Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Thorium dioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thorium dioxide (ThO₂), also called thorium(IV) oxide, is a crystalline solid, often white or yellow in color. Also known as thoria, it is produced mainly as a by-product of lanthanide and uranium production. Thorianite is the name of the mineralogical form of thorium dioxide. It is moderately rare and crystallizes in an isometric system. The melting point of thorium oxide is 3300 °C – the highest of all known oxides. Only a few elements (including tungsten and carbon) and a few compounds (including tantalum carbide) have higher melting points. All thorium compounds are radioactive because there are no stable isotopes of thorium.

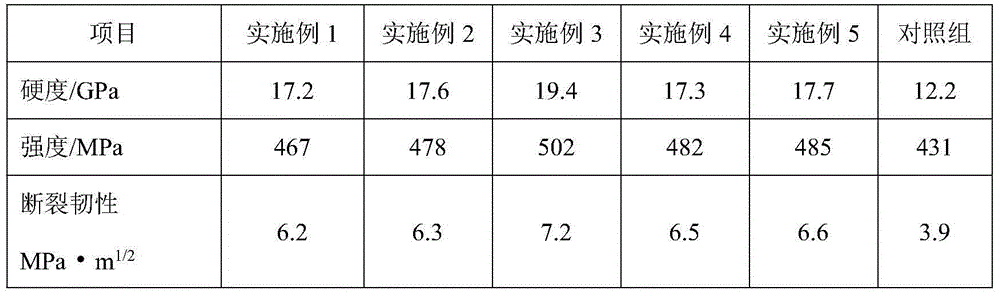

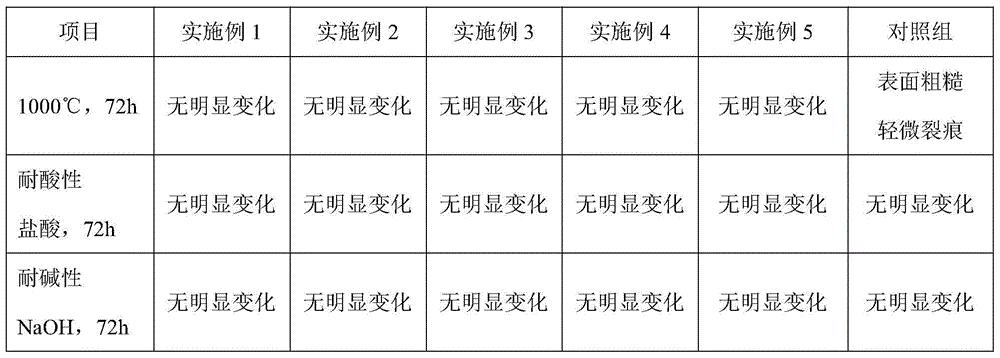

High-temperature-resistant ceramic powder coating material and preparation method thereof

The invention discloses a high-temperature-resistant ceramic powder coating material and a preparation method thereof and relates to the technical field of materials. The coating material consists of the following components in parts by mass: (1) 15-30 parts of silicon carbide; (2) 3-9 parts of nanometer nickel oxide and 6-12 parts of nanometer magnesium oxide; (3) 15-23 parts of nano Al2O3; (4) 2.5-4 parts of Ta2O5; (5) 25-45 parts of silicon dioxide; (6) 4.5-7.5 parts of titanium oxide; and (7) 5-15 parts of nanometer thorium dioxide. The method for preparing the high-temperature-resistant ceramic powder coating material comprises the following preparation steps: (1) weighing; (2) grinding; (3) calcining; and (4) cooling. According to the high-temperature-resistant ceramic powder coating material and the preparation method thereof disclosed by the invention, the provided ceramic nanometer coating material has high strength and toughness and excellent high temperature resistance and wear resistance and has a certain corrosion resistance.

Owner:GUANGXI QINZHOU BEIBU GULF NIXING YUTAO

High-temperature-resistant cermet material and preparation method thereof

The invention belongs to the field of cermet materials, and discloses a high-temperature-resistant cermet material and a preparation method thereof. The high-temperature-resistant cermet material comprises 11-22 parts of nickel sesquioxide, 5-11 parts of magnesium oxide, 7-11 parts of zirconium diboride, 2-4 parts of thorium dioxide, 4-7 parts of bismuth oxide, 5-9 parts of zinc, 7-13 parts of copper, 2-4 parts of germanium and 12-17 parts of iron. The preparation method comprises the following steps: (1) quickly mixing metals and a ceramic material at high speed; (2) carrying out ball milling on the uniform mixture with a ball mill; (3) carrying out high-temperature press fitting on the cermet material subjected to ball milling in a hot-pressing furnace, heating the furnace to 720-780 DEG C, keeping the temperature, continuing heating the hot-pressing furnace to 1520-1610 DEG C, sintering, and cooling to obtain the high-temperature-resistant cermet material.

Owner:佛山市三水华纳陶瓷有限公司

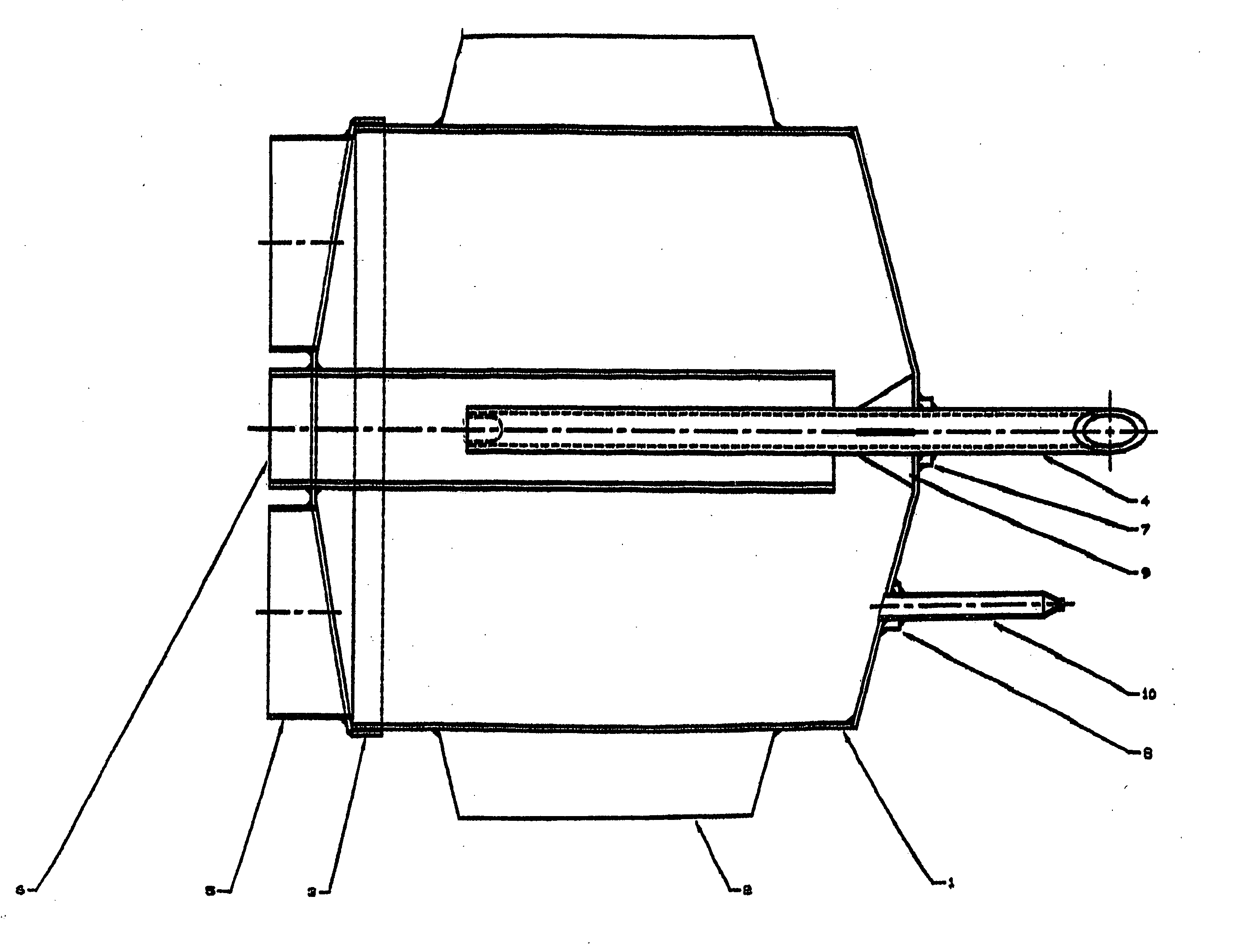

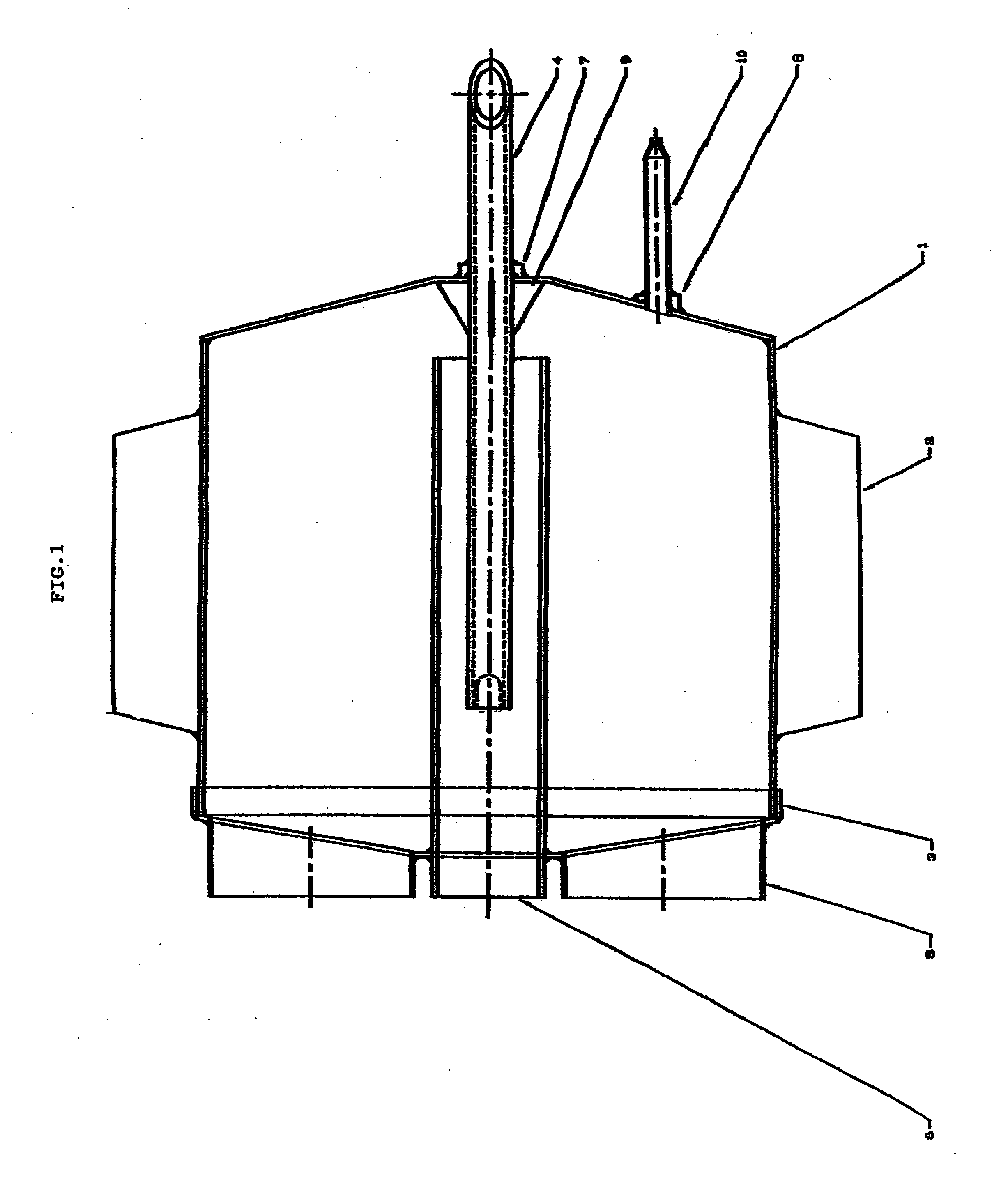

Tank for melting solder glass

InactiveUS20050022560A1Efficient designGlass furnace apparatusGlass pressing apparatusMelting tankIridium

A melting tank for melting solder glass powders typically comprised of PbO and B2O3 and other minor ingredients. The tank contains surfaces exposed to the atmosphere and surfaces in contact with the molten solder glass. The surfaces of the tank that are in contact with the melt are comprised substantially entirely of iridium. Preferably, the surfaces exposed to the atmosphere contain a coating thereon of a metal or metal oxide such as palladium, ruthenium, rhodium, aluminum oxide, calcium oxide, cerium dioxide, dichromium oxide, hafnium dioxide, magnesium oxide, silicon dioxide, thorium dioxide, zirconia, mullite, magnesia spinel or zircon. It is also preferred that the cavity of the tank have a generally circular shape. The melting tank may be readily fabricated by wrought metallurgical processes or by electroforming.

Owner:ENGELHARD CORP

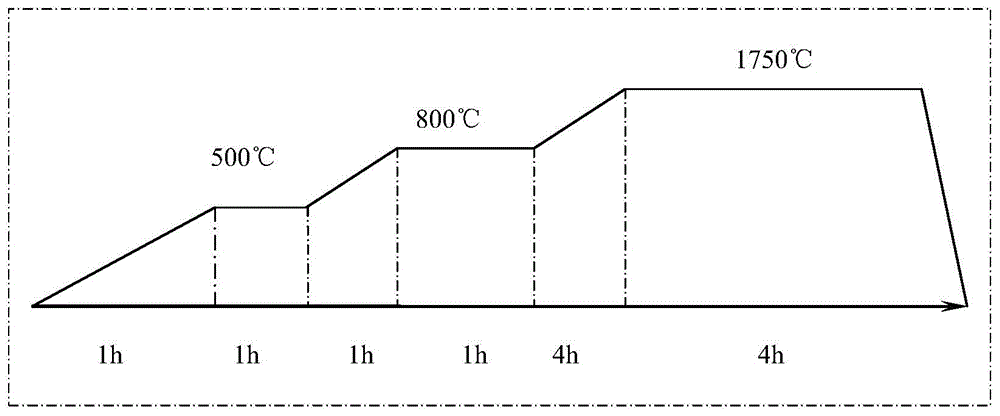

Method for preparing thorium dioxide pellets

The invention belongs to the technical field of manufacturing of nuclear fuel elements, and specifically relates to a method for preparing thorium dioxide pellets. The method comprises a powder granulating process: pressing thorium dioxide powder prepared by adopting an oxalate precipitation method and serving as an original raw material into sheets by adopting a compression molding method, crushing in a granulator, screening by a granulator screen, and shaking in a top-knocked sieve shaker to obtain granules for forming the thorium dioxide pellets; a powder molding process: performing die pressing on the granules to obtain a green blank of the pellets; and a pellet sintering process: putting the green blank of the thorium dioxide pellets into a vacuum atmosphere sintering furnace, vacuumizing, washing the furnace, then introducing argon and sintering. The cobalt pellets are prepared by adopting a powder metallurgy process, so that the difficulty of low density of the green blank of the thorium dioxide powder is overcome; and the pellets prepared by the granulating, molding and sintering processes have high density and grain size meeting the index requirements of preparation of fuel elements.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

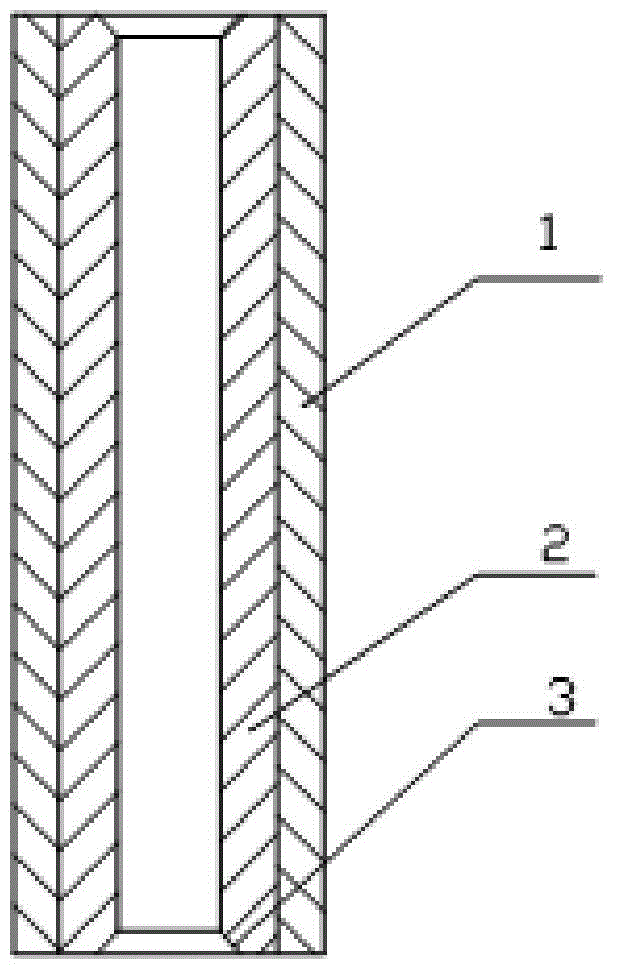

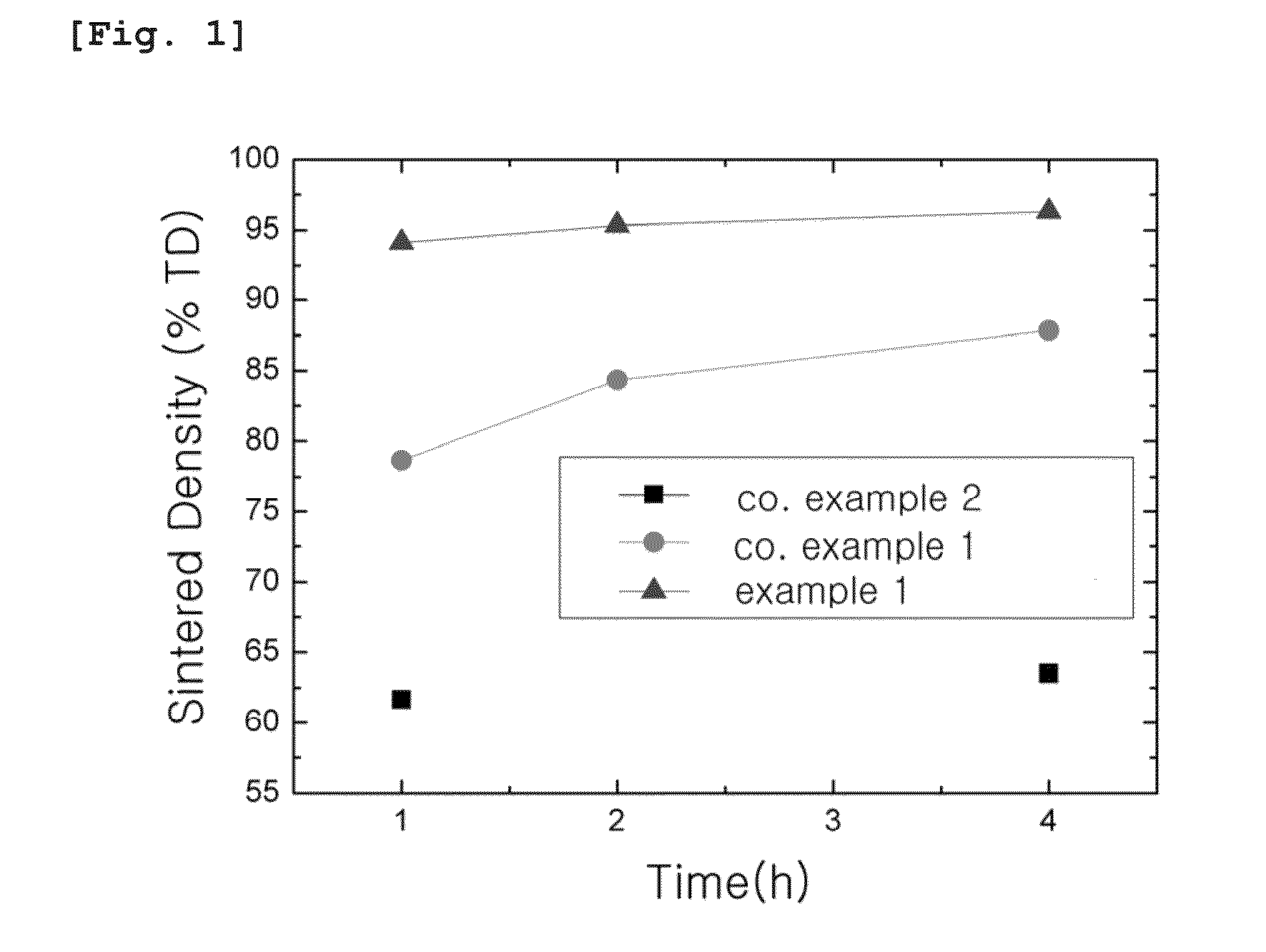

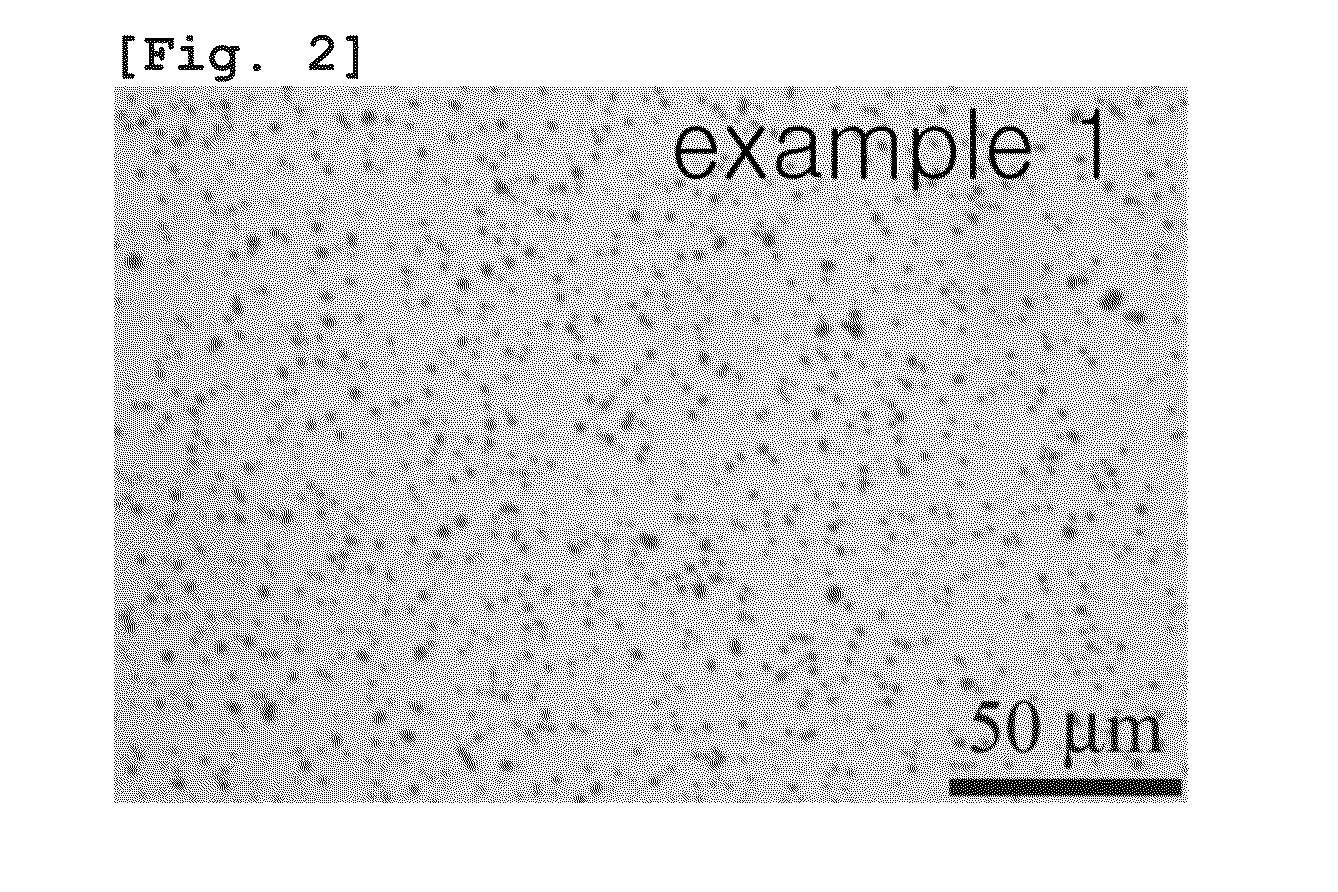

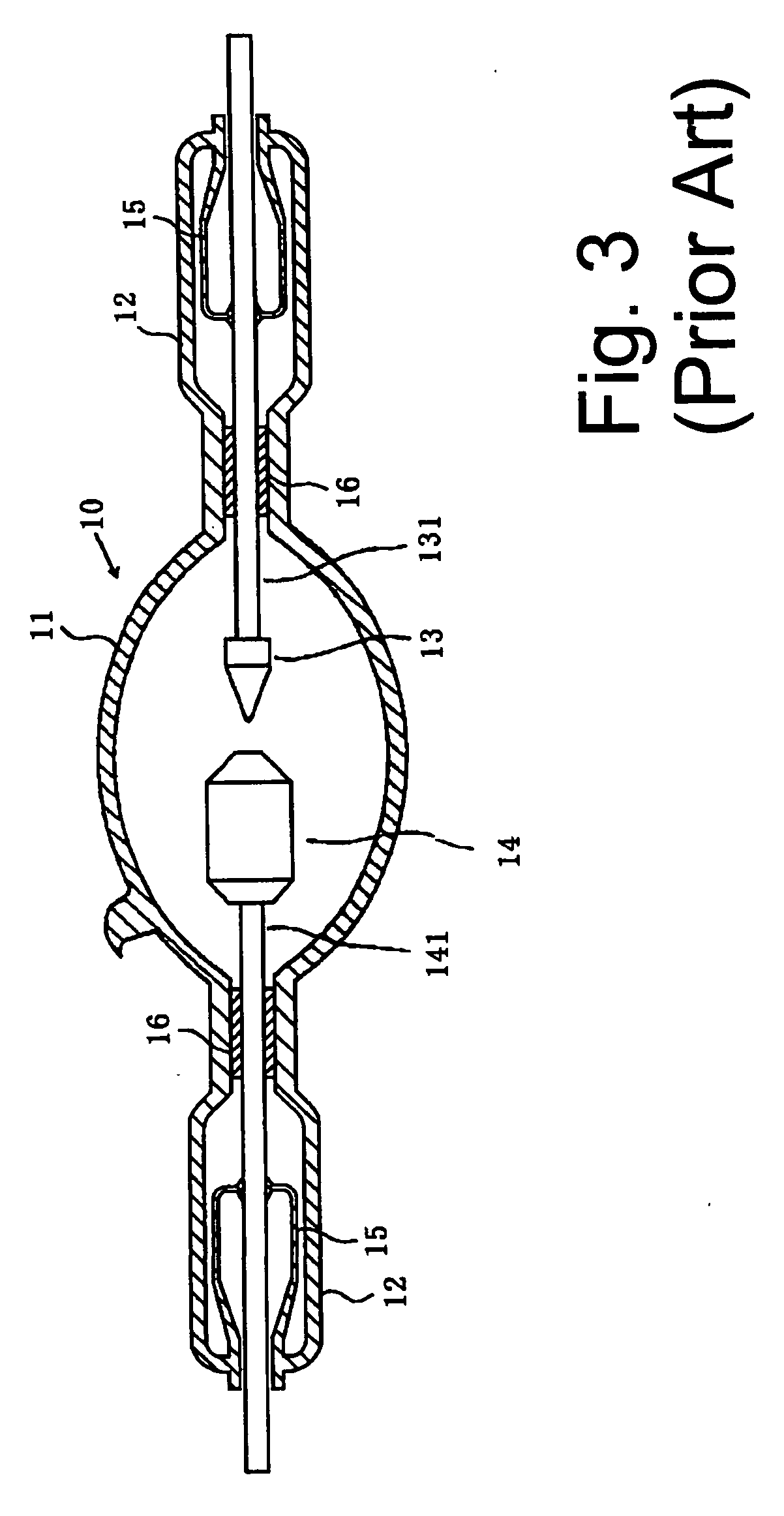

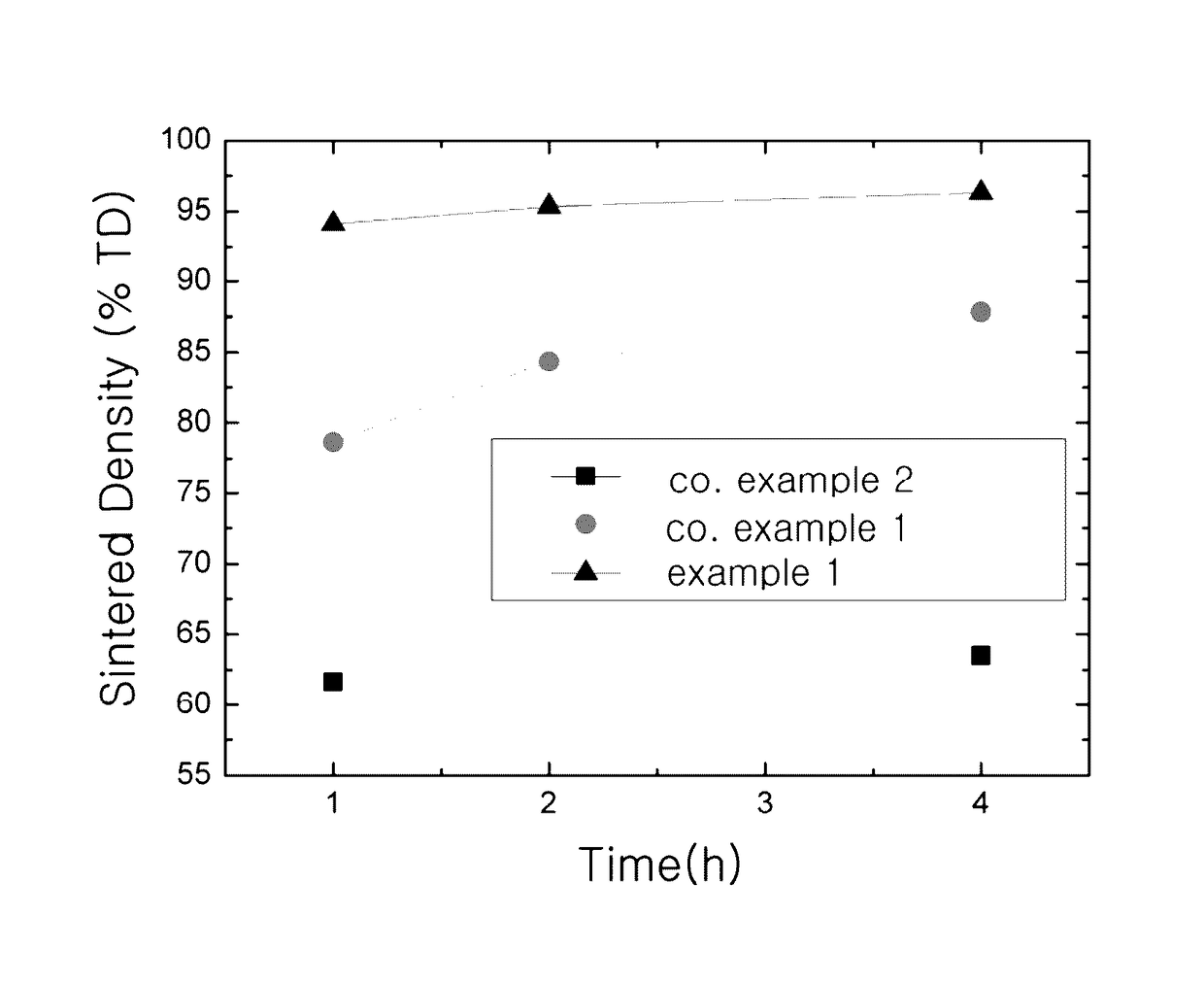

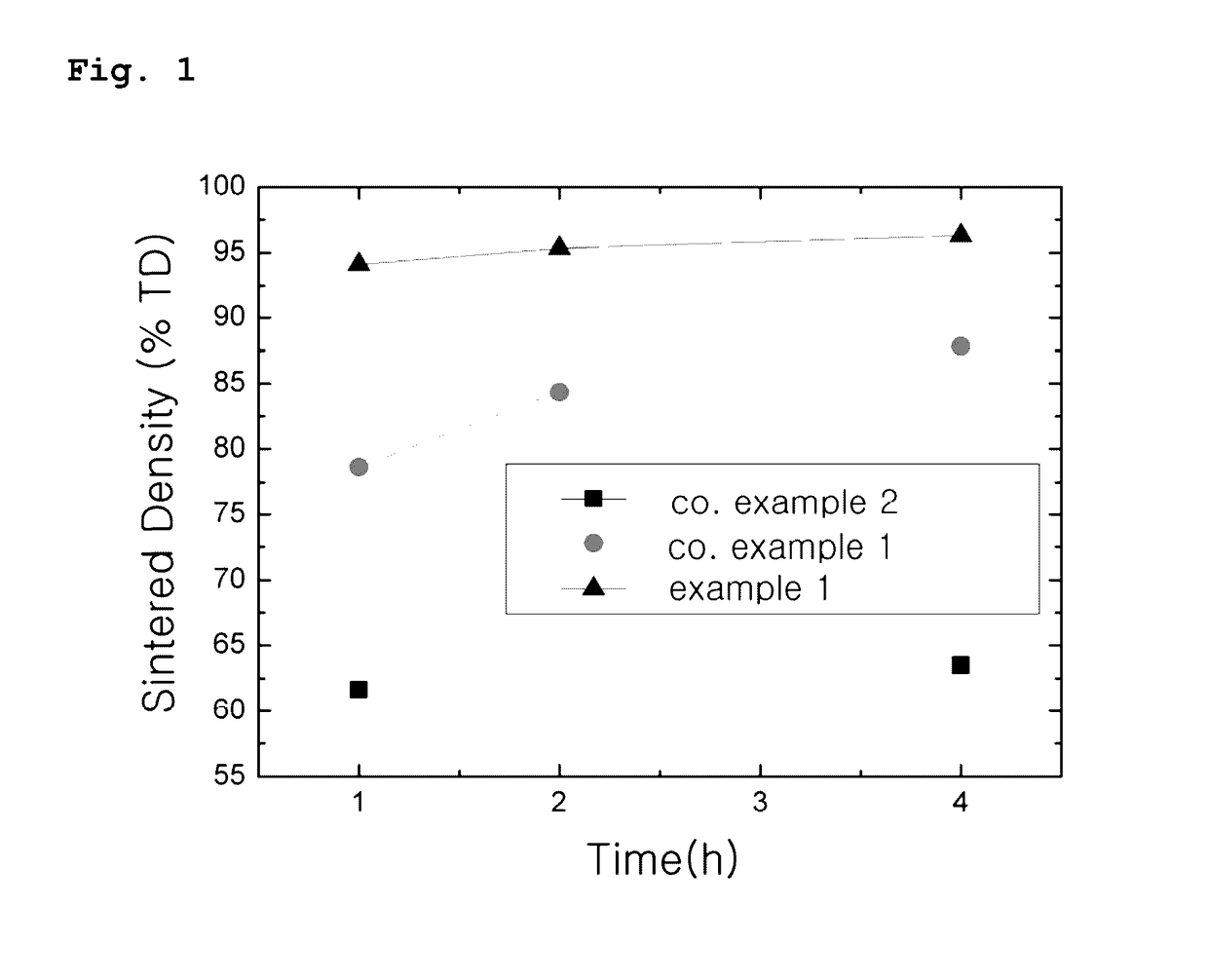

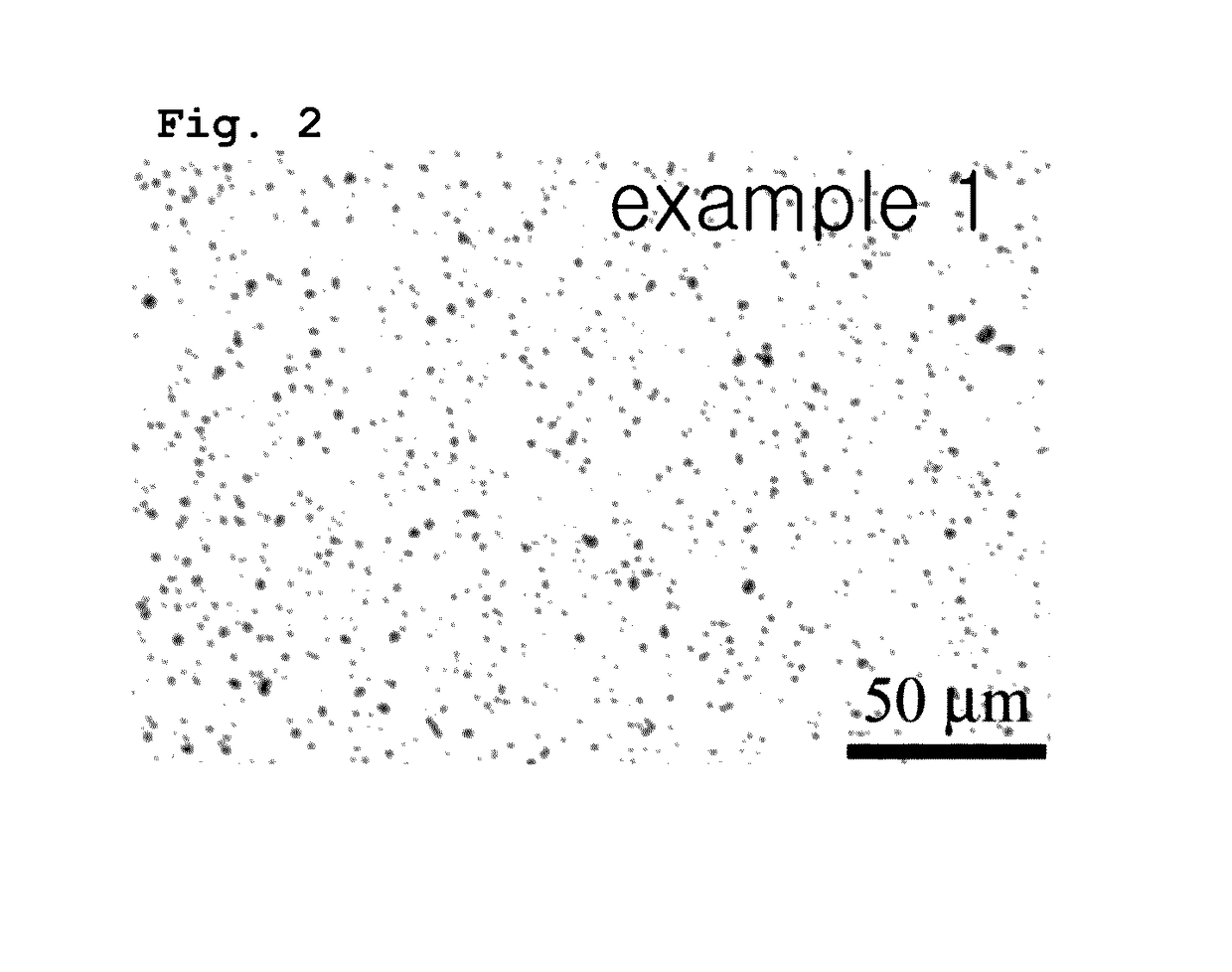

Fabrication method of burnable absorber nuclear fuel pellets and burnable absorber nuclear fuel pellets fabricated by the same

ActiveUS20130223582A1Reduce porosityMinimizing boron volatilizationFuel elementsNuclear energy generationHydrogen atmospherePlutonium dioxide

A fabrication method of burnable absorber nuclear fuel pellets and burnable absorber nuclear fuel pellets fabricated by the same are provided, in which the fabrication method includes adding boron compound and manganese compound to one or more type of nuclear fuel powders selected from the group consisting of uranium dioxide (UO2), plutonium dioxide (PuO2) and thorium dioxide (ThO2) and mixing the same (step 1), compacting the mixed powder of step 1 into compacts (step 2), and sintering the compacts of step 2 under hydrogen atmosphere (step 3). According to the fabrication method, sintering can be performed under hydrogen atmosphere at a temperature lower than the hydrogen atmosphere sintering that is conventionally applied in the nuclear fuel sintered pellet mass production, by adding sintering additives such as manganese oxide or the like.

Owner:KOREA ATOMIC ENERGY RES INST

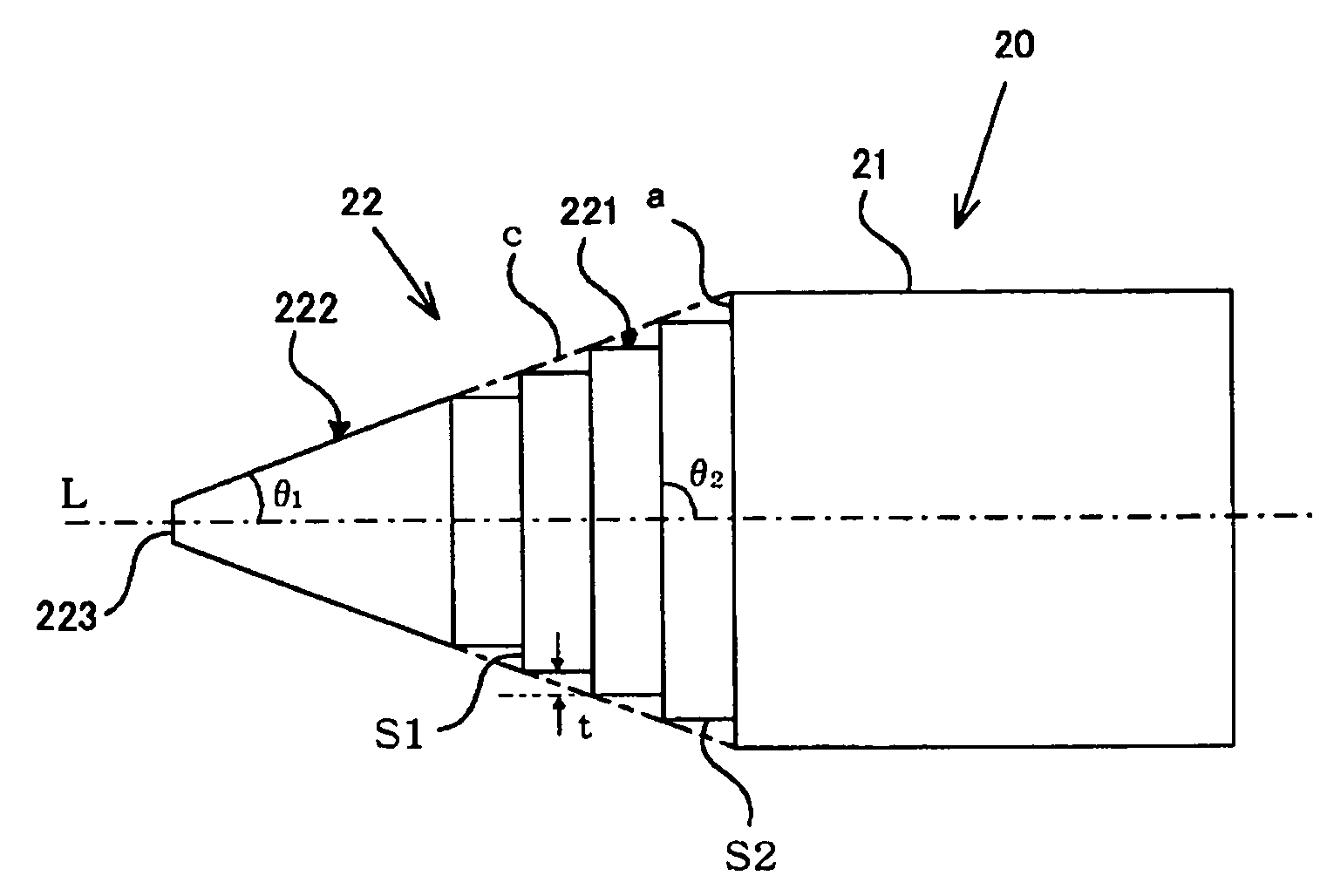

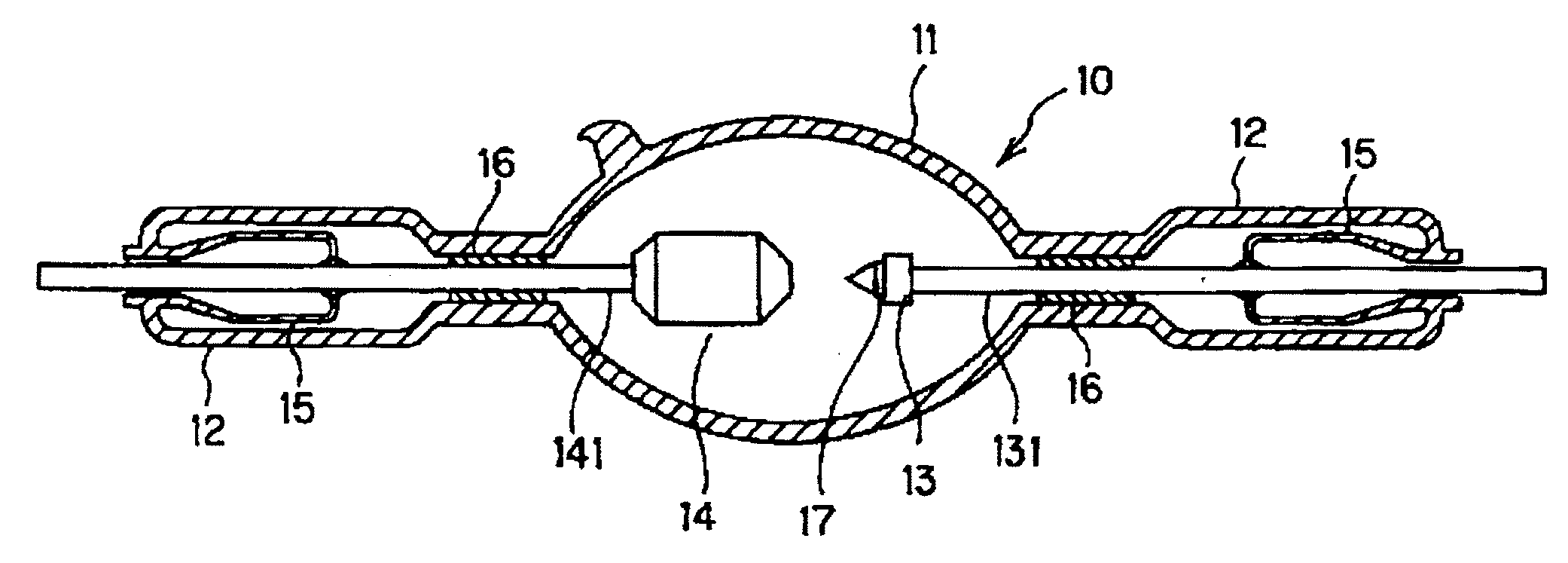

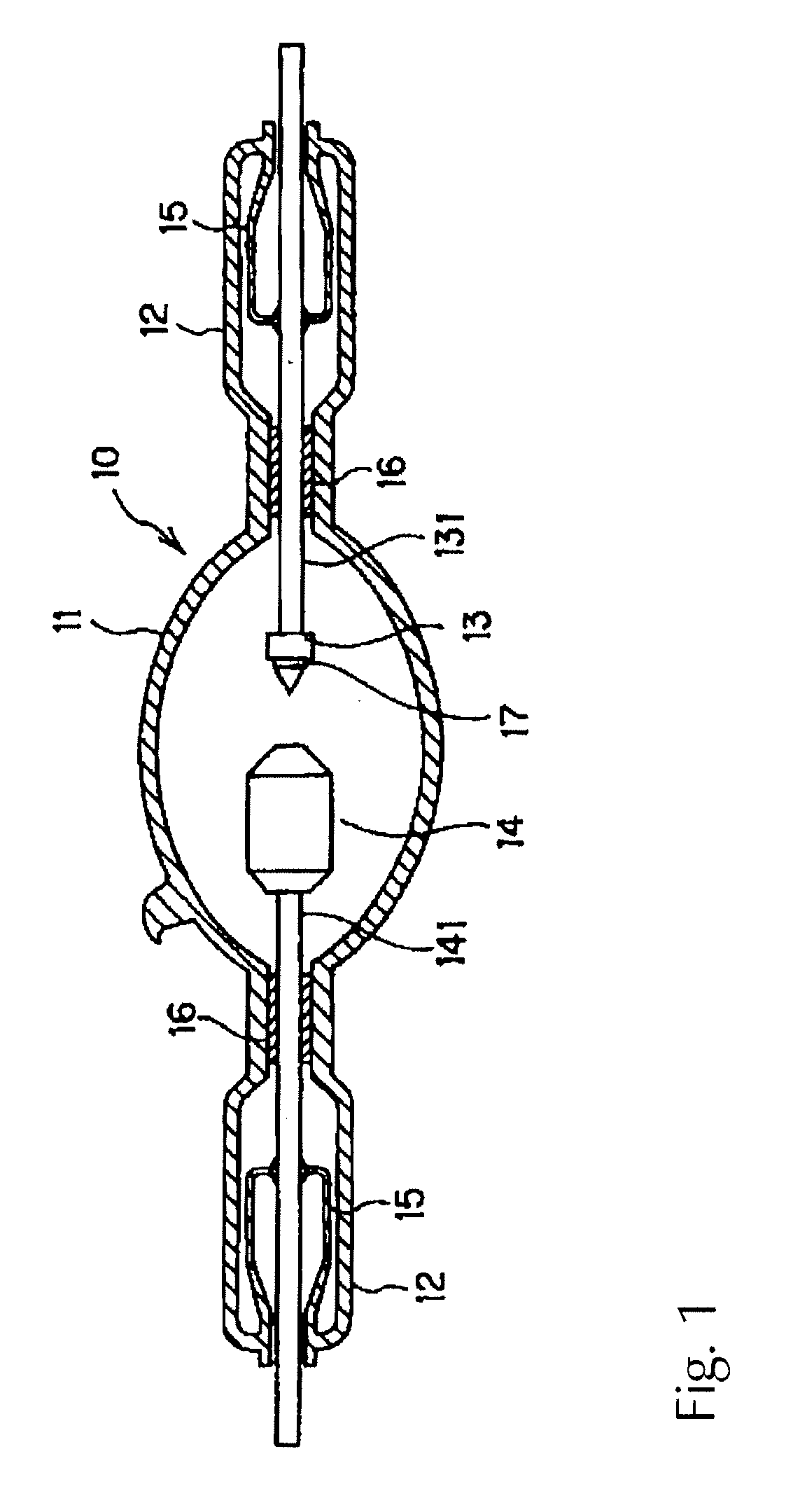

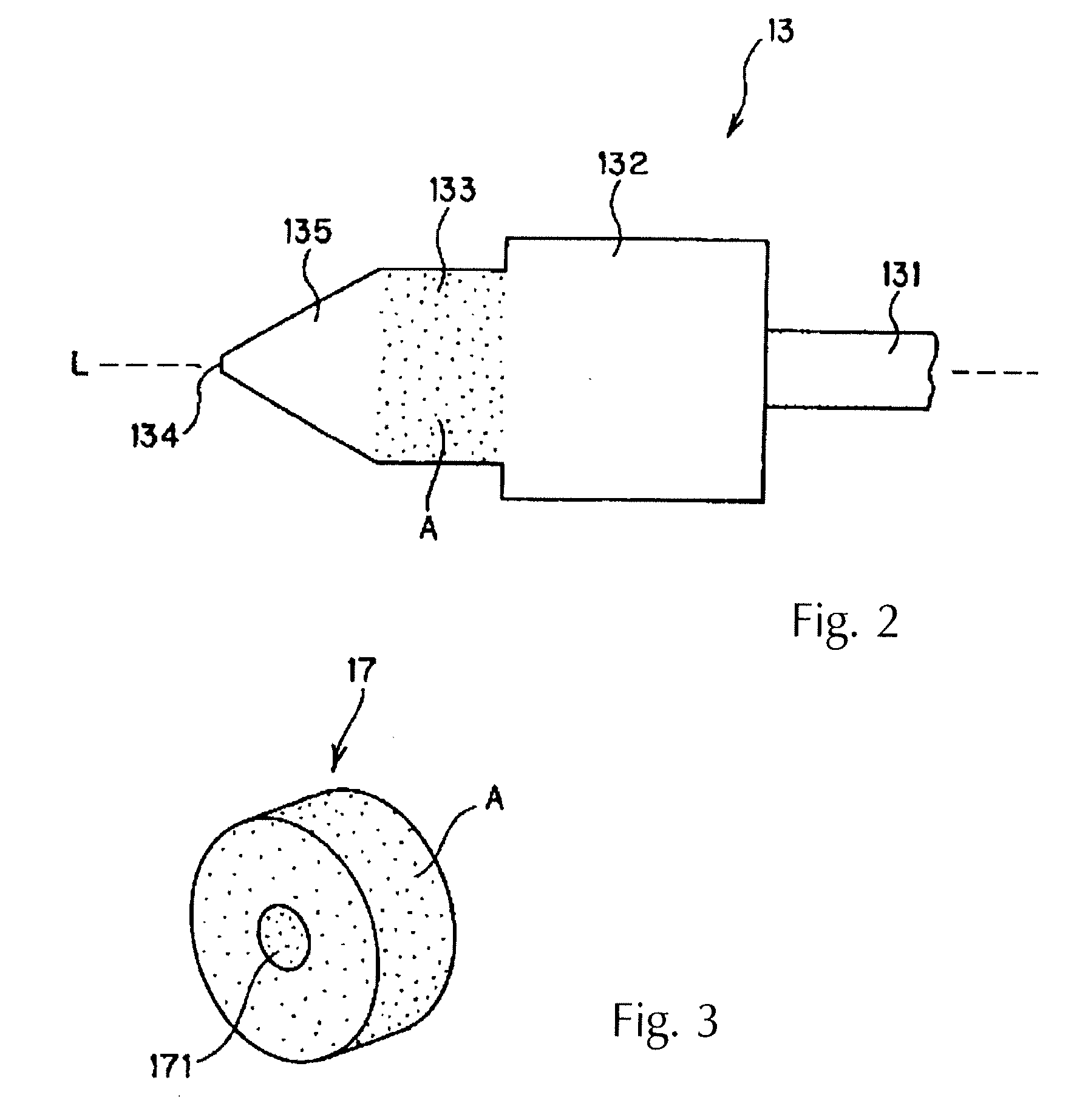

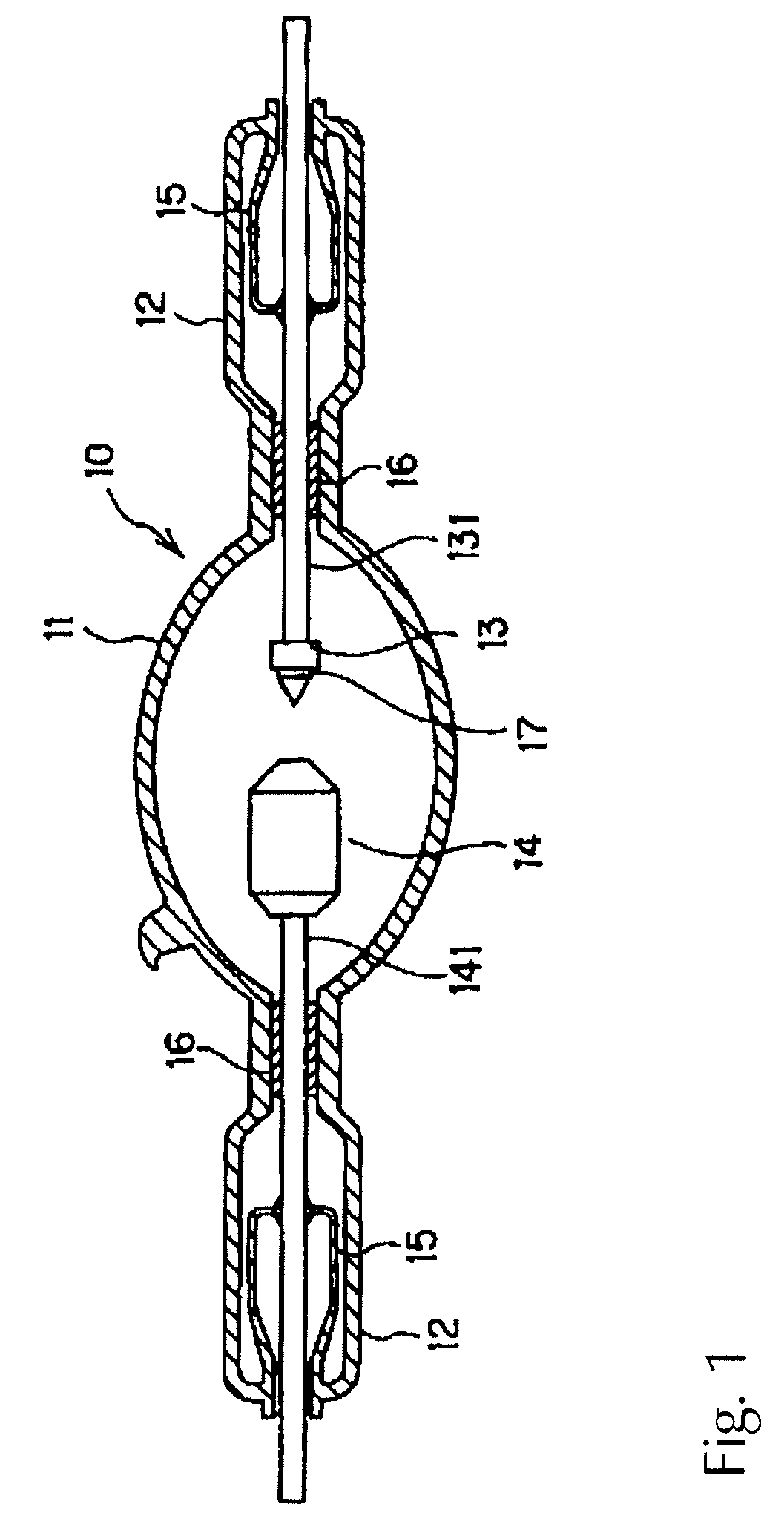

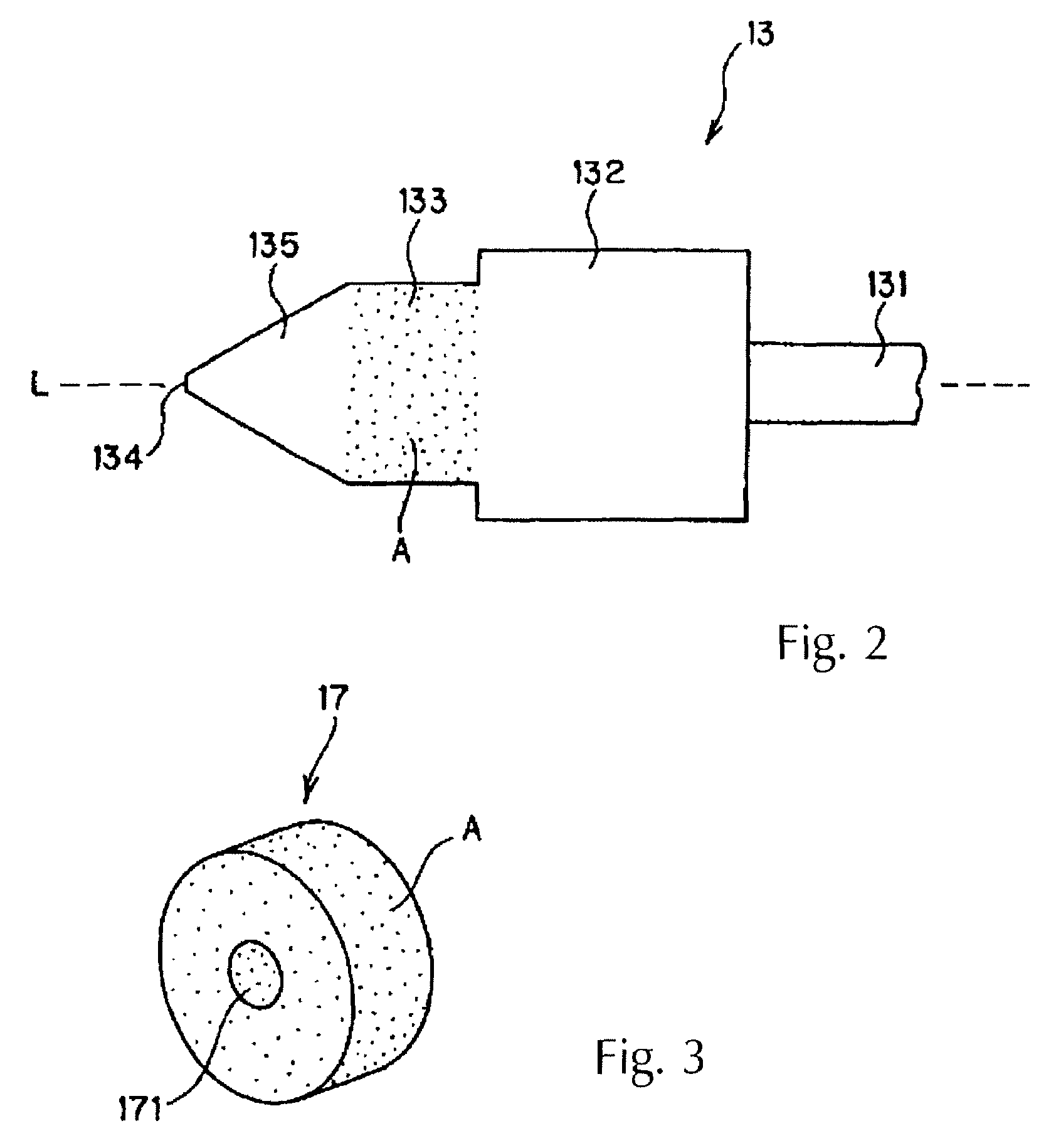

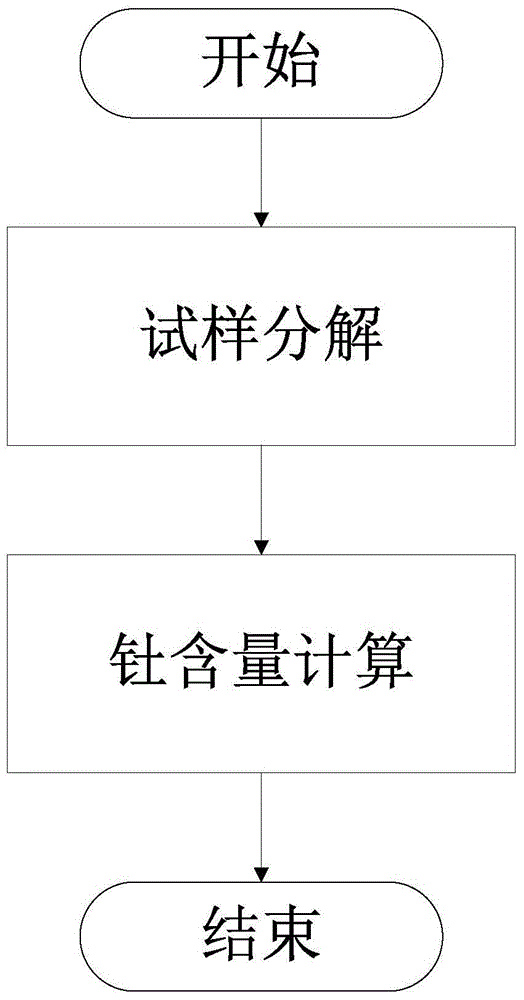

High pressure discharge lamp

ActiveUS20050099121A1Long operating service lifeHigh degree of reductionDischarge tube luminescnet screensLamp incadescent bodiesCircular coneHigh pressure

A high pressure discharge lamp in which the cathode has a cylindrical body part and a conical part which is doped with thorium dioxide (ThO2), and with a diameter which decreases in a direction from the body part toward the tip area of the conical part by at least one light receiving surface area being formed between the body part and the tip area of the cone in a base part of the conical part. The light receiving area lies at an angle with respect to the center axis of the conical part and the body part, said angle which is measured from the side of the body part being greater than the angle of inclination which is formed between the outer periphery of the conical part in the tip area of the cone and the center axis.

Owner:USHIO DENKI KK

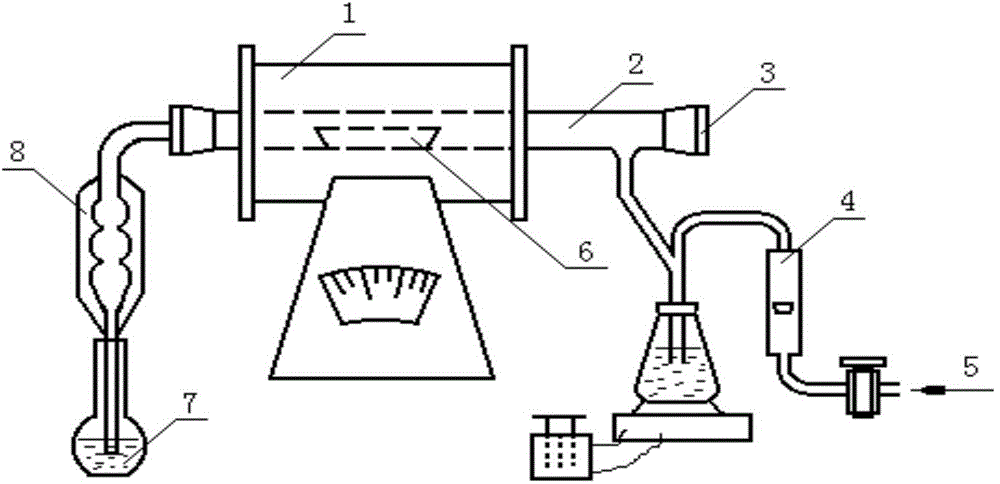

Measuring method of content of rare earth elements in thorium dioxide

InactiveCN105784683AAccurate determination of contentGood precisionPreparing sample for investigationAnalysis by thermal excitationRare-earth elementSubstrate concentration

The invention relates to a novel chemical detection method, and more specifically relates to a method used for measuring the content of 15 rare earth elements in thorium dioxide powder and blocks via inductively coupled plasma-atomic emission spectrometry. The method comprises following steps: sample dissolving, wherein a 0.2-0.5% hydrofluoric acid solution is added in dissolving of thorium dioxide, and adding amount is controlled to be 0.1ml or less; separation of thorium and the rear earth elements, wherein 3mol / L nitric acid is taken as a medium, an extraction agent composed of carbon tetrachloride and tributyl phosphate at 1:1 is used for three times of extraction so as to separate thorium and the rear earth elements; and sample measuring. According to the method, analytical line of the measured elements, sample substrate concentration, sample dissolving method, thorium and the rear earth elements separation method and conditions, and instrument parameters are determined, and inter element measuring interference test is carried out at the same time; an inductive coupling plasma emission spectrometer is used for simultaneous determination of the contents of the elements; method precision is high than 10%; and average recovery rate ranges from 91 to 110%. Operation of the method is simple; and the method is accurate and reliable.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

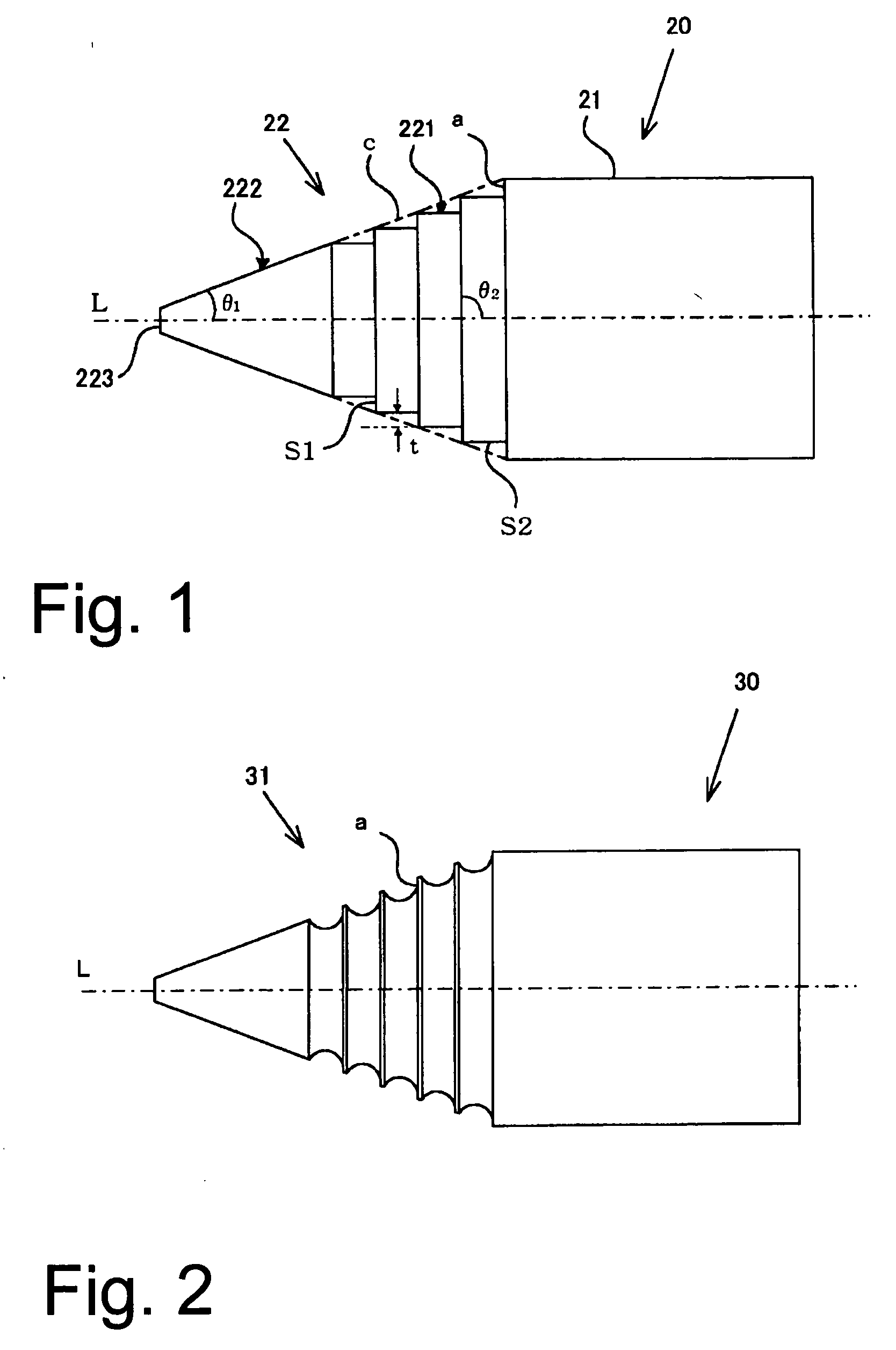

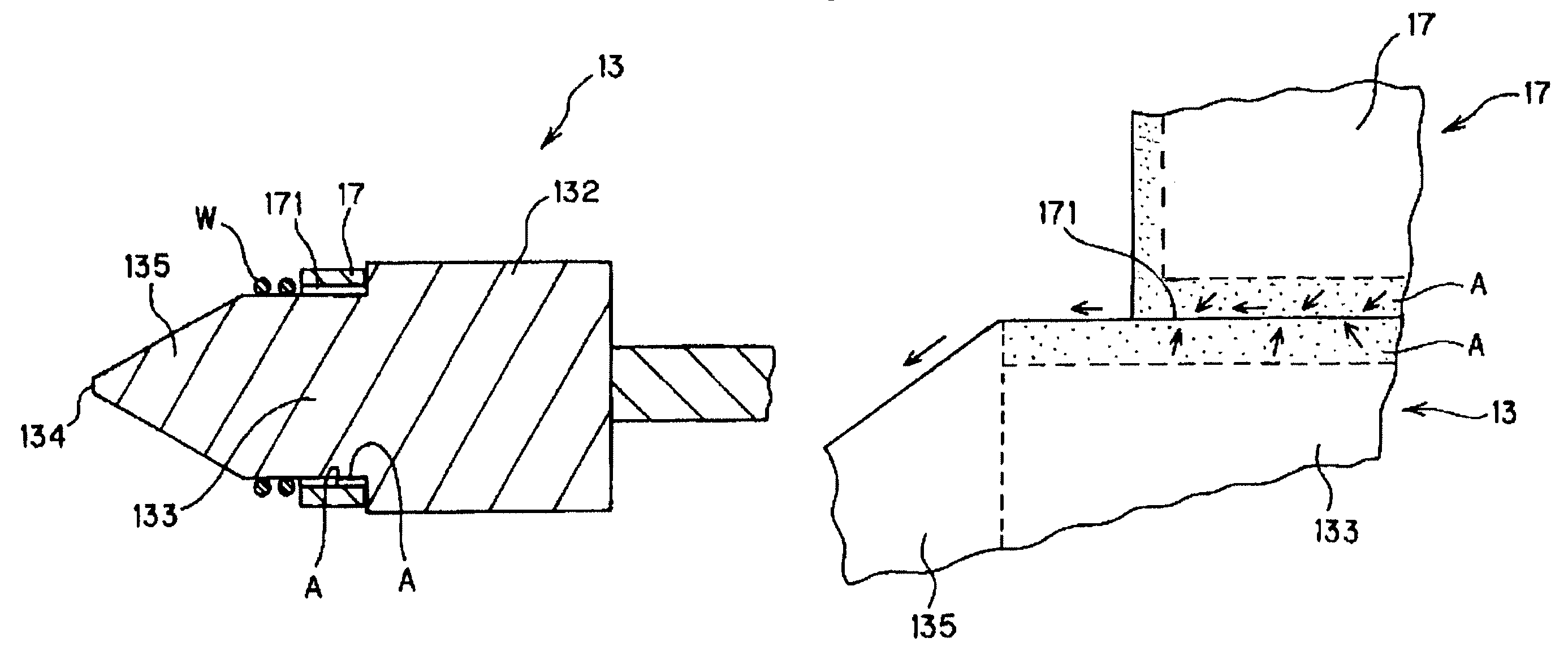

High pressure discharge lamp

InactiveUS20070228982A1Eliminate disadvantagesEasy to useDischarge tube luminescnet screensProjectorsElectric lightCarbide

A high pressure discharge lamp, in which an anode and a cathode are disposed opposite each other in a bulb, achieves a long service life due to thorium (Th) being stably supplied to the cathode tip for a long time after lamp operation has been commence since the formation of the flicker phenomenon is suppressed over a long time due to the cathode being made of tungsten which contains thorium oxide on a surface space from the cathode tip, a carbide layer of tungsten carbide is formed and the cathode being bordered by an emitter containing body of tungsten which contains thorium dioxide, and a carbide layer of tungsten carbide being formed at least in a region bordering the cathode.

Owner:USHIO DENKI KK

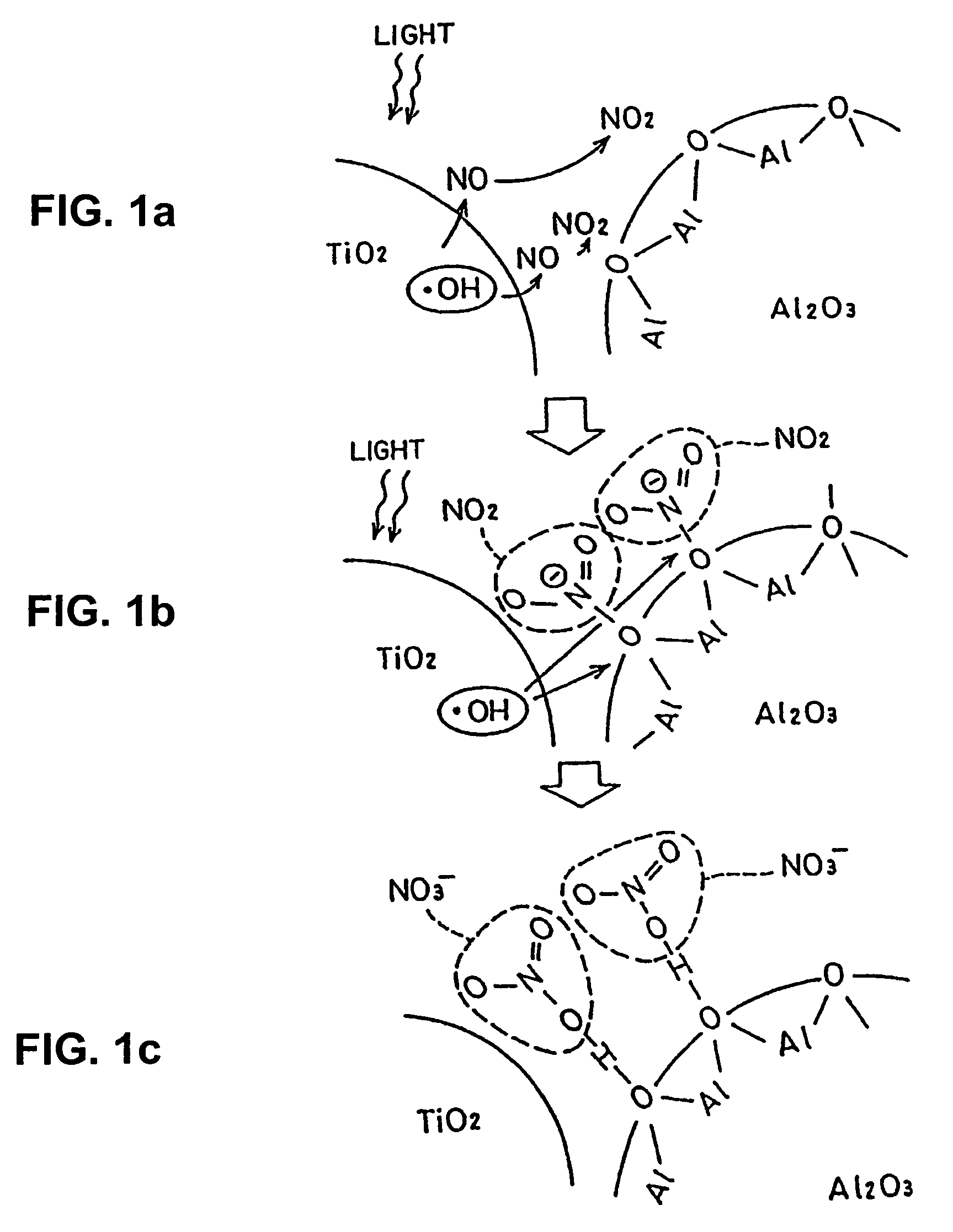

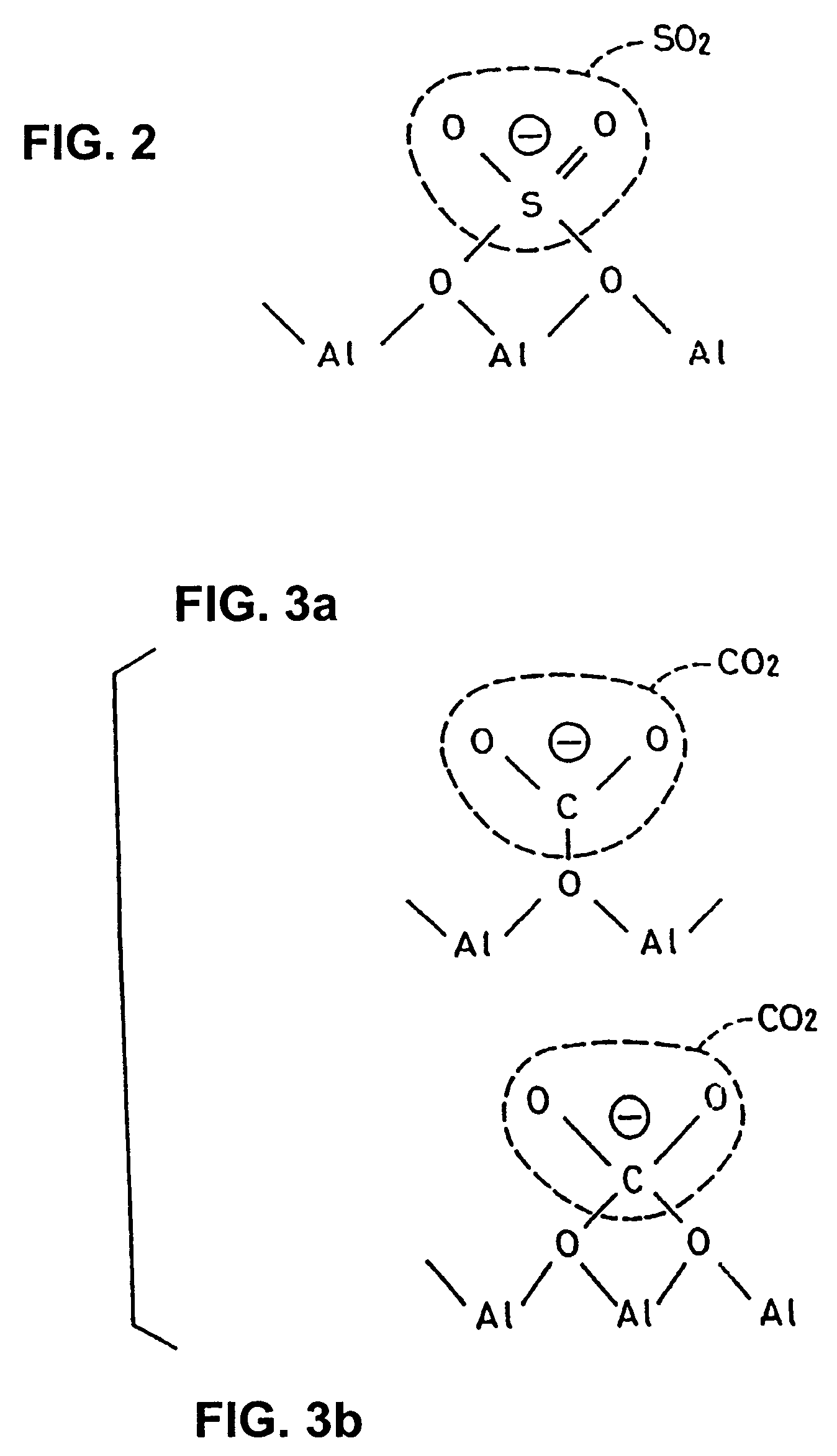

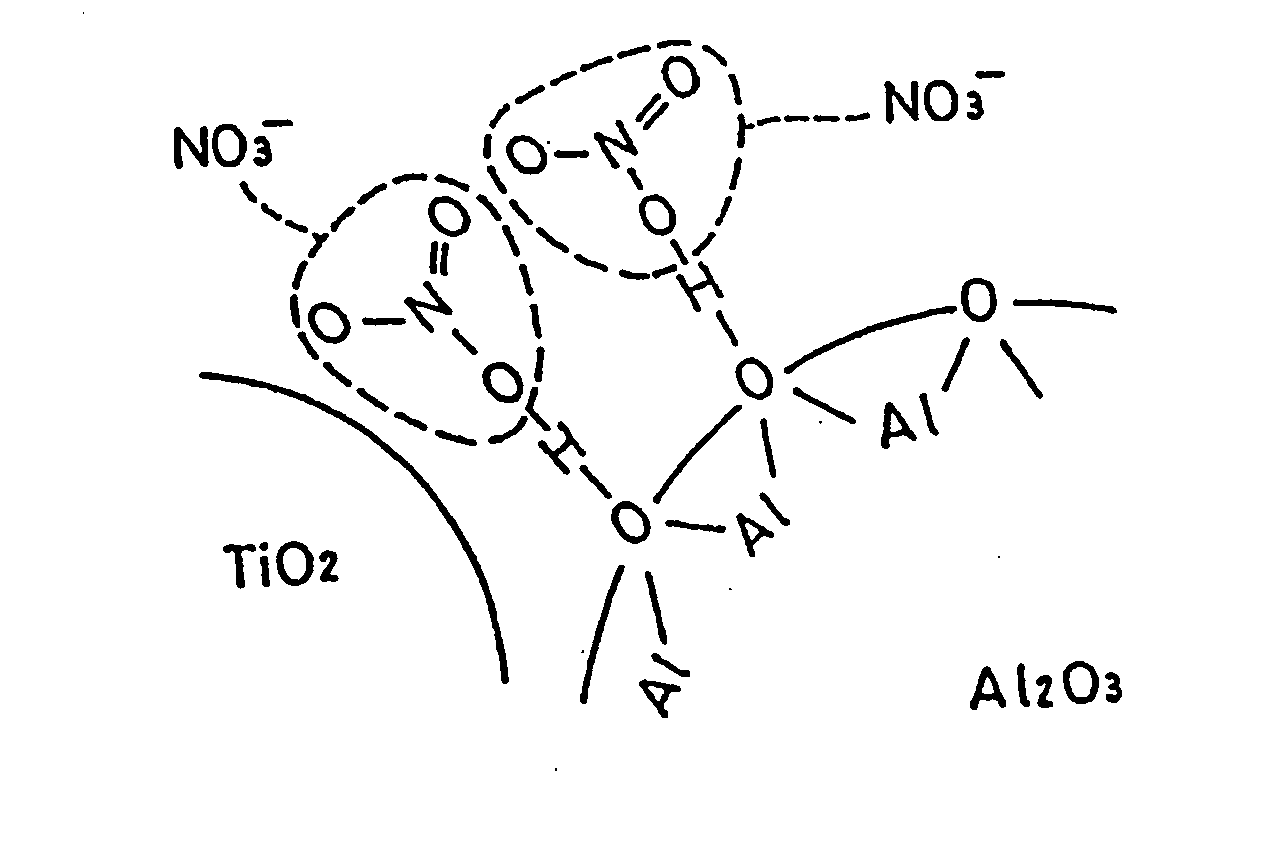

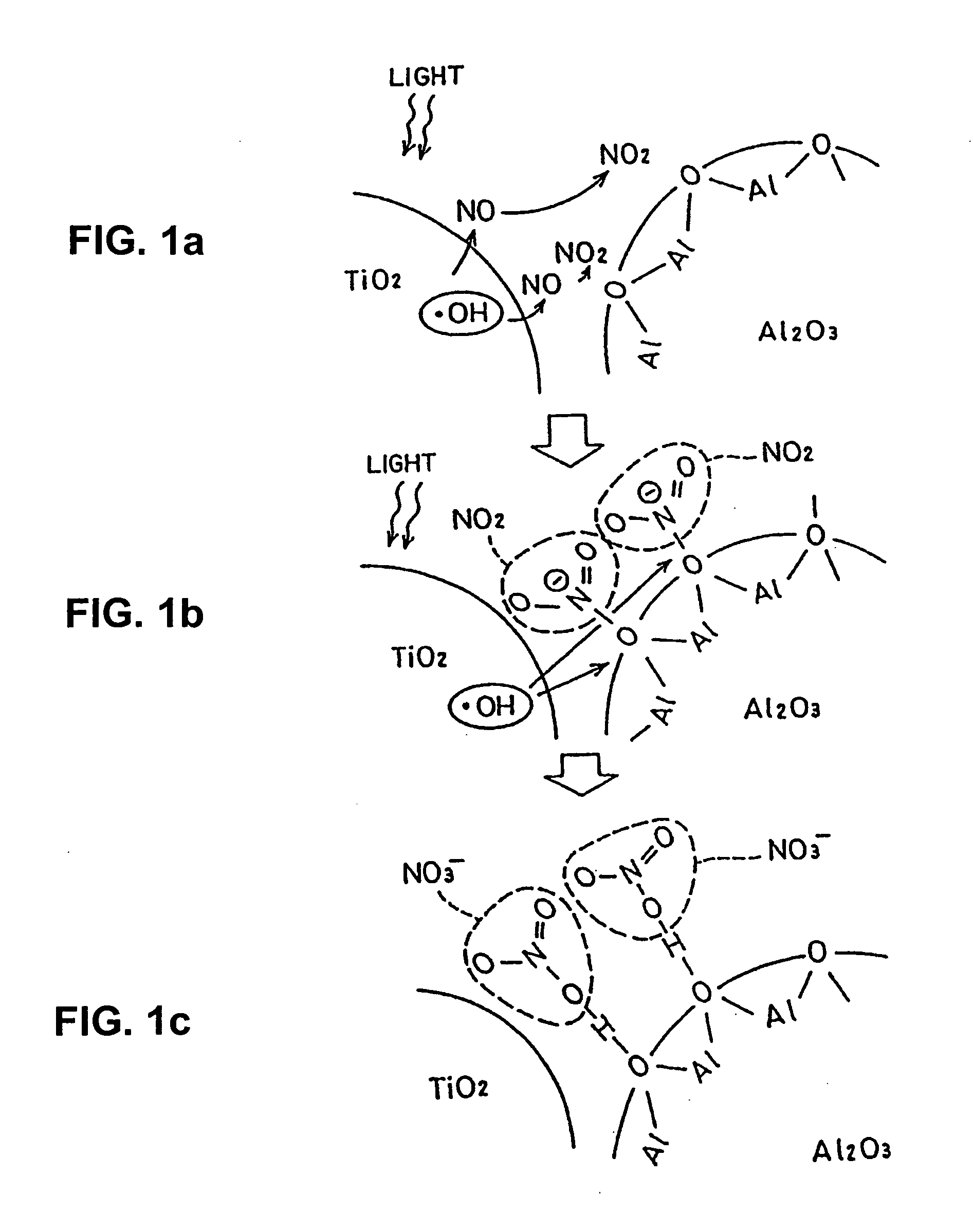

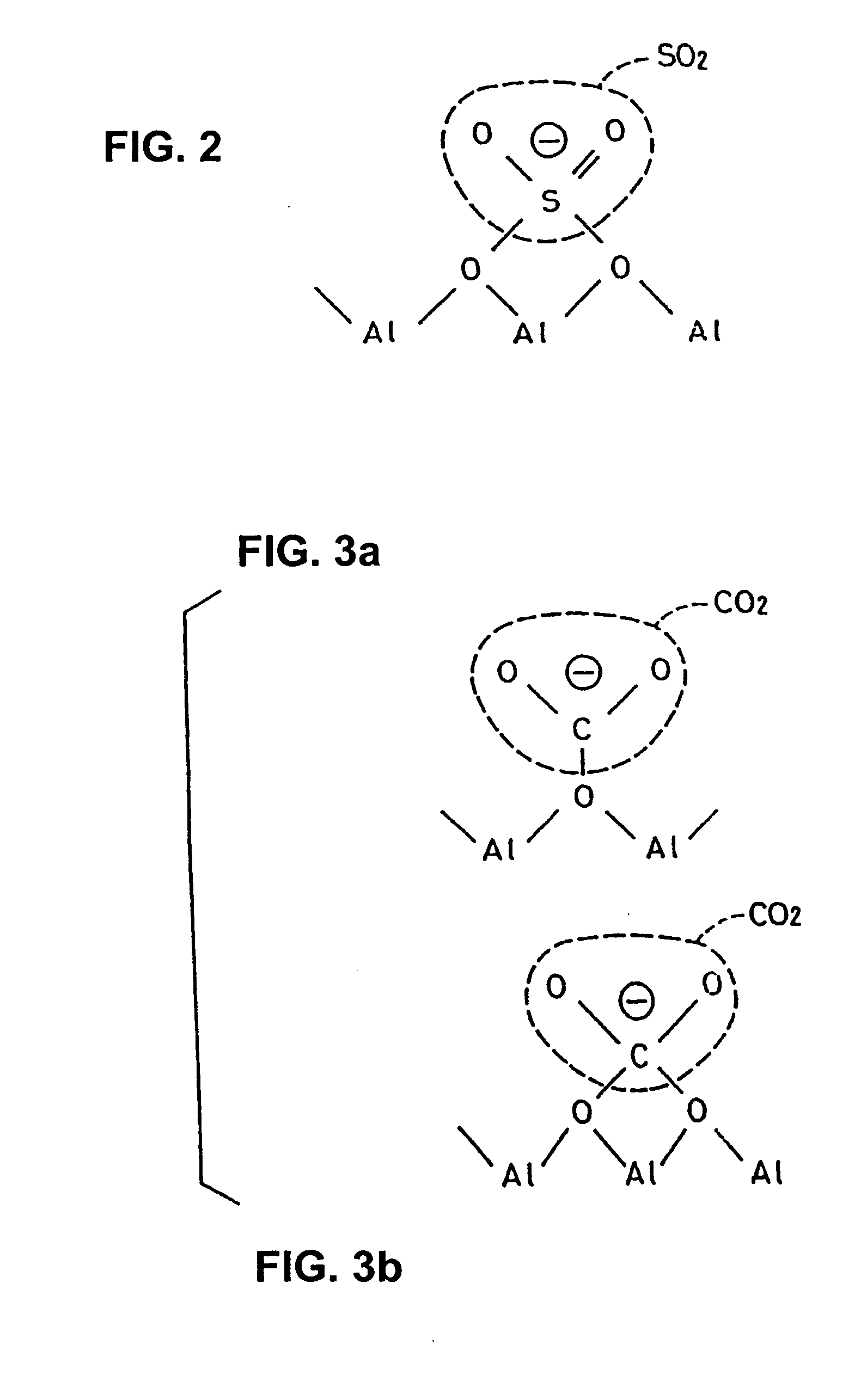

Photocatalytic hydrophilifiable material

InactiveUS7754648B2Speed up the conversion processPercentage reduction of the reactant can be enhancedOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationRubidium oxideSurface layer

A composite material includes a substrate and a self-cleanable hydrophilic surface layer. The surface layer includes a plurality of components: a first component having a photocatalyst which functions as a catalyst upon exposure to light; a second component having one or more of aluminum oxide, zinc oxide, strontium oxide, barium oxide, magnesium oxide, calcium oxide, rubidium oxide, sodium oxide, potassium oxide and phosphorus pentoxide; and a third component having one or more of silicon dioxide, zirconium dioxide, germanium dioxide and thorium dioxide. The first through third components are all situated within the surface layer, which is provided as a single surface layer, such that all of the components are in close proximity to one another within the single surface layer.

Owner:TOTO LTD

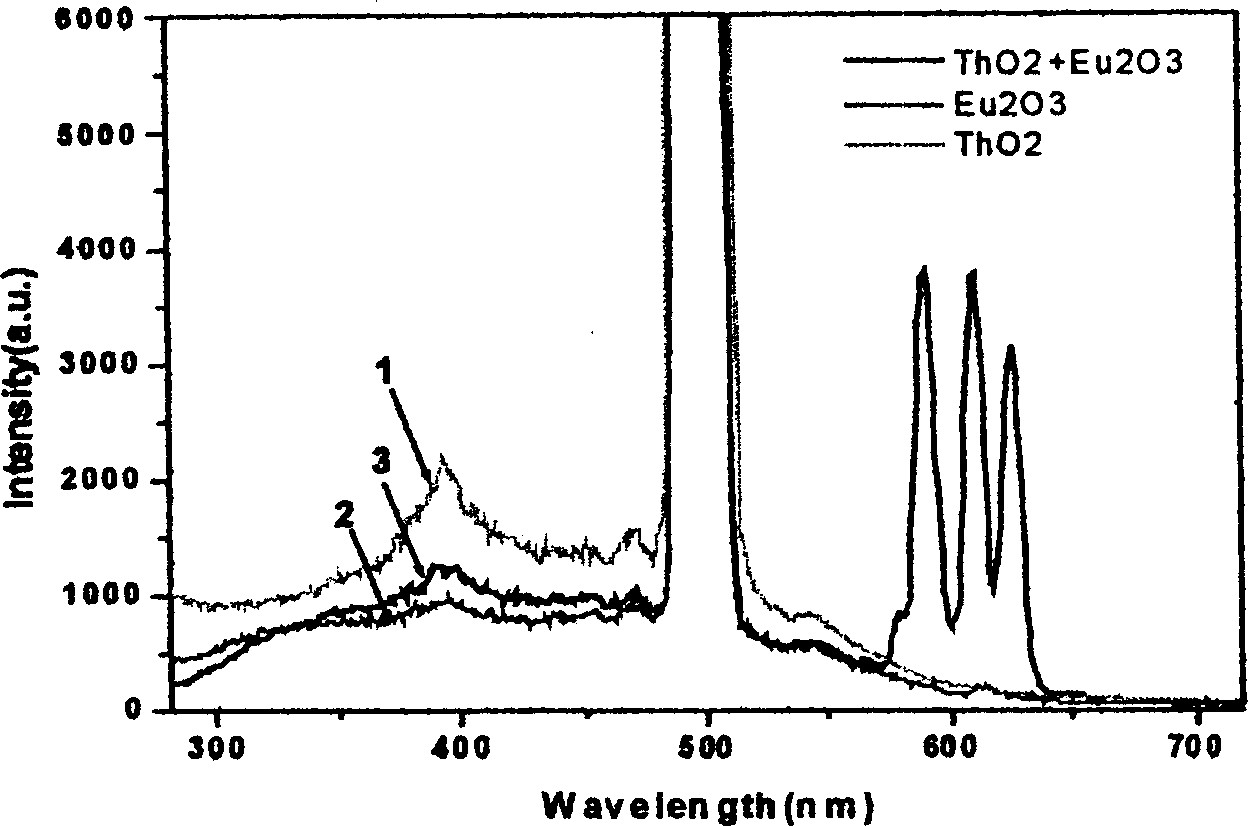

Process for preparing europium oxide doped inorganic lighting material

InactiveCN1752178AEasy to operateConditions are easy to controlLuminescent compositionsRare earthThorium nitrate

Owner:XIAMEN UNIV

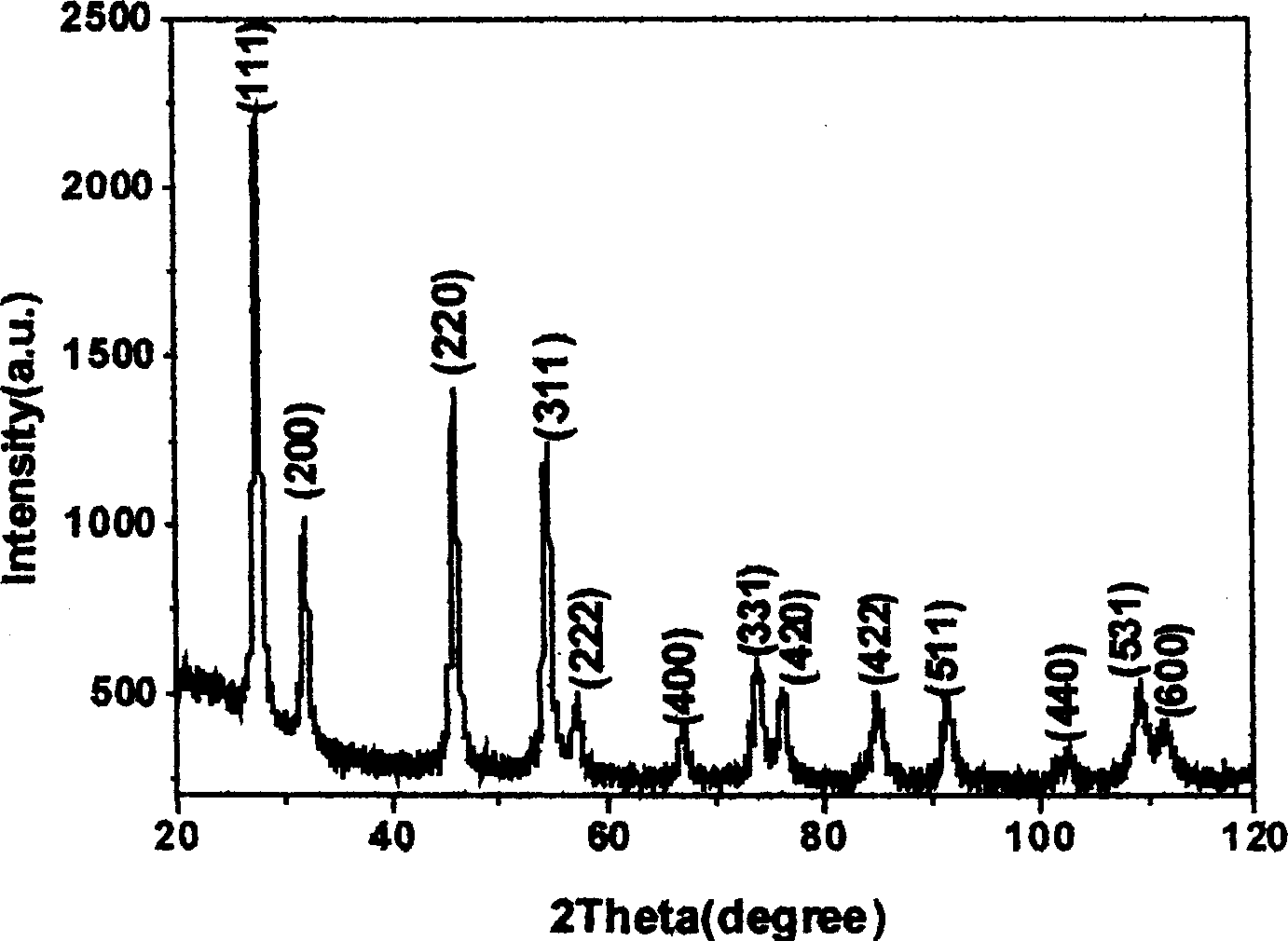

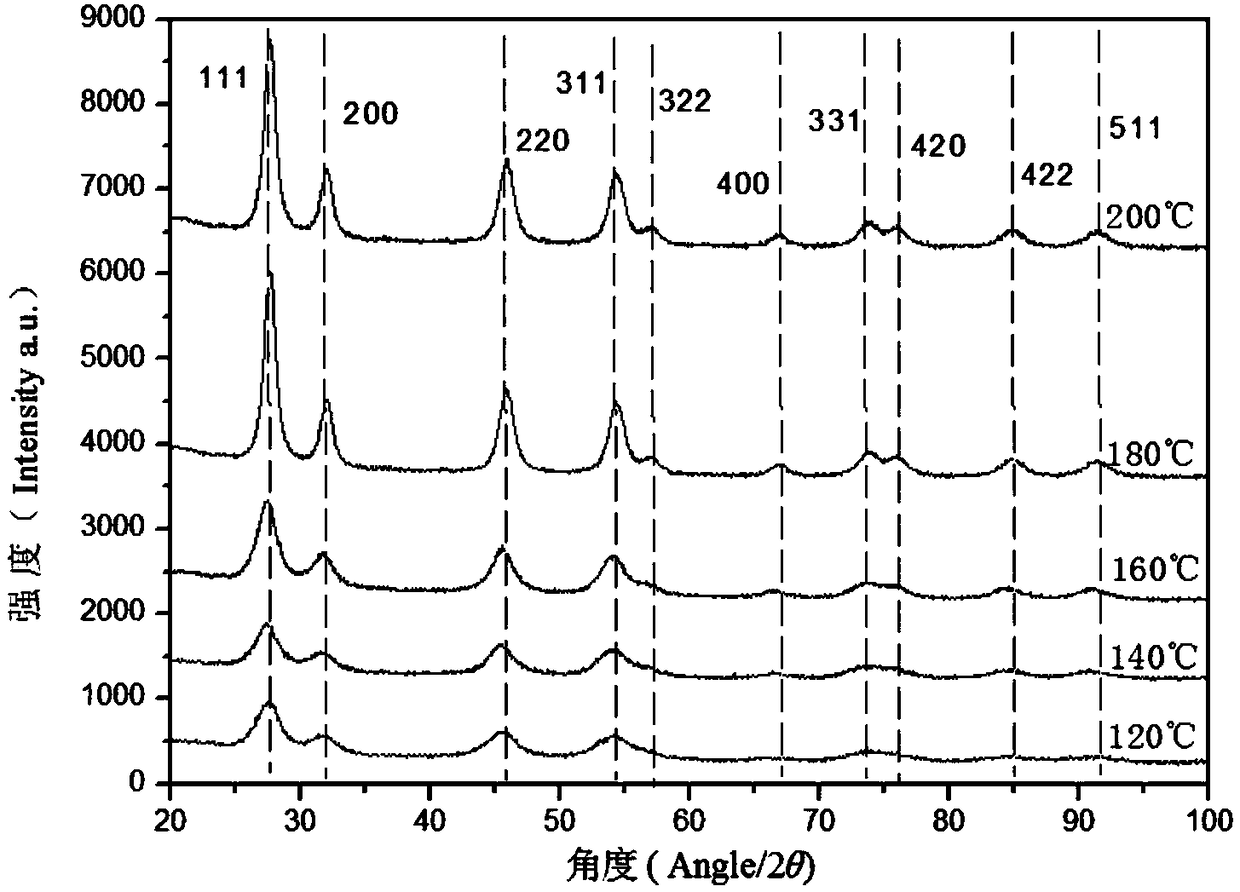

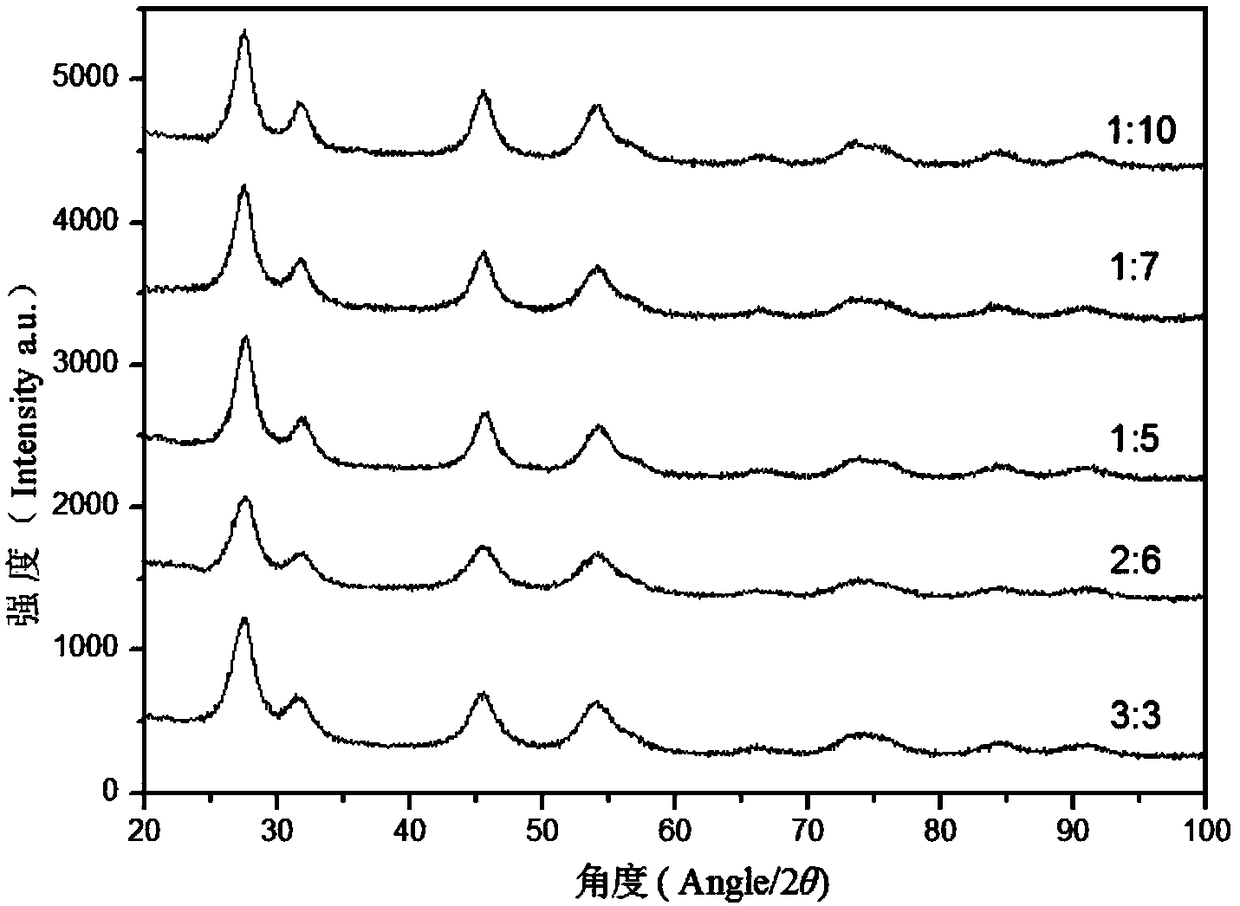

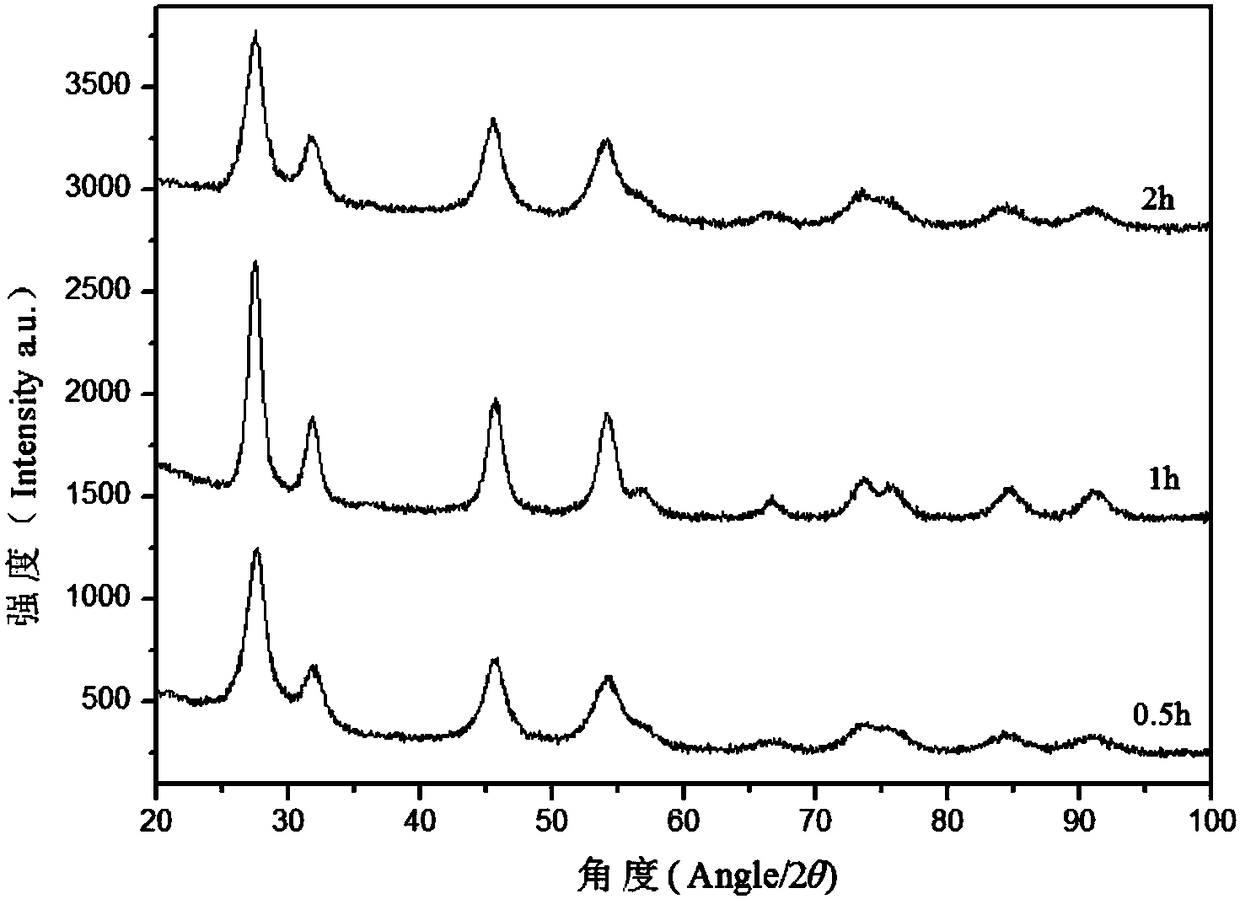

Preparation method for spherical thorium dioxide nano material with sheet-shaped surface structure and spherical thorium dioxide particles obtained from preparation method

ActiveCN108083315ASimple processGood reproducibilityRadium compoundsNanotechnologyMicrowaveReaction temperature

The invention provides a preparation method for a spherical thorium dioxide nano material with a sheet-shaped surface structure. The preparation method comprises the following steps: dissolving thorium nitrate into water to form a thorium nitrate solution; dissolving urea into water to form a urea solution; transferring the thorium nitrate solution and the urea solution into a reaction kettle, wherein a molar ratio of thorium to urea is 1 to (1-10); putting the reaction kettle into a microwave reactor, selecting a reaction temperature of 120-200 DEG C to perform heating reaction for 30-60 minutes, centrifugally separating microwave products obtained in the reaction kettle to obtain precipitates; and drying the precipitates to obtain the spherical thorium dioxide nano material with the sheet-shaped surface structure. The invention further provides spherical thorium dioxide particles prepared from the method. In a word, the preparation method provided by the invention is simple in process and is good in reproducibility; and moreover, used raw materials are inorganic compounds, are cheap and easily available, are relatively low in cost, are environmentally friendly, and are easy for industrial production.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

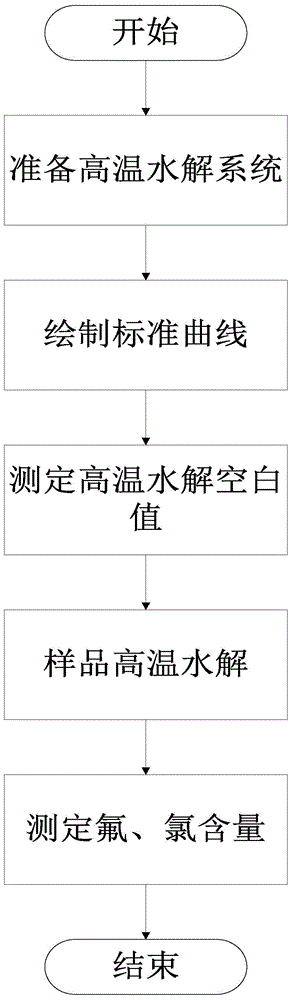

Method for determination of fluorine and chlorine content of thorium dioxide

InactiveCN105806903ASolve the problem of fluorine and chlorine content detectionMaterial electrochemical variablesContent determinationHydrolysis

The invention relates to the technical field of chemical detection methods and concretely relates to a method for determination of fluorine and chlorine content of thorium dioxide. The method solves the problem that the prior art cannot measure fluorine and chlorine content of thorium dioxide. The method comprises high temperature hydrolysis based on a high temperature hydrolysis system, standard curve drawing, high temperature hydrolysis baseline value determination, sample high temperature hydrolysis and fluorine and chlorine content determination. The invention utilizes high temperature hydrolysis to detect fluorine and chlorine content of thorium dioxide, provides analysis related parameters, fills the blank of determination of fluorine and chlorine content of thorium dioxide, solves the problem of detection of fluorine and chlorine content of thorium dioxide in production and scientific research and effectively cooperates engineer-to-order production.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Wearproof ceramic material

InactiveCN108975774AImprove wear resistanceImprove impact resistanceWear resistanceZirconium dioxide

The invention discloses a wearable ceramic material belonging to the field of wearable materials. The wearable ceramic material comprises the following raw materials in parts by weight: 85-90 parts ofnano aluminum oxide, 1-3 parts of quartz sand, 5-7 parts of titanium dioxide, 3-5 parts of zirconium dioxide, 1-3 parts of chromic oxide, 10-13 parts of silicon nitride, 0.5-2 parts of thorium dioxide and 3-7 parts of a binder. The wearproof ceramic material has the advantages of enhancement of abrasive resistance and impact resistance, firmer adhesion, improvement of whole performance of materials and high usage degree.

Owner:ANHUI XINRUI HEAVY IND

Nano ceramic high temperature resistant coating material and preparation method thereof

The invention discloses a nano ceramic high temperature resistant coating material and a preparation method thereof and relates to the technical field of machinery. The coating material comprises thefollowing components in parts by mass: (1) 15-30 parts of silicon carbide, (2) 3-9 parts of nano nickel oxide and 6-12 parts of nano magnesium oxide, (3) 15-23 parts of nano Al2O3, (4) 2.5-4 parts ofTa2O5, (5) 25-45 parts of silicon dioxide, (6) 4.5-7.5 parts of titanium oxide, and (7) 5-15 parts of nano thorium dioxide. The nano ceramic high temperature resistant coating material disclosed by the invention and prepared according to the preparation method is high in strength and toughness and excellent in high temperature resistance, and can be used as a coating material of a machine tool.

Owner:徐州台力福数控科技有限公司

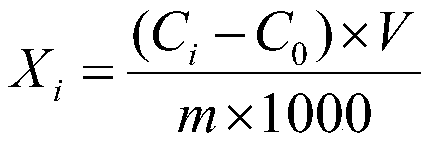

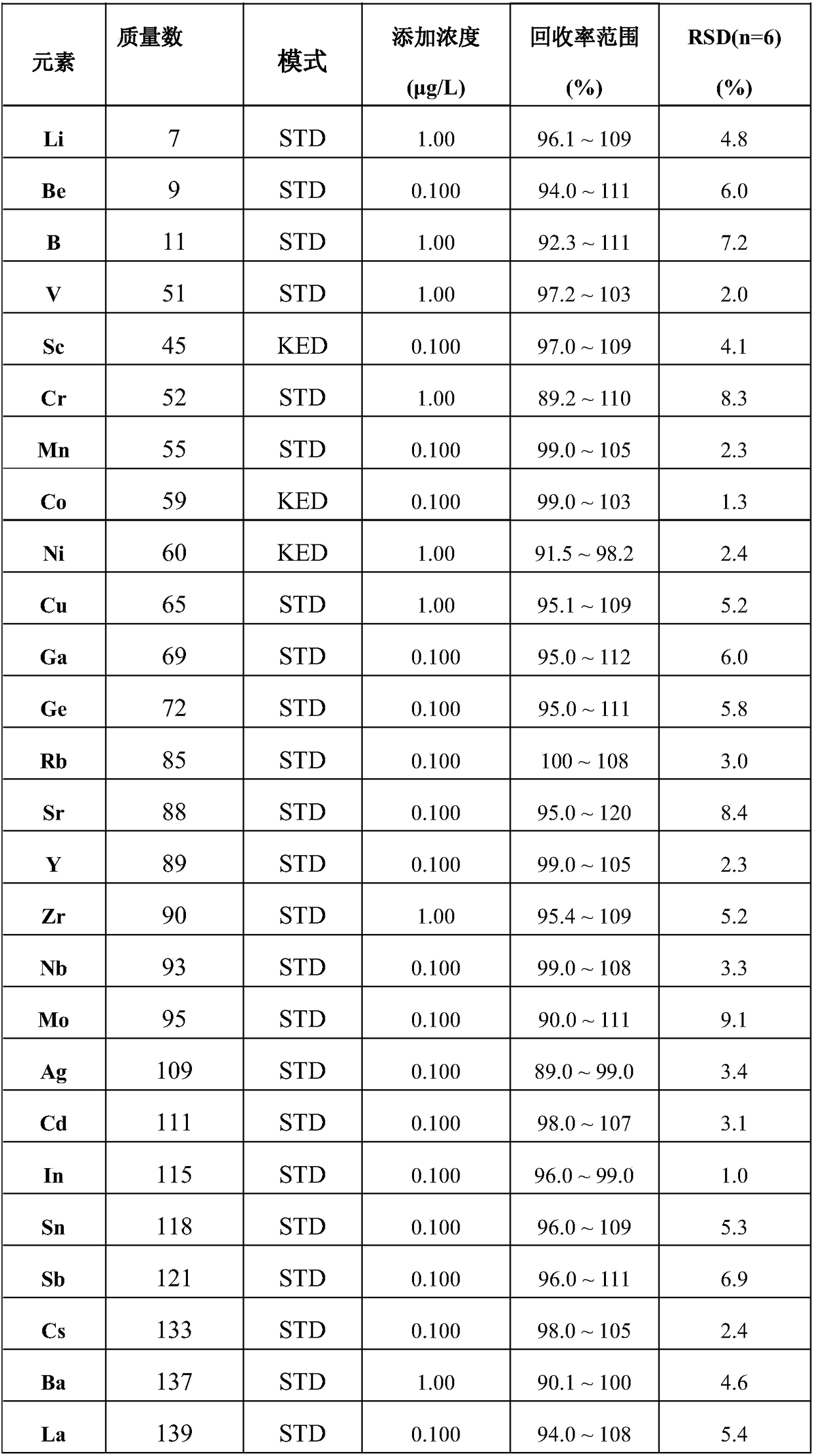

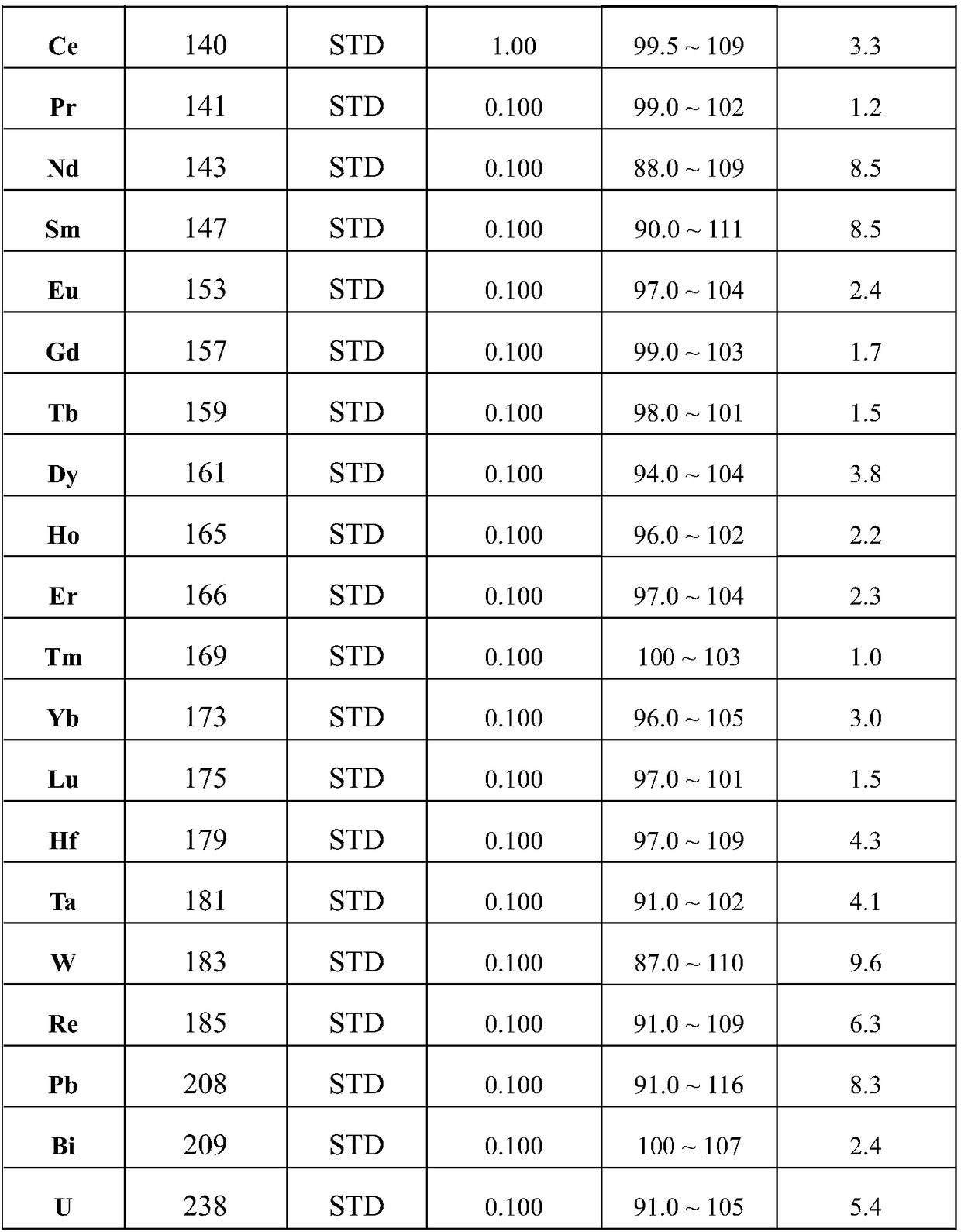

Method for determining content of metal impurities in thorium dioxide

InactiveCN108871927AOvercoming matrix effectEliminate distractionsPreparing sample for investigationMaterial analysis by electric/magnetic meansMetal impuritiesInductively coupled plasma

The invention provides a method for determining the content of metal impurities in thorium dioxide. The method comprises the following steps that a solution to be tested, a blank solution and a standard solution are provided; the solution to be tested, containing a thorium dioxide matrix and the metal impurities, is prepared by digesting a sample to be tested with a microwave digestion method; theblank solution through microwave digestion of a blank sample without containing the sample to be tested is prepared; the standard solution contains the thorium dioxide matrix and the metal impuritieswith a known concentration, and the concentration of the thorium dioxide matrix in the standard solution is identical to the concentration of the thorium dioxide matrix in the solution to be tested;and the standard solution, the blank solution and the solution to be tested are introduced into an inductively coupled plasma source mass spectrometer to obtain the concentrations of the metal impurities in the blank solution and the solution to be tested, and the content of the metal impurities in the sample to be tested is converted according to the quality of the sample to be tested. The methodis simple to operate and solves the problems of tedious operation, poor stability, poor reproducibility and the like.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

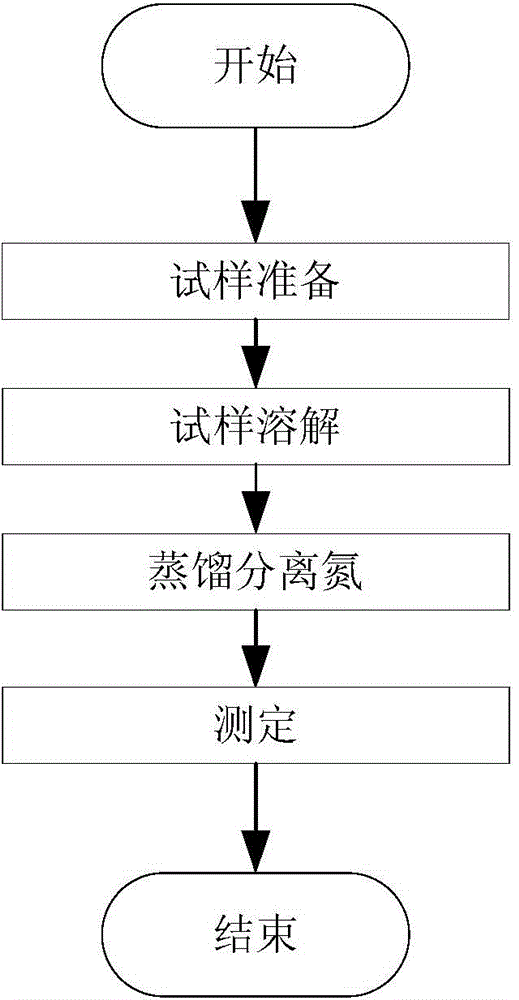

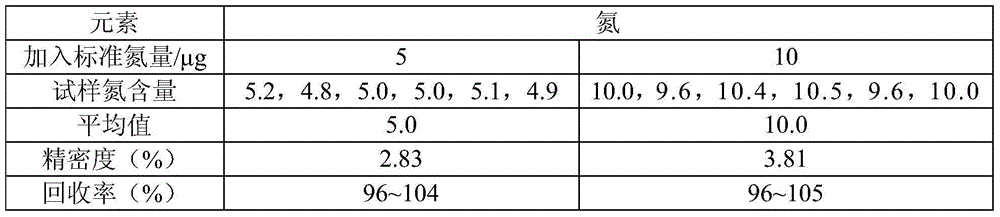

Thorium dioxide powder and method for determining nitrogen content in core block

InactiveCN105806836AGood precisionMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationDistillationNitrogen

The invention belongs to the field of chemical detection technology, and concretely relates to thorium dioxide powder and a method for determining nitrogen content in a core block; and the invention aims at providing the thorium dioxide powder and the method for determining nitrogen content in the core block. The method comprises the following steps: preparation of a sample, dissolving of the sample, distillation and separation of nitrogen, and determination. The trace amount of nitrogen in thorium dioxide is determined by using a Nessler's reagent-spectrophotometry method; dissolving conditions, distillation time, distillation volume, addition of a color developing agent, and developing time of the powder shaped sample are provided; when the sample amount is 0.1-1.0g, the method precision is better than 5%, and the recovery rate is 96-105%.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

High-aluminum blast furnace slag-high-magnesium phosphate tailing expendable pattern casting coating and preparing method thereof

InactiveCN105149502AReduce manufacturing costImprove adhesionFoundry mouldsFoundry coresPhosphorous acidPhosphate

An expendable pattern casting coating superior in using performance and low in production cost is prepared with high-aluminum blast furnace slag, high-magnesium phosphate tailings, quartz milltailings, pyrite tailings, attapulgite, silicon carbide, kaolin fine powder, siliceous shale powder, diaspore, silicon boride, thorium dioxide, gamma-(methylacryloyl oxygen base) MAPTMS, 2-(phosphorous acid 2-glycerol trilaurate) 4-oxygen octyloxy titanate, isooctyl palmitate, dicumyl peroxide, polyving akohol, hydroxy propyl distarch phosphate, carbon fiber, sodium gluconate, petroleum sodium sulfonate, neopentyl glycol, ethanol and water as raw materials. The purposes of comprehensively recycling high-aluminum blast furnace slag and high-magnesium phosphate tailings and reducing the production cost are achieved.

Owner:张燕

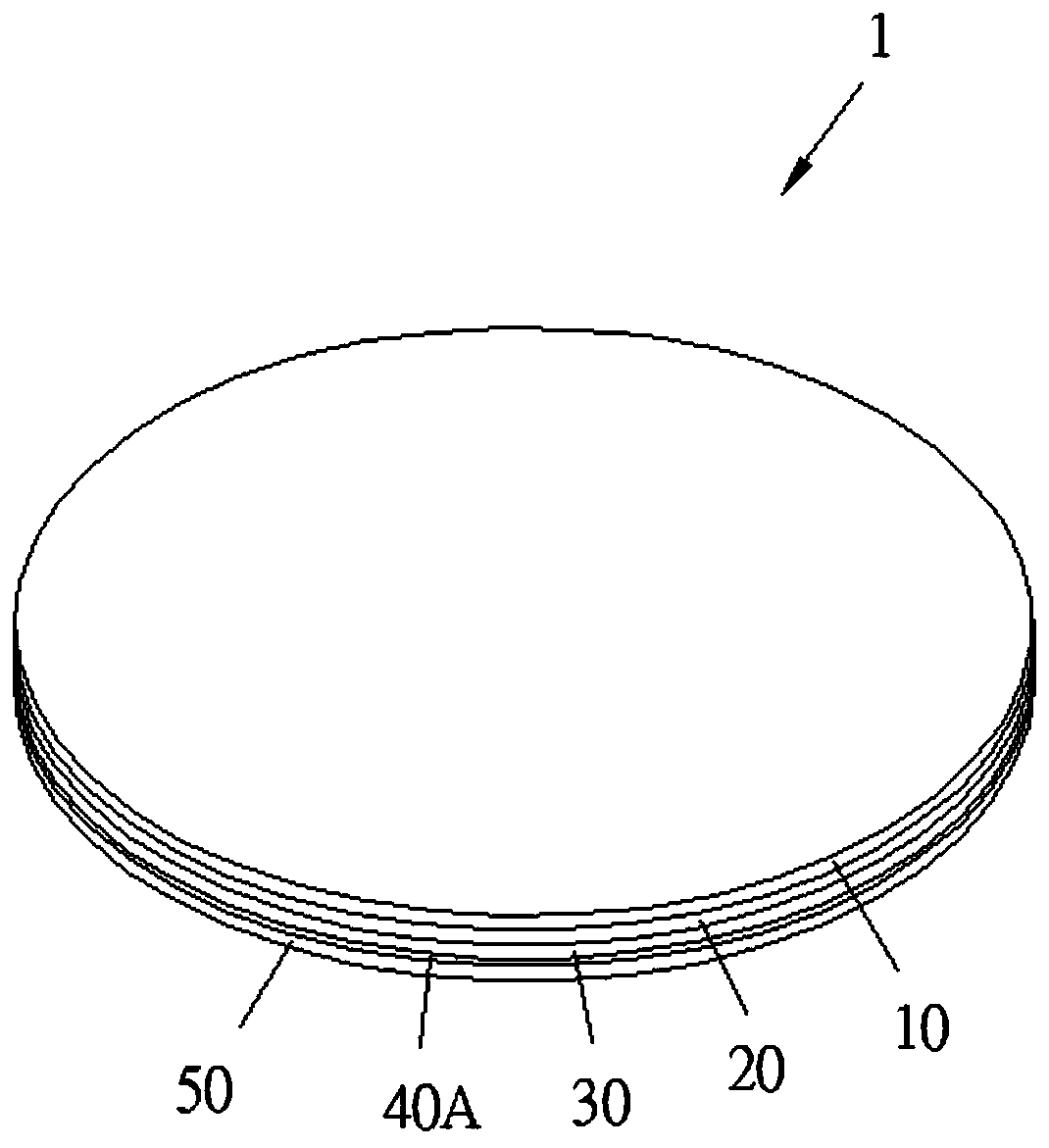

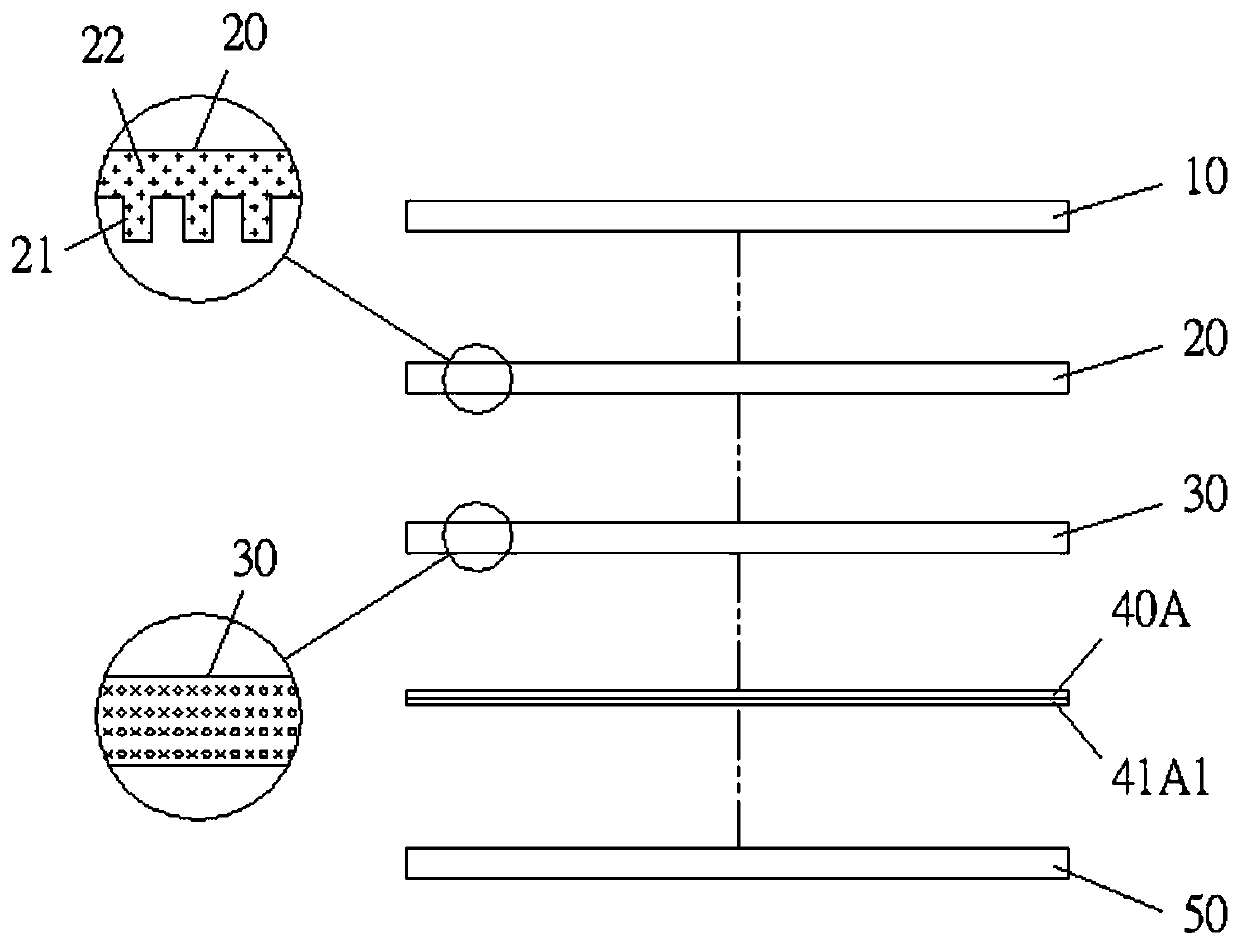

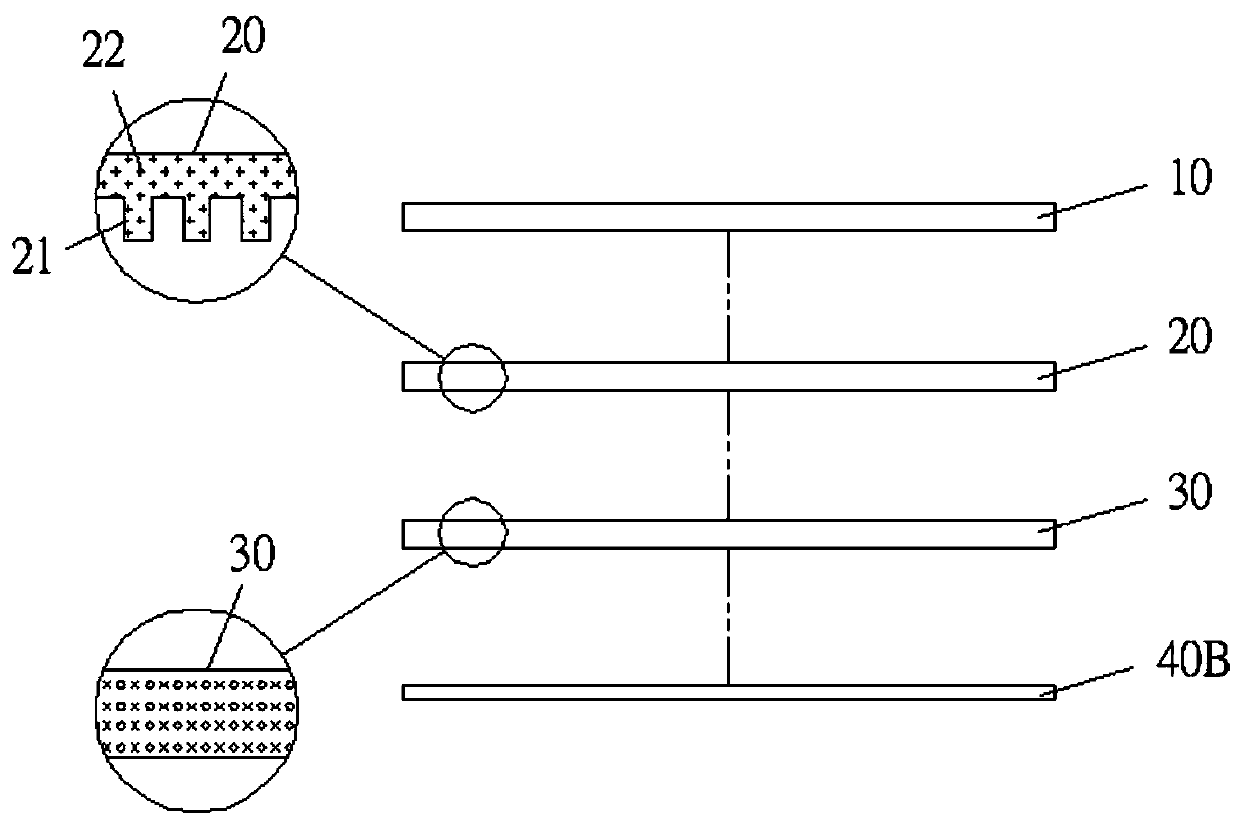

Pain Reduction Patch

A pain reduction patch of the present invention comprises: a first layer body having a plurality of ventilation holes; a second layer body arranged on the bottom surface of the first layer body and having a bottom surface coated with a coating, wherein the coating includes silicon dioxide, aluminum oxide, sodium oxide, potassium oxide, magnesium oxide, calcium oxide, titanium dioxide, iron oxide,zirconium dioxide, zinc oxide, yttrium oxide, cerium dioxide, lanthanum oxide, hafnium oxide, selenium oxide, thorium dioxide, neodymium oxide and hafnium oxide; a third layer body arranged on the bottom surface of the second layer body and containing far-infrared powder or negative ion powder inside; and an adhesive layer arranged on the bottom surface of the third layer body. The bottom surfaceof the adhesive layer is provided with an adhesive to be attached to the human skin so that trace elements, far infrared rays and negative ions can enter the human body.

Owner:惠庭暄 +1

Photocatalytic hydrophilifiable material

InactiveUS20090209410A1Easy to superviseLowering in efficiency of catalytic reactionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationRubidium oxideGermanium dioxide

A composite material includes a substrate and a self-cleanable hydrophilic surface layer. The surface layer includes a plurality of components: a first component having a photocatalyst which functions as a catalyst upon exposure to light; a second component having one or more of aluminum oxide, zinc oxide, strontium oxide, barium oxide, magnesium oxide, calcium oxide, rubidium oxide, sodium oxide, potassium oxide and phosphorus pentoxide; and a third component having one or more of silicon dioxide, zirconium dioxide, germanium dioxide and thorium dioxide. The first through third components are all situated within the surface layer, which is provided as a single surface layer, such that all of the components are in close proximity to one another within the single surface layer.

Owner:TOTO LTD

A kind of high temperature resistant cermet material and preparation method thereof

The invention belongs to the field of cermet materials, and discloses a high-temperature-resistant cermet material and a preparation method thereof. The high-temperature-resistant cermet material comprises 11-22 parts of nickel sesquioxide, 5-11 parts of magnesium oxide, 7-11 parts of zirconium diboride, 2-4 parts of thorium dioxide, 4-7 parts of bismuth oxide, 5-9 parts of zinc, 7-13 parts of copper, 2-4 parts of germanium and 12-17 parts of iron. The preparation method comprises the following steps: (1) quickly mixing metals and a ceramic material at high speed; (2) carrying out ball milling on the uniform mixture with a ball mill; (3) carrying out high-temperature press fitting on the cermet material subjected to ball milling in a hot-pressing furnace, heating the furnace to 720-780 DEG C, keeping the temperature, continuing heating the hot-pressing furnace to 1520-1610 DEG C, sintering, and cooling to obtain the high-temperature-resistant cermet material.

Owner:佛山市三水华纳陶瓷有限公司

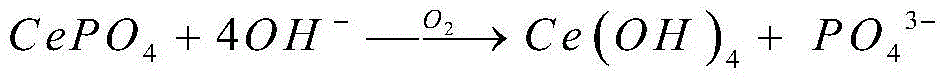

Technique for processing monazite through alkaline method and separating rare earth through extraction

ActiveCN106148691AReduce alkali consumptionRealize safe and clean productionProcess efficiency improvementCeriumRare earth

The invention provides a technique for processing monazite through an alkaline method and separating rare earth through extraction. According to the specific scheme, the monazite is processed through the alkaline method under the non-oxidation protection atmosphere, hydroxide containing trivalent rare earth is obtained, and the hydroxide is directly reacted with an acidic extraction agent to obtain an organic phase containing rare earth. Compared with hydroxide of tetravalent cerium, hydroxide of trivalent cerium has the characteristics of being dissolved easily and capable of reducing acid consumption, and conditions are created for the subsequent situations that the rare earth is dissolved by an acidulous extraction agent preferentially and the rare earth is separated from impurities such as indissolvable thorium dioxide. The hydroxide of the trivalent rare earth is directly dissolved with the acidic extraction agent, the problem that acid-base consumption is too high due to the fact that the rare earth is separated through organic liquid caustic soda or in an ammonium hydroxide saponification mode is solved, and procedures are simplified.

Owner:永州市湘江稀土有限责任公司

Nano ceramic coating material for machine tool and preparation method thereof

The invention discloses a nano ceramic coating material for a machine tool and a preparation method thereof and relates to the technical field of machining. The coating material is prepared from the following components in parts by mass: (1) 15-30 parts of silicon carbide; (2) 3-9 parts of nano nickel oxide and 6-12 parts of nano magnesium oxide; (3) 15-23 parts of nano Al2O3; (4) 2.5-4 parts of Ta2O5; (5) 25-45 parts of silicon dioxide; (6) 4.5-7.5 parts of titanium oxide; and (7) 5-15 pats of nano thorium dioxide. The ceramic nano coating material provided by the nano ceramic coating material for the machine tool and the preparation method thereof have good strength and toughness as well as excellent high temperature resistance and wear resistance, have certain corrosion resistance and can be used as a coating material of the machine tool.

Owner:徐州台力福数控科技有限公司

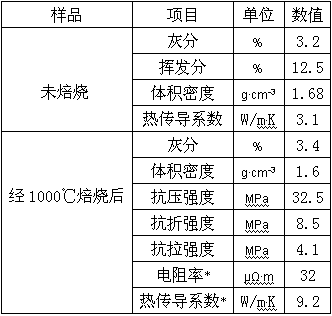

Industrial conductive material and preparation method thereof

ActiveCN105513664ASimple preparation processHigh process control precisionConductive materialCable/conductor manufactureConductive materialsHigh resistivity

The invention discloses an industrial conductive material and a preparation method thereof. The industrial conductive material is prepared by the following main materials according to weight ratio: 4.5-6 parts of electric calcined anthracite, 2-4 parts of calcined petroleum coke, 1.2-1.5 parts of resin modified bitumen, 0.03-0.06 parts of attapulgite, 0.03-0.12 parts of thorium dioxide, and 1.8-2.0 parts of intermediate-temperature coal bitumen powder. The industrial conductive material according to the invention has advantages of high industrial control precision, high strength, high resistivity, high heat conductivity, high sintering performance, high thermal shock resistance, high oxidation resistance, simple manufacture process and relatively low production cost.

Owner:徐州佳利泰新型材料科技有限公司

Discharge lamp having a cathode and emitter assembly composed of tungsten and thorium oxide and joined through a carbide interface region

InactiveUS7586263B2Eliminate disadvantagesEasy to useDischarge tube luminescnet screensProjectorsGas-discharge lampCarbide

A high pressure discharge lamp, in which an anode and a cathode are disposed opposite each other in a bulb, achieves a long service life due to thorium (Th) being stably supplied to the cathode tip for a long time after lamp operation has been commence since the formation of the flicker phenomenon is suppressed over a long time due to the cathode being made of tungsten which contains thorium oxide on a surface space from the cathode tip, a carbide layer of tungsten carbide is formed and the cathode being bordered by an emitter containing body of tungsten which contains thorium dioxide, and a carbide layer of tungsten carbide being formed at least in a region bordering the cathode.

Owner:USHIO DENKI KK

High-temperature-resistant metal coating material for machine tool and preparation method thereof

The invention discloses a high-temperature-resistant metal coating material for a machine tool and a preparation method thereof and relates to the technical field of machinery. The coating material iscomposed of, by mass, 15-30 parts of silicon carbide, 3-9 parts of nano nickel oxide, 6-12 parts of nano magnesium oxide, 15-23 parts of nano Al2O3, 2.5-4 parts of Ta2O5, 25-45 parts of silicon dioxide, 4.5-7.5 parts of titanium oxide and 5-15 parts of nano thorium dioxide. Nanomaterial technology is utilized to modify an existing coating material, and resistance to high temperature is substantially improved by adding nanoscale particles into the coating material, so that the high-temperature-resistant metal coating material has high strength and toughness and excellent high-temperature-resistant performance and can be used for the machine tool.

Owner:徐州台力福数控科技有限公司

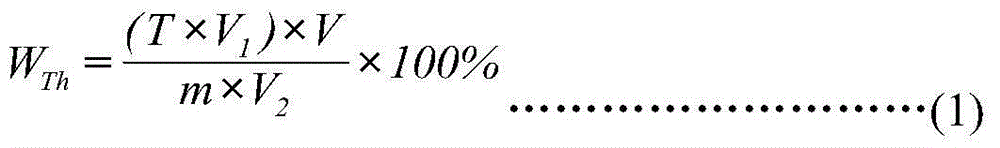

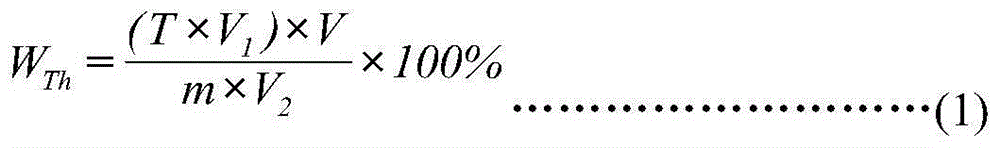

Method for determination of thorium content of thorium dioxide

InactiveCN105806835ADoes not affect precision measurementHigh precisionMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationDecompositionTest sample

The invention relates to the technical field of chemical detection methods and concretely relates to a method for determination of thorium content of thorium dioxide. The method solves the problem that the existing thorium content determination method has a high cost and a complex operation process. The method comprises test sample decomposition and thorium content calculation. The method utilizes an EDTA volumetric method to realize determination of thorium content of thorium dioxide, is suitable for determination of thorium content of thorium dioxide and is suitable for determination of thorium content of thorium nitrate. A trace amount of rare earth impurities do not influence precision determination of thorium content. The method has the characteristics of high precision, accuracy and reliability. The method has thorium content determination RSD% less than 0.2%.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Fabrication method of burnable absorber nuclear fuel pellets and burnable absorber nuclear fuel pellets fabricated by the same

ActiveUS9653188B2Reduce porosityVolatilization can be minimizedFuel elementsNuclear energy generationHydrogen atmospherePlutonium dioxide

A fabrication method of burnable absorber nuclear fuel pellets and burnable absorber nuclear fuel pellets fabricated by the same are provided, in which the fabrication method includes adding boron compound and manganese compound to one or more type of nuclear fuel powders selected from the group consisting of uranium dioxide (UO2), plutonium dioxide (PuO2) and thorium dioxide (ThO2) and mixing the same (step 1), compacting the mixed powder of step 1 into compacts (step 2), and sintering the compacts of step 2 under hydrogen atmosphere (step 3). According to the fabrication method, sintering can be performed under hydrogen atmosphere at a temperature lower than the hydrogen atmosphere sintering that is conventionally applied in the nuclear fuel sintered pellet mass production, by adding sintering additives such as manganese oxide or the like.

Owner:KOREA ATOMIC ENERGY RES INST

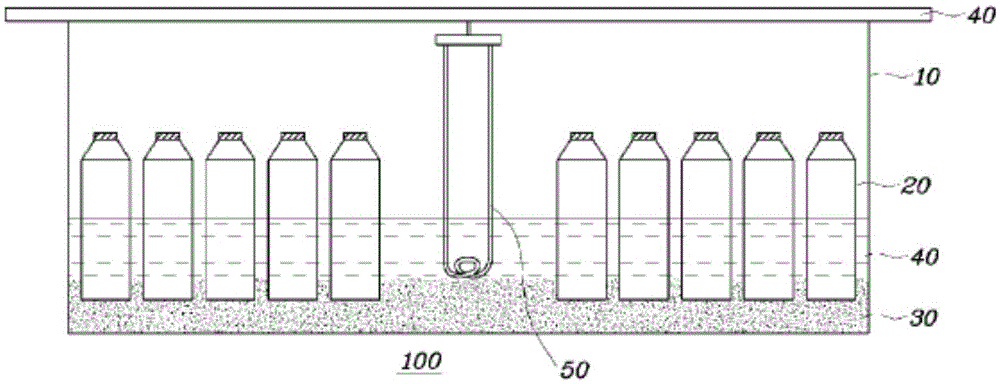

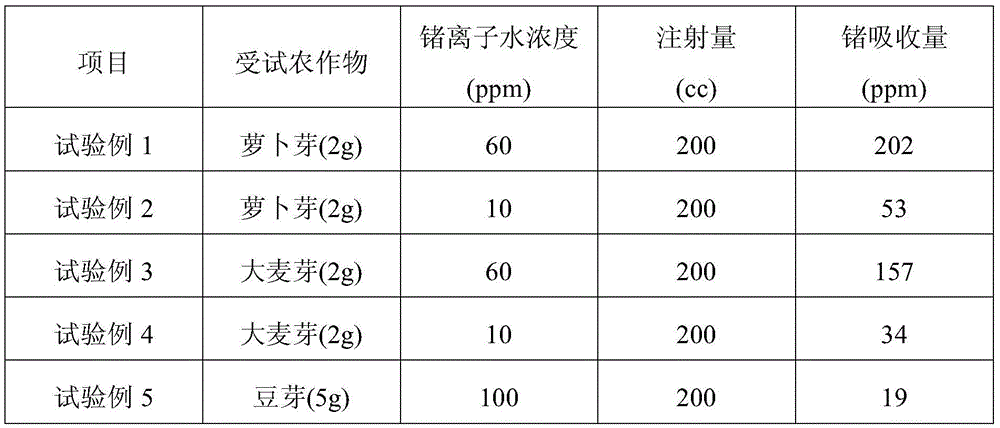

Germanium ion water producing method and crop cultivating method using germanium ion water

InactiveCN105578869AReduce manufacturing costEasy to produceMixing methodsWater/sewage treatment by substance additionPhysical chemistryGermanium dioxide

A germanium ion water producing method, according to one embodiment of the present invention, comprises the steps of: putting, into water, thorium dioxide (ThO2) or thorium ore powder so as to produce a radiation-emitting solution; mixing germanium dioxide (GeO2) powder with water in a reaction container, and depositing the reaction container such that the reaction container is immersed in the radiation-emitting solution; and heating the radiation-emitting solution.

Owner:朴万祚

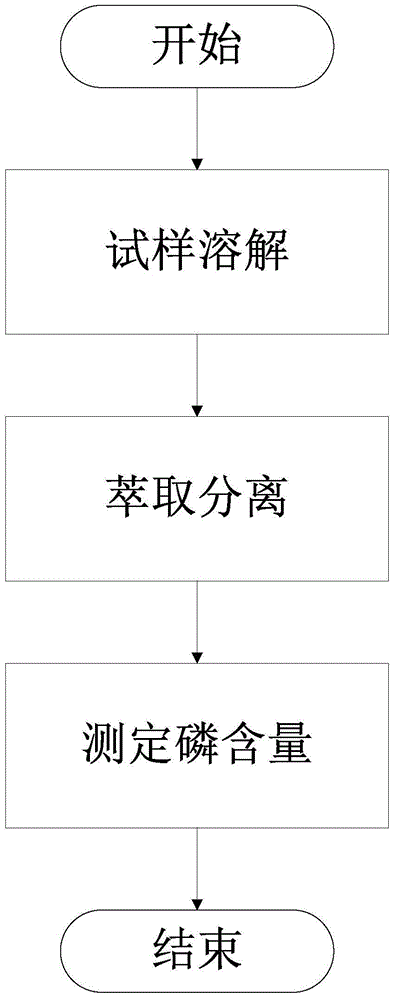

Method for determination of phosphorus content of thorium dioxide

InactiveCN105806834ASolve the measurement workAccurate determination of contentMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationTest sampleDissolution

The invention relates to the technical field of chemical detection methods and concretely relates to a method for determination of phosphorus content of thorium dioxide. The method solves the problem that the existing method cannot determine phosphorus content of thorium dioxide. The method comprises test sample dissolution, extraction separation and phosphorus content determination. The method utilizes a spectrophotometry method to detect phosphorus in thorium dioxide powder and a thorium dioxide core block, realizes accurate determination of microscale phosphorus content of thorium dioxide powder under experiment conditions, solves the problems of determination of phosphorus in thorium dioxide powder and a thorium dioxide core block, provides accurate detection data and cooperates with scientific research and production.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

High-temperature-resisting ceramic coating material and preparation method thereof

The invention provides a high-temperature-resisting ceramic coating material and a preparation method thereof and relates to the technical field of machinery. The coating material is prepared from thefollowing components in parts by mass: (1) 15 to 30 parts of silicon carbide; (2) 3 to 9 parts of nano nickel oxide and 6 to 12 parts of nano magnesium oxide; (3) 15 to 23 parts of nano Al2O3; (4) 2.5 to 4 parts of Ta2O5; (5) 25 to 45 parts of silicon dioxide; (6) 4.5 to 7.5 parts of titanium oxide; (7) 5 to 15 parts of nano thorium dioxide. According to the high-temperature-resisting ceramic coating material and the preparation method thereof, the high-temperature-resisting ceramic coating material has good strength and toughness, and excellent high-temperature-resisting performance, and canbe used as a coating material of machine tools and the like.

Owner:徐州台力福数控科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com