Industrial conductive material and preparation method thereof

A conductive material and industrial technology, applied in the direction of conductive materials, conductive materials, cable/conductor manufacturing, etc., can solve the problems of unstable product quality, poor thermal shock resistance, high production cost, etc. , low production cost, good sintering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

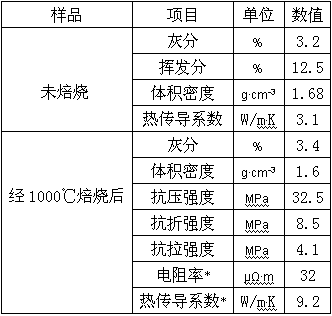

Examples

Embodiment 1

[0033] Example 1 An industrial conductive material prepared from the following main raw materials in parts by weight (each part is 80Kg): 4.5 parts of electric calcined anthracite, 2 parts of calcined petroleum coke, 1.2 parts of resin modified pitch, attapulgite 0.03 parts of soil, 0.03 parts of thorium dioxide, and 1.8 parts of medium temperature coal tar pitch powder.

[0034] The preparation method of above-mentioned industrial conductive material is:

[0035] (1) Crushing and grading the electric calcined anthracite (purchased from Ningxia Wanboda Carbon Products Co., Ltd.), wherein the particle size of 8-15mm is the primary particle material, and the particle size of 4-8mm is the secondary particle material;

[0036] (2) The calcined petroleum coke (calcined petroleum coke was purchased from Panjin Jiahe Carbon Products Co., Ltd.) was sieved and pulverized and then classified, among which the granular material with a particle size of 2-4mm was the third-grade granular ma...

Embodiment 2

[0040] Example 2 An industrial conductive material prepared from the following main raw materials in parts by weight (each part is 80Kg): 6 parts of electric calcined anthracite, 4 parts of calcined petroleum coke, 1.5 parts of resin modified pitch, attapulgite 0.06 parts of soil, 0.12 parts of thorium dioxide, and 2.0 parts of medium temperature coal tar pitch powder.

[0041] The preparation method of above-mentioned industrial conductive material is:

[0042] (1) Crushing and grading the electric calcined anthracite (purchased from Ningxia Wanboda Carbon Products Co., Ltd.), wherein the particle size of 8-15mm is the primary particle material, and the particle size of 4-8mm is the secondary particle material;

[0043] (2) The calcined petroleum coke (calcined petroleum coke was purchased from Panjin Jiahe Carbon Products Co., Ltd.) was sieved and pulverized and then classified, among which the granular material with a particle size of 2-4mm was the third-grade granular mate...

Embodiment 3

[0047] Example 3 An industrial conductive material prepared from the following main raw materials in parts by weight (each part is 80Kg): 4.8 parts of electric calcined anthracite, 2.4 parts of calcined petroleum coke, 1.26 parts of resin modified pitch, attapulgite 0.037 parts of soil, 0.05 parts of thorium dioxide, and 1.86 parts of medium-temperature coal tar pitch powder.

[0048] The preparation method of above-mentioned industrial conductive material is:

[0049] (1) The electric calcined anthracite (purchased from Shizuishan Jinlin Corundum Refractory Co., Ltd.) was crushed and classified, among which the granular material with a particle size of 8-15mm was the primary granular material, and the granular material with a particle size of 4-8mm was the secondary granular material;

[0050] (2) After the calcined petroleum coke (purchased from Ruichi Carbon Products Co., Ltd.) is sieved and pulverized, it is classified, among which the particle size of 2-4mm is the third-g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com