tripropylene glycol methyl ether, a mixture thereof, or a similar solvent and the pressurized fluid solvent is preferably densified carbon dioxide.

Owner:RACETTE TIMOTHY L +2

Special liquid crystal display screen cleaning agent

InactiveCN107354016AEasy to cleanEffective dissolutionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsEpoxyPhenyl Ethers

The invention discloses a special liquid crystal display screen cleaning agent, which comprises the following raw materials by weight: fatty alcohol polyoxyethylene ether, diethylene glycol monohexyl ether, polyoxyethylene alkyl phenyl ether, tripropylene glycol methyl ether, ethylene glycol monoethyl ether, polyoxyethylene sorbitan monooleate, coconut fatty acid diethanolamide, alkyl polyglucoside, nanometer titanium dioxide, an Enteromorpha extract, 5-chloro-2-methylisothiazolinone, N-methyl-2-pyrrolidine, sodium hydrogen ferric DTPA, and dicarboxymethyl alanine trisodium. Compared to the cleaning agent in the prior art, the cleaning agent of the present invention contains the small-molecule acids extracted from the marine plants, can effectively dissolve dust, bug dead bodies, residual glues and other dirt adhered on the liquid crystal display screen surface, can effectively clean the impurities on the surface of light-emitting diode epoxy resin materials, does not corrode liquid crystal display screens and substrates, and further has advantages of safety to environment, environmental protection, no toxicity, and no harm.

Owner:HEFEI HUIKE PRECISION DIE CO LTD

Electronic part washing agent and preparation method thereof

InactiveCN104450231ANo damageImprove cleaning efficiencyInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsMonomethyl etherCoconut oil

The invention relates to an electronic part washing agent and a preparation method thereof. The electronic part washing agent comprises the following components in percentage by weight: 25%-35% of coconut oil glycol amide, 5%-10% of diethanol amine, 3%-6% of sodium silicate, 1%-5% of citric acid, 3%-8% of tripropylene glycol monomethyl ether, 3%-5% of an antirust agent, 1%-35 of a penetrating agent, 0.3%-1% of a stabilizer and the balance of deionized water. The preparation method of the electronic part washing agent comprises the following steps: preparing all the components according to the weight ratio, mixing coconut oil glycol amide, diethanol amine, sodium silicate, citric acid and tripropylene glycol monomethyl ether with the deionized water, heating to 40-50 DEG C by stirring at a rotation rate of 800-1000 rotations per minute, adding the antirust agent, the penetrating agent and the stabilizer, and continuing to stir for 10-15 minutes. The electronic part washing agent is high in washing efficiency, strong in decontamination capability, high in safety performance, free of the environment pollution and low in washing cost; the energy is saved; the damage to electronic parts in the washing process can be avoided.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Organic carrier used for front silver paste and preparation method thereof

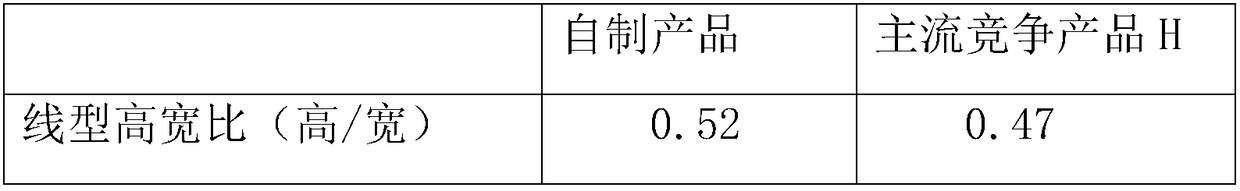

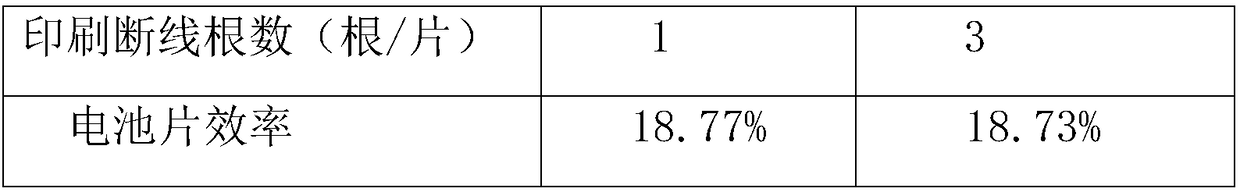

ActiveCN109390074AGuaranteed Aspect RatioImprove efficiencyNon-conductive material with dispersed conductive materialSemiconductor devicesAcrylic resinTG - Triglyceride

The invention discloses an organic carrier used for a front silver paste. The organic carrier is characterized by being composed of the following raw materials by weight: 25% to 35% of diethylene glycol octyl ether, 15% to 27%vof tripropylene glycol methyl ether, 10% to 18% of butyl group carbitol acetate, 20% to 25% of triglyceride-modified silicone resin, 0.3% to 2% of rosin-modified acrylic resin, 1%~ 4% of dispersant (BYK-110), and 1% to 4% of dispersant (BYK-111). According to the invention, the triglyceride-modified silicone resin is introduced in the organic carrier prepared by the invention, so the depth-width ratio of the line type is ensured; the efficiency of a cell sheet is improved, and the organic carrier has excellent printing characteristics; by introducing a small amount of rosin-modified acrylic resin, the adhesion of the silver film layer and the silicon substrate after the silver paste is dried is ensured; falling-off phenomena will not occur; the solderability of the silver film layer after sintering with the soldering ribbon is promoted; and improvement of the adhesion is ensured.

Owner:上海银浆科技有限公司

Method for preparing dipropylene glycol methyl ether by means of continuous reaction

The invention discloses a method for preparing dipropylene glycol methyl ether by means of continuous reaction. The method includes steps of mixing and preheating 2-methoxy-1-propanol, propylene epoxide and strong-alkali catalysts with one another; then feeding the 2-methoxy-1-propanol, the propylene epoxide and the strong-alkali catalysts into pipeline reactors; carrying out etherification reaction; ultimately collecting the dipropylene glycol methyl ether from reaction products. The dipropylene glycol methyl ether is a target product. The method for preparing the dipropylene glycol methyl ether has the advantages that the continuous etherification reaction is carried out, the method includes simple processes, is few in byproducts and high in production efficiency and is safe and environmentally friendly, and separation can be facilitated; the propylene epoxide conversion rate is 100%, the total content of deep reaction byproducts (including tripropylene glycol monomethyl ether) in the etherification products is lower than 4%, the yield of the dipropylene glycol methyl ether is higher than or equal to 96%, and the content (the sum of isomers) of the dipropylene glycol methyl etheris higher than or equal to 99.8%.

Owner:JIANGSU HUALUN CHEM +1

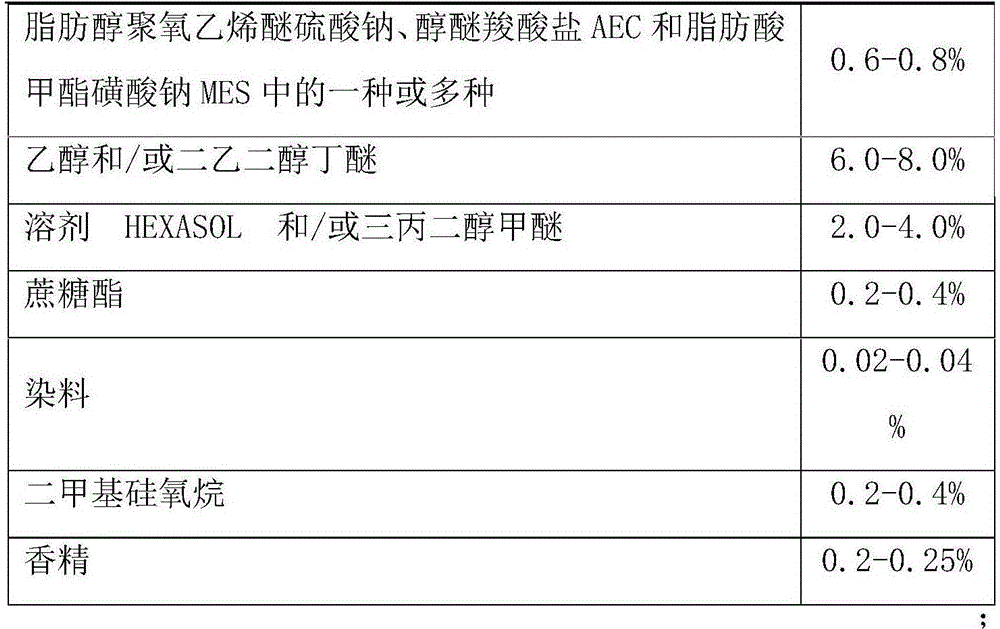

Glass cleaner and preparation method thereof

InactiveCN106479721AGood cleaning and anti-fog abilityNon-ionic surface-active compoundsOrganic detergent compounding agentsDiethylene glycol monobutyl etherSolvent

The invention relates to a glass cleaner and a preparation method thereof. The preparation method of the glass cleaner comprises the following steps: firstly, adding water into a blending tank, starting stirring, adding one or several kinds of compounds consisting of modified alkyl polyglucoside AS 48, alkyl ethoxy polyglycosides and ethylene oxide-propylene oxide block copolymer LF3300, one or several kinds of compounds consisting of sodium alcohol ether sulphate, alcohol ether carboxylate AEC and fatty acid methyl ester sulfonate MES, ethanol and / or diethylene glycol monobutyl ether, solvent HEXASOL and / or tripropylene glycol monomethyl ether, ethylene glycol PO-EO block copolymer Genapol ED3060, dimethyl siloxane, an essence and a dye into the blending tank, uniformly stirring the mixture, and allowing the mixture to settle for 24 hours, and filtering the mixture. The product has good cleaning and anti-fog capability, and the product quality conforms to the industry standard QB / T4086.

Owner:长兴净安环保科技有限公司

Electronic element cleaning agent and preparation method thereof

InactiveCN104388216ANo corrosionAvoid corrosionSurface-active non-soap compounds and soap mixture detergentsPhosphoric acidCleansing Agents

The invention relates to an electronic element cleaning agent and a preparation method thereof. The electronic element cleaning agent comprises the following components in percentage by weight: 20-30% of fatty alcohol polyoxyethylene, 3-12% of diethanol amine, 3-8% of organic phosphoric acid, 3-6% of tripropylene glycol monomethyl ether, 1-5% of rust inhibitor, 1-3% of penetrating agent, 0.5-1.5% of PH regulator and the balance of deionized water. The preparation method comprises the steps of preparing all the components according to the weight ratio; sequentially placing the fatty alcohol polyoxyethylene, diethanol amine, organic phosphoric acid, tripropylene glycol monomethyl ether and deionized water into a stirrer to mix, heating to 40 DEG C, and uniformly stirring all the components; and then, adding the rust inhibitor, the penetrating agent and the PH regulator to stir for 10-15 minutes. The electronic element cleaning agent is capable of rapidly dissolving and clearing various kinds of dirt and impurities attached on an electronic element, incapable of generating new ionic pollution, free of corrosion to the electronic element and good in cleaning effect.

Owner:WUXI NUIST WEATHER SENSOR NETWORK TECH

Aluminum metal detergent and preparation method thereof

InactiveCN107675189AGood removal effectImprove cleaning efficiencyMonomethyl etherSODIUM METHYL COCOYL TAURATE

The invention relates to the field of chemical materials, provides an aluminum metal detergent and meanwhile further provides a preparation method of the aluminum metal detergent. The aluminum metal detergent is characterized by comprising the following components of, by weight, 20-30 parts of a surfactant, 5-10 parts of a detergent assistant, 1-5 parts of a chelating agent, 5-10 parts of a penetrant, 5-10 parts of an additive, 2-4 parts of sodium methyl cocoyl taurate, 2-5 parts of tripropylene glycol monomethyl ether and 50-60 parts of water. The preparation method comprises the following steps that the surfactant, the detergent assistant, the chelating agent and the penetrant are added into the water, stirring is conducted for 10-15 min, then other surplus materials are added, stirringis conducted for 10-15 min again, and under heating, stirring continues to be conducted for 50-60 min. The aluminum metal detergent has the characteristics that the use quantity is small and the cleaning effect is good.

Owner:ZHEJIANG HANQIANG AUTOMATION EQUIP

Glass cleaning agent based on tripropylene glycol methyl ether and tripropylene glycol butyl ether

InactiveCN105623905AEffectively removeSimple recipeAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsCoconut diethanolamideTetradecyldimethylamine oxide

The invention discloses a glass cleaning agent based on tripropylene glycol methyl ether and tripropylene glycol butyl ether. The glass cleaning agent comprises the following raw materials by mass percentage: 8-14% of tripropylene glycol methyl ether, 11-17% of tripropylene glycol butyl ether, 5-8% of tetradecyldimethyl amine oxide, 16-22% of glyceryl monostearate, 4-9% of sodium alkyl benzene sulfonate, 11-22% of ethanol, 2-6% of coconut diethanolamide, and 17-28% of deionized water. The glass cleaning agent based on tripropylene glycol methyl ether and tripropylene glycol butyl ether can effectively remove surface spots on the glass, and has the advantages of simple formula, low cost, and convenient usage.

Owner:NANJING AILU NEW ENERGY TECH CO LTD

Special cleaning agent for kitchen appliances

InactiveCN107937172ACompatibility is reasonableReduce consumptionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium metasilicateSurface cleaning

The invention discloses a special cleaning agent for kitchen appliances. The special cleaning agent for the kitchen appliances is mainly prepared from the following active components: sodium dodecyl benzene sulfonate, trisodium phosphate, acetone, a gynostemma pentaphylla alcohol extract, tripropylene glycol monomethyl ether, diethanolamine, lauryl betaine, sodium tartrate, dodecyl glucoside, sodium metasilicate pentahydrate, polyvinylpyrrolidone and a Chinaberry seed extract. The raw materials of the tile surface cleaning agent are combined reasonably, so that the cleaning agent has high dirt-removing ability and small side effect, and is safe and convenient to use. The cleaning efficiency is high, the cleaning time is obviously shortened and the consumption of medicines can be obviouslyreduced. The cleaning efficiency is high and the cleaning effect is good. The glaze of a kitchen cabinet and the glass surface or plate material on the surfaces of the kitchen appliances are not damaged.

Owner:TIANE HONGCHANG AGRI MACHINERY SPECIALIZED COOP

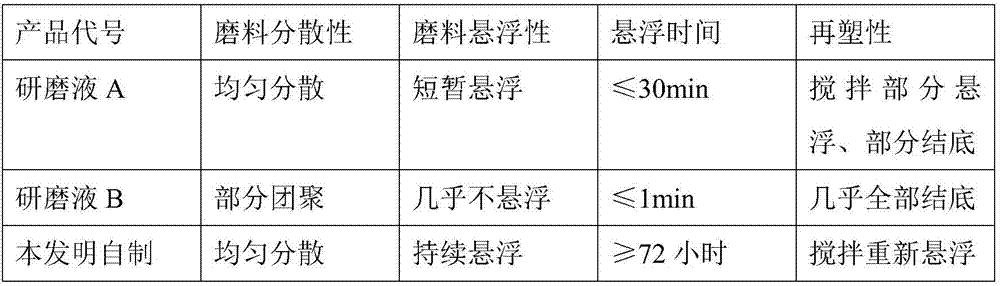

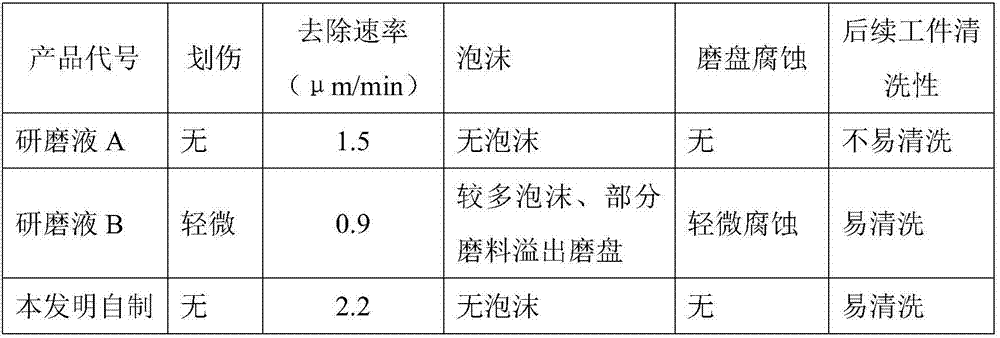

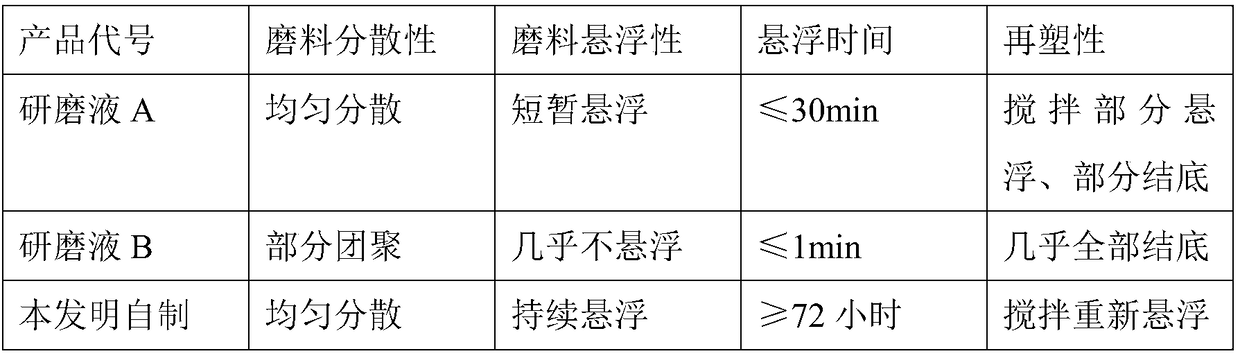

Water-based grinding fluid suspension additive

ActiveCN106939145AImprove permeabilityImprove rust resistancePolishing compositions with abrasivesWater basedElectrolysis

The invention discloses a water-based grinding fluid suspension additive. The water-based grinding fluid suspension additive comprises main components: a suspension stabilizer SF-1, a thickening agent ACRYSOL TT-935, a moisturizing agent VK-N80, ammonium polyphosphate, tripropylene glycol monomethyl ether, a lubricant MPEG-600, a defoaming agent Surfynol DF-75, and alkaline electrolysis water. The water-based grinding fluid suspension additive can be used for uniformly dispersing and suspending various types of unprocessed abrasive particles, such as alumina, zirconia, silicon carbide, boron carbide, natural or synthetic diamond, garnet and the like. The water-based grinding fluid suspension additive has excellent suspension performance, can save as much as 50% of an abrasive, and also can achieve the same or better grinding rate and grinding quality. The water-based grinding fluid suspension additive has excellent chemical and physical performance, is widely applied in industrial grinding, and is suitable for the field of sapphire grinding.

Owner:CHINA THREE GORGES UNIV

Polystyrene composite high-toughness storage battery shell body

The invention discloses a polystyrene composite high-toughness storage battery shell body and relates to the technical field of storage battery shell bodies. The polystyrene composite high-toughness storage battery shell body is prepared from the following components: polyadipic acid ethylene glycol, N,N-diethyl aniline, sepiolite powder, potassium zirconium carbonate, dioctyl sebacate, polyvinylchloride, polystyrene, sodium hypophosphite hydrate, an anti-impact modifier ACM, paraformaldehyde, chlorinated spirocyclic phosphate, aluminum chloride hexahydrate, triethylamine, tripropylene glycolmonomethyl ether, ammonium octamolybdate and carbon nanotubes. The polystyrene composite high-toughness storage battery shell body disclosed by the invention has the advantages of high efficiency andimpact resistance, high heat resistance, high toughness, fatigue resistance, weather resistance, resistance to corrosion caused by alkali and acid, oil and halogenated hydrocarbon, and strong hydrolysis resistance; a preparation technology is environmentally friendly and utilized equipment is simple, convenient to operate and low in preparation cost, so that the polystyrene composite high-toughness storage battery shell body has very high practical value.

Owner:四会市启德信息咨询服务有限公司

Tile cleaning agent

InactiveCN108277120AProtection hasReasonable formulaSurface-active non-soap compounds and soap mixture detergentsCyclohexanoneSodium bicarbonate

The invention provides a tile cleaning agent, which is characterized by being prepared from the following raw materials in parts by weight: 6 to 12 parts of tripropylene glycol methyl ether, 2 to 4 parts of lauryl sodium sulfate, 1 to 3 parts of diamond micro-powder, 3 to 5 parts of diosgenin, 3 to 7 parts of cyclohexanone, 2 to 6 parts of sodium bicarbonate, 10 to 18 parts of methyl salicylate, 12 to 16 parts of eugenol, 10 to 20 parts of deionized water and 1 to 3 parts of a thickener. The tile cleaning agent can achieve an effect of protecting tiles, is reasonable in formula and easy to operate, can deeply clean stubborn stains, and has the advantages of protecting the tiles and not damaging the hard surfaces of the tiles.

Owner:张烨健

Zero-VOC hard surface cleaning agent composition

PendingCN113528254AEfficient removalStrong decontaminationCationic surface-active compoundsOrganic detergent compounding agentsActive agentCleansing Agents

The invention discloses a zero-VOC hard surface cleaning agent composition which comprises the following components in percentage by mass: 2.0-8.0% of a composite surfactant, 4.0%-10.0% of a compound alcohol ether solvent; 2.0%-6.0% of an alkaline auxiliary agent; 0.1%-0.5% of a chelating agent; 0.1%-0.5% of a bacteriostatic agent; and the balance of water. The composite surfactant is selected from at least two of octyl decyl glucoside, lauramide propyl betaine and octadecanamide propyl betaine; the compound alcohol ether solvent is selected from at least two of 4-hydroxymethyl-2-isobutyl-2-methyl-1, 3-dioxolame, tripropylene glycol monomethyl ether and tripropylene glycol butyl ether, the alkaline auxiliary agent is selected from at least one of triethanolamine and diisopropanolamine; the chelating agent is selected from at least one of sodium citrate, EDTA-4Na and sodium gluconate; the raw materials are compounded according to a specific ratio, so that living stains such as oil stains, soap scales and the like can be effectively removed, and the VOC detection result of the whole composition is zero.

Owner:广州超威生物科技有限公司

A water-based abrasive suspension additive

ActiveCN106939145BGood suspension and dispersion performanceUniform suspension statePolishing compositions with abrasivesWater basedElectrolysis

The invention discloses a water-based grinding fluid suspension additive. The water-based grinding fluid suspension additive comprises main components: a suspension stabilizer SF-1, a thickening agent ACRYSOL TT-935, a moisturizing agent VK-N80, ammonium polyphosphate, tripropylene glycol monomethyl ether, a lubricant MPEG-600, a defoaming agent Surfynol DF-75, and alkaline electrolysis water. The water-based grinding fluid suspension additive can be used for uniformly dispersing and suspending various types of unprocessed abrasive particles, such as alumina, zirconia, silicon carbide, boron carbide, natural or synthetic diamond, garnet and the like. The water-based grinding fluid suspension additive has excellent suspension performance, can save as much as 50% of an abrasive, and also can achieve the same or better grinding rate and grinding quality. The water-based grinding fluid suspension additive has excellent chemical and physical performance, is widely applied in industrial grinding, and is suitable for the field of sapphire grinding.

Owner:CHINA THREE GORGES UNIV

Reinforced heat-resistant optical cable filler composition

InactiveCN108976789AImprove thermal conductivityReduce bloatTetramethylammonium hydroxideSodium Pyrithione

The invention discloses a reinforced heat-resistant optical cable filler composition and relates to the field of communication material related technologies. The reinforced heat-resistant optical cable filler composition disclosed by the invention comprises the following components: 2,4-imidazolidinone, tripropylene glycol monomethyl ether, octamethylcyclotetrasiloxan, octaphenyl-POSS, tetramethylammonium hydroxide, dimethylacetamide, octaphenylcyclotetrasiloxane, 4,4'-diaminodiphenyl ether, 20-25% of ammonium hydroxide, a high temperature regulator, benzenetetracarboxylic anhydride, aramid fibers, N-methyl-2-pyrrolidone, modified high density polyethylene, dibutyl phthalate, polyisobutene, zinc pyrithione, silicon carbide, trimethylethoxylethylenediamine, nylon, epoxidized soybean oil, aresistance agent and silicon dioxide thickening poly alpha-olefin. The reinforced heat-resistant optical cable filler composition disclosed by the invention is excellent in bending performance and anti-pressure ability, excellent in thermal stability, radiation stability and mechanical protectiveness, high in anti-pressure ability, capable of well avoiding external environment damage and long in storage time.

Owner:ANHUI COMM IND SERVICE CO LTD

Environmentally safe and non-toxic automotive front glass cleaning solution

InactiveCN109207280APlay a cleaning roleTransparent and clear visionInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsTectorial membraneAntioxidant

The invention discloses an environmentally safe and non-toxic automotive front glass cleaning solution and belongs to the technical field of glass cleaners. The cleaning solution is prepared from thefollowing components (by weight): 28-45 parts of a surfactant, 20-38 parts of coconut diethanol amide, 5-8 parts of a stabilizer, 4-9 parts of ethylene glycol, 18-28 parts of sodium dodecyl sulfate, 16-18 parts of lauryl betaine, 5-12 parts of tripropylene glycol methyl ether, 3-6 parts of glycerol, 3-9 parts of sodium hydrogen carbonate, 1-3 parts of mint essence, 2-5 parts of an antistatic agent, 2-5 parts of an antioxidant, and 45-75 parts of deionized water. According to the invention, the dust on the automotive glass can be removed efficiently and quickly, the friction between a wiper andthe glass surface can be effectively reduced, and a protective film is formed on the surface of the glass. As a result, the dual function of protecting the glass and the wiper is achieved. The cleaning solution provided by the invention has an obvious cleaning effect, and is nontoxic, environmentally-friendly, anti-fog, de-icing, corrosion-resistant and incombustible.

Owner:肖圣华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com