Ceramic with spatial three-dimensional conductive network structure and preparation method thereof

A technology of network structure and ordered structure, which is applied in the field of preparation of composite conductive ceramic materials, can solve problems such as mismatching of mechanical properties and electrical conductivity, reduction of mechanical properties of composite materials, improvement of electrical conductivity of non-conductive network lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Al provided 2 O 3 , CuO, MgO powder, SiO 2 Powder, TiO 2 The purity of the raw materials of the powder is greater than 99.0%. The mass fraction of graphite is 15%-25% of the ceramic powder, the purity of the graphite is greater than 99.85%, and the particle size is less than or equal to 50 μm.

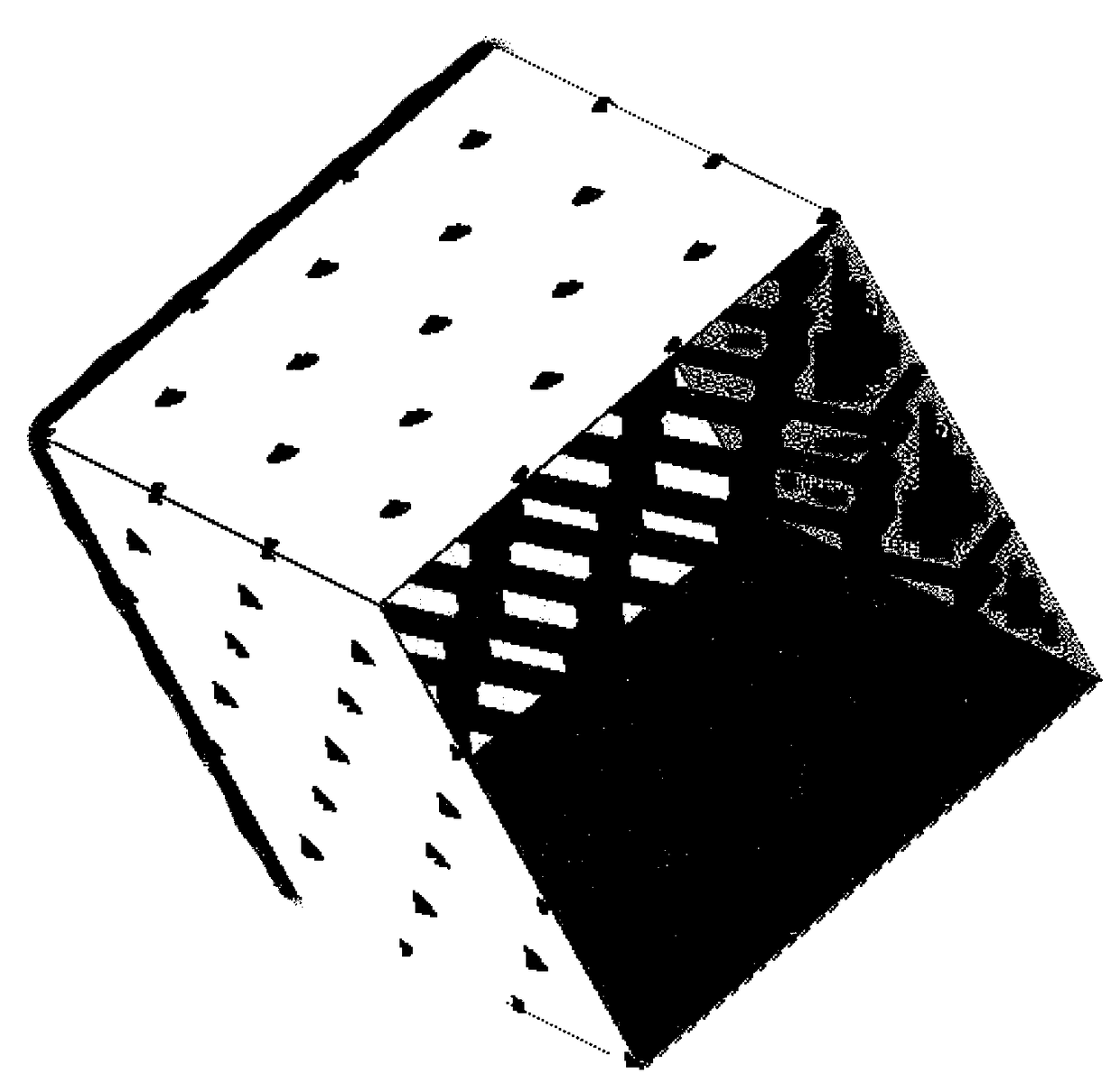

[0024] 1) Preparation of graphite skeleton: the flake graphite powder, SiC powder and bonding powder are mixed in a ratio of 6:1:3, and the laser sintering 3D printer is used to print the graphite skeleton drawing according to the designed three-dimensional ordered structure of graphite. The skeleton is a diamond structure, with good stability and strength, and good three-dimensional hierarchical connection. The frame size is 1mm (diameter), the side length is 4mm, the structure is like figure 1 , image 3 Shown. Then the graphite skeleton is impregnated with phenolic resin and epoxy resin to increase the strength and carbonization of the graphite skeleton to improve its stability...

Embodiment 2

[0031] Al provided 2 O 3 , CuO, MgO powder, SiO 2 Powder, TiO 2 The raw material purity of the powder is greater than 99.0%. The mass fraction of graphite is 15%-25% of the ceramic powder, the purity of the graphite is greater than 99.85%, and the particle size is less than or equal to 50 μm.

[0032] 1) Preparation of graphite skeleton: the flake graphite powder, SiC powder and bonding powder are mixed in a ratio of 6:1:3, and the laser sintering 3D printer is used to print the graphite skeleton drawing according to the designed three-dimensional ordered structure of graphite. The skeleton is composed of three basic layers. The three basic layers are arranged by graphite structures on different sides, which are superimposed to form a honeycomb structure. A single Y-shaped frame has a size of 1mm (width), a height of 1mm, and a side length of 2mm, such as figure 2 , 4 and 5. Then the graphite skeleton is impregnated with phenolic resin and epoxy resin to increase the strength a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com