A kind of coal-water slurry additive containing cardanol sulfonate and its application

A technology of cardanol sulfonate and additives, which is applied in the field of coal water slurry additives, and achieves the effects of low cost, abundant sources and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

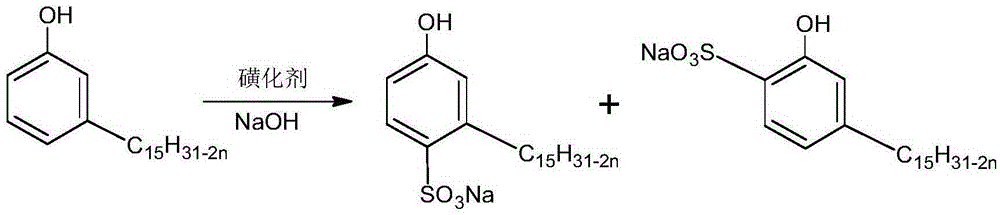

Method used

Image

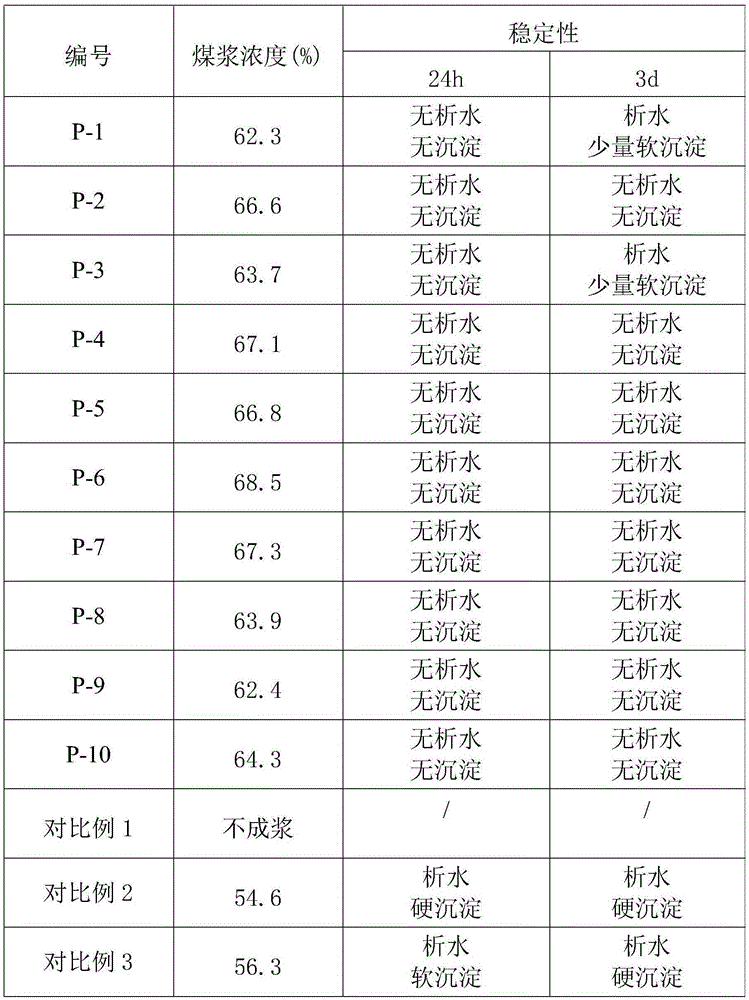

Examples

Embodiment 1

[0026] Add 50 g of cardanol sulfonate sodium salt and 50 g of alkali lignin into water to fully dissolve to obtain a compound liquid coal-water slurry additive with a concentration of 2%; add 667 kg of coal, the aforementioned liquid coal-water slurry additive and water into the ball mill at the same time Grind to obtain a homogenate, numbered P-1.

Embodiment 2

[0028] Add 75g of cardanol sulfonate sodium salt and 25g of alkali lignin into water to fully dissolve to obtain a compound liquid coal-water slurry additive with a concentration of 3%; prepare 667kg of coal powder for pulping, and then add the aforementioned liquid coal-water slurry while stirring Additives and water, stirred for more than 30 minutes to obtain a homogenate, code P-2.

Embodiment 3

[0030] Add 50 g of cardanol sulfonate potassium salt and 50 g of sodium lignin sulfonate into water to fully dissolve to obtain a compound liquid coal-water slurry additive with a concentration of 4%; add 667 kg of coal, the aforementioned liquid coal-water slurry additive and water to the Grind in a rod mill to obtain a homogenate, numbered P-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com