Kitchen oil stain cleaning agent and preparation method thereof

A technology for oil pollution and kitchen, which is applied in the field of kitchen oil pollution cleaning and its preparation, can solve the problems of damage to the range hood, inconvenient cleaning method, etc., and achieves the effect of strong dissolving cleaning effect and good cleaning ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

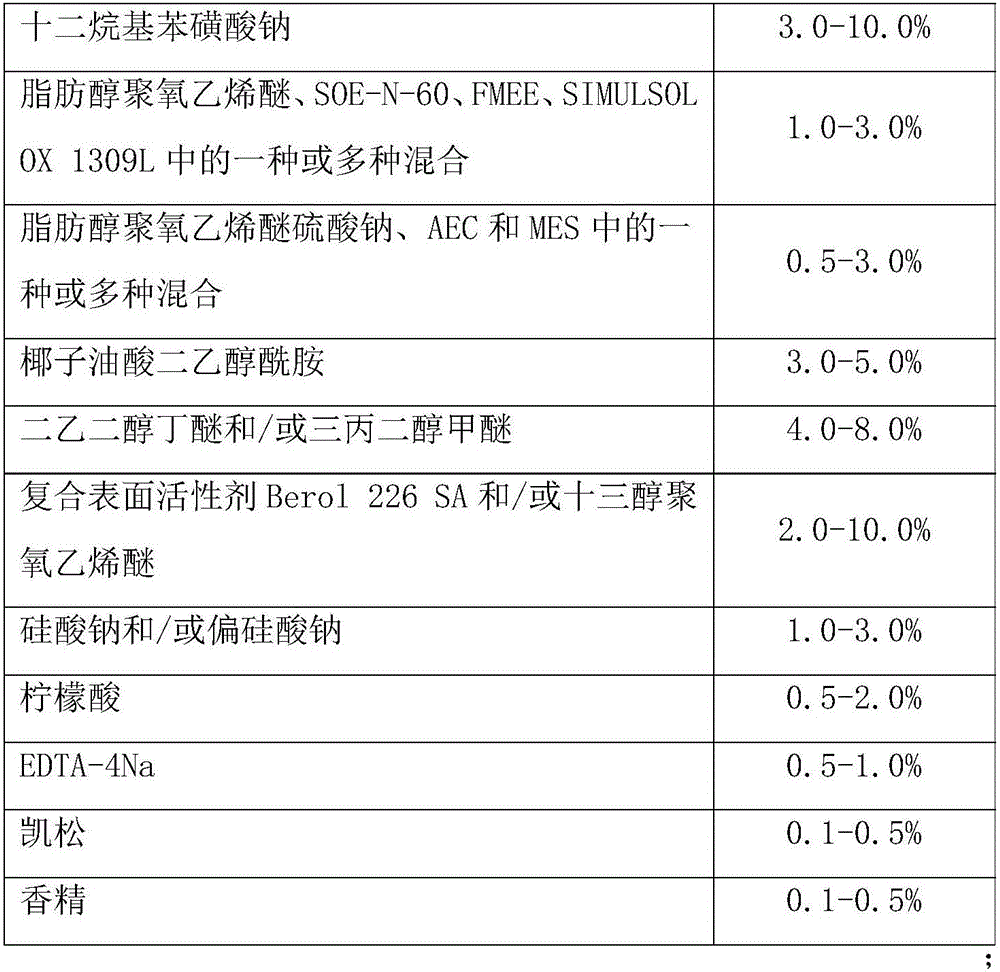

[0015] A kind of kitchen greasy dirt net, this kitchen greasy dirt net consists of the following components by weight percentage:

[0016] raw material formula,% single component action Sodium dodecyl benzene sulfonate 5.0 clean Fatty alcohol polyoxyethylene ether 2.0 clean Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 1.5 clean Coconut Oleic Acid Diethanolamide 4.0 Anti-stain redeposition Diethylene glycol butyl ether 6.0 clean Berol 226SA (compound surfactant) 5.0 clean Sodium silicate 2.0 corrosion inhibition citric acid 1.5 pH regulation EDTA-4Na 0.8 Metal ion chelation Cayson 0.5 Anti-corrosion essence 0.2 odor regulation water margin solvent

[0017] The preparation method of the above-mentioned kitchen grease cleaner comprises the following steps: first add water into the batching tank, start stirring, mix sodium dodecylbenzenesulfonate, fatty alcohol pol...

Embodiment 2

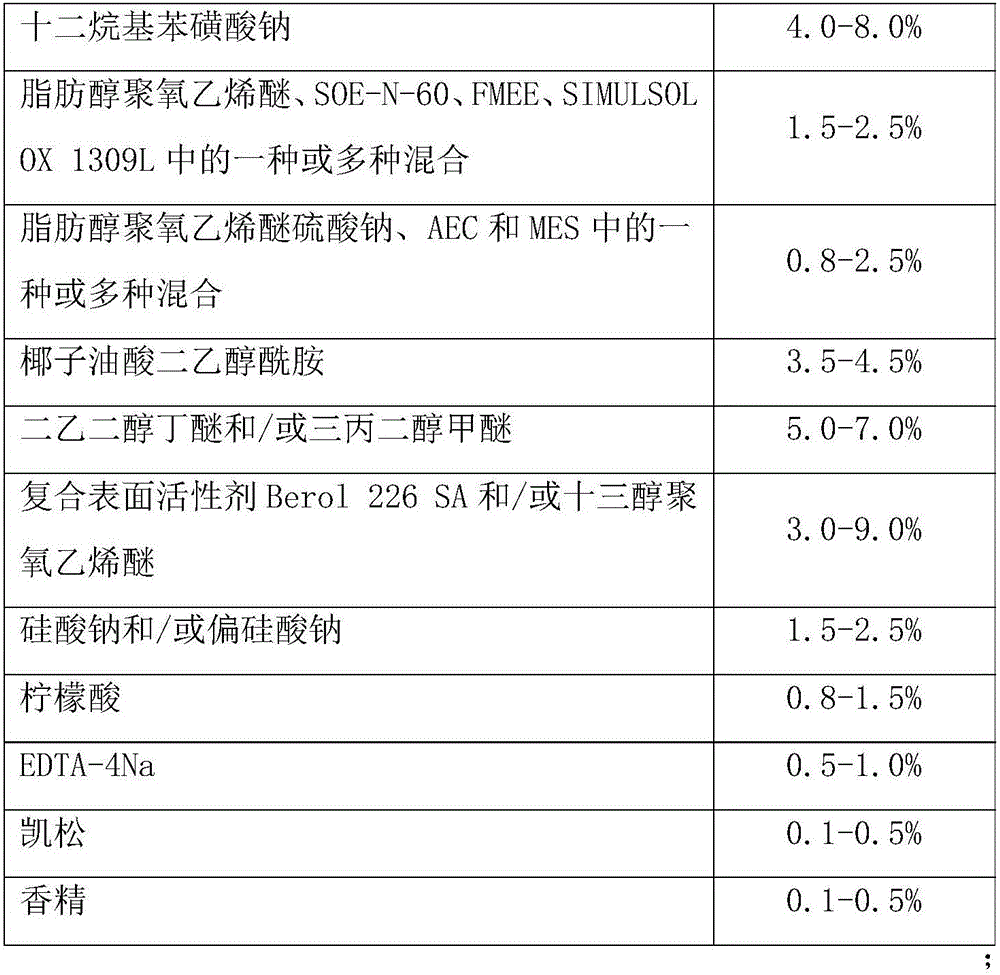

[0020] A kind of kitchen greasy dirt net, this kitchen greasy dirt net consists of the following components by weight percentage:

[0021]

[0022]

[0023] The preparation method of the above-mentioned kitchen grease cleaner comprises the following steps: first add water into the batching tank, start stirring, mix sodium dodecylbenzenesulfonate, fatty alcohol polyoxyethylene ether, fatty alcohol polyoxyethylene ether Add sodium sulfate, coconut oleic acid diethanolamide, tripropylene glycol methyl ether, Berol 226SA, sodium silicate, and EDTA-4Na into the batching tank, stir well, adjust the pH value with citric acid, add Cayson and essence, stir well and settle for 24 hour filter.

[0024] The above-mentioned fatty alcohol polyoxyethylene ether can use any of the three raw materials of modified grease ethoxylate SOE-N-60 or fatty acid methyl ester ethoxylate FMEE or isomeric tridecyl alcohol polyoxyethylene ether SIMULSOL OX 1309L an alternative.

Embodiment 3

[0026] A kind of kitchen greasy dirt net, this kitchen greasy dirt net consists of the following components by weight percentage:

[0027] raw material formula,% single component action Sodium dodecyl benzene sulfonate 6.0 clean Fatty alcohol polyoxyethylene ether 1.0 clean SOE-N-60 1.0 clean Alcohol ether carboxylate AEC 0.5 clean Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 1.5 clean Coconut Oleic Acid Diethanolamide 4.0 Anti-stain redeposition Diethylene glycol butyl ether 6.0 clean Tripropylene glycol methyl ether 1.0 clean Berol 226SA (compound surfactant) 5.0 clean Sodium silicate 2.0 corrosion inhibition citric acid 1.5 pH regulation EDTA-4Na 0.8 Metal ion chelation Cayson 0.5 Anti-corrosion essence 0.2 odor regulation water margin solvent

[0028] The preparation method of the above-mentioned kitchen grease cleaner includes the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com