A water-based abrasive suspension additive

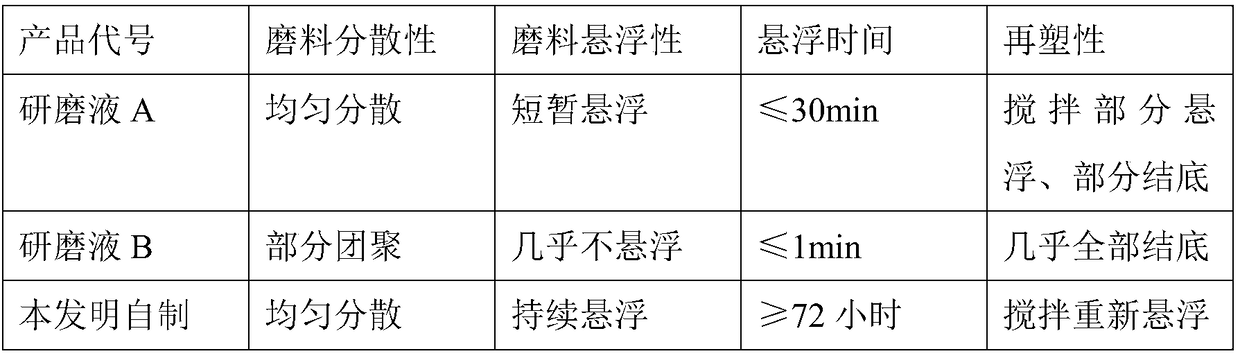

A technology of additives and grinding fluids, which is applied in the field of suspension additives for water-based grinding fluids, which can solve the problems of fast grinding fluid loss, workpiece scratches, and slow grinding speed, and achieve good suspension and dispersion performance, prevent acidification and corrosion, and increase grinding speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 3 parts of suspension stabilizer SF-1, 5 parts of humectant VK-N80, 8 parts of tripropylene glycol methyl ether, 76 parts of alkaline electrolyzed water, 8 parts of ammonium polyphosphate, among which ammonium polyphosphate with a degree of polymerization of 10 is selected.

[0027] The preparation method of above-mentioned embodiment:

[0028] 1) Add the suspension stabilizer SF-1 into the alkaline electrolyzed water, fully stir and swell with a tissue homogenizer at a speed of 4000r / min, and obtain a transparent gel for use;

[0029] 2) Dissolve humectant VK-N80 and ammonium polyphosphate with alkaline electrolyzed water to obtain a solution for later use;

[0030] 3) Slowly add the material obtained in step 1) into tripropylene glycol methyl ether by using a nano-disperser while adding and dispersing at room temperature, and fully stir and disperse;

[0031] 4) Preheat the material obtained in the above step 3) to 78°C by microwave, and slowly add the material in st...

Embodiment 2

[0033] 5 parts of suspension stabilizer SF-1, 1 part of humectant VK-N80, 7 parts of tripropylene glycol methyl ether, 66 parts of alkaline electrolyzed water, 6 parts of ammonium polyphosphate, and 15 parts of triethanolamine. Among them, ammonium polyphosphate with a degree of polymerization of 6 is selected.

[0034] The preparation method of above-mentioned embodiment:

[0035] 1) Add the suspension stabilizer SF-1 into the alkaline electrolyzed water, fully stir and swell with a tissue homogenizer at a speed of 4000r / min, and obtain a transparent gel for use;

[0036] 2) Dissolve humectant VK-N80, ammonium polyphosphate, and triethanolamine in alkaline electrolyzed water to obtain a solution for later use;

[0037] 3) Slowly add the material obtained in step 1) into tripropylene glycol methyl ether by using a nano-disperser while adding and dispersing at room temperature, and fully stir and disperse;

[0038] 4) Preheat the material obtained in the above step 3) to 75°C...

Embodiment 3

[0040] 2 parts of suspension stabilizer SF-1, 4 parts of humectant VK-N80, 5 parts of tripropylene glycol methyl ether, 81 parts of alkaline electrolyzed water, 5 parts of ammonium polyphosphate, 2 parts of thickener ACRYSOL TT-935, lubricant MPEG -600 0.5 parts, defoamer Surfynol DF-750.5 parts. Among them, ammonium polyphosphate with a degree of polymerization of 18 is selected.

[0041] The preparation method of above-mentioned embodiment:

[0042] 1) Add the suspension stabilizer SF-1 and the thickener ACRYSOL TT-935 into the alkaline electrolyzed water, and use a tissue homogenizer to fully stir and swell at a speed of 4000r / min to obtain a transparent gel for use;

[0043] 2) Dissolve humectant VK-N80, ammonium polyphosphate, lubricant MPEG-600, and defoamer Surfynol DF-75 in alkaline electrolyzed water to obtain a solution for later use;

[0044] 3) Slowly add the material obtained in step 1) into tripropylene glycol methyl ether by using a nano-disperser while adding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com