Antifogging water-ripple-proof glass cleaning agent and preparation method thereof

A cleaning agent and glass technology, applied in chemical instruments and methods, detergent compositions, detergent compounding agents, etc., can solve the problems of cleaning marks, blurring, hair on the glass surface, etc., and achieve good cleaning and anti-fogging ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

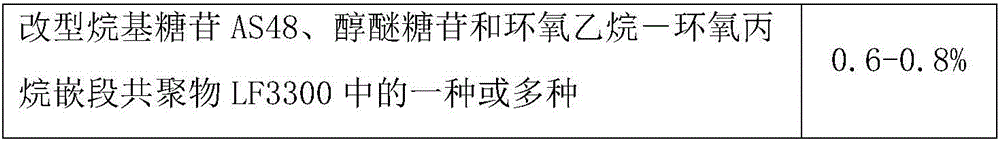

[0016] An anti-fog and water-resistant glass cleaner, the anti-fog and water-resistant glass cleaner consists of the following components by weight percentage:

[0017]

[0018]

[0019] The preparation method of the above-mentioned anti-fog and waterproof glass cleaner, the method comprises the following steps: first add water into the batching tank, start stirring, and mix AS48 (modified alkyl glucoside), fatty alcohol polyoxyethylene ether sodium sulfate, Add ethanol, HEXASOL (polyol), sucrose ester, dimethyl siloxane, flavor and dye to the batching tank, stir evenly, settle for 24 hours and filter.

Embodiment 2

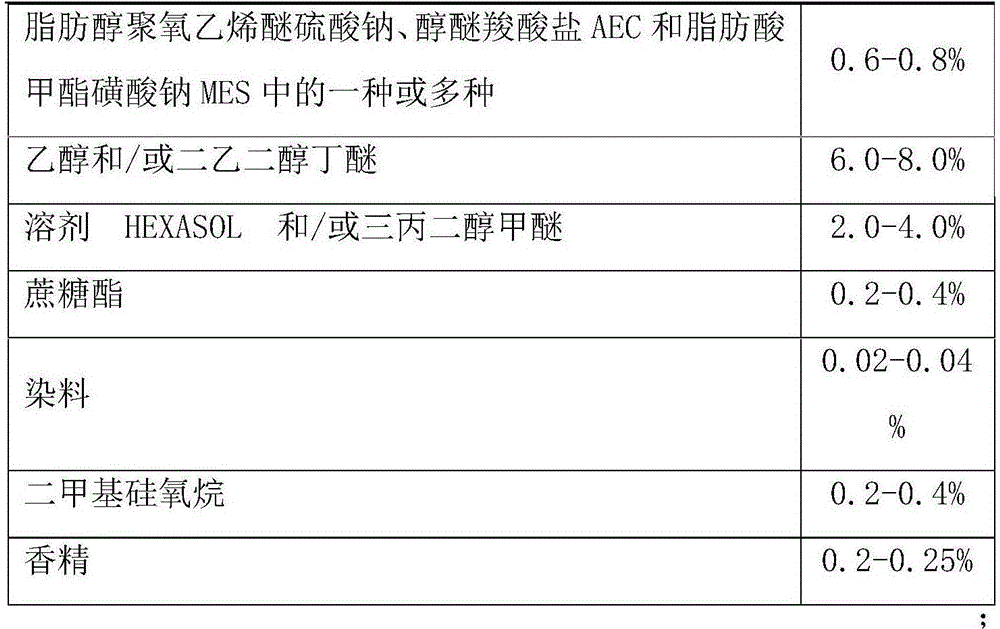

[0021] An anti-fog and water-resistant glass cleaner, the anti-fog and water-resistant glass cleaner consists of the following components by weight percentage:

[0022] raw material formula,% single component action LF3300 0.6 wet AEC 0.6 wet Diethylene glycol butyl ether 8.0 decontamination, quick drying Tripropylene glycol methyl ether 4.0 Decontamination Sucrose esters 0.3 waterproof pattern Dyes (lemon yellow, brilliant blue, carmine) 0.03 adjust color Dimethicone 0.4 anti-fog essence 0.2 odor regulation water margin solvent

[0023] The preparation method of the above-mentioned anti-fog and water-proof glass cleaner, the method comprises the following steps: first add water into the batching tank, start stirring, mix LF3300, AEC, diethylene glycol butyl ether, tripropylene glycol methyl ether, sucrose ester , dimethyl siloxane, essence, and dyes are added to the batching tank, stirred...

Embodiment 3

[0025] An anti-fog and water-resistant glass cleaner, the anti-fog and water-resistant glass cleaner consists of the following components by weight percentage:

[0026]

[0027]

[0028] The preparation method of the above-mentioned anti-fog and waterproof glass cleaner, the method comprises the following steps: first add water into the batching tank, start stirring, and mix AS48 (modified alkyl glucoside), LF3300, fatty alcohol polyoxyethylene ether sulfuric acid Add sodium, AEC, ethanol, diethylene glycol butyl ether, HEXASOL (polyol) tripropylene glycol methyl ether, sucrose ester, dimethyl siloxane, essence, and dyes into the batching tank, stir evenly, settle for 24 hours and filter.

[0029] The detection data of the physical and chemical indicators of the anti-fog and waterproof glass cleaner prepared in the above-mentioned Examples 1-3 are as follows:

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com