Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Nickel sesquioxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel sesquioxide, nickel trioxide. Identifiers CAS Number. ... Nickel(III) oxide is the inorganic compound with the formula Ni 2 O 3. It is not well characterised, sometimes referred to as black nickel oxide. Traces of Ni 2 O 3 on nickel surfaces have been mentioned.

Manufacturing method of electrothermal film

ActiveCN104080208AImprove stabilityImprove temperature resistanceHeating element materialsNickel sesquioxideManganese

The invention discloses a manufacturing method of an electrothermal film. The manufacturing method comprises the following steps of A, preparing an electrothermal film treatment solution which comprises tin tetrachloride, titanium trichloride, antimony trichloride, calcium chloride, chromic oxide, manganese dioxide, nickel sesquioxide, isopropanol, alcohol and water, B, masking a substrate, C, heating the substrate to be 400-700 DEG C and then spraying the electrothermal film treatment solution on the substrate by a spray gun to form a semifinished electrothermal film, D, annealing the semifinished electrothermal film, and E, coating silver oxide paste on the surfaces of the two ends of the annealed semifinished electrothermal film, loading the semifinished electrothermal film into an electrode oven, baking and fusing the semifinished electrothermal film to form a whole, and obtaining the finished electrothermal film. The manufacturing method has the advantages that the stability of the electrothermal film is improved by adding antimony; the temperature resistance of the electrothermal film is improved by adding titanium; the infrared emitting ability of the electrothermal film is improved by adding nickel and manganese; and an adhesive force between the electrothermal film treatment solution and the substrate is increased by adding isopropanol.

Owner:成都世纪经尧科技有限公司

High-temperature-resistant cermet material and preparation method thereof

The invention belongs to the field of cermet materials, and discloses a high-temperature-resistant cermet material and a preparation method thereof. The high-temperature-resistant cermet material comprises 11-22 parts of nickel sesquioxide, 5-11 parts of magnesium oxide, 7-11 parts of zirconium diboride, 2-4 parts of thorium dioxide, 4-7 parts of bismuth oxide, 5-9 parts of zinc, 7-13 parts of copper, 2-4 parts of germanium and 12-17 parts of iron. The preparation method comprises the following steps: (1) quickly mixing metals and a ceramic material at high speed; (2) carrying out ball milling on the uniform mixture with a ball mill; (3) carrying out high-temperature press fitting on the cermet material subjected to ball milling in a hot-pressing furnace, heating the furnace to 720-780 DEG C, keeping the temperature, continuing heating the hot-pressing furnace to 1520-1610 DEG C, sintering, and cooling to obtain the high-temperature-resistant cermet material.

Owner:佛山市三水华纳陶瓷有限公司

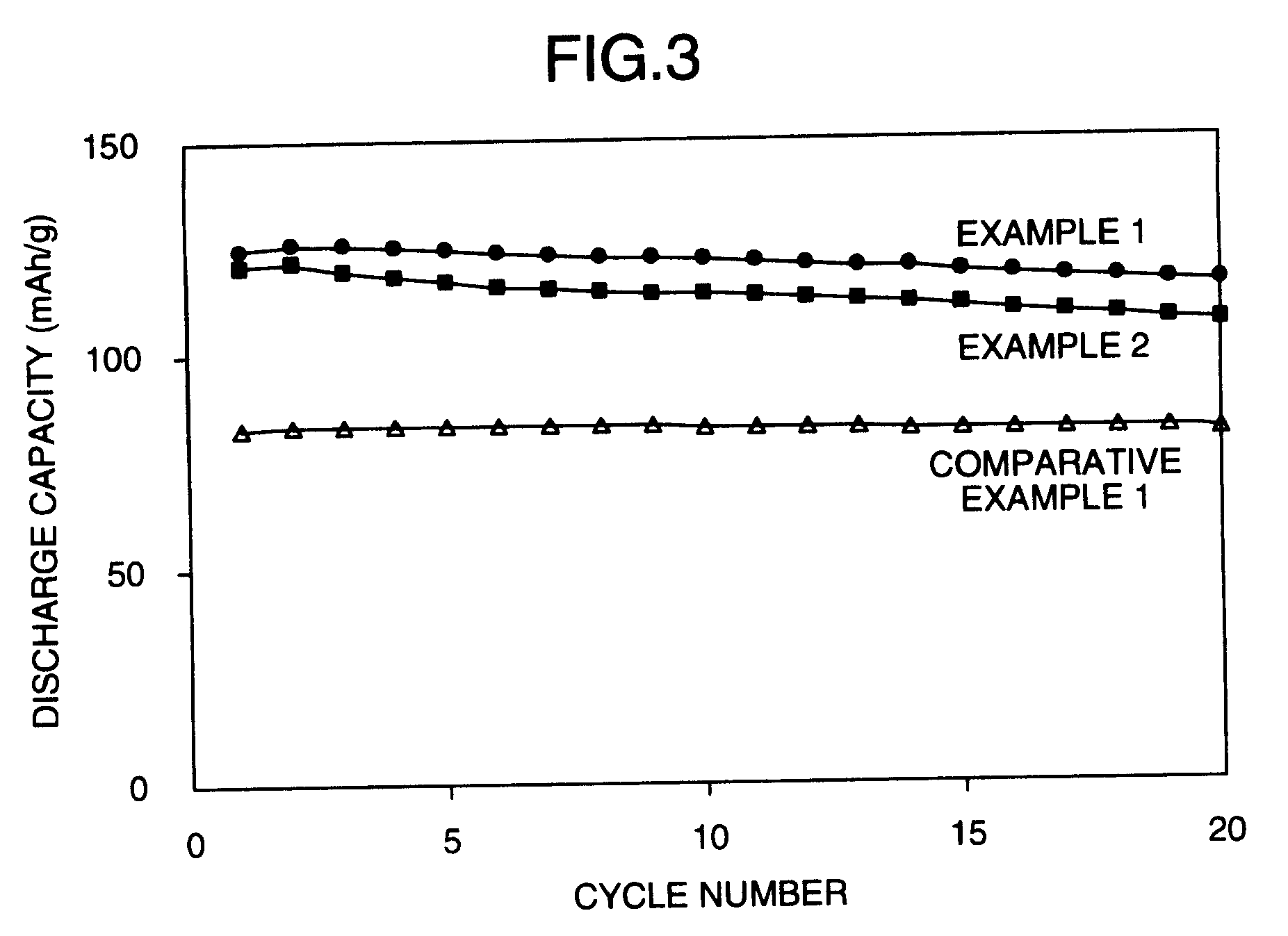

Process for preparing spinel-type lithium manganate as positive electrode active material of lithium ion storage battery

InactiveCN1569650ASmall attenuationCell electrodesLithium compoundsNickel sesquioxideLithium carbonate

The invention relates to a process for preparing spinel-type lithium manganate as positive electrode active material of lithium ion storage battery by doping lithium carbonate, manganese dioxide, alumina, nickel sesquioxide and dichromium trioxide to improve the cycling stability of the spinelle type lithium maganate anode material. The spinelle type lithium manganate anode material exhibites fine performance through overcharge and discharge rotational test.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

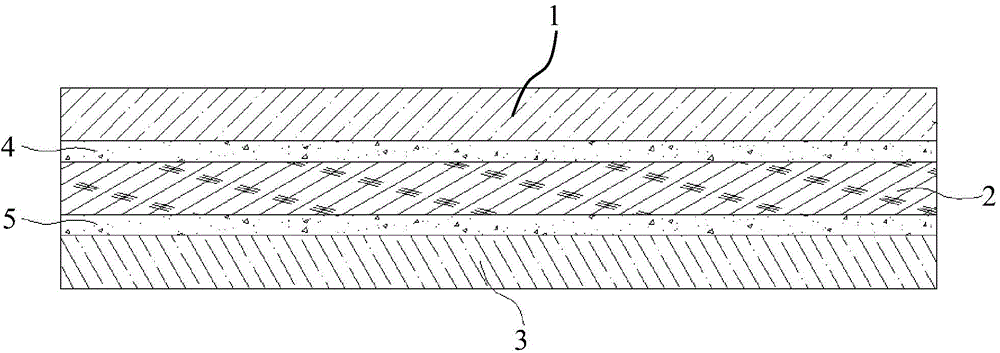

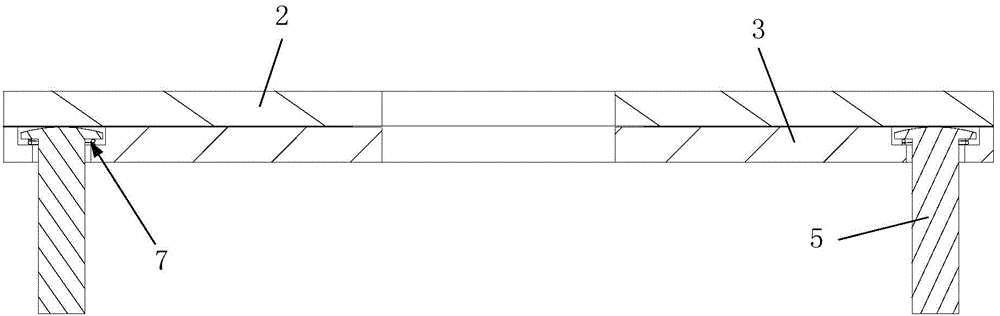

Wave-absorbing plate for electromagnetic shielding

ActiveCN104893605AHigh thermal conductivityGood for stickingOther chemical processesMagnetic/electric field screeningIsooctyl acrylateAdditive ingredient

The invention discloses a wave-absorbing plate for electromagnetic shielding. The wave-absorbing plate comprises graphite flake used as a reflecting layer, a wave-absorbing layer and a release material layer. A first adhesive layer is arranged between the graphite flake and the wave-absorbing layer. A second adhesive layer is disposed between the wave-absorbing layer and the release material layer. The wave-absorbing layer is composed of the following ingredients: a wave-absorbing powder, butyl acrylate, acrylic acid, 2-ethylhexyl acrylate, methyl methacrylate, vinyl acetate, methacrylic acid-2-hydroxyl ethyl, sodium polyacrylat and methylethyl ketone peroxide. The wave-absorbing powder is composed of the following ingredients: BaFe12O19, nickel sesquioxide, nano-graphite powder, cobalt naphtenate, unsaturated polyester and an acrylic leveling agent. Attenuation rate of the wave-absorbing plate reaches 88% at 2-10 GHz of electromagnetic wave, thus being beneficial to gluing of a polymer and uniform dispersing of mixed powders in the polymer. Therefore, reliability of electromagnetic property is guaranteed.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

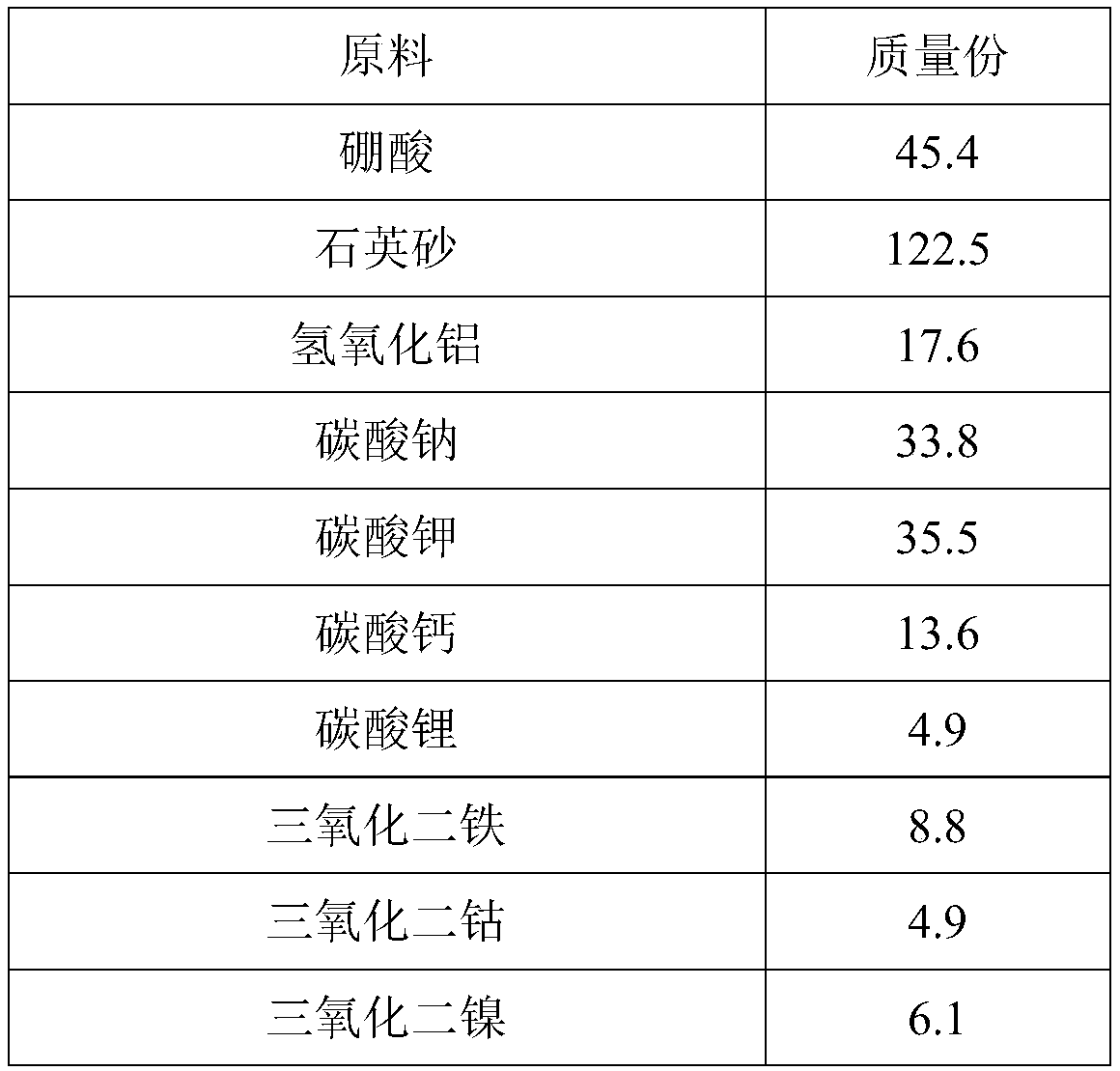

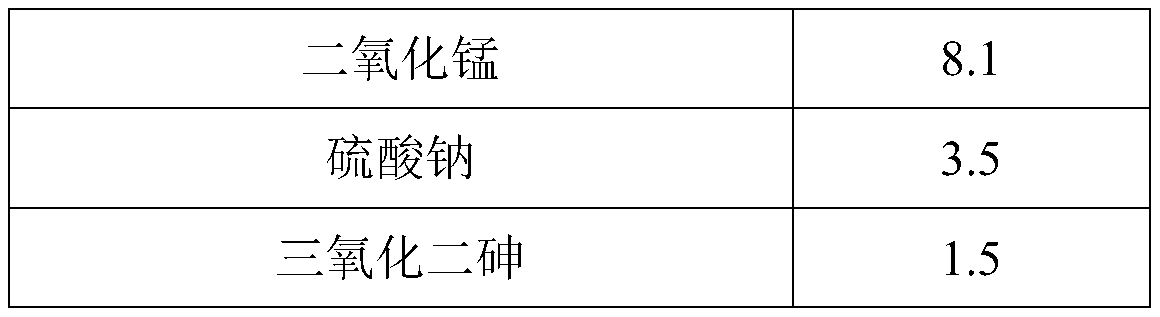

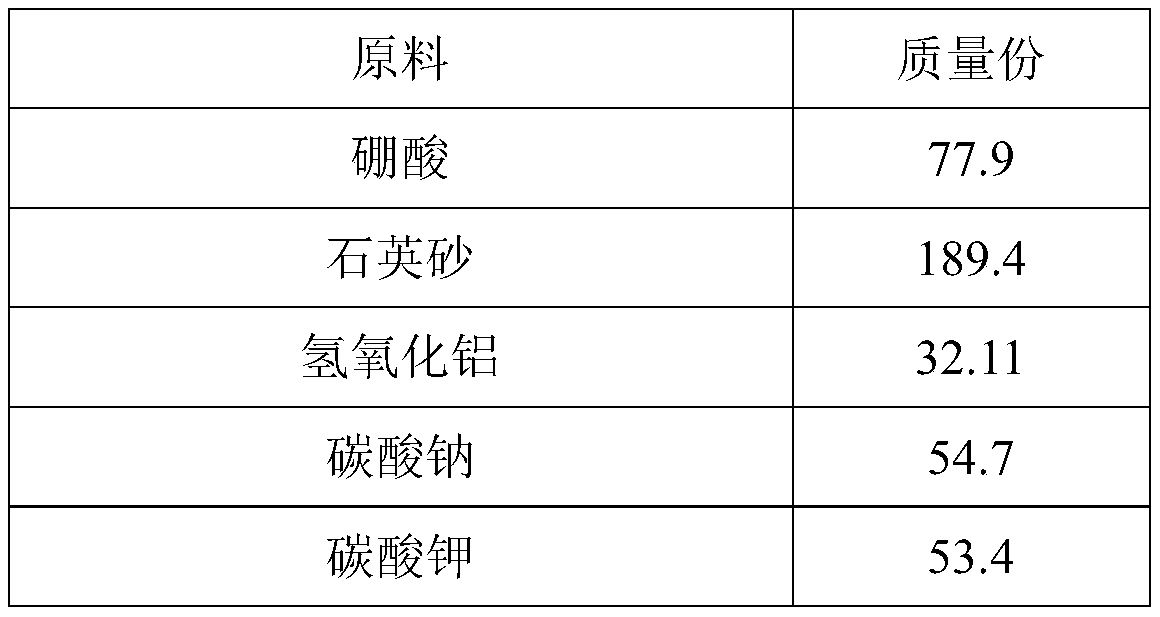

Stray light absorbing glass for optical fiber image inverter and preparation method of stray light absorbing glass

ActiveCN109851218AHigh glossStrong anti-devitrification abilityGlass shaping apparatusGlass productionNickel sesquioxideSpectral transmittance

The invention discloses stray light absorbing glass for an optical fiber image inverter and a preparation method of the stray light absorbing glass. The stray light absorbing glass for an optical fiber image inverter is prepared from the raw materials: boric acid, quartz sand, aluminum hydroxide, potassium carbonate, sodium carbonate, calcium carbonate, lithium carbonate, titanium dioxide, ferricoxide, cobalt oxide, nickel sesquioxide, manganese dioxide, sodium sulfate and arsenic trioxide. A preparation method of the stray light absorbing glass for the optical fiber image inverter is also disclosed. The black absorbing glass which can be applied to the optical fiber image inverter has a spectral transmittance of 5-10% at wavelengths of 350-900 nm under the control condition of a thickness of 1.00+ / -0.01 mm, meanwhile, the smelt glass has no stone, and the glass has high glossiness; and meanwhile the glass has a softening temperature range of 620-750 DEG C, the crystallization lower-limit temperature is >= 850 DEG C, and the glass has high anti-crystallization ability and good chemical stability, and can meet the requirements of the optical fiber inverter for the process performance of the black absorbing glass.

Owner:GUANGZHOU HONSUN OPTOELECTRONICS

Wave-absorbing material for electromagnetic field shielding

The invention discloses a wave-absorbing material for electromagnetic field shielding. The wave-absorbing material is composed of the following ingredients: 100 parts of a wave-absorbing powder, 20-35 parts of butyl acrylate monomer, 10-20 parts of acrylic acid, 20-35 parts of 2-ethylhexyl acrylate, 10-30 parts of methyl methacrylate, 1-3 parts of vinyl acetate, 0.1-1 part of methacrylic acid-2-hydroxyl ethyl, 0.5-2 parts of sodium polyacrylate and 0.4-1 part of methylethyl ketone peroxide. The wave-absorbing powder is composed of the following ingredients: BaFe12O19, nickel sesquioxide, nano-graphite powder, cobalt naphtenate, nonsaturated polyester and an acrylic acid leveling agent. Attenuation rate of electromagnetic wave at 2-10 GHz reaches 88%, which is beneficial to polymer gluing and uniform dispersion of mixed powders in the polymer. Thus, reliability of electromagnetic performance is guaranteed.

Owner:斯迪克新型材料(江苏)有限公司

Method for preparing positive electrode active material for non-aqueous secondary battery

InactiveUS20080206643A1Large capacityPrepared easily and simplyElectrode thermal treatmentPrimary cellsNickel sesquioxideManganese

There is provided a simple and easy method of preparation of a positive electrode active material for a non-aqueous secondary battery which comprises a compound comprising lithium, nickel and manganese and having a layered structure. Said method comprises firing a mixture of (1) at least one member selected from the group consisting of dinickel trioxide and boron compounds and (2) one or more metal compounds comprising lithium, nickel and manganese as their metal elements.

Owner:SUMITOMO CHEM CO LTD

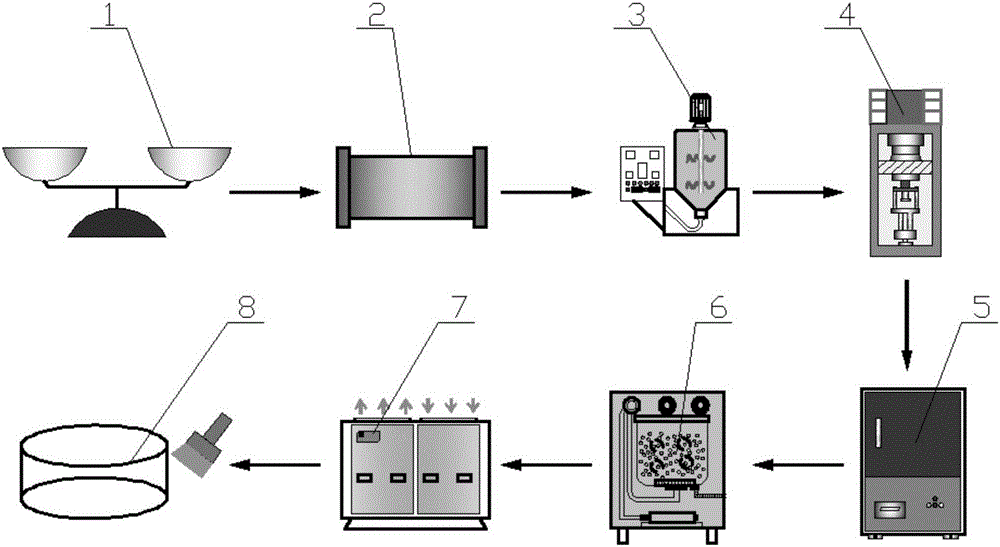

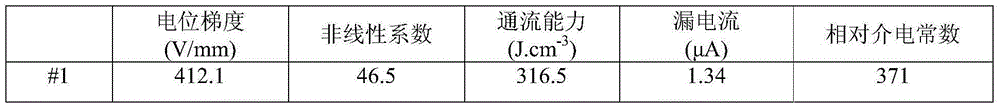

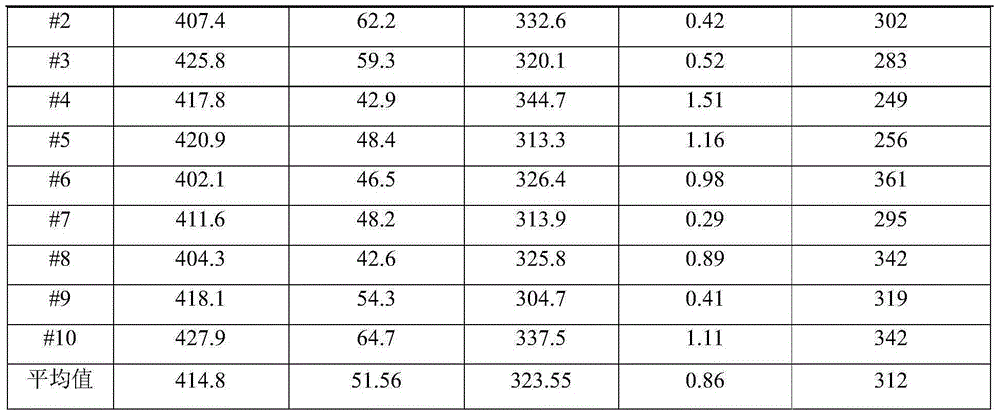

Production process of zinc oxide resistance chip with high electric potential gradient and strong through-current capability

The invention discloses a production process of a zinc oxide resistance chip with high electric potential gradient and strong through-current capability. The zinc oxide resistance chip comprises the following raw materials: a main ingredient zinc oxide and a dopant, wherein the dopant comprises bismuth sesquioxide, cobalt sesquioxide, nickel sesquioxide, chromium sesquioxide, stibium sesquioxide, silica, yttrium sesquioxide and zirconia; the mass percent of zinc oxide is not less than 90%. The production process comprises the following steps: (1) ball-milling mixing; (2) drying granulation; (3) dry pressing; (4) sintering; and (5) silver electrode coating. By virtue of the production process, the zinc oxide resistance chip with high electric potential gradient and strong through-current capability can be prepared based on a solid-phase synthesis method.

Owner:STATE GRID CORP OF CHINA +2

Zinc oxide varistor and preparation method thereof

The invention discloses a zinc oxide varistor. The zinc oxide varistor is made from the following raw materials in parts by weight: 95-105 parts of zinc oxide, 3.8-4.8 parts of bismuth trioxide, 1.0-1.5 parts of cobalt sesquioxide, 3.2-4.2 parts of antimonous oxide, 0.5-1.2 parts of manganese carbonate, 0.4-0.8 part of chromium sesquioxide, 0.01-0.035 part of silica, 0.05-0.12 part of nickel sesquioxide, 0.05-0.02 part of stannic oxide and 0.1-0.4 part of calcium carbonate. The invention also relates to a preparation method of the zinc oxide varistor. The zinc oxide varistor disclosed by the invention is reasonable in formula and proportioning, simple in production method and strong in operability. The main index parameters of the zinc oxide varistor disclosed by the invention are excellent, and the maximal control voltage, residual voltage ratio, flow capacity, leakage current, voltage temperature coefficient, current temperature coefficient, nonlinear voltage coefficient, insulation resistance, static capacitance and the like of the zinc oxide varistor hold an advantage in the similar products.

Owner:JIANGSU SHIXING ELECTRONICS TECH

Wear-resistant anti-impact metal material and preparation method thereof

The invention discloses a wear-resistant anti-impact metal material which comprises, by weight, 0.2-0.4 part of molybdenum, 4-7 parts of manganese, 6-11 parts of magnesium oxide, 2-4 parts of nickel, 0.2-0.6 part of boron, 8-12 parts of nickel sesquioxide, 2-3 parts of antimony, 2-4 parts of thorium dioxide, 3-4 parts of niobium, 3-5 parts of tungsten, 6-9 parts of zinc, 7-13 parts of copper, 4-6 parts of chromium, 1-3 parts of zirconium, 2-4 parts of germanium, smaller than or equal to 0.020 part of P, smaller than or equal to 0.020 part of S and the balance of iron. Elements in alloy are reasonable in proportion, so that wear resistance and impact resistance of the metal alloy material are improved remarkably; the metal material embodies high strength, thereby reaching level of high-hardness materials and maintaining comprehensive performance indexes like enough high obdurability and high impact resistance, wear resistance and erosion corrosion resistance, so that industrial application of the metal material in the field of high-reliability wear under working conditions of high impact wear is realized.

Owner:丹阳市宸兴环保设备有限公司

Piezoresistor blank, preparation method thereof, piezoresistor and preparation method thereof

ActiveCN105084886AHigh mechanical strengthSolve the problem of forming varistors with different shapesTin dioxideNickel sesquioxide

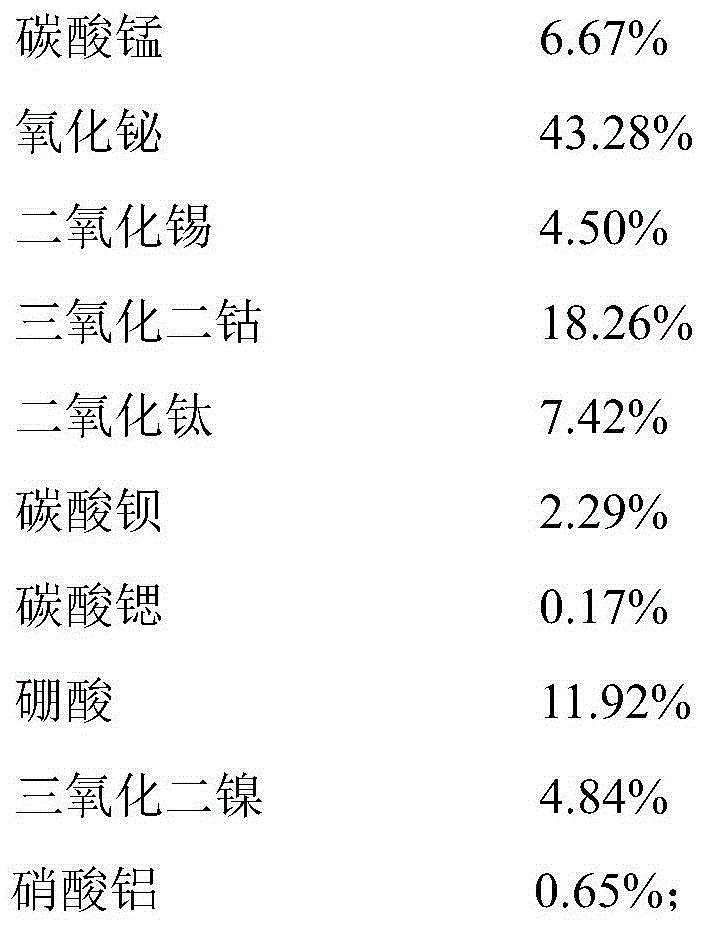

The invention discloses a piezoresistor blank, a preparation method thereof, a piezoresistor and a preparation method thereof. The preparation method of the piezoresistor blank includes (1), mixing 70-95wt% of piezoresistor powder and 5-30wt% of binder to be pug, cooling the pug to room temperature, and then breaking the pug into granules for injection molding, wherein the piezoresistor powder comprises, by weight, 85-95% of zinc oxide and 5-15% of additive which comprises, by weight, 5-8% of manganese carbonate, 35-50% of bismuth oxide, 2-4% of tin dioxide, 15-25% of cobalt oxide, 5-10% of titanium dioxide, 1-3% of barium carbonate, 0.1-1% of strontium carbonate, 5-20% of boric acid, 2-10% of nickel sesquioxide and 0.1-1% of aluminum nitrate, and the binder comprises, by weight, 30-88% of paraffin, 5-30% of polymethyl methacrylate, 5-30% of ethylene-vinyl acetate copolymer and 2-10% of stearic acid; (2), subjecting the granules to injection molding to obtain the piezoresistor blank. The piezoresistor is high in uniformity and production efficiency and large and uniform in density.

Owner:SHENZHEN SUNLORD ELECTRONICS

Colored glaze

A colored glaze is characterized by being prepared from, by weight, 50%-60% of quartz sand with the particle size ranging from 2 mm to 4 mm, 10%-15% of potassium nitrate which serves as a fluxing agent, 10%-15% of antimony trioxide which serves as a clarifying agent, 4%-10% of manganese dioxide, 2%-8% of copper oxide, 3%-9% of nickelic trioxide, 1% of organic bentonite and 2% of sodium water glass, wherein the manganese dioxide, the copper oxide and the nickelic trioxide serve as a coloring agent. In practical use, the good-quality colored glaze art craft can be prepared through the colored glaze formula.

Owner:TAICANG CITY SHUANGFENG TOWN BOCAI ARTWORK FACTORY

Lining brick of lean iron ore magnetizing and roasting rotary kiln and preparation method of lining brick

The invention relates to a lining brick of a lean iron ore magnetizing and roasting rotary kiln and a preparation method of the lining brick. The lining brick is characterized by taking 60 weight percent to 65 weight percent of high-purity magnesia particle as aggregate, and taking 10 weight percent to 15 weight percent of rho-Al2O3 micro-powder, 20 weight percent to 25 weight percent of light-burnt magnesia fine powder and 1 weight percent to 4 weight percent of nickel sesquioxide micro-powder as a matrix material; the preparation method comprises the following steps: preparing the materials according to the content of the aggregate and the components and content of the matrix material; uniformly mixing the matrix material; adding the uniformly mixed matrix material into the aggregate and uniformly mixing; additionally adding zirconium sol which accounts for 5 weight percent to 8 weight percent of the sum of the matrix material and the aggregate, and uniformly mixing; vibrating and molding; curing and drying; finally, putting a mixture into a muffle furnace and rising the temperature to be 1500 DEG C to 1600 DEG C at the temperature rate of 3 DEG C / min to 5 DEG C / min; keeping the heat for 1h to 2h; cooling along a furnace to prepare the lining brick of the lean iron ore magnetizing and roasting rotary kiln. The lining brick of the lean iron ore magnetizing and roasting rotary kiln and the preparation method of the lining brick have the characteristics of low cost and simple process flow; the prepared lining brick of the lean iron ore magnetizing and roasting rotary kiln has high slag corrosion resistance, small coefficient of heat conductivity and great cold-state compressive strength.

Owner:乐陵市回弹仪厂

Microwave sample pretreatment method applied to organic carbon detection

InactiveCN102998166AFast heatingAdequate responsePreparing sample for investigationPretreatment methodNickel sesquioxide

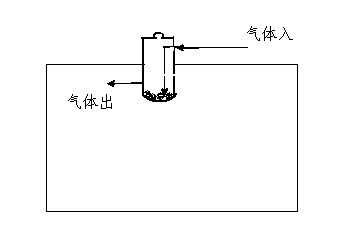

The invention discloses a microwave sample pretreatment method applied to organic carbon detection, which is characterized in that when the sample is heated by a wave-absorbing material in a manner of direct contacting, silicon iron, nickel sesquioxide, cobalt sesquioxide, molybdenum sulfide, ferric sulfide, ferroferric oxide, manganese dioxide, nickel oxide, tungsten trioxide, molybdenum sulfide, copper pyrite, cuprous sulfide, ferrite compound, or other wave-absorbing materials free from carbon are adopted as wave-absorbing media; and when the sample is indirectly heated by the wave-absorbing material, carbon, silicon carbide, silicon iron, nickel sesquioxide, cobalt sesquioxide, molybdenum sulfide, ferric sulfide, ferroferric oxide, manganese dioxide, nickel oxide, tungsten trioxide, molybdenum disulfide, copper pyrite, cuprous sulfide, ferrite compound, or other wave-absorbing materials are taken as the wave-absorbing media. The sample pretreatment method disclosed by the invention has the advantages of being rapid in temperature raising speed, complete in reaction and the like, and is suitable for pretreatment of detection of various organic carbon samples.

Owner:TIANJIN NORMAL UNIVERSITY

Method for improving fermentation level of glucoamylase

ActiveCN101831415BPromote growth and developmentPromoters can promote growth and developmentMicroorganism based processesEnzymesNickel sesquioxideNutrition

The invention discloses a method for improving fermentation level of glucoamylase, which comprises the following steps of: producing the glucoamylase by fermentation of Aspergillus Niger, and adding growth and metabolism accelerator into fermentation culture solution during growth and propagation of the Aspergillus Niger, wherein the growth and metabolism accelerator mainly comprises vitamin B1, vitamin B2, nicotinic acid, nickel sesquioxide, cobalt chloride, ferric trichloride, ammonium molybdate, oleic acid, manganese sulfate, pantothenic acid, inositol and diammonium hydrogen phosphate. The method and the growth and metabolism accelerator can promote the growth and development of the Aspergillus Niger, improve the vital movement strength of microbes, increase the production of the glucoamylase, radically avoid various adverse effects on production and product quality due to insufficient nutrition during producing strains, and can totally provide various nutrients required for the growth and propagation stages of the strains so that the strains can keep good fermentation performance all the time. After the method is used, the fermentation level of the glucoamylase can be improved by over 40 percent compared with the original level.

Owner:江苏博立生物制品有限公司

Method for improving fermentation level of glucoamylase

ActiveCN101831415APromote growth and developmentPromoters can promote growth and developmentMicroorganism based processesEnzymesNutritionNickel sesquioxide

The invention discloses a method for improving fermentation level of glucoamylase, which comprises the following steps of: producing the glucoamylase by fermentation of Aspergillus Niger, and adding growth and metabolism accelerator into fermentation culture solution during growth and propagation of the Aspergillus Niger, wherein the growth and metabolism accelerator mainly comprises vitamin B1, vitamin B2, nicotinic acid, nickel sesquioxide, cobalt chloride, ferric trichloride, ammonium molybdate, oleic acid, manganese sulfate, pantothenic acid, inositol and diammonium hydrogen phosphate. The method and the growth and metabolism accelerator can promote the growth and development of the Aspergillus Niger, improve the vital movement strength of microbes, increase the production of the glucoamylase, radically avoid various adverse effects on production and product quality due to insufficient nutrition during producing strains, and can totally provide various nutrients required for the growth and propagation stages of the strains so that the strains can keep good fermentation performance all the time. After the method is used, the fermentation level of the glucoamylase can be improved by over 40 percent compared with the original level.

Owner:江苏博立生物制品有限公司

High-resistivity soft-magnetic ferrite magnetic core and processing method thereof

InactiveCN109694245AHigh resistivityOptimizing the sintering processInorganic material magnetismInductances/transformers/magnets manufactureTransformerNickel sesquioxide

The invention provides a high-resistivity soft-magnetic ferrite magnetic core and a processing method thereof. Raw materials of the high-resistivity soft-magnetic ferrite magnetic core comprise, by weight, 53-56 parts of ferric oxide, 6-11 parts of zinc oxide, 27-31 parts of manganese oxide, 3-5 parts of copper hydroxide, 2.5-3.6 parts of nickel sesquioxide, 0.9-1.3 parts of sodium polyacrylate, 0.4-0.7 part of silica sol, 0.7-1.1 parts of polyvinyl alcohol, 1.2-1.6 parts of polyamide resin, 0.7-1.3 parts of sodium silicate and 3-7 parts of deionized water. The soft-magnetic ferrite magnetic core has a high resistivity, has a low eddy current loss under an alternating magnetic field, and is an ideal material for manufacturing high-freency transformers, broadband transformers, adjustable inductors and other high-frequency circuits.

Owner:TIANCHANG CITY ZHAOTIAN MAGNETOELECTRICITY TECH

Process for preparing spinel-type lithium manganate as positive electrode active material of lithium ion storage battery

InactiveCN1238260CSmall attenuationCell electrodesLithium compoundsNickel sesquioxideLithium carbonate

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Far infrared emission film layer and manufacturing method thereof, electric heating disc and cooking utensil

ActiveCN105992404AEasy to prepareEasy to operateDomestic stoves or rangesLighting and heating apparatusThermal energyNickel sesquioxide

The invention provides a far infrared emission film layer and a manufacturing method thereof, an electric heating disc and a cooking utensil. A mixture containing manganese dioxide, nickel sesquioxide and chromium oxide is adopted, a far infrared emission film layer is manufactured on the surface of a high-temperature 500 to 600-DEG insulated substrate, and then, the far infrared emission film layer and the insulated substrate are subjected to an annealing and film forming process to enable the far infrared emission film layer to be attached on the insulated substrate. The far infrared emission film layer manufacturing method provided by the invention is simple, the operation is convenient, the manufactured far infrared emission film layer can be matched with an electrothermal film layer for use to convert radiation thermal energy into far infrared thermal energy, rapid temperature rise is realized, the temperature lost due to moisture eliminating can be reduced, the speed of added thermal energy absorption is enhanced, thermal energy loss is reduced, the radiation thermal conduction efficiency is thus effectively improved, the energy-saving purpose is achieved, and thus, requirements on energy conservation of products by the country can be better met.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Metal ceramic die material resistant to high temperature

The invention discloses a metal ceramic die material resistant to high temperature. The metal ceramic die material is composed of, by weight, 4-7 parts of potassium feldspar, 15-20 parts of nanosilicon dioxide, 1-5 parts of molybdenum disilicide, 3-7 parts of silicon nitride, 5-15 parts of silicon carbide, 2-5 parts of zirconium diboride, 2-5 parts of magnesium oxide, 2-6 parts of acetic acid n-butyl ester, 4-7 parts of ethylenediamine tetraacetic acid disodium, 1-3 parts of ceric oxide, 5-10 parts of nickel sesquioxide and 15-20 parts of iron. The metal ceramic die material is high in strength and toughness and resistant to high temperature.

Owner:QINGDAO HONGYU ENVIRONMENTAL PROTECTION AIR CONDITIONING EQUIP

Ethylamine catalyst prepared by mechanochemical method and usage method of catalyst

PendingCN108212174AFew preparation stepsEven distribution of active sitesOrganic compound preparationHeterogenous catalyst chemical elementsIndiumNickel sesquioxide

The invention provides an ethylamine catalyst prepared by a mechanochemical method. By adopting the mechanochemical method, the catalyst for the catalytic amination of ethylamine is obtained by carrying out ball milling on a mixture prepared from sepiolite, aluminum oxide, nickel sesquioxide, cobaltosic oxide, indium sesquioxide and silver oxide, then adding nitric acid to carry out a first ball milling reaction, and then adding ammonium carbonate to carry out a second ball milling reaction. The preparation of the ethylamine catalyst by adopting the mechanochemical (ball milling) method has the advantages that preparation steps are a few; the output of wastewater is low; the price of raw materials are relatively lower. The catalyst provided by the invention is used for a reaction for the catalytic amination of ammonia and ethanol in a hydrogen-containing condition to produce the ethanol, and the catalyst is indicated to have higher activity and selectivity.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Screen protecting film for electronic product

ActiveCN104875441AGuaranteed reliabilityHigh thermal conductivityProtective equipmentSynthetic resin layered productsIsooctyl acrylatePolyester

The invention discloses a screen protecting film for an electronic product. The screen protecting film comprises a PET insulation layer, a metal layer, a wave absorbing layer and a mold release material layer, wherein a first adhesive layer is arranged between the PET insulation layer and the metal layer; a second adhesive layer is arranged between the metal layer and the wave absorbing layer; the wave absorbing layer comprises the following constituents: 100 parts of wave absorbing powder, 25 to 35 parts of butyl acrylate, 12 to 15 parts of acrylic acid, 20 to 35 parts of iso-octyl acrylate, 10 to 30 parts of methyl methacrylate, 1 to 3 parts of vinyl acetate, 0.1 to 1 part of 2 hydroxyethyl methacrylate, 0.5 to 2 parts of sodium polyacrylate, and 0.4 to 1 part of methyl ethyl ketone peroxide; the wave absorbing powder comprises the following constituents: 100 parts of barium ferrite powder, 18 to 25 parts of nickel sesquioxide, 8 to 12 parts of nano-graphite powder, 8 to 12 parts of cobaltous chloride, 60 to 70 parts of unsaturated polyester and 40 to 50 parts of sodium dodecyl benzene sulfonate. The screen protecting film has the advantages that the wave absorbing property of a protecting adhesive tape can be improved remarkably; over centralization of heat is avoided; convenience is brought for heat diffusion.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

Heating element based on thermo-electronic film and preparation method thereof

PendingCN111970772AHigh emissivityReduced energy storageHeating element materialsNickel sesquioxideSesquioxide

The invention discloses a heating element based on a thermo-electronic film and a preparation method thereof. The preparation method comprises the following steps that 1, SnCl4.5H2O is added into a mixed solution of ethyl alcohol and deionized water, heating and stirring are conducted till the SnCl4. 5H2O is fully dissolved, antimony trichloride, bismuth trichloride and titanium tetrachloride areadded and stirred to be uniform, and an electric heating film solution is obtained; 2, the preheated tubular base body is placed in a high-temperature furnace, vaporous electrothermal film liquid is introduced into the high-temperature furnace, the vaporous electrothermal film liquid is deposited on the surface of the tubular base body, heat preservation is conducted, then natural cooling is conducted, and an electrothermal film layer is obtained; wherein the tubular base body rotates around the central axis of the tubular base body in the high-temperature furnace; and 3, manganese dioxide, nickel sesquioxide, cobalt sesquioxide and chromium oxide are mixed, and the mixture is sprayed on the outer side of the electrothermal film layer to obtain the infrared emission film layer.

Owner:长春电子科技学院

A kind of high temperature resistant cermet material and preparation method thereof

The invention belongs to the field of cermet materials, and discloses a high-temperature-resistant cermet material and a preparation method thereof. The high-temperature-resistant cermet material comprises 11-22 parts of nickel sesquioxide, 5-11 parts of magnesium oxide, 7-11 parts of zirconium diboride, 2-4 parts of thorium dioxide, 4-7 parts of bismuth oxide, 5-9 parts of zinc, 7-13 parts of copper, 2-4 parts of germanium and 12-17 parts of iron. The preparation method comprises the following steps: (1) quickly mixing metals and a ceramic material at high speed; (2) carrying out ball milling on the uniform mixture with a ball mill; (3) carrying out high-temperature press fitting on the cermet material subjected to ball milling in a hot-pressing furnace, heating the furnace to 720-780 DEG C, keeping the temperature, continuing heating the hot-pressing furnace to 1520-1610 DEG C, sintering, and cooling to obtain the high-temperature-resistant cermet material.

Owner:佛山市三水华纳陶瓷有限公司

High-heat-radiation wave-absorption shielding film

InactiveCN108219699AImprove thermal conductivityGood for stickingProtective equipmentFilm/foil adhesivesIsooctyl acrylatePolyester

The invention discloses a high-heat-radiation wave-absorption shielding film. A third adhesive layer, a polypropylene film layer and a fourth adhesive layer are sequentially arranged between a wave-absorption layer and a release material layer of the shielding film; a plurality of convex points are arranged on the contact surfaces of the fourth adhesive layer and the release material layer; the wave-absorption layer is prepared from the following ingredients including 100 parts of wave absorption powder, 20 to 35 parts of butyl acrylate, 10 to 20 parts of acrylic acid, 20 to 35 parts of 2-ethylhexyl acrylate, 10 to 30 parts of methyl methacrylate, 1 to 3 parts of vinyl acetate, 0.1 to 1 part of methacrylate-2-HEA, 0.5 to 2 parts of polyacrylate sodium and 0.4 to 1 part of methyl ethyl ketone peroxide; the wave absorption powder is prepared from the following ingredients including 100 parts of carbonyl iron powder, 60 parts of nickel sesquioxide, 9 parts of nanometer graphite powder, 15parts of cobalt chloride, 62 parts of unsaturated polyester and 42 parts of sodium dodecyl benzene sulfonate. The high-heat-radiation wave-absorption shielding film is favorable for diffusing the heat generated by electromagnetic waves; the performance stability is improved; the service life of the product is prolonged.

Owner:斯迪克新型材料(江苏)有限公司

Low-melting-point high-tenacity ceramic material and preparation method and application thereof

The invention discloses a low-melting-point high-tenacity ceramic material and a preparation method and application thereof, belonging to the technical field of industrial and civil ceramic materials. The ceramic material comprises the following components in percentage by mass: 48-60 percent of silicon dioxide, 7.2-8.3 percent of titanium dioxide, 7.2-8.3 percent of aluminum oxide, 5.5-7.5 percent of diboron trioxide, 5-6 percent of sodium oxide, 5.5-6.7 percent of lithium oxide, 3.0-4.0 percent of diantimony trioxide, 1.0-2.0 percent of cobalt sesquioxide, 1.0-2.0 percent of dichromium trioxide, 1.0-2.5 percent of nickel sesquioxide, 1.0-2.0 percent of strontium oxide and 1.0-3.0 percent of zinc oxide. The invention has the advantages that: over 50 percent of energy consumption can be reduced, the toughness can be improved, the process steps are simple, the process requirements are not severe, the technical effects of low melting point and high toughness of the ceramic material can be ensured, ceramic coatings can be formed on the surface of a workpiece or two faces of a steel plate in a simple way, and the problem of enameling on two faces of a reaction kettle in the prior art is solved.

Owner:李训竹

Preparation method of conductive ceramic material

The invention provides a preparation method of a conductive ceramic material. The material is prepared from the following components: stannic oxide, copper oxide, aluminum oxide, iron sesquioxide, zinc oxide, cobaltous oxide, lead oxide, magnesium oxide and nickel sesquioxide in a weight ratio of (86-96%) to (0-0.5%) to (0.5-1%) to (0.5-2%) to (0-0.5%) to (0-1%) to (0.5-2%) to (2-4%) to (0.5-3%). The preparation method is characterized by comprising the following steps: firstly, ball-milling pure stannic oxide for 30-40 hours, wherein the ratio of stannic oxide to balls to water is 2 to 4 to 1; then, drying and carrying out treatment by a 500mesh sieve; then, mixing and dosing according to components; grinding the components for 3-5 hours; adding a 5-15wt% PVA aqueous solution to prill, sieving by a 70-90mesh sieve and drying; then, extrusion-forming by 5-8 tons of pressures; then, putting in a sintering furnace to be sintered in an oxidizing atmosphere at the sintering temperature of 1600-1800 DEG C; and then insulating for 4-8 hours and naturally cooling.

Owner:QINGDAO KANGHEWEIYE COMML

Molybdenum dioxide conductive ceramic material

The invention provides a molybdenum dioxide conductive ceramic material. The material is composed of molybdenum dioxide, copper oxide, ferric oxide, zinc oxide, lead oxide and nickel sesquioxide, and is characterized in that the weight ratio of the above components is 92-96%:0.5-1%:0.5-1%:1.5-2%:1-2%:0.5-2%.

Owner:QINGDAO RUNXIN WEIYE TECH & TRADE

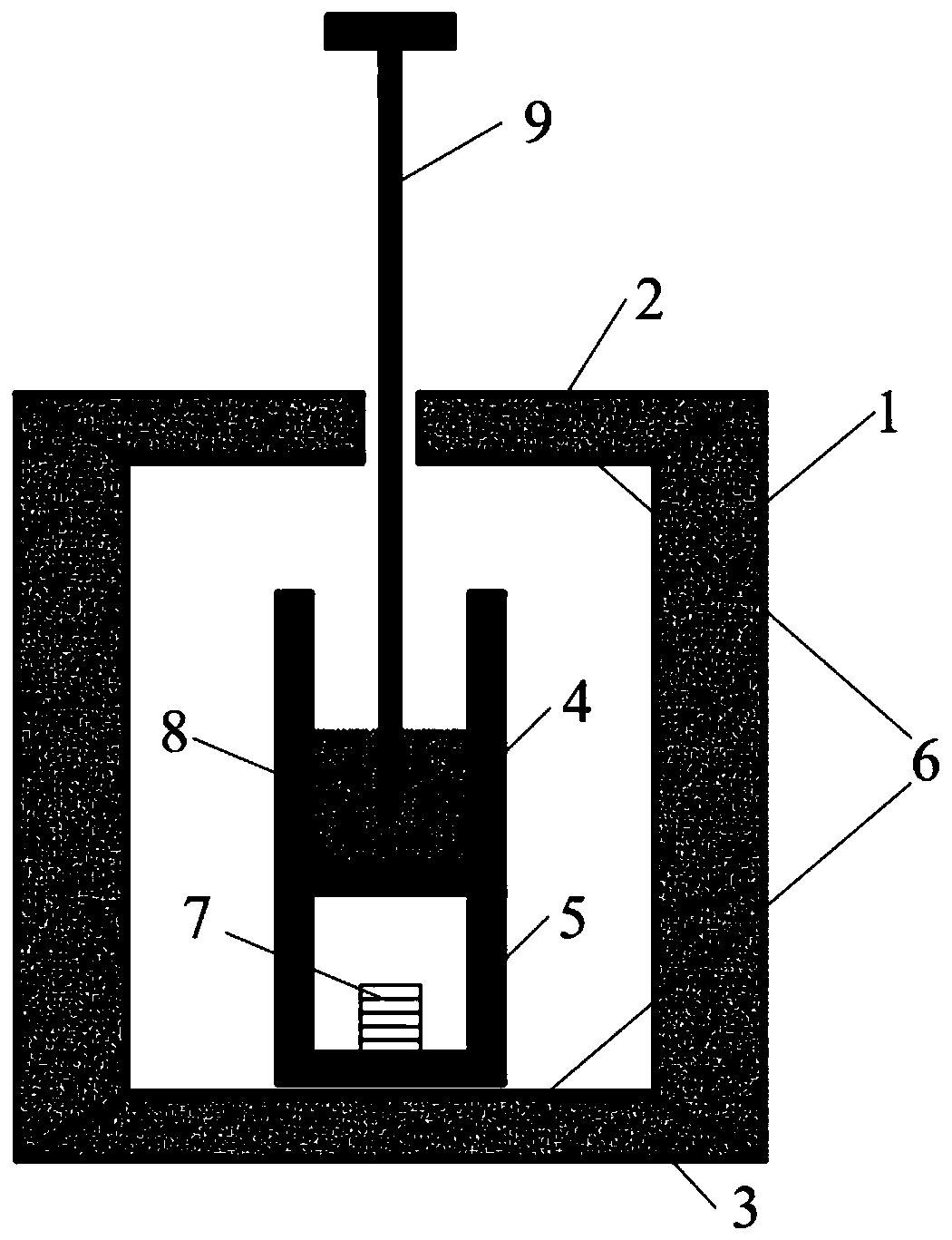

Heat preservation device for microwave sintering and microwave sintering method of zinc oxide pressure-sensitive ceramic

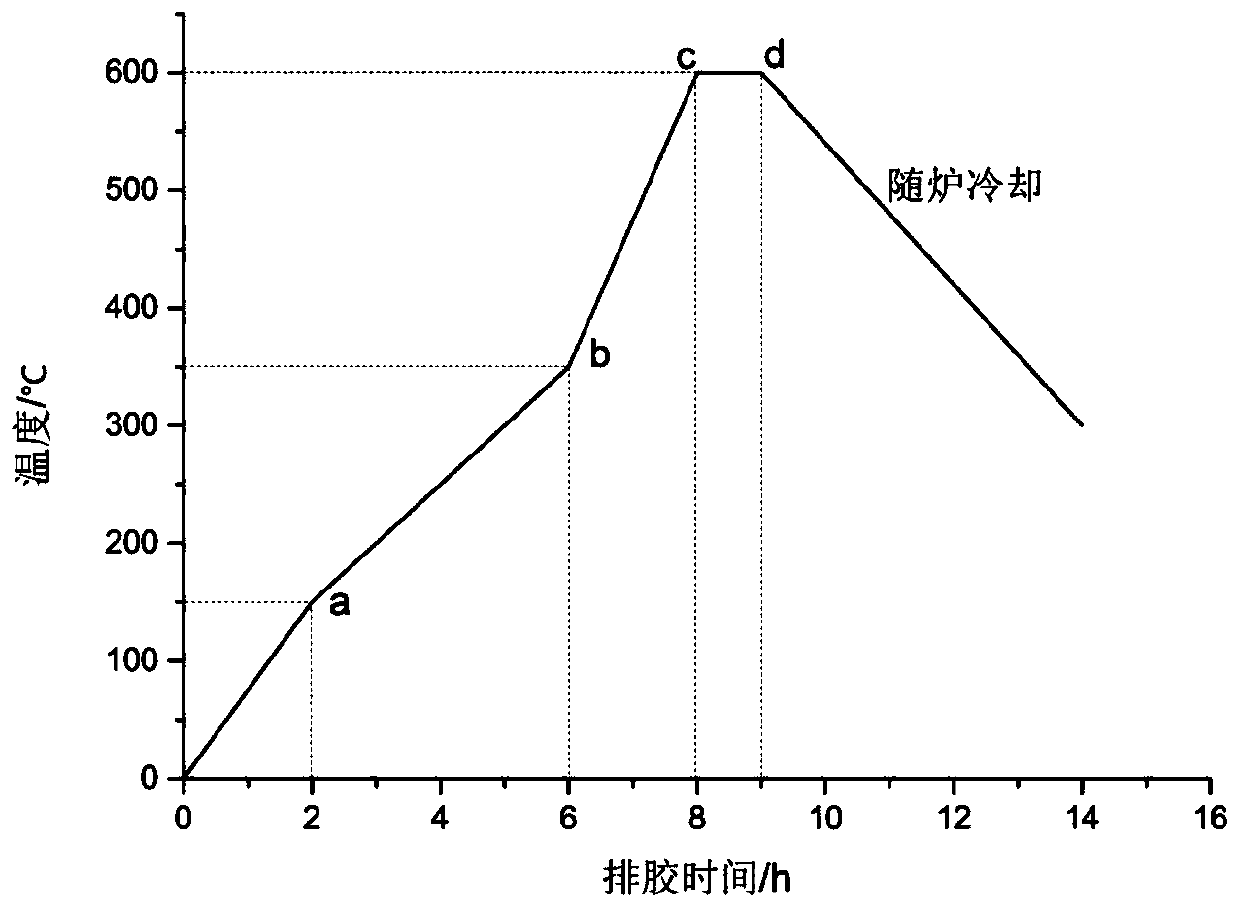

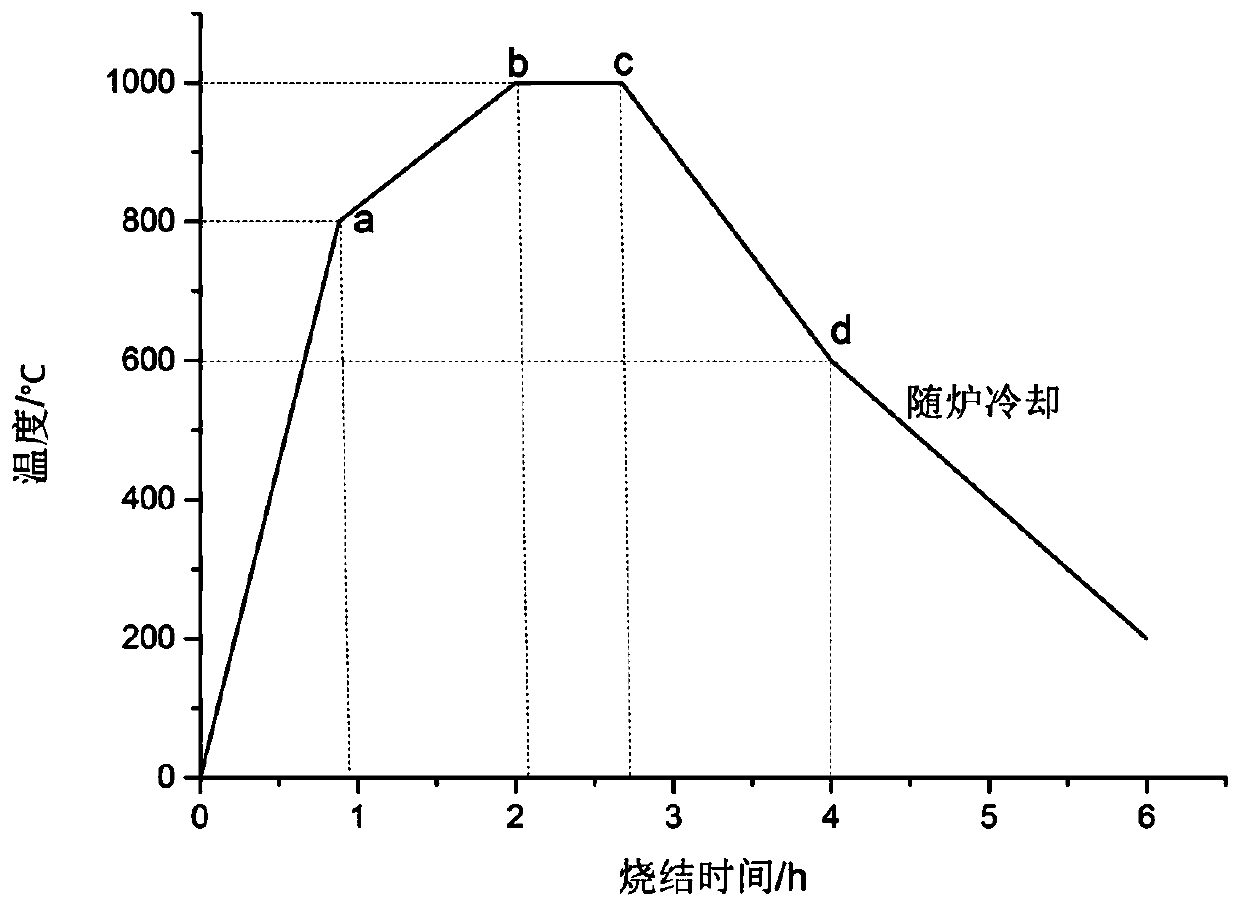

ActiveCN111548142AImprove performanceImprove featuresThermometers using electric/magnetic elementsUsing electrical meansCrazingNickel sesquioxide

The invention discloses a heat preservation device for microwave sintering and a microwave sintering method of zinc oxide pressure-sensitive ceramic. The method comprises the following steps: carryingout ball milling on zinc oxide, bismuth oxide, cobaltosic oxide, manganese carbonate, antimony oxide, nickel sesquioxide, titanium dioxide, an aluminum nitrate nonahydrate solution, a dispersing agent and the like, granulating, carrying out dry pressing molding, discharging glue, putting into a heat preservation device, and carrying out microwave sintering to obtain the zinc oxide pressure-sensitive ceramic. The heat preservation device comprises a box body, a high crucible, a short crucible, powder for pressing a ceramic chip green body, an end cover and a thermocouple; the high crucible isstacked on the short crucible; end covers are arranged on the top surface and the bottom surface in the box body; the thermocouple and the high crucible are in connection. The heat preservation deviceis adopted for microwave sintering, the temperature difference between materials and the surrounding environment is reduced, and the phenomena of cracks, deformation and uneven colors are eliminated.Compared with a traditional method, the method of the invention has the advantages that the sintering time is shortened by 50%, volatilization of low-melting-point substances and abnormal growth of crystal grains are reduced, and the performance of the obtained product is better than that of the traditional method.

Owner:SOUTH CHINA UNIV OF TECH +1

Preparation method of analytically pure nickel sesquioxide

InactiveCN102030377AEfficient removalLow impurity contentNickel oxides/hydroxidesOxalateNickel sesquioxide

The invention relates to the field of preparation methods of inorganic compounds, in particular to a preparation method of analytically pure nickel sesquioxide. The method comprises the steps of adding hydrogen peroxide to nickel nitrate solution for oxidation, adding sodium carbonate to remove iron ions, adding ammonium fluoride to remove calcium and magnesium ions, then reacting with oxalic acid to generate nickel oxalate and calcining nickel oxalate to obtain the analytically pure nickel sesquioxide. The method is easy to operate and control and the prepared analytically pure nickel sesquioxide has low impurity content and high purity, thus improving the market competitiveness of a product.

Owner:TIANJIN CHEM REAGENT RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com