Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Optimizing the sintering process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soft-magnetic nickel-copper-zinc ferrite material and preparation method thereof

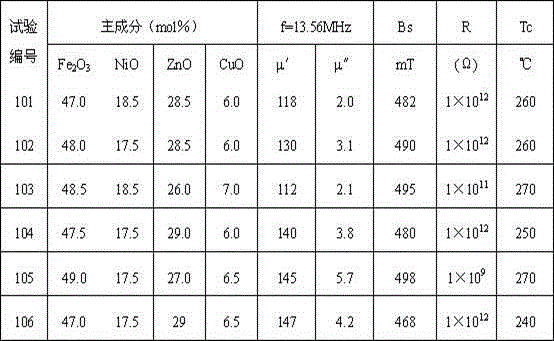

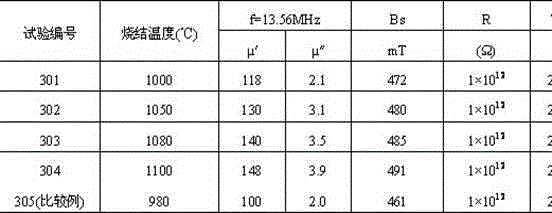

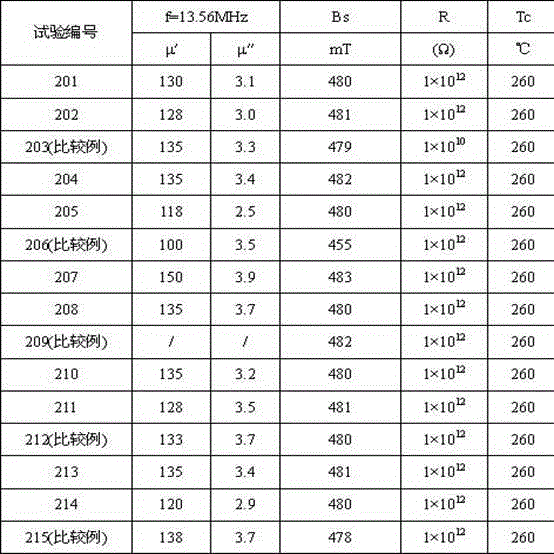

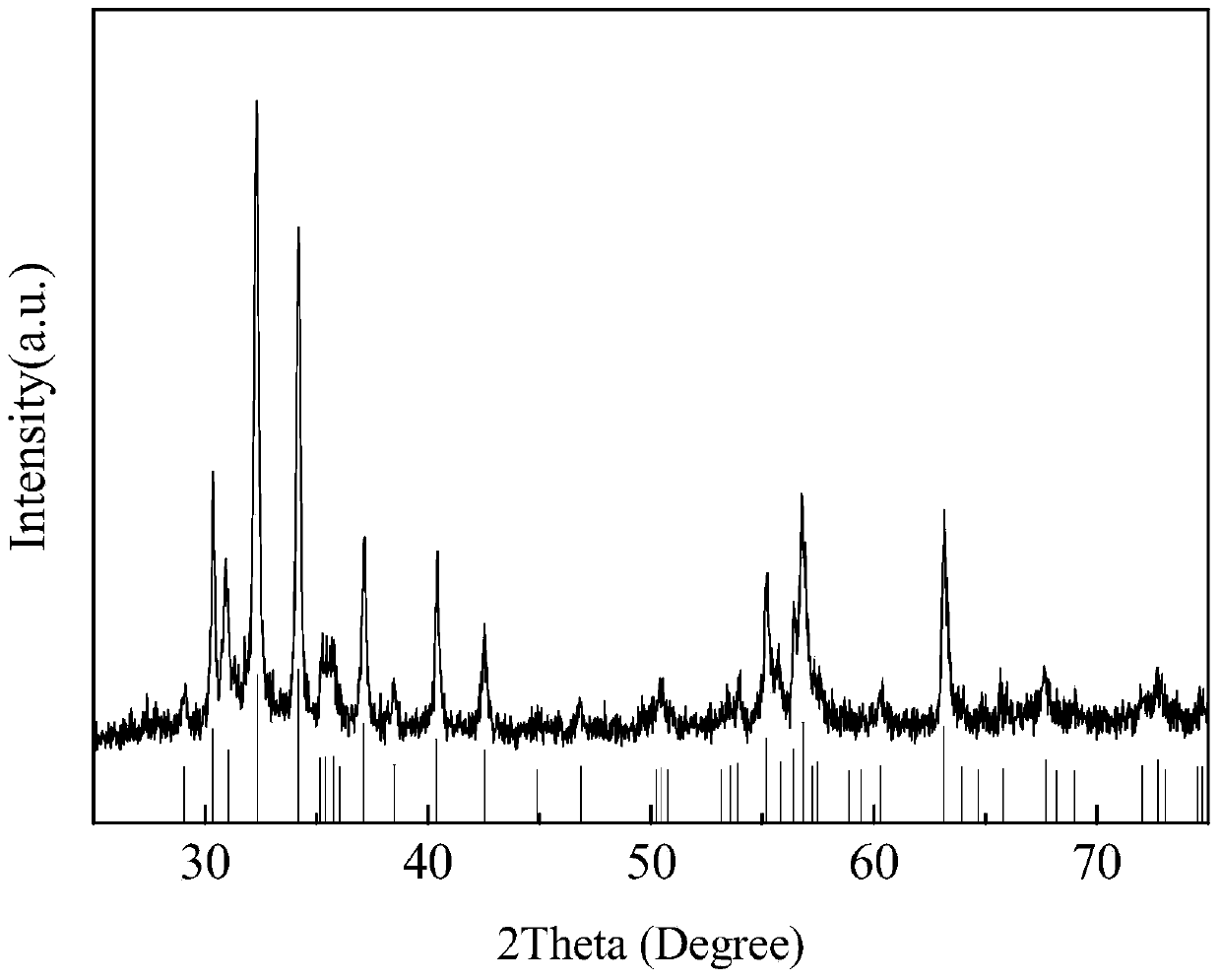

The invention belongs to the field of soft-magnetic ferrite materials. The objective of the invention is to provide a soft-magnetic nickel-copper-zinc ferrite material and a preparation method thereof. The material provided by the invention comprises major components and minor components. The major components comprise the following raw materials in mole percentage: 47.0-49.0mol% of Fe2O3, 17.5-18.5mol% of NiO, 26.0-29mol% of ZnO and 6.0-7.0mol% of CuO. The minor components comprise, based on the total weight of the major components, 0.1-0.40% of MnO, 0.1-0.5% of Bi2O3 and 0.3-0.5% of Co2O3. Under a high frequency of 13.56 MHz, the material provided by the invention has the characteristics of high magnetic conductivity ([mu]' is approximately equal to 130), low complex magnetic permeability [mu]''(namely low loss), high resistivity, high Curie temperature, high saturation magnetic induction density Bs, and the like.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

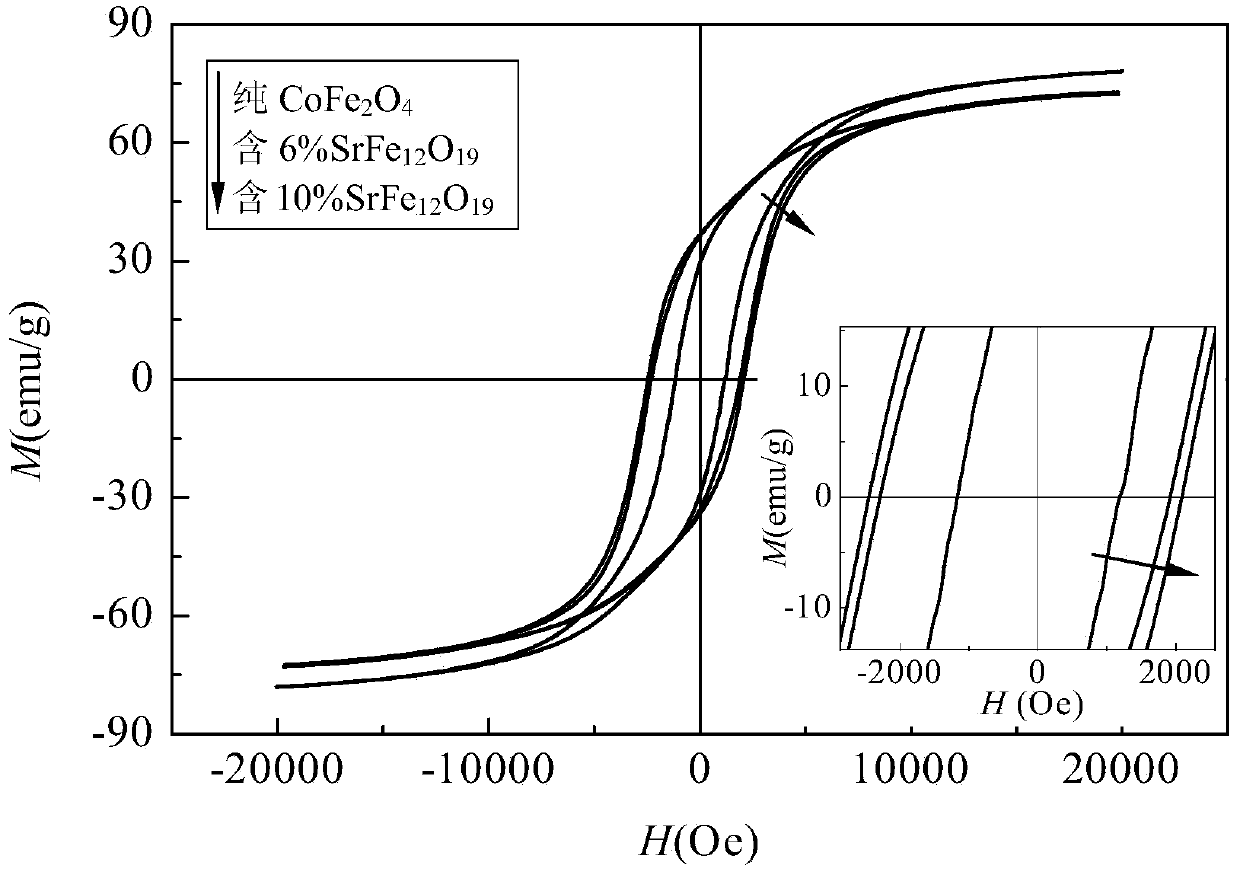

Method for improving coercive force of spinelle iron-cobalt ferrite CoFe2O4

ActiveCN104211387AGuaranteed saturation magnetizationImprove coercive forceMass ratioMaterials science

The invention discloses a method capable of significantly improving the coercive force of spinelle CoFe2O4 ferrite and belongs to the technical field of preparation of ferrite materials. The method comprise the following steps: respectively preparing CoFe2O4 and SrFe12O19 nanopowder by virtue of a hydrothermal method, and then doping a small amount of SrFe12O19 nanopowder (mass ratio of 6%-10%) into the CoFe2O4 ferrite, evenly mixing, tabletting and sintering at a temperature of 700 DEG C-900 DEG C for 2 hours. According to the method, by virtue of the exchange coupling effect between the CoFe2O4 and SrFe12O19 nanocrystalline phases and the pinning effect of SrFe12O19 ferrite, the coercive force of the CoFe2O4 ferrite is significantly improved and the coercive force can be improved by 93% to a maximum extent. The method has important value for further practical application of the CoFe2O4 ferrite.

Owner:安徽中马磁能科技股份有限公司

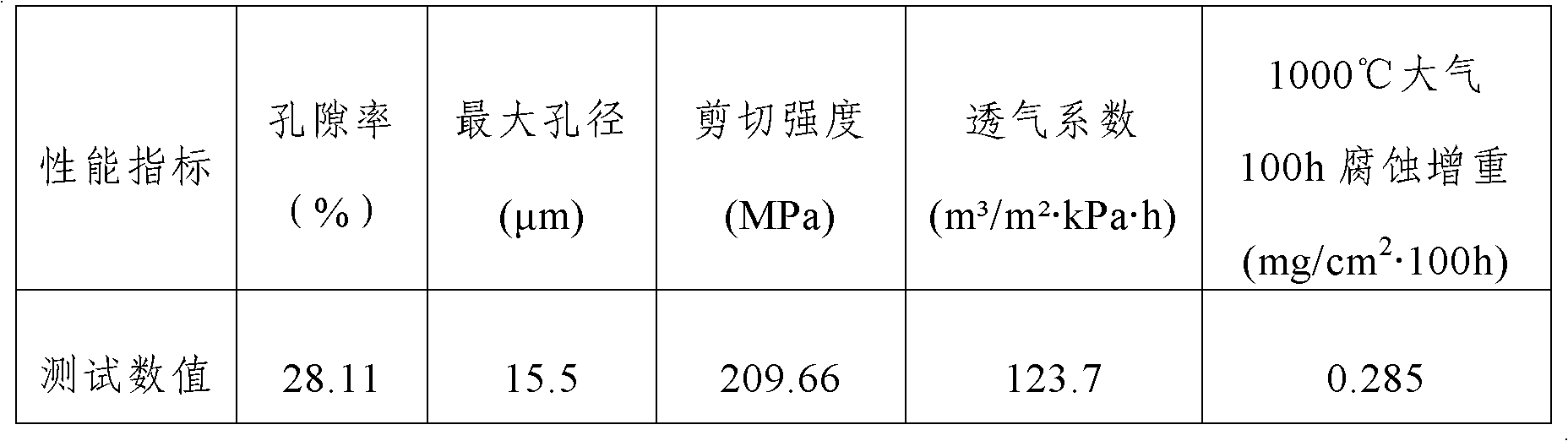

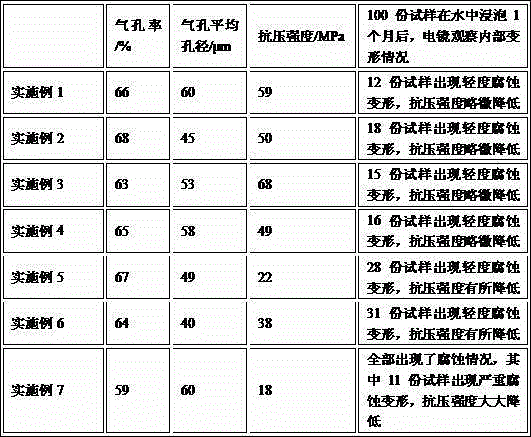

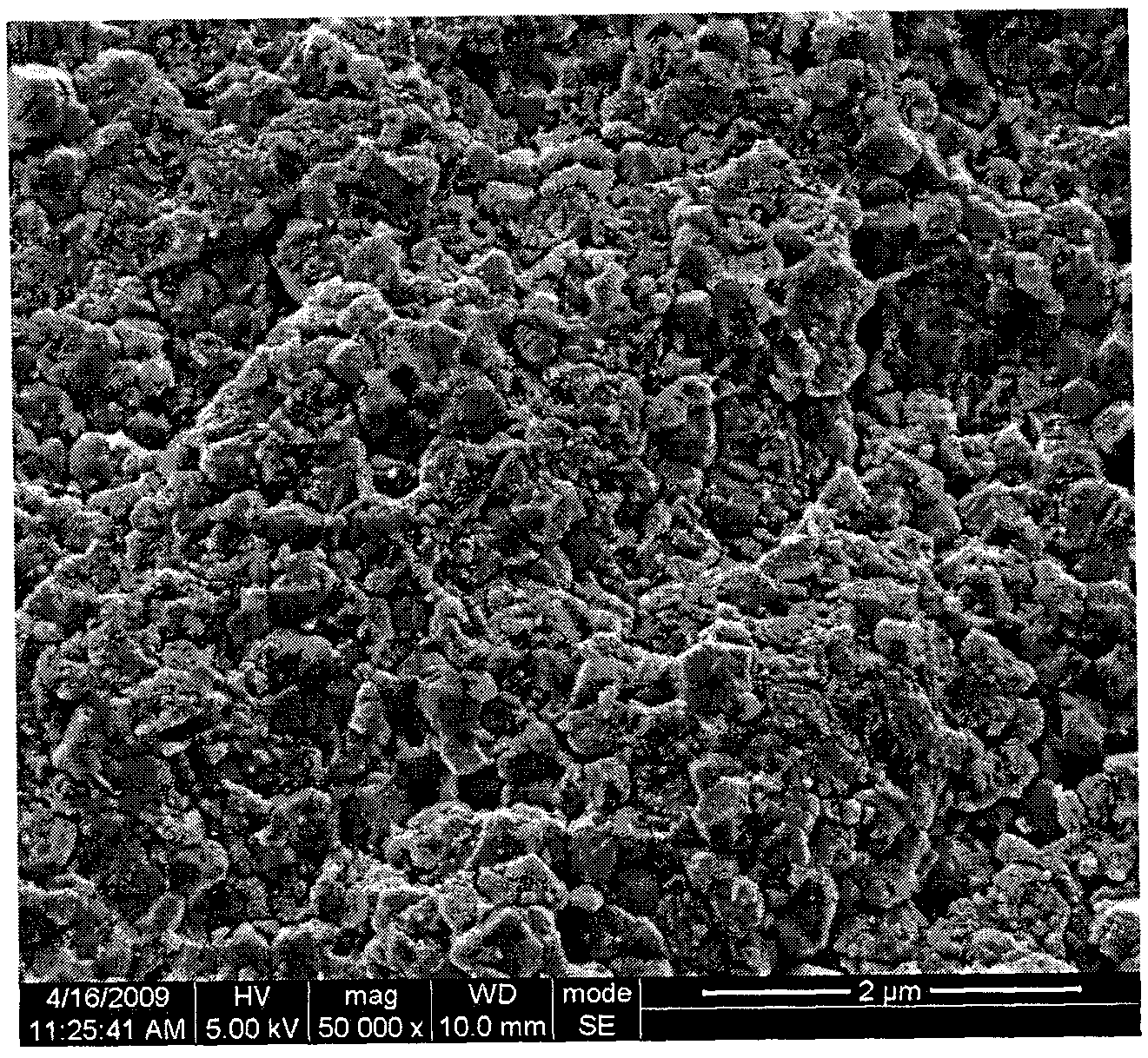

Porous material for purifying high-temperature gas and preparation method thereof

The invention discloses a porous material for purifying high-temperature gas, which is prepared from the following components in percentage by mass: 10-20% of Cr, 5-12% of Al, 1-3% of Fe, 0-0.1% of Y and the balance of Ni and inevitable impurities. The invention also discloses a preparation method of the porous material. Since the principal elements of the porous material are high-temperature alloy principal elements Ni and Cr, the porous material has the advantages of high strength, good toughness and good weldability in the high-temperature alloy, and the maximum application temperature is up to 800 DEG C; and since high-content Al is added, a compact and stable aluminum oxide film is formed on the surface of the pore walls of the porous material in the application process, thereby ensuring the excellent corrosion resistance under the conditions of high temperature and complex atmosphere. The powder classification and pressing technique ensures the uniformity of the porous material;and by adopting the vacuum sintering technique, the porous material has favorable comprehensive properties in the aspects of strength, toughness and filtering quality.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method of composite sagger

InactiveCN106083083AImprove corrosion resistanceImprove bindingCharge supportsFiberAluminium hydroxide

The invention relates to a preparation method of a composite sagger. The method adopts mullite and cordierite as the main raw materials, takes attapulgite, calcined kaolin, diopside, fused magnesia, red mud, nano aluminum hydroxide sol, silica powder and reinforced fiber as auxiliary materials, at the same time in the preparation process, water quenching, oil cooling and post-treatment processes are employed to improve the physicochemical properties of the product, the prepared sagger has good thermal stability, strong compressive strength, corrosion resistance, and difficult cracking.

Owner:姚焕根

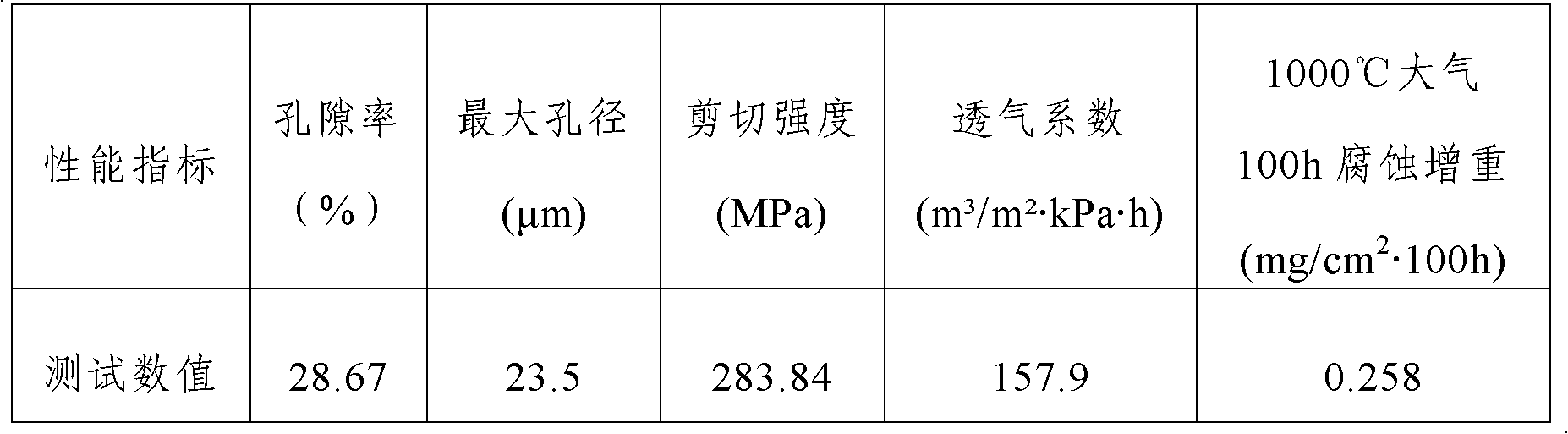

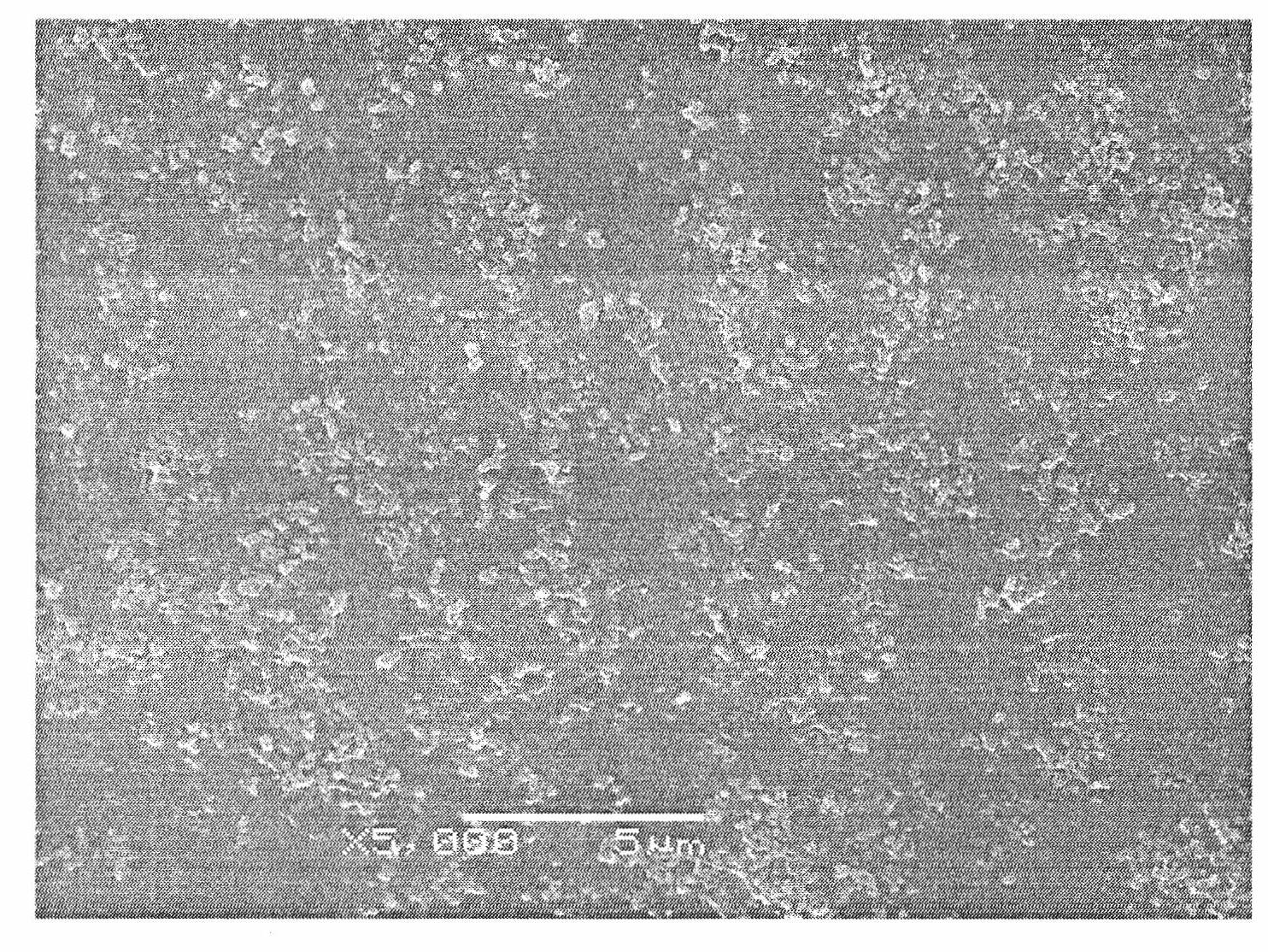

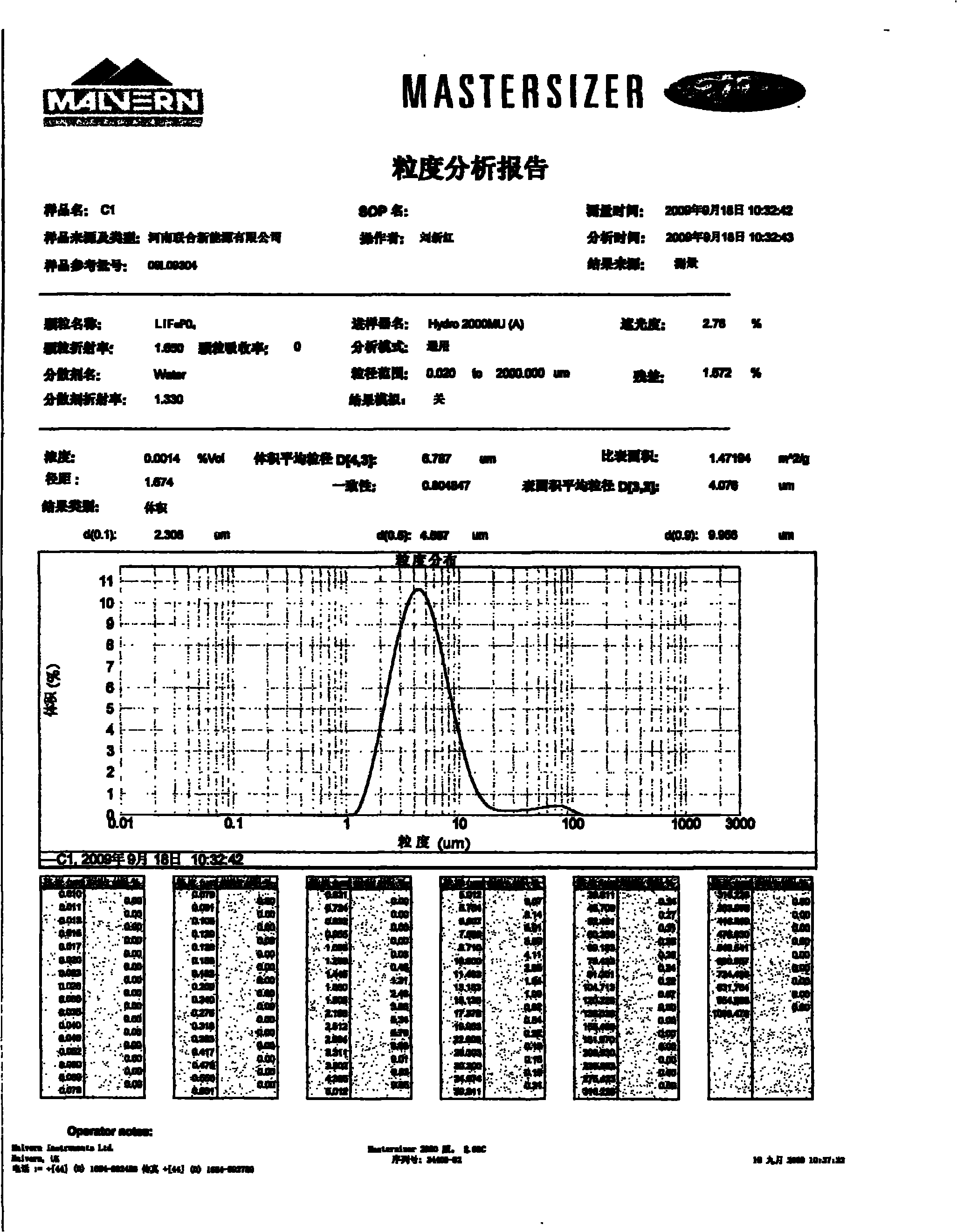

Method for preparing lithium iron phosphate by sintering lithium iron phosphate precursor and microwave sintering equipment

InactiveCN102092699APromote densificationEvenly distributedCell electrodesPhosphorus compoundsLithium iron phosphateControl treatment

The invention discloses a method and equipment for preparing lithium iron phosphate from a lithium iron phosphate precursor. The method comprises the three process steps of pretreatment of the lithium iron phosphate precursor material, pre-sintering and sintering; and in a non-oxidizing environment, the precursor material is heated by a certain number of microwave heaters, and the three process steps are finished by controlling treatment temperature and treatment time to finally prepare the lithium iron phosphate product. The equipment comprises a material inlet, a material feeding ventilation chamber, a pretreatment unit furnace, a pre-sintering unit furnace, a sintering unit furnace, a material discharging ventilation chamber, a cooling material discharging mechanism, a material outlet,a vacuumizing device, a protective gas input device and an equipment control circuit. In the method, the pretreatment and pre-sintering process steps are added to optimize a lithium iron phosphate microwave sintering process and solve keys problems on product quality control. The equipment provided by the invention realizes continuous microwave sintering by a plurality of unit furnaces so as to improve the sintering efficiency and realize large-scale industrial production.

Owner:HENAN UNION NEW ENERGY

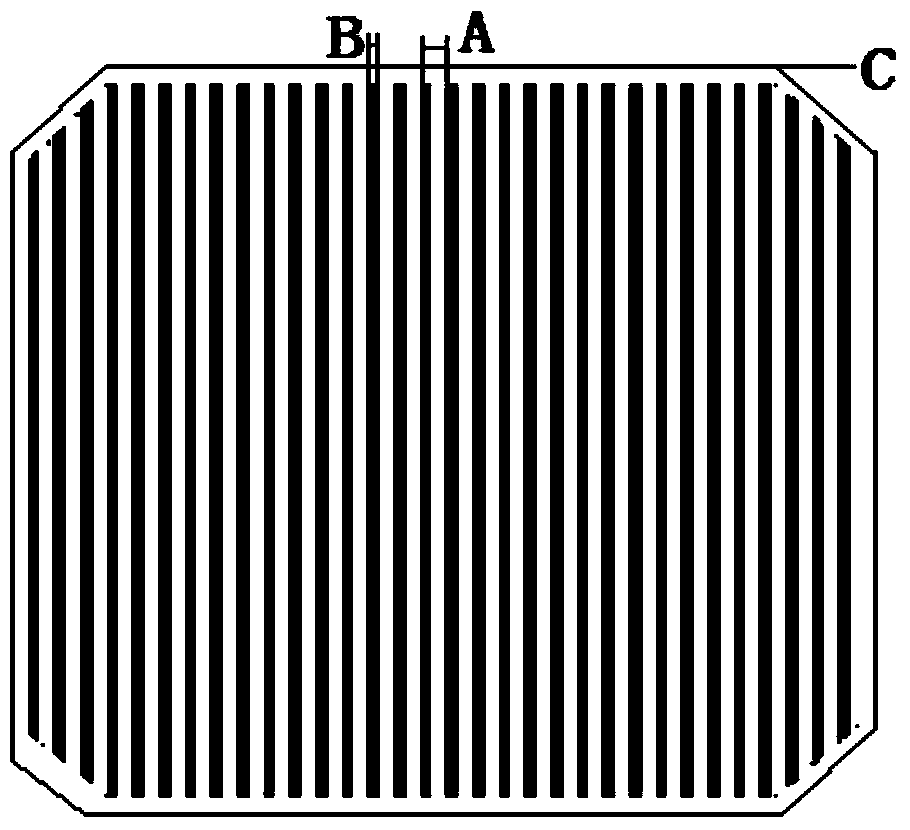

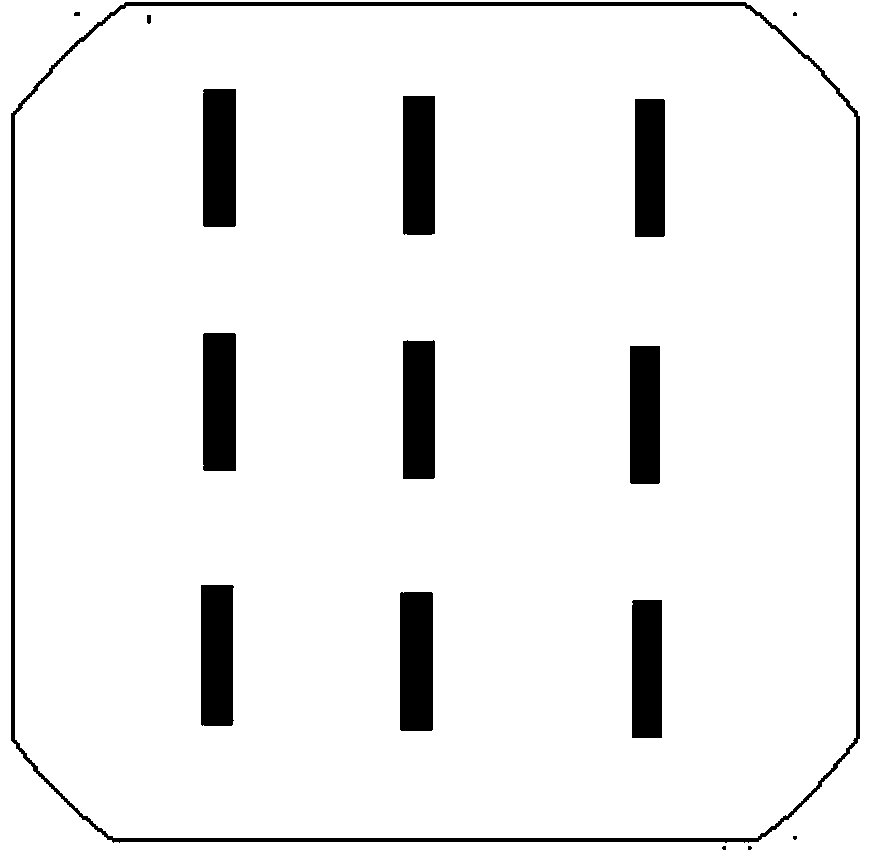

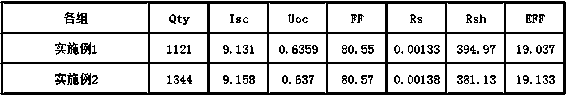

Front electrode diffraction type local back surface field passivation type crystalline silicon cell preparation method

ActiveCN103746026AReduce shading areaImprove efficiencyFinal product manufactureSemiconductor devicesBack surface fieldElectrode Contact

The invention discloses a front electrode diffraction type local back surface field passivation type crystalline silicon cell preparation method. A row of cavities which are arranged uniformly are formed in a silicon wafer substrate at the front electrode main gate position through a laser device to replace the main gate electrode and the gate electrode is led to the back surface of the cell to reduce the shading area of the main gate electrode and place the front electrode on the back surface; a layer of Al2O3 is deposited on the back surface of the silicon wafer through atomic layer deposition or the PECVD method to passivate the back surface f the cell, a layer of thick SiNx is deposited on the surface of the film to protect the passivation effect of the Al2O3, and then a back open-membrance pattern is designed, and a back electrode conductive window is prepared through laser or chemical corrosion method; and the back electrode, a back matched aluminum back surface field, a back front electrode and a front gate electrode are printed successively, and the printing and sintering processes are optimized to make the electrode contact region has the advantage of good filling effect.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

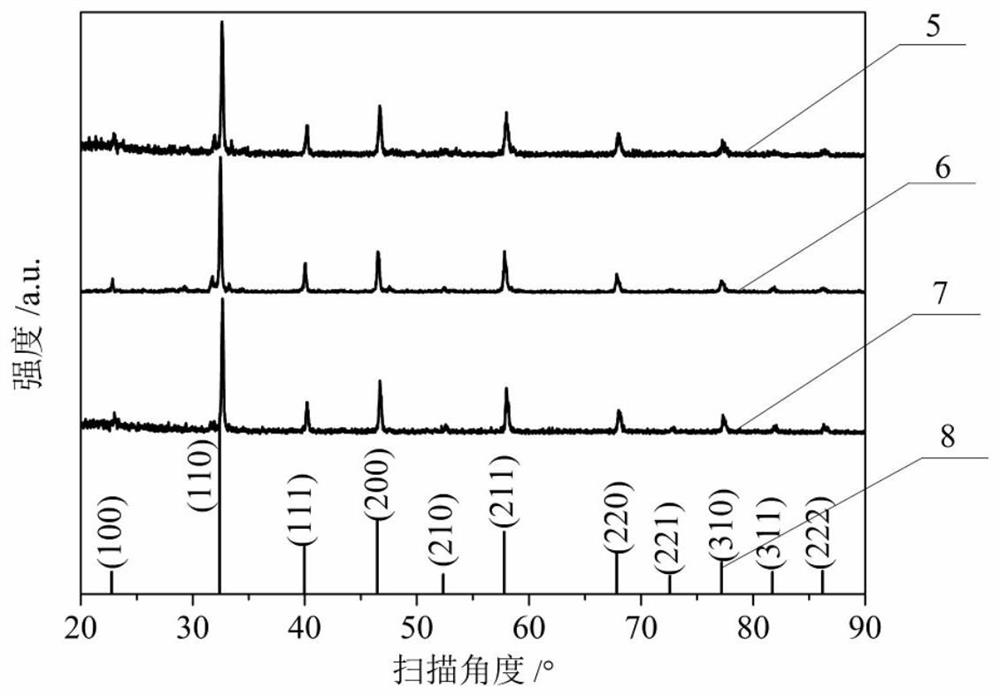

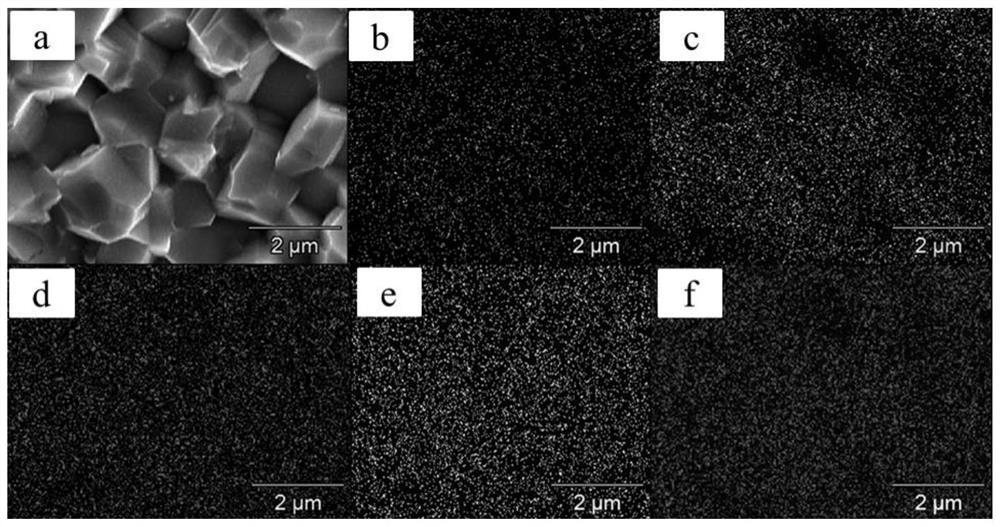

A-site high-entropy perovskite oxide MeTiO3 thermoelectric ceramic and preparation method thereof

The invention discloses A-site high-entropy perovskite oxide MeTiO3 thermoelectric ceramic and a preparation method thereof. The A-site high-entropy perovskite oxide MeTiO3 has a single-phase perovskite structure, the elements in the A-site high-entropy perovskite oxide MeTiO3 are uniformly distributed without agglomeration, and the A-site high-entropy perovskite oxide MeTiO3 has thermoelectric performance and can be used in the field of thermoelectric materials. The chemical composition of the A-bit high-entropy perovskite oxide MeTiO3 is (Ca < 0.2 > Sr < 0.2 > Ba < 0.2 > La < 0.2 > Pb < 0.2 >) TiO3, (Ca < 0.25 > Sr < 0.25 > Ba < 0.25 > La < 0.25 >) TiO3, (Ca < 0.25 > Sr < 0.25 > Ba < 0.25 > Pb < 0.25 >) TiO3, (Ca < 0.25 > Sr < 0.25 > Ba < 0.25 > Nd < 0.25 >) TiO3, (Ca < 0.25 > Sr < 0.25 > Ba < 0.25 > Sm < 0.25 >) TiO3, and (Ca < 0.25 > Sr < 0.25 > Ba < 0.25 > Eu < 0.25 >) TiO3. According to the invention, the high entropy of the perovskite structure is realized, the disorder degree of atom arrangement in the material composition is improved, the phonon scattering is increased, and the thermal conductivity is reduced, so that the thermoelectric performance is improved. In the sintering process, oxygen atoms are migrated and discharged through oxygen vacancies in material crystal lattices, the porosity is reduced, the ceramic density is improved, meanwhile, the oxygen vacancy concentration is improved, and the carrier concentration of the material is improved. By adopting a reduction annealing process of argon and carbon powder, the semiconduction of perovskite oxide is realized, the carrier concentration of the ceramic is improved, the conductivity is improved, and the thermoelectric performance is further improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

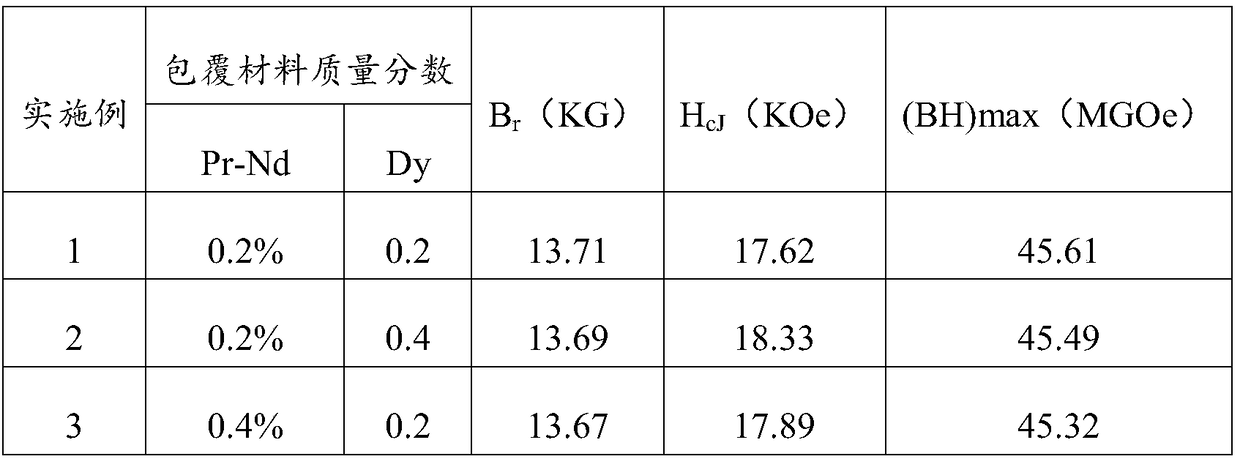

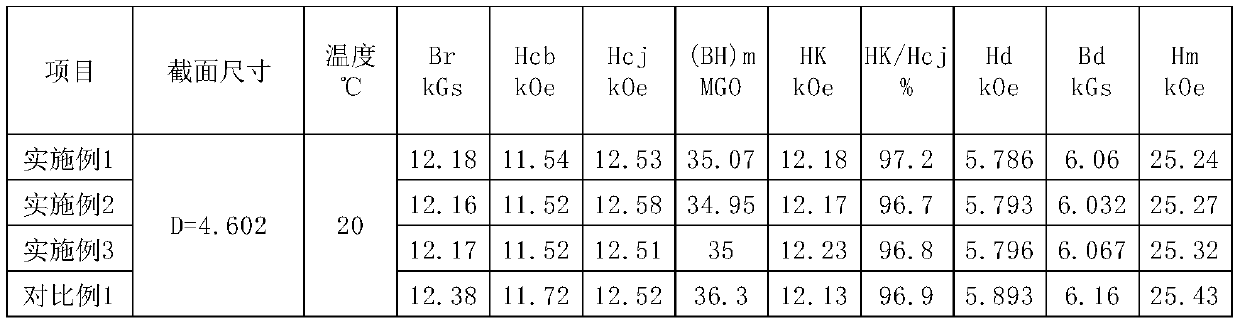

Preparation method of high-magnetic-energy-product and high-coercivity sintered neodymium iron boron magnet

InactiveCN108766753AReduce manufacturing costReduce usageInductances/transformers/magnets manufactureMagnetic materialsRare earthDisproportionation

The invention discloses a preparation method of a high-magnetic-energy-product and high-coercivity sintered neodymium iron boron magnet; the preparation method comprises the following steps of preparing materials according to the design ingredients, performing smelting on the ingredients, carrying out rapid hardening and casting, and obtaining a rapid hardened cast sheet; performing hydrogen crushing, a disproportionation reaction and airflow grinding and powder making on the neodymium-iron-boron cast sheet to obtain neodymium-iron-boron fine powder of 0.5-10[mu]m; adopting a thermal resistance evaporation deposition method to enable Dy / Tb particles and Pr / Nd particle element particles to be deposited on neodymium-iron-boron fine powder in a step-by-step manner or synchronously; and performing magnetic field orientation compression molding, cold isostatic pressing, vacuum sintering and heat treatment on the neodymium-iron-boron fine powder coated with Dy / Tb particles and Pr / Nd particles to finally obtain the high-magnetic-energy-product and high-coercivity sintered neodymium iron boron magnet. By coating the surface of the neodymium-iron-boron magnetic powder with the Pr / Nd and Dy / Tb thin layer, the volume ratio of the ferromagnetic phase is effectively increased, the rare-earth-rich phase distribution of the grain boundary is improved, the utilization rate of heavy rare earthelements is increased, and the magnetic energy product and the coercive force of the magnet are remarkably improved.

Owner:BAOTOU RES INST OF RARE EARTHS +1

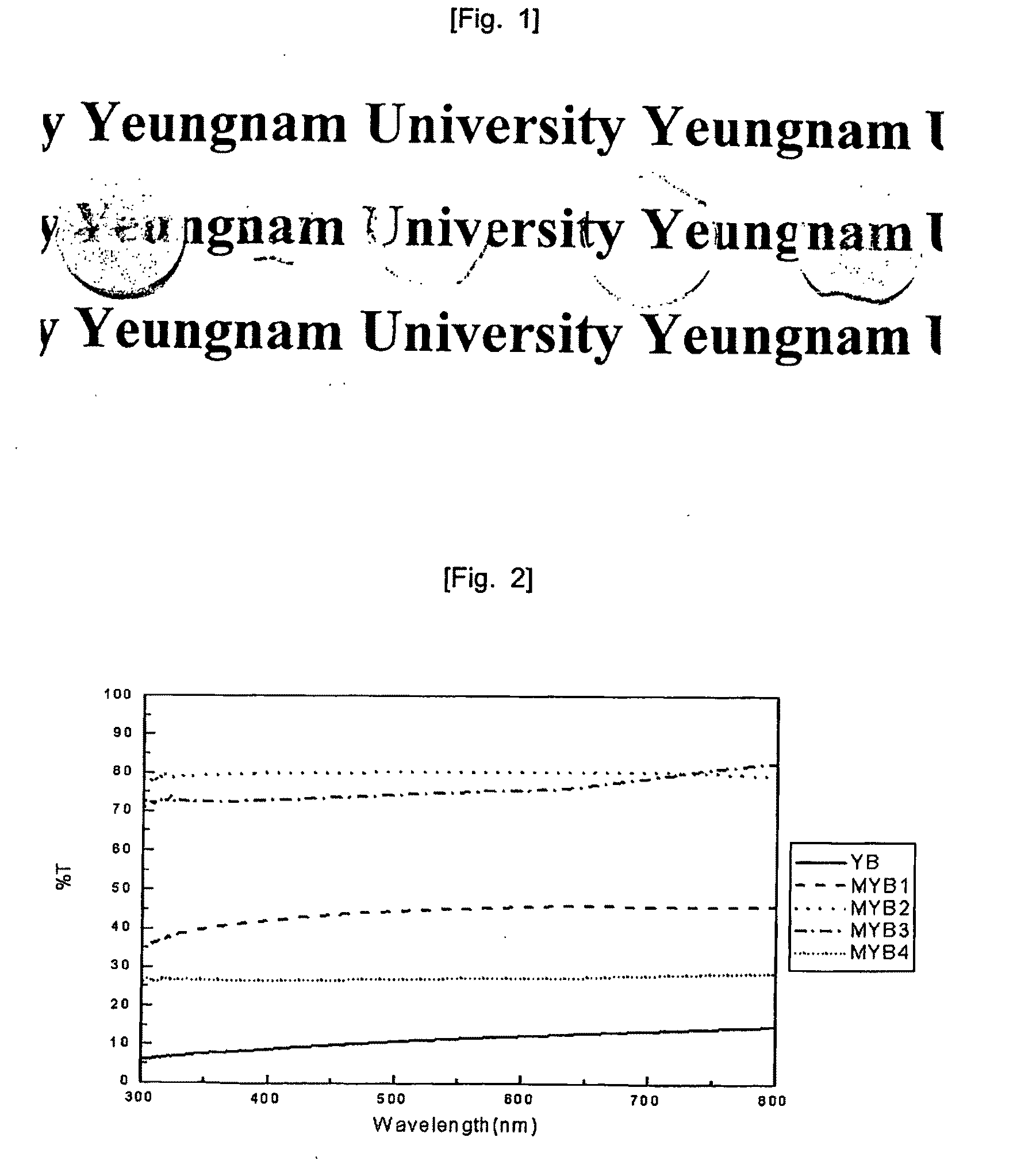

Method for manufacturing transparent polycrystalline aluminum oxynitride

InactiveUS20100167907A1Simple processOptimizing the sintering processNitrogen compoundsPorosityPolycrystalline aluminum

The present invention relates to a method of manufacturing a transparent polycrystalline aluminum oxynitride. Aluminum oxynitride manufactured by prior art methods has a great number of porosities therein and thus has low transparency. The present invention is directed to solving such a problem. In the method of manufacturing aluminum oxynitride of the present invention, a sintering additive added to a source powder includes less than 0.5 wt. % MgO. Further, the source powder is presintered at 1550° C. to 1750° C. so that a relative density becomes 95% or more and is then resintered at 1900° C. or more so that a relative density higher than that of presintering can be accomplished. According to the present invention, a cubic-phased polycrystalline aluminum oxynitride ceramic can be obtained, wherein porosities therein are nearly eliminated and its substantial transparency becomes 95% or more.

Owner:RES COOPERATION FOUND OF YEUNGNAM UNIV

Graphene-containing graphene/ceramic conductive composite material and preparation method thereof

ActiveCN108774052AImprove density and strengthImprove conductivityAdditive manufacturing apparatusGraphiteCvd grapheneConductive materials

The invention discloses a graphene-containing graphene / ceramic conductive composite material and a preparation method thereof, and belongs to the field of preparation of conductive materials. The preparation method mainly comprises the following steps: preparation of a graphite skeleton, strengthening treatment of the skeleton, preparation of a ceramic slurry, casting and drying of graphite / ceramic, and sintering. The graphite / ceramic conductive composite material prepared through the method is prepared by directly controlling composition components and the size structure of the graphite and improving the strengthening post-treatment of the conductive performance of the graphite skeleton, the sintering process and the drying process. The addition of graphene improves the internal loose porous structure problem of the graphite skeleton, increases conductive pathways, improves the strength of the graphite skeleton, and improves the conductive performance of the material while ensuring mechanical performances. The graphite / ceramic composite material has the conductive performance of the graphite, and also has the structure characteristics of ceramic.

Owner:CHINA THREE GORGES UNIV

Preparation method of composite sagger

The invention relates to a preparation method of a composite sagger. The method adopts forsterite and mullite as the main raw materials, takes potassium feldspar, calcined bauxite, sepiolite, montmorillonite, aluminum phosphate, zirconium silicate, aluminum nitride and high aluminum fiber as the auxiliary materials, at the same time adopts the process of water quenching, oil cooling and post-treatment during preparation to improve the physical and chemical properties of the prepared product. The prepared sagger has the advantages of good thermal stability, strong compressive ability, corrosion resistance, and difficult cracking.

Owner:姚焕根

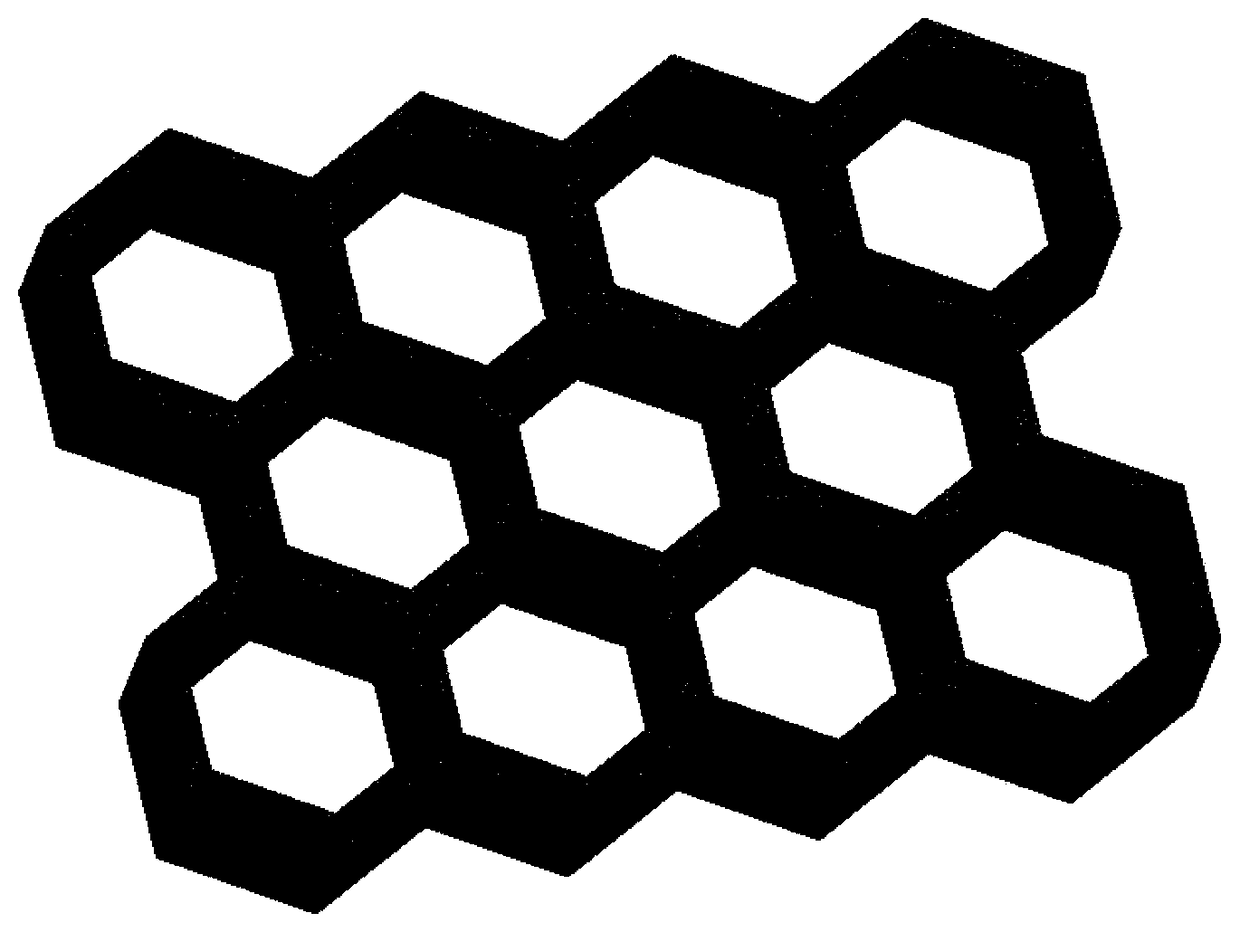

Ceramic with spatial three-dimensional conductive network structure and preparation method thereof

The invention discloses a ceramic with a spatial three-dimensional conductive network structure and a preparation method thereof, and belongs to the field of preparation of conductive materials. The preparation method mainly includes four steps of designing and strengthening treatment of a graphite framework three-dimensional structure, preparation of ceramic slurry, pouring process and drying andsintering process. A graphite / alumina ceramic composite material prepared by the method can be directly prepared by control of the composition, the size structure and post-treatment of the graphite and the improvement of the sintering process and the drying process. Under the premise that the conductivity is improved, the mechanical properties are guaranteed to achieve on-demand distribution of the graphite. The graphite / alumina ceramic composite material can have the conductivity of the graphite and structure characteristics of the ceramic, such as chemical stability, high temperature resistance, oxidation resistance, radiation resistance, corrosion resistance and the like, thereby having broad application prospects.

Owner:CHINA THREE GORGES UNIV

High-strength and light refractory aggregate

The invention discloses a production process of high-strength and light refractory aggregate. The high-strength and light refractory aggregate is prepared from main raw materials including, by weight, 60-62 parts of aluminium oxide, 18-20 parts of fused magnesite, 0.5-0.8 part of alpha-Al2O3 nanometer powder with the mass fraction of 99.9%, 0.5 part of perlite micropowder, 0.6-0.9 part of stone micropowder and 0.2 part of sericite, the temperature is kept at 15 DEG C after the main raw materials are evenly ball-milled, 25 parts of Soochow clay, 0.8-1.1 parts of SDBS foaming agents, 0.5 part of sodium tripolyphosphate and 6-6.5 parts of dextrin continue to be added and continue to be evenly stirred to form mixed mud, the prepared mud is poured and formed in a mold, demolding is conducted after natural drying, a dried wet blank is sintered in an electric furnace, sintering is conducted in 3 steps, and the finished product is obtained through furnace cooling. The high-strength and light refractory aggregate is light in mass and high in porosity, strength and water resistance.

Owner:无锡市宜刚耐火材料有限公司

Process for improving translucency of CAD/CAM in-ceram zirconia dental materials

InactiveCN101926734AGuaranteed liquidityEnsure consistencyImpression capsDentistry preparationsRoom temperatureTransmittance

The invention provides a process for improving translucency of CAD / CAM in-ceram zirconia dental materials, comprising the following steps: a. preparing nano zirconia powder by reverse coprecipitation; b. adding organic bonds for pelleting; c. carrying out dry pressing under 20-30MPa and carrying out static pressure treatment under 200-250MPa to preform green bodies; d. pumping oxygen when the green bodies are sintered to 200-800 DEG C from room temperature, preserving heat for 30min when the green bodies are sintered to 1250 DEG C, then raising the temperature to the final sintering temperature of 1400-1500 DEG C at a rate of 200 DEG C / h and preserving heat for 2h, thus obtaining the in-ceram zirconia materials with translucency. The invention also provides the in-ceram zirconia materials prepared by the method. With the integral transmittance of visible light of 17.50-18.01%, the in-ceram zirconia materials can meet the requirement of the oral clinical in-ceram restorations for beauty.

Owner:SICHUAN UNIV

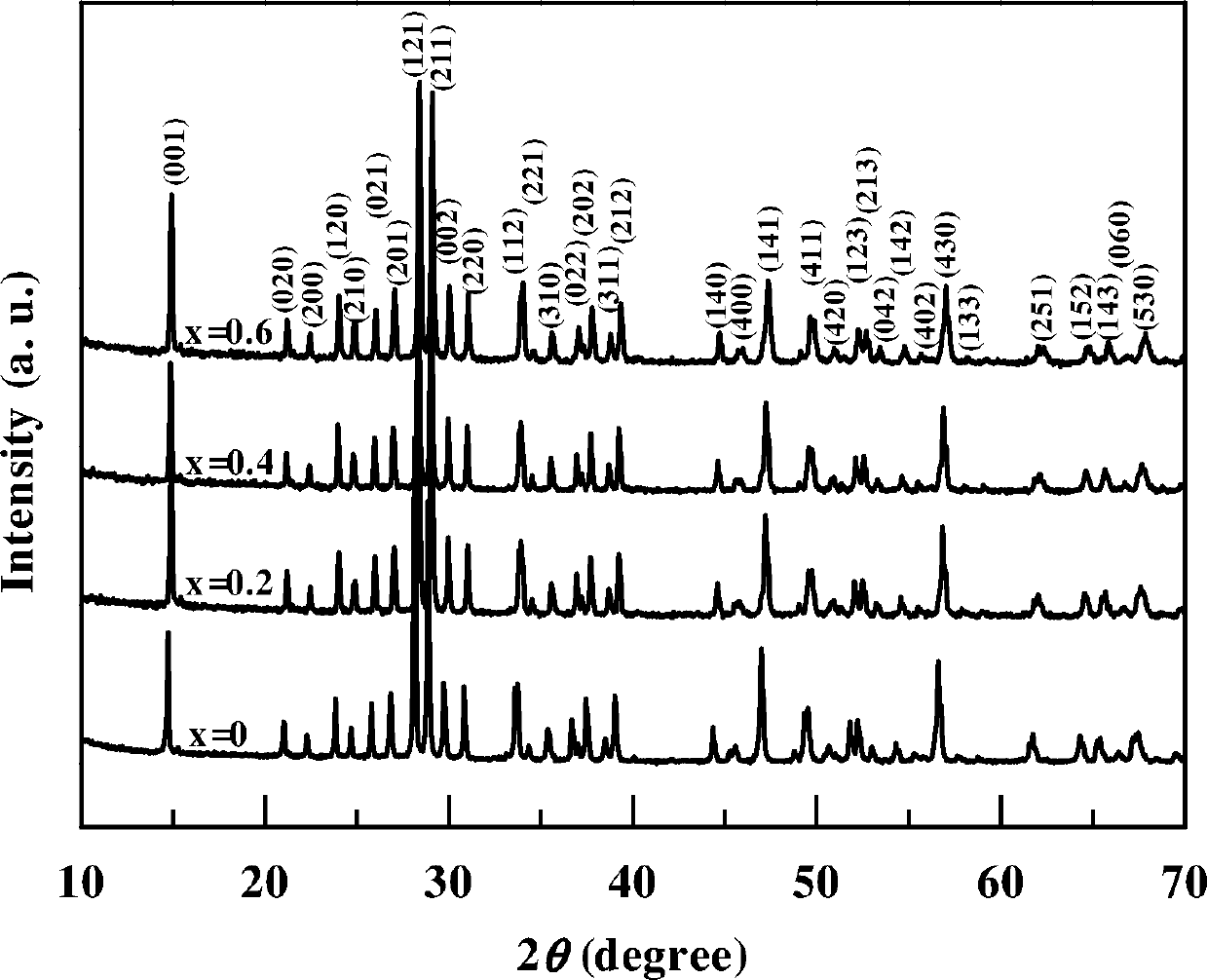

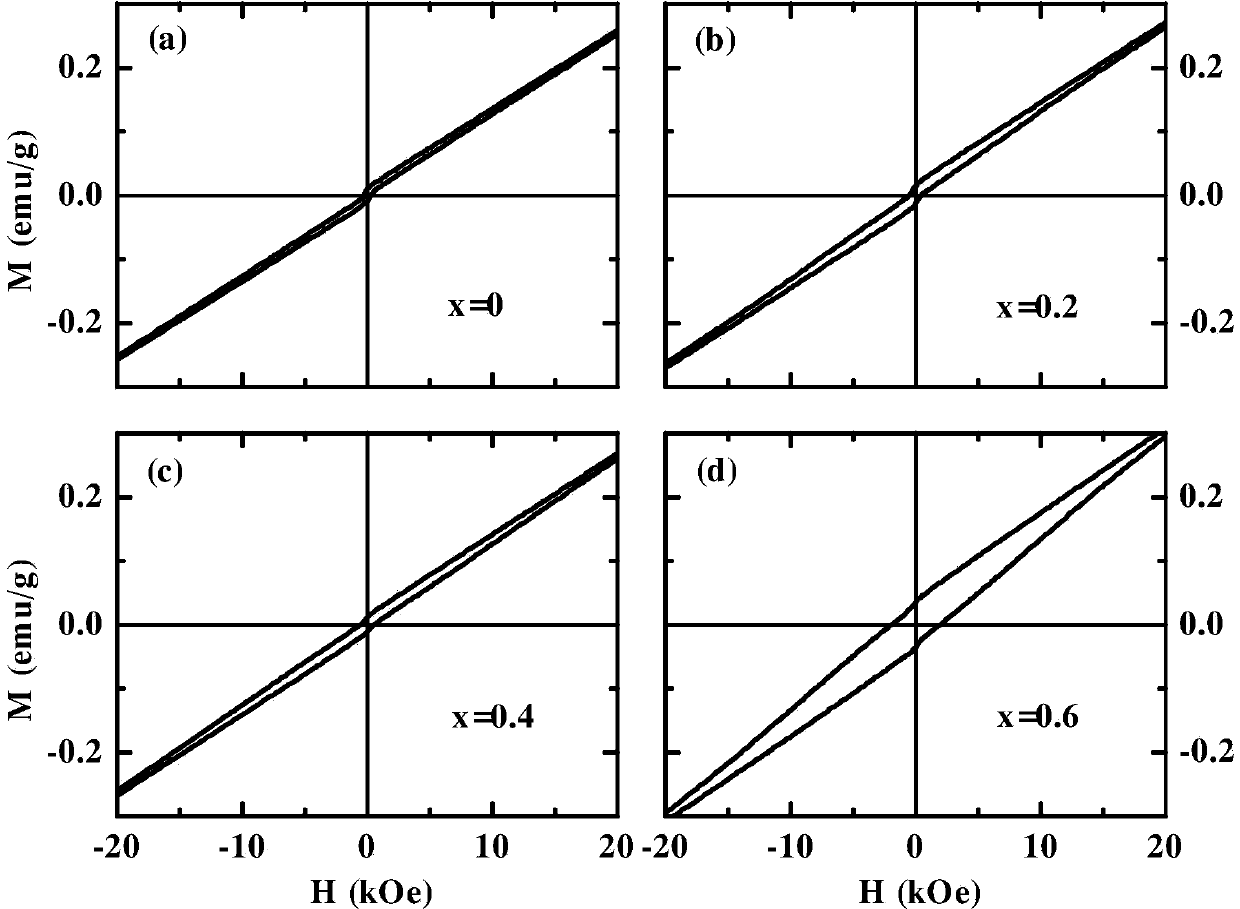

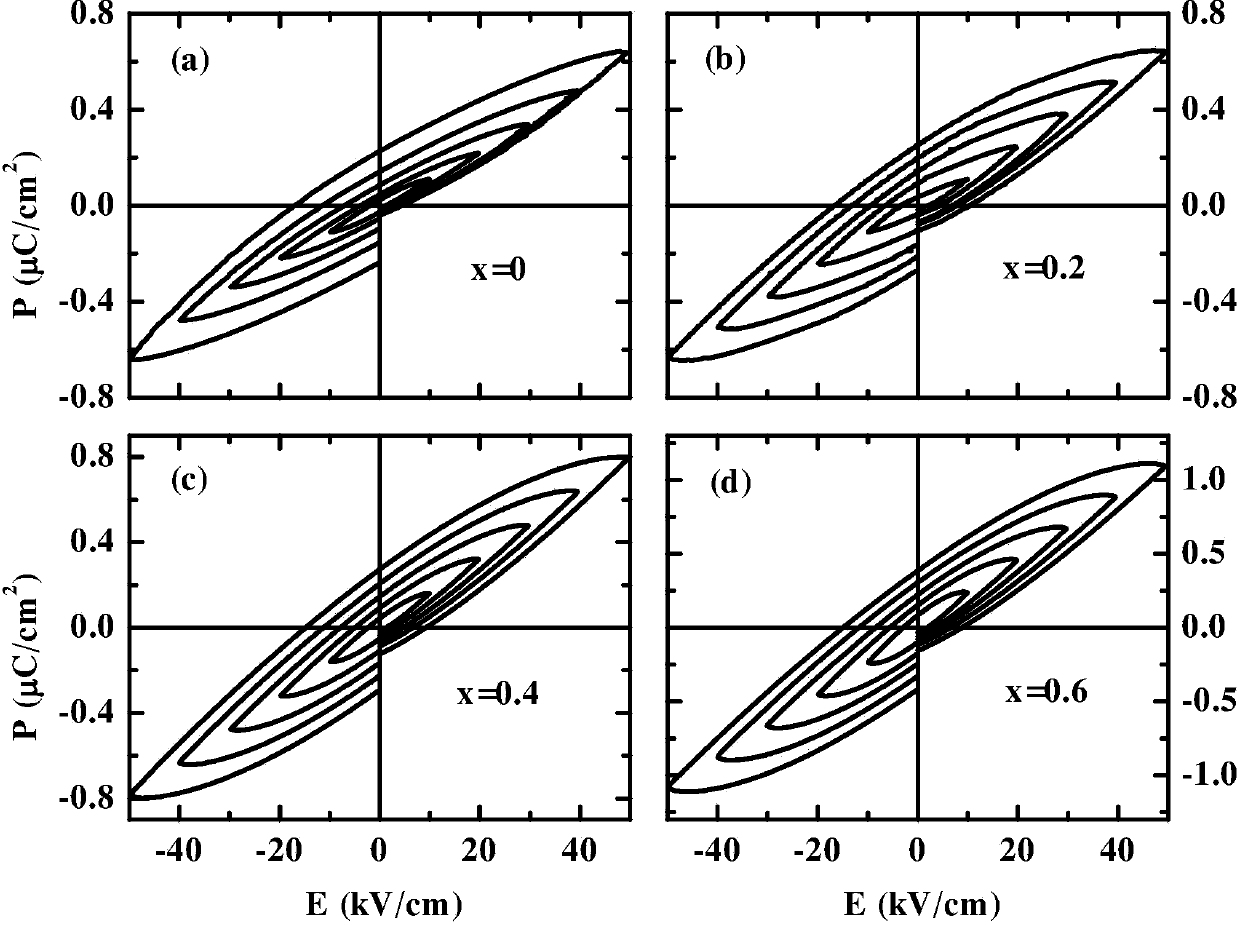

Al<3+>-doped Bi2Fe4O9 multiferroic ceramic material and preparation method thereof

The invention relates to an Al<3+>-doped Bi2Fe4O9 multiferroic ceramic material and a preparation method thereof. A citric acid-nitrate sol-gel process is adopted through high-temperature treatment to obtain the multiferroic ceramic material of which the molecular formula is Bi2Fe[4-x]AlxO9 (x=0, 0.2, 0.4, 0.6). The ceramic material has single-phase structure and room-temperature multiferroic property, and the room-temperature magnetism and ferroelectricity of the material can be adjusted by changing the doping amount of the Al<3+>. The method has the advantages of simple preparation technique, low sintering temperature, short sintering time, low cost, no need of reducing atmosphere, environmental protection, no toxicity and no pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

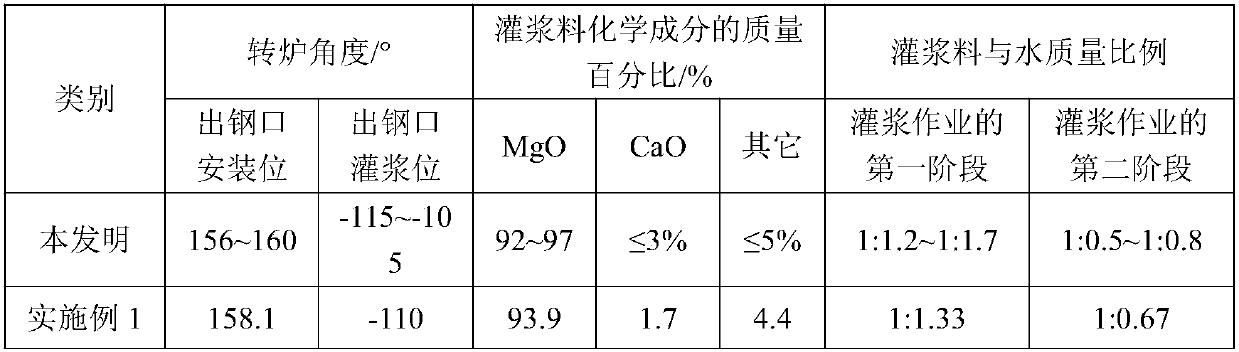

Quick change method of converter tap hole

The invention discloses a quick change method of a converter tap hole. The quick change method is mainly used for solving the technical problems that in the prior art, the replacement time of a converter tap hole is long, the replacement operation is complex, and the replacement quality is poor. According to the technical scheme, the quick change method of the converter tap hole comprises the steps of preparing a mounting hole for the new tap hole; mounting the new tap hole; filling a gap between the new tap hole with a refractory material and the mounting hole of the new tap hole in a converter body; and after 5-8 minutes since grouting is completed, returning the converter to a zero position, so that replacement of the new tap hole is completed. By means of the method, rapid replacementof the converter tap hole is achieved, and the replacement quality is controllable.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

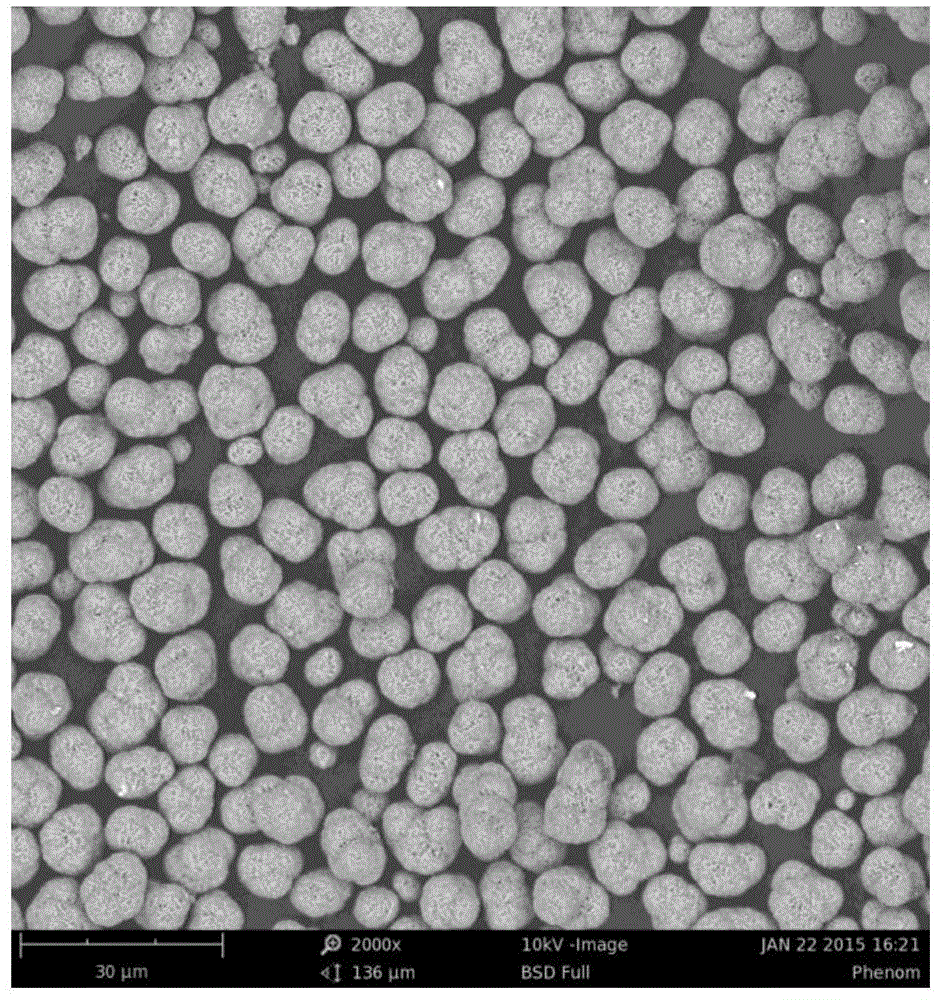

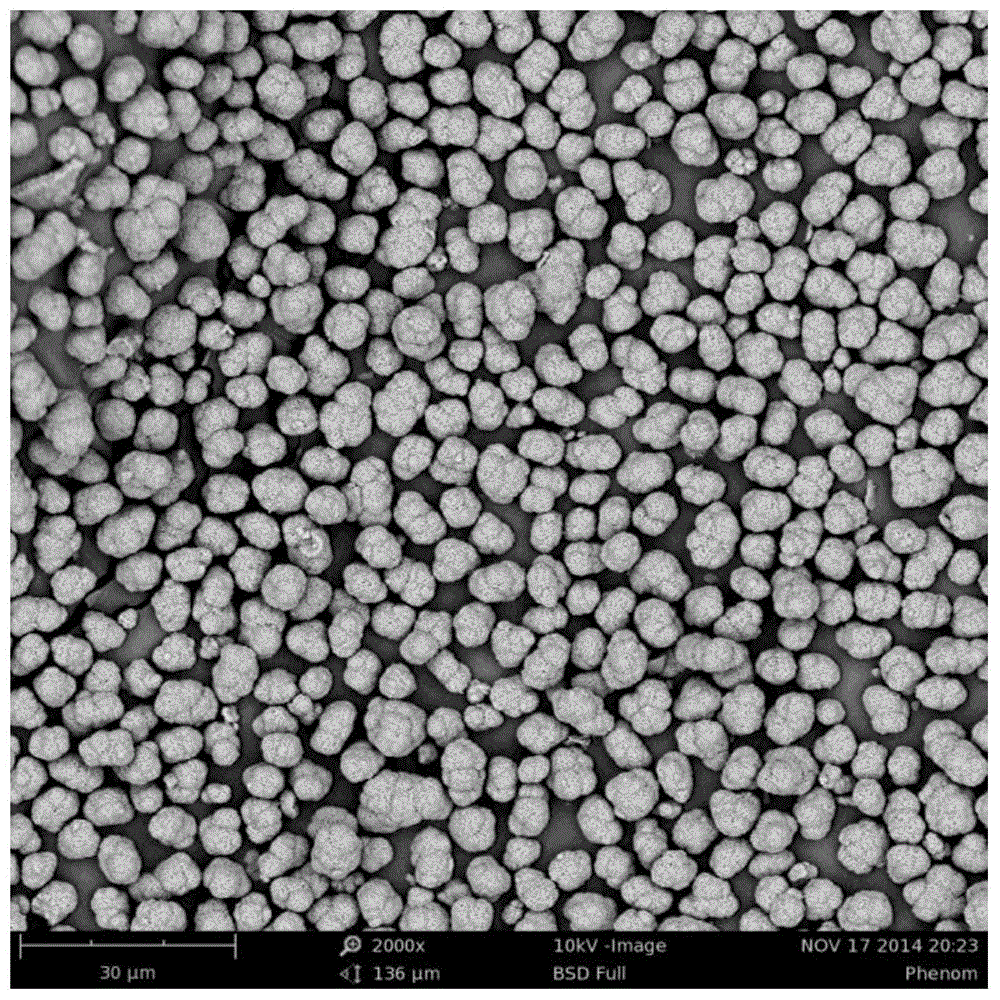

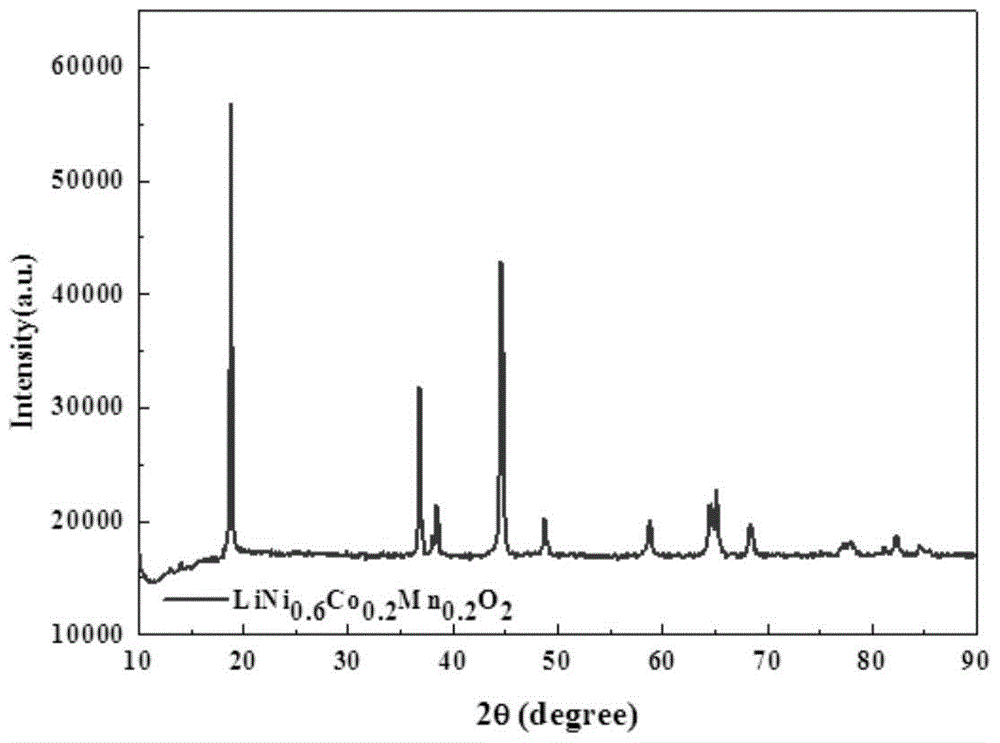

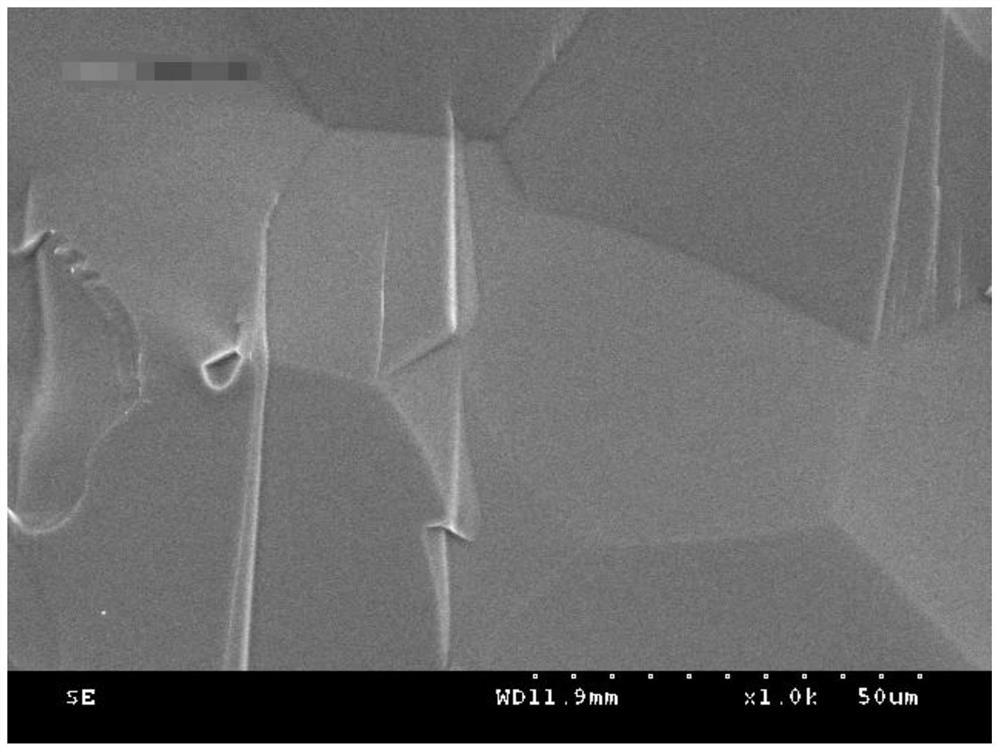

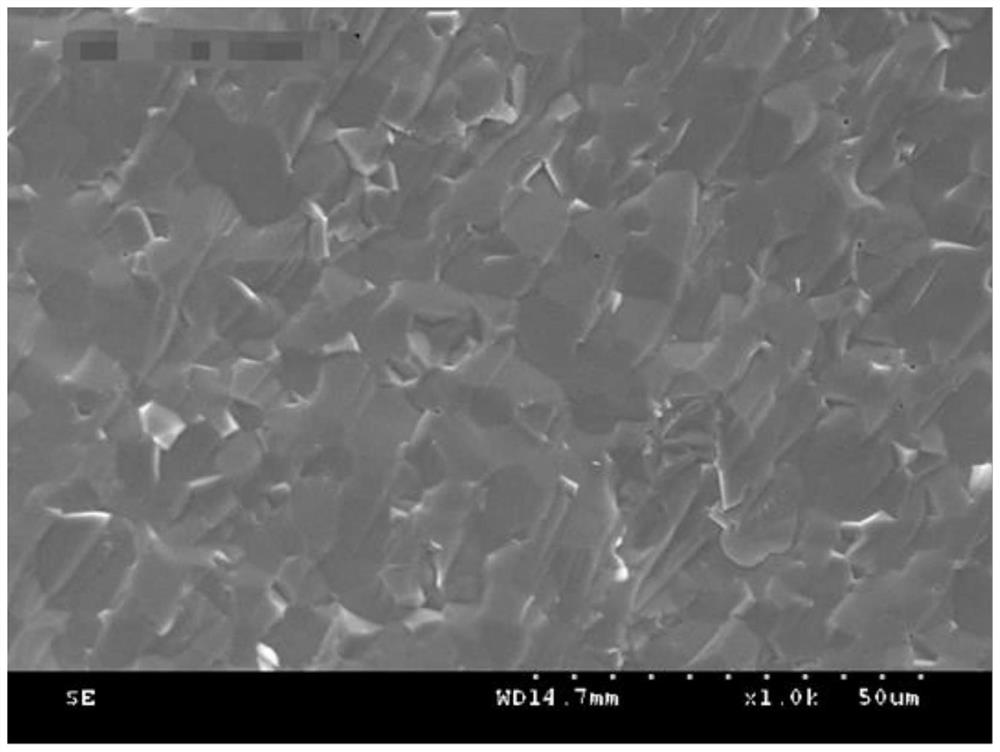

Preparation method of high-capacity, fast charge-discharge lithium-ion battery ternary cathode material

ActiveCN104852038BHigh tap densityHigh specific capacityCell electrodesSecondary cellsLithium electrodeLarge capacity

The invention relates to a preparation method of a high-capacity quickly-chargeable / dischargeable lithium ion battery ternary anode material, and aims to solve the technical problem that a ternary nickelate-cobaltate-manganate lithium ion battery anode material prepared with an existing preparation method cannot meet the market demand of rapid discharging / discharging. The method comprises the following preparation steps: performing a co-precipitation reaction on a nickelate-cobaltate-manganate solution and a mixed solution of a complexing agent and a precipitating agent under an appropriate condition to obtain a solid-liquid mixture of a precursor; performing filtration, washing and vacuum drying to obtain the precursor; and lastly, mixing the precursor with lithium salt powder, and performing segmented ventilation and sintering to obtain a target product. The anode material prepared with the preparation method has high tap density, high specific capacity, and high coulombic efficiency and excellent rate performance during first-time charging / discharging. When current density 20C is used for performing constant-current charging / discharging, the discharge specific capacity is over 110mAh / g; the cycle performance is high; and the market demand on high-capacity and high-rate power batteries can be met.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Microwave ferrite material for third-order intermodulation circulator and preparation method thereof

PendingCN114031389AAppropriate saturation magnetizationSuitable width and Curie temperatureInorganic material magnetismInductances/transformers/magnets manufactureCommunications systemInterference (communication)

The invention provides a microwave ferrite material for a third-order intermodulation circulator and a preparation method thereof, the chemical formula of the microwave ferrite material is Y3-aCaaSnaInbMncFe5-a-b-cO12, 0.1 < = a < = 0.3, 0.01 < = b < = 0.1, and 0.001 < = c < = 0.1. The preparation method comprises the following steps: (1) weighing; (2) primary ball milling; (3) drying and preheating; (4) secondary ball milling; (5) granulating; and (6) post-treatment. According to the microwave ferrite material provided by the invention, intermodulation interference between combined signals is reduced, the performance of a communication system and the coverage capability and capacity of a network are further improved, meanwhile, the stability and repeatability of a preparation process are maintained at a good level, and the microwave ferrite material is suitable for large-scale production and application.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

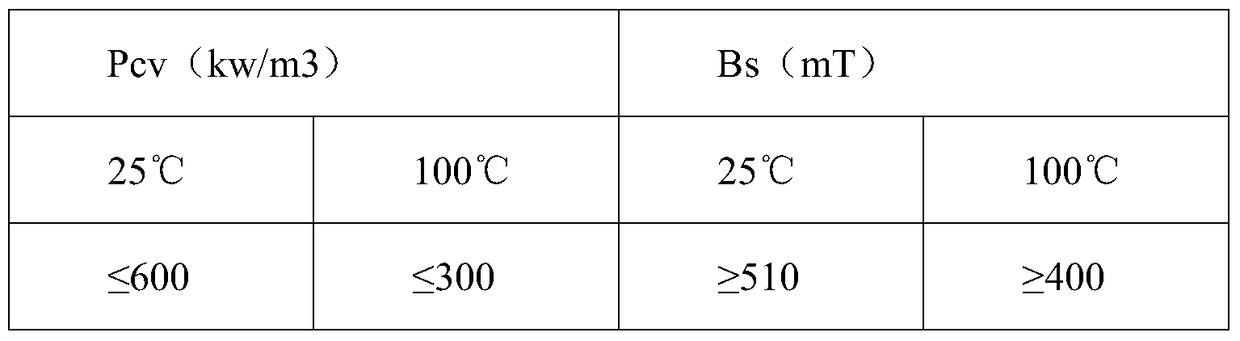

A kind of soft magnetic ferrite material with high frequency, low loss and high saturation magnetic flux density and its preparation method

ActiveCN106830913BHigh magnetic flux densityReduce lossInorganic material magnetismSoft magnetHigh flux

The invention discloses a high-frequency low-consumption high-saturation flux density soft magnetic ferrite material and a preparation method thereof. The ferrite material consists of main components and secondary components, wherein the main components comprise 54.5-55.5 mol% of Fe2O3, 3.5-6 mol% of ZnO, 0.10-0.25 mol% of Co2O3 and the balance of MnO on the basis of respective oxides; the secondary components comprise one or more of Nb2O5, CaCO3, V2O5, ZrO2 and Ta2O5. The preparation method comprises steps of material preparation, sand milling, pre-calcining, thermal treatment, molding and sintering. Due to addition of Co2O3 in the main components, and constitution contents of the main components and the secondary components are controlled, a sintering process is optimized, and the soft magnetic ferrite material simultaneously has properties of high frequency, low consumption and high flux density.

Owner:天通凯立科技有限公司

High-resistivity soft-magnetic ferrite magnetic core and processing method thereof

InactiveCN109694245AHigh resistivityOptimizing the sintering processInorganic material magnetismInductances/transformers/magnets manufactureTransformerNickel sesquioxide

The invention provides a high-resistivity soft-magnetic ferrite magnetic core and a processing method thereof. Raw materials of the high-resistivity soft-magnetic ferrite magnetic core comprise, by weight, 53-56 parts of ferric oxide, 6-11 parts of zinc oxide, 27-31 parts of manganese oxide, 3-5 parts of copper hydroxide, 2.5-3.6 parts of nickel sesquioxide, 0.9-1.3 parts of sodium polyacrylate, 0.4-0.7 part of silica sol, 0.7-1.1 parts of polyvinyl alcohol, 1.2-1.6 parts of polyamide resin, 0.7-1.3 parts of sodium silicate and 3-7 parts of deionized water. The soft-magnetic ferrite magnetic core has a high resistivity, has a low eddy current loss under an alternating magnetic field, and is an ideal material for manufacturing high-freency transformers, broadband transformers, adjustable inductors and other high-frequency circuits.

Owner:TIANCHANG CITY ZHAOTIAN MAGNETOELECTRICITY TECH

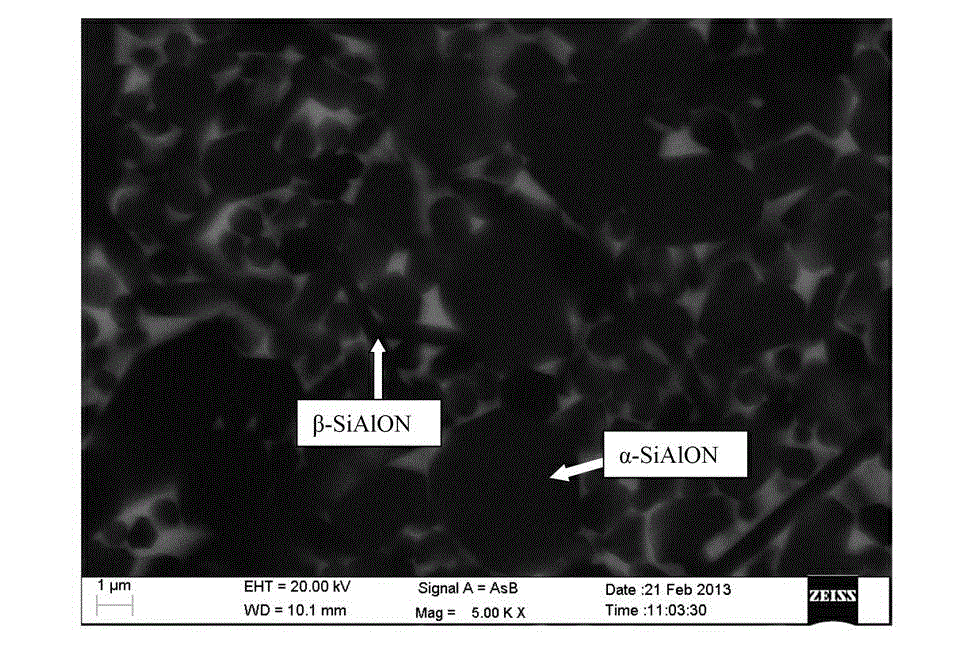

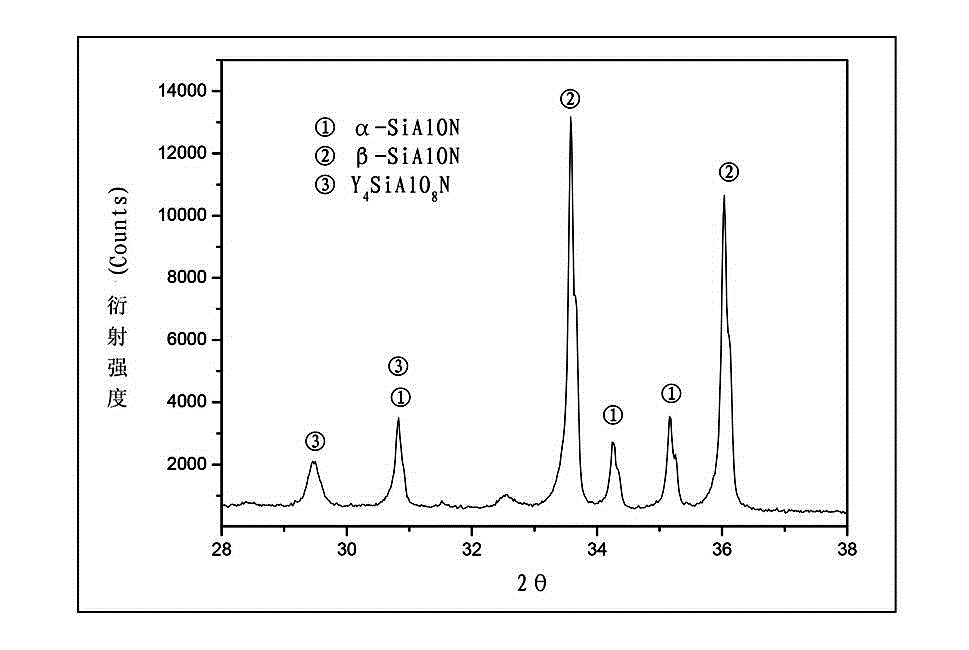

SiAlON ceramic containing crystalline phase Y4SiAlO8N, and preparation method and application thereof

The invention discloses a SiAlON ceramic containing crystalline phase Y4SiAlO8N. In the crystalline phase structure of the ceramic, main phase crystals mainly comprise alpha-SiAlON or an alpha-SiAlON and beta-SiAlON composite phase, Y4SiAlO8N exists in the crystal boundary of the main phase crystals, an alpha phase contains alpha-Si3N4, and a beta phase contains beta-Si3N4. A preparation method of the SiAlON ceramic comprises the following steps: uniformly mixing raw materials according to a ratio, adding an organic solvent and an adhesive, and ball-milling to obtain a mixed slurry; carrying out spray drying granulation of the mixed slurry, carrying out compression molding, and degreasing to form a green compact; and pre-burning the green compact in nitrogen atmosphere, carrying out furnace cooling, carrying out sintering heat-insulation of the obtained pre-burned body in the nitrogen atmosphere, and carrying out furnace cooling to obtain the SiAlON ceramic. The SiAlON ceramic has a good high-temperature stability and a good oxidation resistance.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

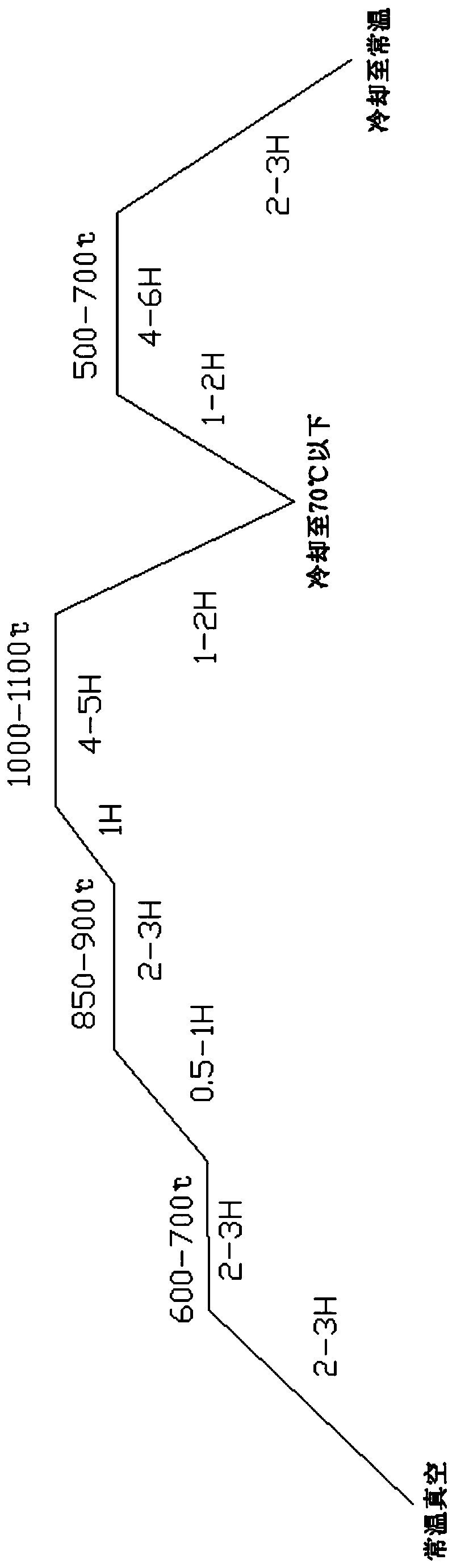

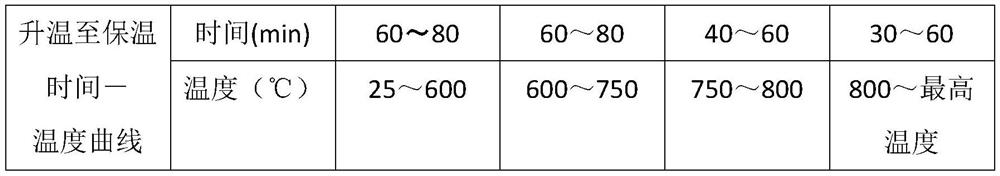

Sintering process of lanthanum cerium-containing sintered NdFeB

InactiveCN110323023AOptimizing the sintering processUtilization doubledInductances/transformers/magnets manufactureMagnetic materialsCeriumDehydrogenation

The invention discloses a sintering process of a lanthanum cerium-containing sintered NdFeB. The sintering process comprises the following steps of (1) performing deflation dehydrogenation, in which ablank is sent into a vacuum sintering furnace, a temperature is raised to 600-700 DEG C, and heat preservation is performed; (2) performing secondary deflation, in which the temperature is raised to850-900 DEG C, and heat preservation is performed; (3) performing high-temperature compactness, in which the temperature is raised to 1,000-1,100 DEG C, and heat preservation is performed; and (4) performing one-step aging and tempering, in which cooling is performed to 70 DEG C or below, the temperature is raised to 500-700 DEG C, cooling is performed to a room temperature after heat preservation, and a blank product is obtained. The sintering process of the lanthanum cerium-containing sintered NdFeB is optimized and transformed, the one-step aging process is taken, the aging temperature eachstage is determined, the sintering period is greatly reduced (the reduction period is 10 hours or above), water and power consumption is saved, the power charge is reduced by approximate one third, meanwhile, the utilization rate of sintering equipment is doubled, and no influenced is generated on the magnetic performance of the product.

Owner:宁波合盛磁业有限公司

MIM sintering process of 316L stainless steel

ActiveCN112427639ASmooth feedingIncrease partial pressure sintering pressureSS - Stainless steelSintering

The invention discloses an MIM sintering process of 316L stainless steel. The MIM sintering process comprises the following steps: (1) preparation of 316L stainless steel feeds: stainless steel powderand a binding agent are mixed according to a ratio of 9:1 for uniform mixing; and the obtained mixture is put in a feed crusher to prepare granular feeds with uniform sizes; (2) injection molding; (3) piece arrangement; (4) degreasing; (5) sintering; (6) piece arrangement by rotating a plate; and (7) secondary sintering: semi-sintered pieces prepared in the step (6) and a ceramic tool 2 are put in a sintering furnace in the step (5) for secondary sintering to prepare 316L stainless steel products without deforming and breaking. According to the sintering principle, the sintering process and the ceramic support mode are optimized, so that the sintering deformation problem is improved essentially; the sintering difficulties of some products with special structures are solved; and the production cost is reduced to a certain extent.

Owner:广东精研科技发展有限公司

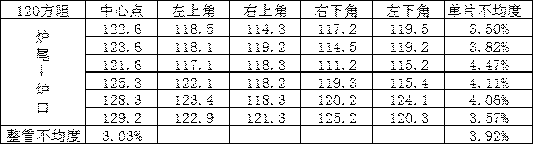

High-uniformity shallow junction diffusion process in low-pressure environment

ActiveCN110137307AImprove uniformityReduce junction depthFinal product manufactureSemiconductor/solid-state device manufacturingVacuum pumpingMetallurgy

The invention discloses a high-uniformity shallow junction diffusion process in low-pressure environment, which comprises the following steps: (1) introducing a silicon wafer into a quartz boat, and introducing the quartz boat into a purified furnace tube at constant temperature and at atmospheric pressure; (2) carrying out vacuum pumping until the pressure of the furnace body is 50-100mbar, and carrying out segmented diffusion heating, constant-temperature deposition and constant-temperature segmented advance heating on the furnace body; (3) cooling and annealing the furnace body at 50-100mbar; and (4) restoring the pressure to the atmospheric pressure by nitrogen charging, and taking the quartz boat out. Compared with the prior art, the surface diffusion concentration can be reduced by adjusting the uniformity of cell PN junctions, and a junction with better uniformity can better match sintering, so that the ohmic contact quality of the surface can be improved, the minority carrier life can be prolonged by the annealing process, the electrical performance parameters of cells can be improved, and the conversion efficiency can be improved ultimately.

Owner:ZHEJIANG BEYONDSUN PV +1

Wide-temperature ultralow-loss manganese zinc ferrite material and preparation method thereof

The invention discloses a wide-temperature ultralow-loss manganese zinc ferrite material and a preparation method thereof. The wide-temperature ultralow-loss manganese zinc ferrite material is prepared from main components and auxiliary components, the main components comprise the following components in percentage by oxide: 50-52 mol% of Fe2O3, 10-12 mol% of ZnO and the balance of MnO, and the total amount of the formula of the main components is 100%; according to the total weight of the main components, the auxiliary components are any five or a combination of more than five of 200 to 600 ppm of CaO, 200 to 400 ppm of ZrO2, 3000 to 10000 ppm of Co2O3, 20 to 100 ppm of SiO2, 200 to 400 ppm of Nb2O5, 400 ppm to 800 ppm of SnO2 and 300 to 600 ppm of TiO2; the problem that the high and low temperature loss of the manganese-zinc soft magnetic ferrite material in the prior art is higher than 310 kW / m < 3 > is solved.

Owner:贵州正业龙腾新材料开发有限公司

Sintering method capable of improving sintering desulfurization rate

The invention discloses a sintering method capable of improving sintering desulfurization rate. The sintering method capable of improving the sintering desulfurization rate is characterized by comprising the following steps: mixing iron ore powder with the granularity of 2 to 10 mm, a certain proportion of fuel and a quick lime-containing flux in a certain proportion to form a sintering material; paving a grate-layer material on a sintering machine, and then uniformly paving the sintering material on the grate-layer material, wherein the thickness of the sintering material is 700 to 800 mm; finally, igniting and sintering, wherein the igniting temperature is 1,000 to 1,200 DEG C. The sintering desulfurization rate can be improved, and meanwhile, the using amount of coke and the cost of raw ore powder are reduced by sintering by the sintering method; the overall resources are saved; the production cost is reduced; obvious economic benefit is brought to a sintering plant.

Owner:YUNNAN DESHENG STEEL CO LTD

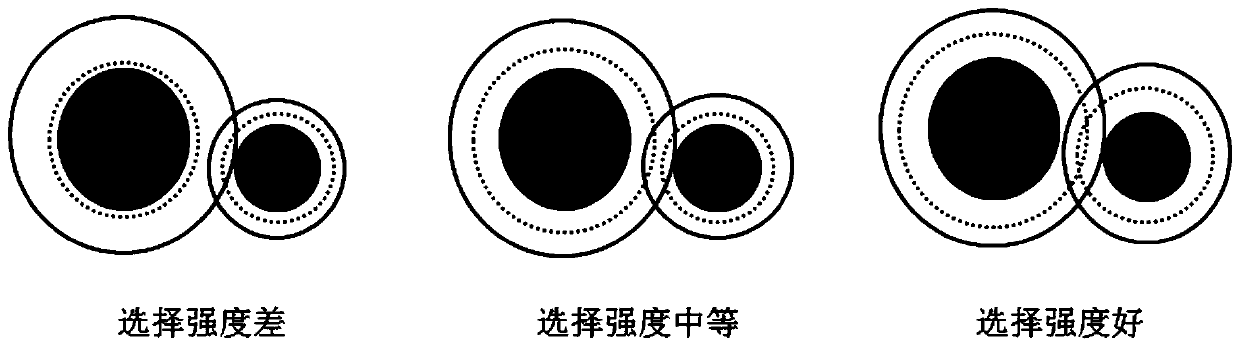

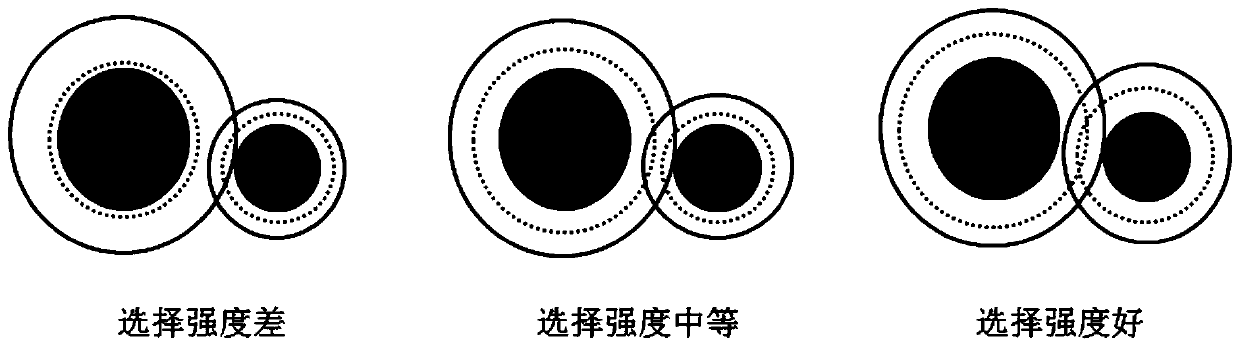

Method for judging granulation selectivity strength among different iron ore powder particles

The invention discloses a method for judging the granulation selectivity strength between different iron ore powder particles. The method comprises the following steps: (1) taking a certain size fraction of iron ore powder A and iron ore powder B, and calculating the average particle sizes DA and DB of the iron ore powder A and the iron ore powder B at the corresponding size fractions; (2) calculating the maximum molecular water film thicknesses DFA and DFB and the maximum capillary water film thicknesses DMA and DMB of fraction samples taken from the iron ore powder A and the iron ore powderB; (3) calculating values of DMA / DA and DMB / DB, and judging whether the selective strength is good or bad when the iron ore powder A and the iron ore powder B are used as adhesive particles at the same time; and (4) calculating the value of |DMA-DMB|, comparing |DMA-DMB|, DFA and DFB, and judging the mutual selective strength during the contact granulation of the iron ore powder A and the iron orepowder B. The method is high in operability, can quantitatively judge the selection behavior of the particles in the iron ore powder granulation process, and has high practical significance in deeplyresearching the behavior of the iron ore powder particle granulation process.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Sub-nanometer spherical silicone micro powder-containing high-tenacity composite ceramic

The invention discloses a sub-nanometer spherical silicone micro powder-containing high-tenacity composite ceramic. The sub-nanometer spherical silicone micro powder-containing high-tenacity composite ceramic is prepared from matrix raw materials and auxiliary agents, wherein the matrix raw materials is prepared from the following components in parts by weight: 65 to 80 parts of zirconium oxide, 5 to 10 parts of aluminum oxide, 5 to 7 parts of kaoline, 3 to 6 parts of lithium feldspar, 3 to 8 parts of alkali-earth metal carbonate, 0 to 0.5 part of rare-earth metal oxide, 4 to 8 parts of basalt fiber and 3.5 to 7.5 parts of sub-nanometer spherical silicone micro powder; and the auxiliary agents comprise the following components in parts by weight: 3 to 5 parts of sodium silicate, 0.5 to 2 parts of ethylene glycol monobutyl ether, 1 to 2 parts of barium hydroxide, 1 to 3 parts of carboxymethyl cellulose, 0.5 to 1.5 parts of polyethylene fiber, 1.2 to 2 parts of potassium sulphate and 1.5 to 3 parts of lauryl sodium sulfate. A plurality of tenacity reinforcing measures are taken to improve elasticity and structural mechanical property of the ceramic, particularly, the compactness of a ceramic matrix is improved by the sub-nanometer spherical silicone micro powder, and the ceramic matrix has enough tenacity, strength, hardness and abrasion resistance.

Owner:苏州吉云新材料技术有限公司

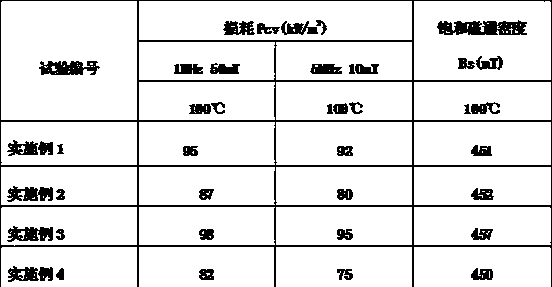

Ultrahigh saturation flux density manganese-zinc ferrite material and preparation method thereof

PendingCN111039666AOptimizing the sintering processAdapt to the needs of inductanceInorganic material magnetismTransformerManganese

The invention discloses an ultrahigh saturation magnetic flux density manganese-zinc ferrite material, which is composed of a main component and an auxiliary component. The main component is composedof 55.25-56.25 mol% of Fe2O3, 2.5-3.5 mol% of ZnO, 0.10-0.20 mol% of Co2O3 and the balance of MnO in terms of oxide; and the auxiliary component includes 0.01-0.06 wt% of Nb2O5, 0.05-0.15 wt% of CaCO3, 0-0.05 wt% of NiO, 0.01-0.04 wt% of V2O5, 0-0.01 wt% of SiO2, 0-0.05 wt% of TiO2 and 0-0.05 wt% of Ta2O5. The manganese-zinc ferrite material prepared by the invention has the power consumption of less than 250kW / m<3> at the temperature of 25 DEG C and 100 DEG C under 3MHz and 30mT, and the saturation flux density at the temperature of 100 DEG C reaches 460 mT or above, so that the manganese-zinc ferrite material adapts to the requirements of a high-frequency transformer and a server inductor.

Owner:TDG HLDG CO LTD

A low-temperature sintering process for manganese-zinc ferrite

ActiveCN105399411BOptimizing the sintering processLower sintering temperatureMetallurgyEnergy consumption

The invention discloses a process for low-temperature sintering of manganese zinc ferrite. The process comprises a step (1) of primary sanding, a step (2) of presintering, a step (3) of secondary sanding, a step (4) of granulation and a step (5) of sintering. The process for low-temperature sintering of manganese zinc ferrite is improved and optimized, the process steps are simple, the maneuverability is high, the temperature of the manganese zinc ferrite can be reduced by 100-200 DEG C, the production energy consumption is greatly reduced, and the production cost is reduced.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com