Process for improving translucency of CAD/CAM in-ceram zirconia dental materials

A zirconia, semi-permeable technology, used in dental preparations, dental prostheses, compression mold cups, etc., to improve transmittance, ensure consistency, and reduce porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 The comparative test of technique of the present invention and existing technique

[0033] The performance of the sample processed according to this improved process is shown in Table 1. The Cercon ceramic block was sintered at the sintering temperature 1350°C recommended by the manufacturer, and a sample of the same specification with a thickness of 0.50±0.01mm was made as a control sample. The results are shown in Table 1:

[0034] Table 1 Optical and mechanical properties of dental CAD / CAM zirconia all-ceramic materials

[0035]

[0036] It can be seen from Table 1 that the zirconia all-ceramic material prepared by the process of the present invention has higher sintering density, transmittance and three-point bending strength than Cercon after controlling the powder particle size and sintering temperature. The relative density of the sample is 99.15-99.39%, and the visible light integral transmittance is 17.50-18.01%, which can fully meet the optica...

Embodiment 2

[0038] Embodiment 2 Preparation of dental CAD / CAM zirconia all-ceramic material of the present invention

[0039] by ZrOCl 2 ·8H 2 O using the reverse co-precipitation method to prepare nano-ZrO 2 Powder: First, high-purity Y 2 o 3 The powder was dissolved in 2M dilute nitric acid and heated on a magnetic heating stirrer to obtain Y(NO 3 ) 3 crystallization; the precursor zirconium salt ZrOCl 2 ·8H 2 O and Y (NO 3 ) 3 Heat the crystals together and dissolve them in absolute ethanol, prepare a 0.3M ethanol solution, and filter to remove impurities; put the above solution into a separatory funnel, drop it into 2M excess ammonia ethanol solution at a speed of 50 drops / min, and control the pH >9, after the reaction is complete, filter the precipitate on a suction filter flask and wash repeatedly with absolute ethanol. The filter cake is dried in an oven at 100°C for 24 hours, crushed and calcined to obtain nano-ZrO 2 Powder, the particle size range of powder is controll...

Embodiment 3

[0053] Embodiment 3 Preparation of dental CAD / CAM zirconia all-ceramic material of the present invention

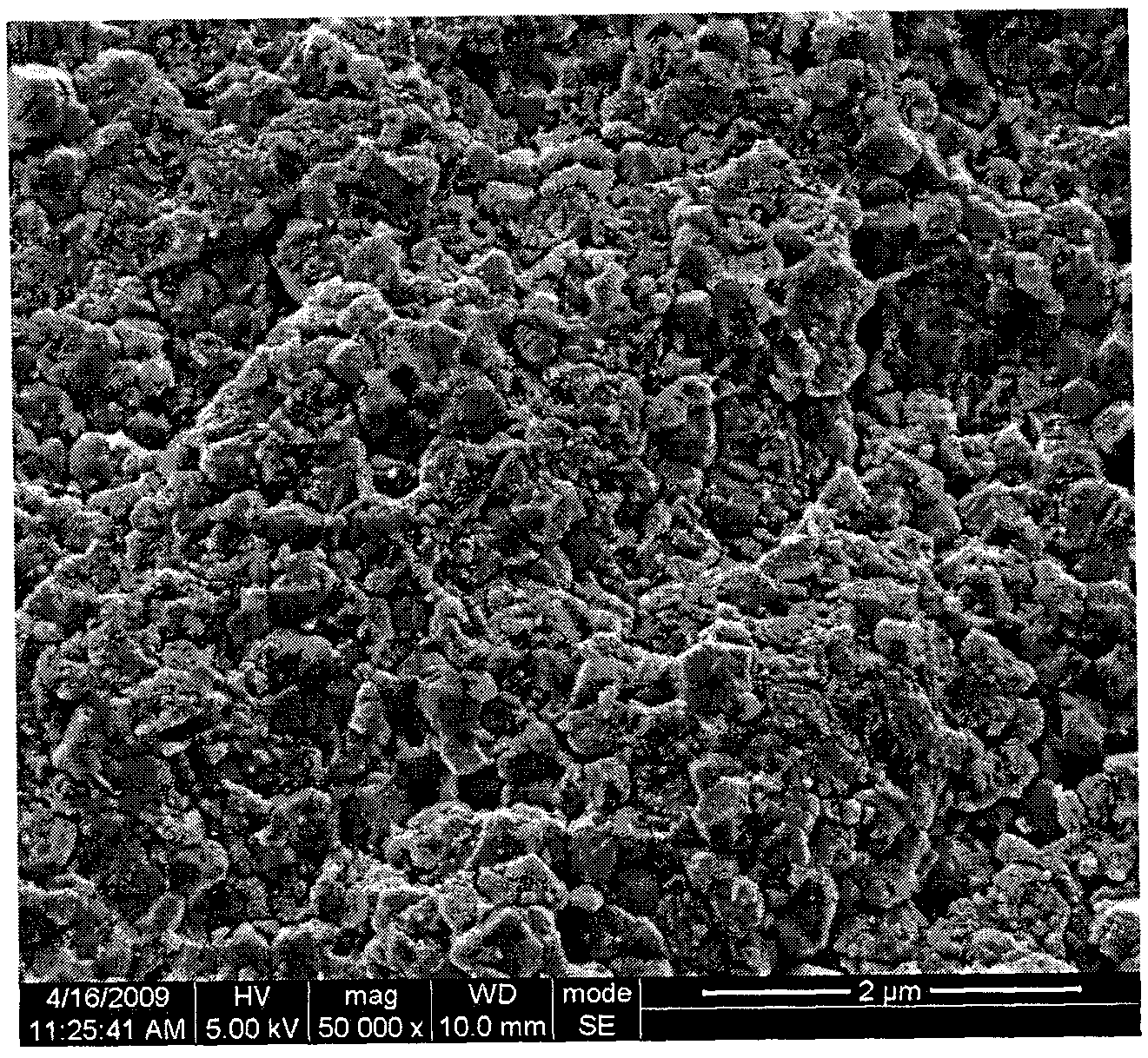

[0054] In the sintering system, the final sintering temperature is 1450° C., and other conditions and processes are the same as in Example 2. The sintered density of the zirconia sample obtained in this embodiment is 6.0627±0.0074g / cm 3 , the relative density reaches 99.39%, basically achieves densification, and the visible light integral transmittance is 17.83±0.16%. The crystals observed by the scanning electron microscope section are all tetragonal zirconia grains, the grain size is 200-400nm, the distribution is uniform, the sintered body is dense, and no obvious pores are seen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com