Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Optimize the drying process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing persimmon cake

InactiveCN101558841AOptimize the drying processOvercome quality defectsFood preservationFood preparationWater contentNutrient content

The invention discloses a method for processing persimmon cake, which leads hot-air drying and microwave drying and sterilizing to be combined and applied to the processing production of the persimmon cake, wherein the hot-air drying is performed by the following step: a plastic plate loaded with mashed fruit is placed in a hot-air dryer and is kept for 5-8h at a heating temperature of 65-75 DEG C so as to lead the water content of the material to be lowered at 30-35 percent; the microwave drying and sterilizing is performed by the following step: the plastic plate loaded with the mashed fruit is placed in a microwave drying sterilization machine and is kept for 5-8min at a heating temperature of 60-65 DEG C so as to lead the water content of the material to be lowered at 20-25 percent and play a role of sterilization. The technical scheme overcomes the shortcomings of the prior method for drying the persimmon cake and the quality defect of the product, effectively lightens the damage of the drying process to nutrient content in the persimmon cake, optimizes the processing procedure, greatly shortens the processing time, is beneficial to lower the energy consumption and the production cost, and improves the efficiency.

Owner:广州市从化龙丰园果子食品厂

Moisture content measuring method for wood drying process and wood drying method

ActiveCN108802352AAccurate moisture contentReduce drying defectsWeighing by removing componentWood testingNarrow rangeSolid wood

The invention discloses a moisture content measuring method for a wood drying process and a wood drying method. The moisture content measuring method for the wood drying process and the wood drying method include: measuring an initial moisture content and initial weight of to-be-dried wood, and stacking the to-be-dried wood in a drying kiln; measuring temperature and wind speed of media flowing through two sides of the stacked to-be-dried wood, acquiring saturated vapor pressure of moist air according to dry-bulb temperature, acquiring relative humidity of the moist air according to temperatures of wet and dry bulbs, and finally acquiring density and moisture content of the moist air so as to obtain moisture contents of the to-be-dried wood at different times; according to the moisture contents of the to-be-dried wood, drying the to-be-dried word according to wood drying standards so as to obtain high-quality dry wood. The moisture content measuring method is precise, simple, low in input, applicable to any wood moisture content measurement, less in measuring parameters, simple in calculation, systematically stable, capable of overcoming the defects of large measuring error and narrow range of an electric measuring method and improving quality of solid wood plates, high in efficiency and low in cost.

Owner:BEIJING FORESTRY UNIVERSITY

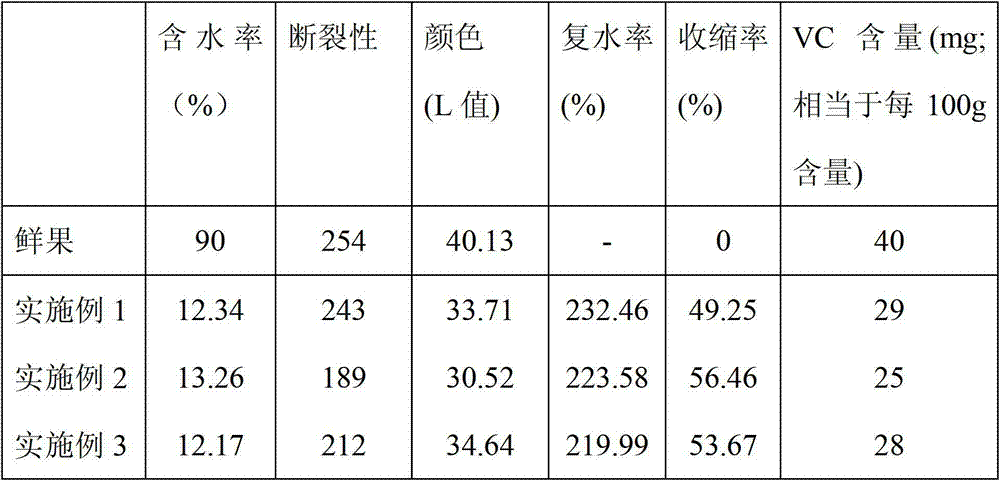

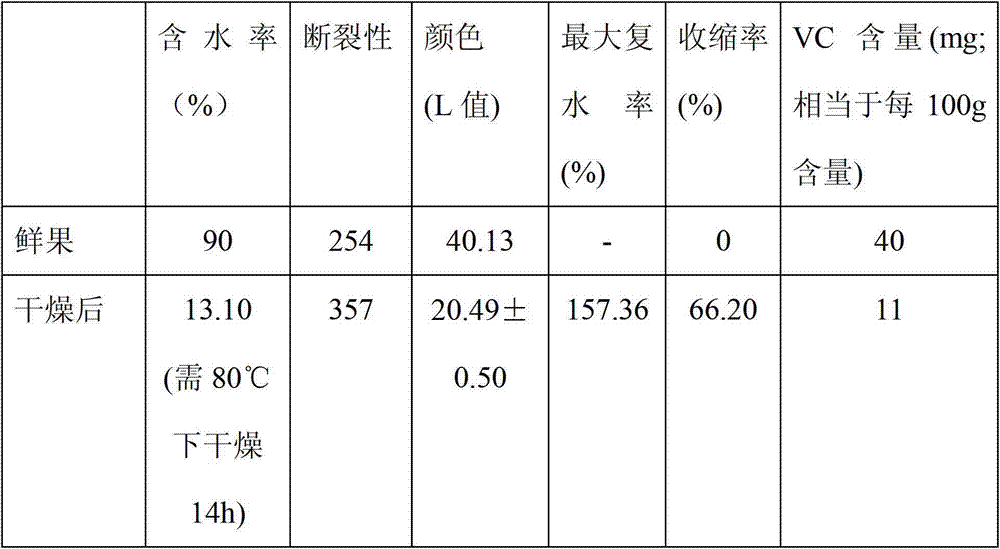

Vacuum microwave combined processing method for okra

InactiveCN103081982AHigh nutritional valueShorten drying timeFruits/vegetable preservation by dehydrationMicrowaveVitamin C

The invention discloses a vacuum microwave combined processing method for okra. The vacuum microwave combined processing method specifically comprises the following steps: step 1, selecting fresh okra fruits which are fresh, free of diseases and insect pests and uniform in color as raw materials; step 2, cleaning, namely, removing the root parts of the proper okra fresh fruits and the impurities on the surfaces of the okra fresh fruits; step 3, draining, namely, horizontally paving the cleaned fresh okra fruits on a bamboo sieve for draining; and step 4, carrying out vacuum microwave-drying, namely, putting the okra fresh fruits in a vacuum microwave drying chamber for drying to obtain the okra. According to the vacuum microwave combined processing method, after the vacuum microwave-drying, the color of the okra is maintained well, bigger in rehydration ratio, smaller in shrinking percentage, big in vitamin C content retention rate, good in product quality and high in drying efficiency.

Owner:HAINAN UNIVERSITY

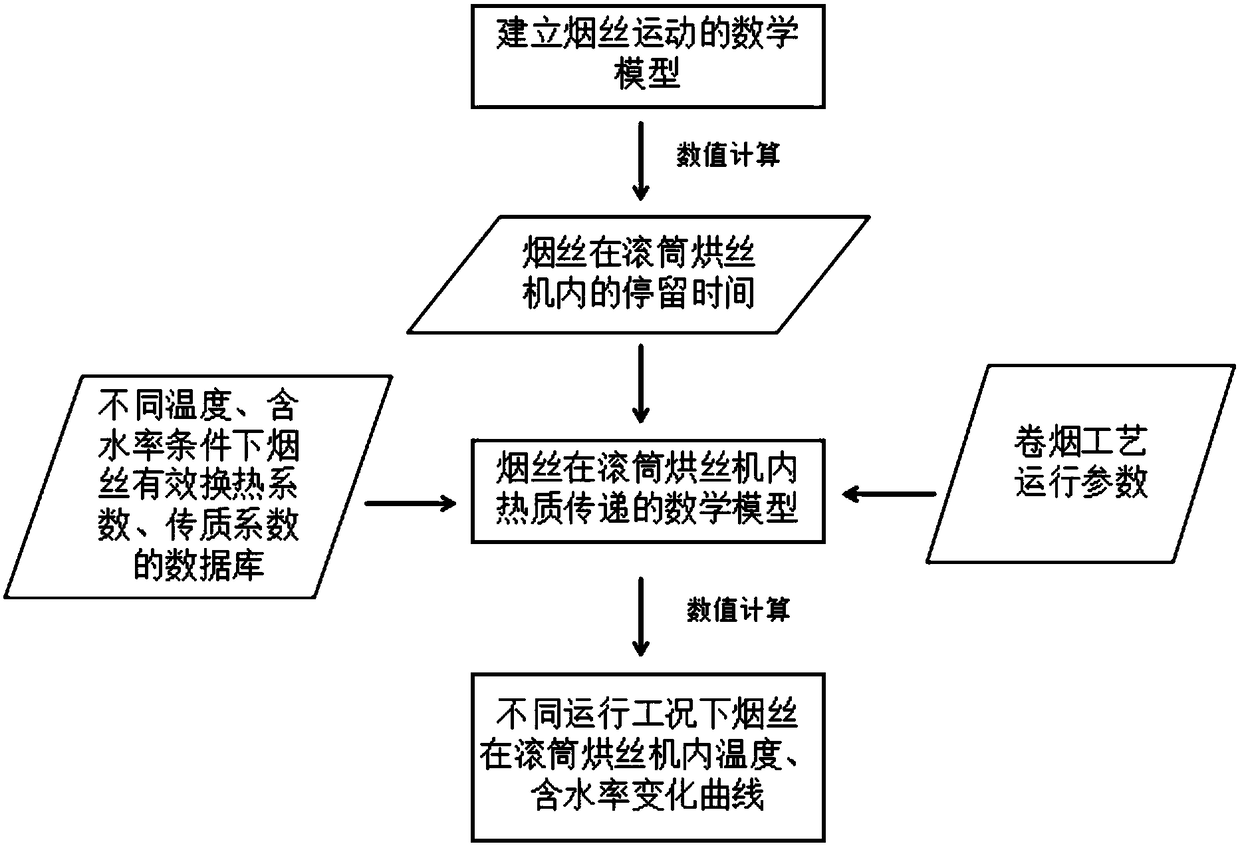

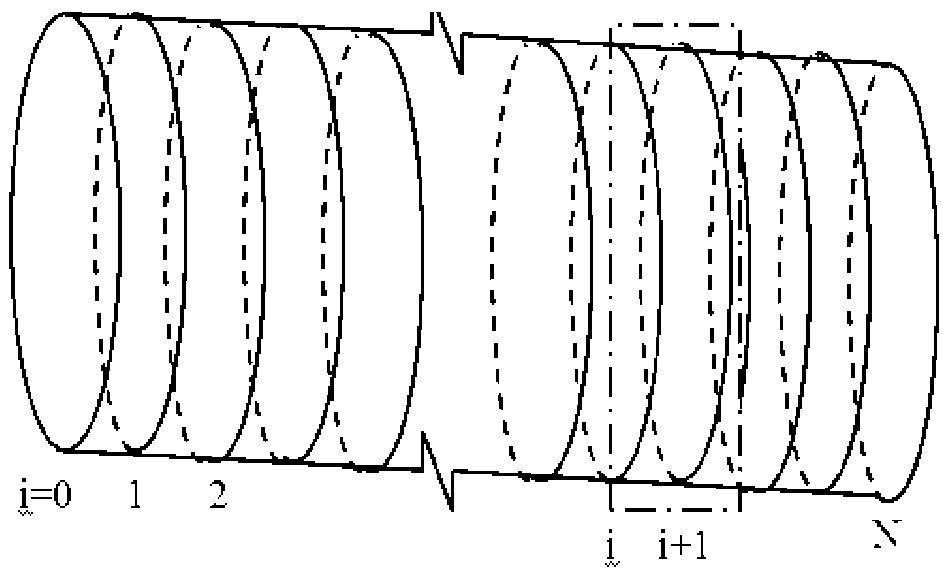

Numerical method for predicting heat and mass transfer law of tobacco shreds in drum dryer

ActiveCN109259291AOptimize the drying processReduce pollutionTobacco preparationDesign optimisation/simulationMathematical modelEmpirical formula

The invention discloses a numerical method for predicting the heat and mass transfer law of tobacco shreds in a drum dryer. The drum cut-tobacco dryer is axially divided into a plurality of equidistant micro-units, and a mathematical model of heat and mass transfer is established for tobacco shreds and air flow in each micro-unit. Based on mass conservation equation, energy conservation equation and heat-mass balance equation, the program is solved by computer language. The residence time involved in the mathematical model of heat and mass transfer of tobacco shreds was calculated by the motion model of tobacco shreds and the modified empirical formula. The effective heat transfer coefficient and mass transfer coefficient of tobacco under different temperature and moisture content were measured by experiment method, and the database was established. The data of the database was directly transferred into the program when calculating the temperature and moisture content of tobacco alongthe drum dryer axis. Finally, the operating parameters of the production process can be inputted into the simulation system to obtain the tobacco outlet temperature, moisture content and the drum dryer along the axial temperature and moisture content curves.

Owner:JIANGSU UNIV OF SCI & TECH

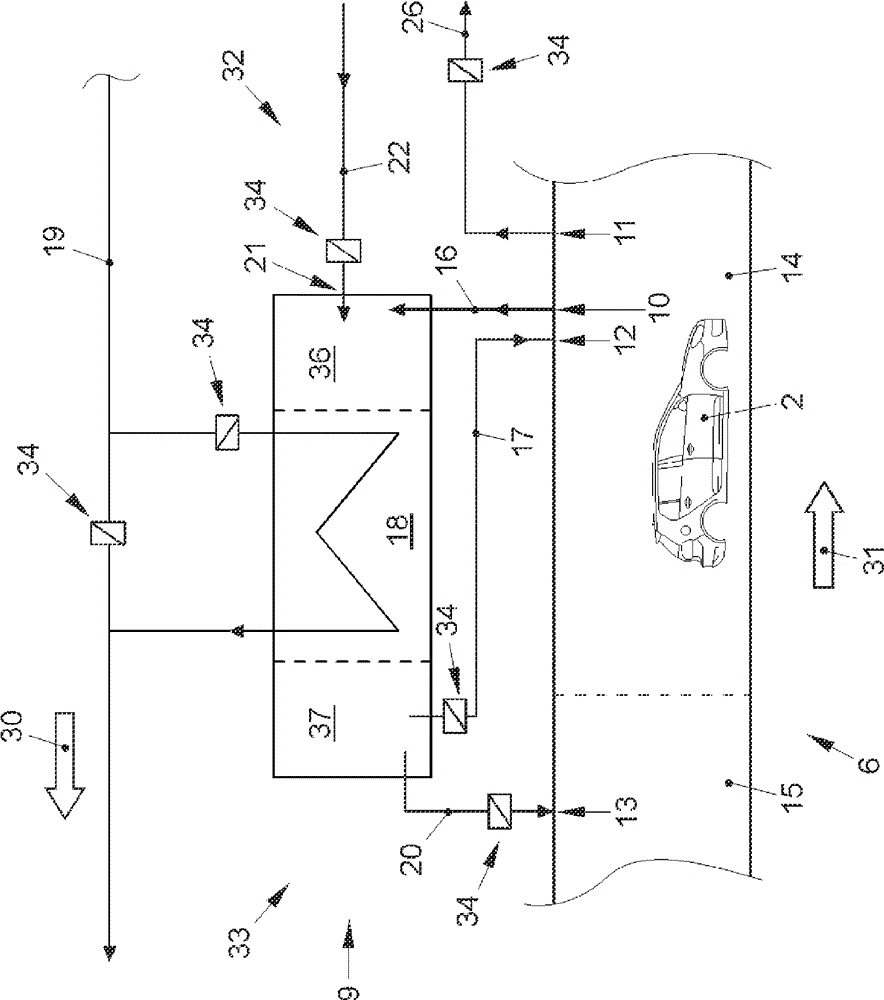

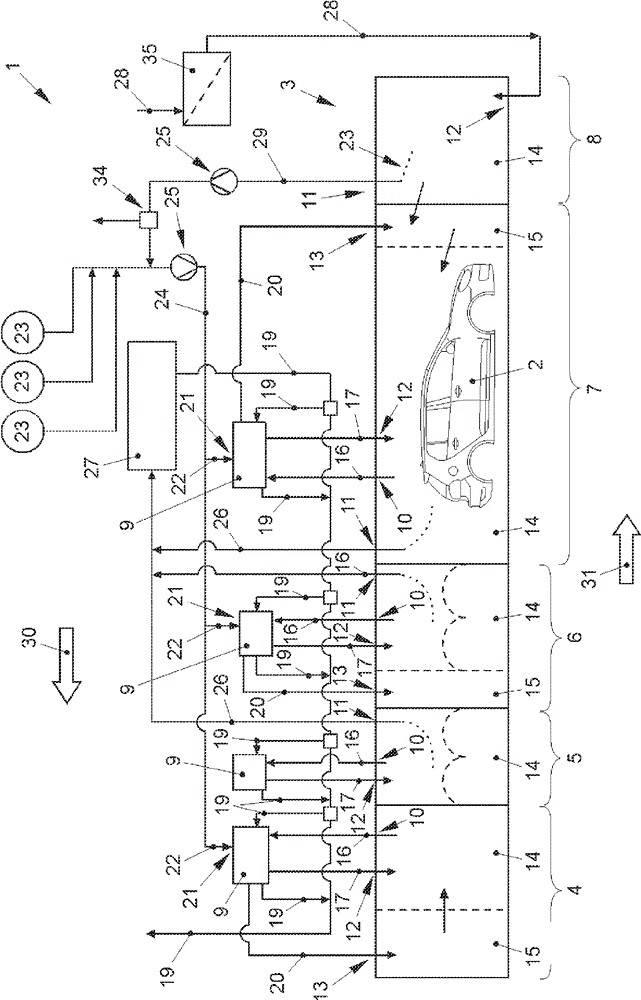

Device for drying a workpiece and method for operating such a device

ActiveCN104056765AReduce the introductionReduce formationPretreated surfacesDrying machines with progressive movementsAir exchangeHeating energy

The invention relates to a device for drying a workpiece and a method for operating such a device. The device has multiple tunnel portions comprising an air outlet and an air inlet and attached with a circulating air heating unit. Chamber exhaust air is supplied to the circulating air heating unit, the air circulating heating unit is provided with a heat exchanger, heat energy can be transmitted to the chamber supply air from primary air in the circulating air heating unit, the chamber supply gas can be transmitted tunnel portions through the air inlet, the circulating air heating unit comprises a fresh air intake and a mixing device, the fresh air is supplied to the circulating air heating unit through the fresh air intake, and the mixing device is used for mixing the fresh air with the chamber exhaust air. In the method for operating the device, before the fresh air supplied to independent tunnel portions is introduced to the tunnel portions, the fresh air is mixed with the chamber exhaust air to form the chamber supply air through the circulating air heating unit of the tunnel portions so that air exchange can be changeably adjusted.

Owner:VOLKSWAGEN AG

Method for preparing purple sweet potato powder by enzymolysis technology

The invention discloses a method for preparing purple sweet potato spray-dried powder, belonging to the technical field of intensive processing and production of agricultural products. The method comprises the following steps: selecting fresh purple sweet potatoes with no serious damage caused by plant diseases and insect pests; cleaning the purple sweet potatoes with water; peeling off and slicing the purple sweet potatoes with thickness of 2-4mm; carrying out hot iron with steam for 2-3min; beating the purple sweet potato slices with water by mass ratio of 12:88 and transmitting the mixture to a colloid mill for colloid milling twice; regulating the pH value of the purple sweet potato serosity to be 6.0-6.5; adding intermediate temperature alpha-amylase or heat-resistant alpha-amylase which accounts for 0.05-0.5% of the weight of the fresh sweet potatoes; stirring, preserving the temperature for 60-80min and carrying out enzyme denaturalixation; regulating the pH value of the purple sweet potato serosity after enzymolysis to be the initial value; and carrying out spray-drying with air inlet temperature of 120-180 DEG C and air outlet temperature of 50-90 DEG C. In the invention, starch in the purple sweet potatoes is decomposed into glucose maltose and other reducing sugars, thereby helping spray-drying competition, improving product mouthfeel and widening product application range.

Owner:JIANGSU UNIV

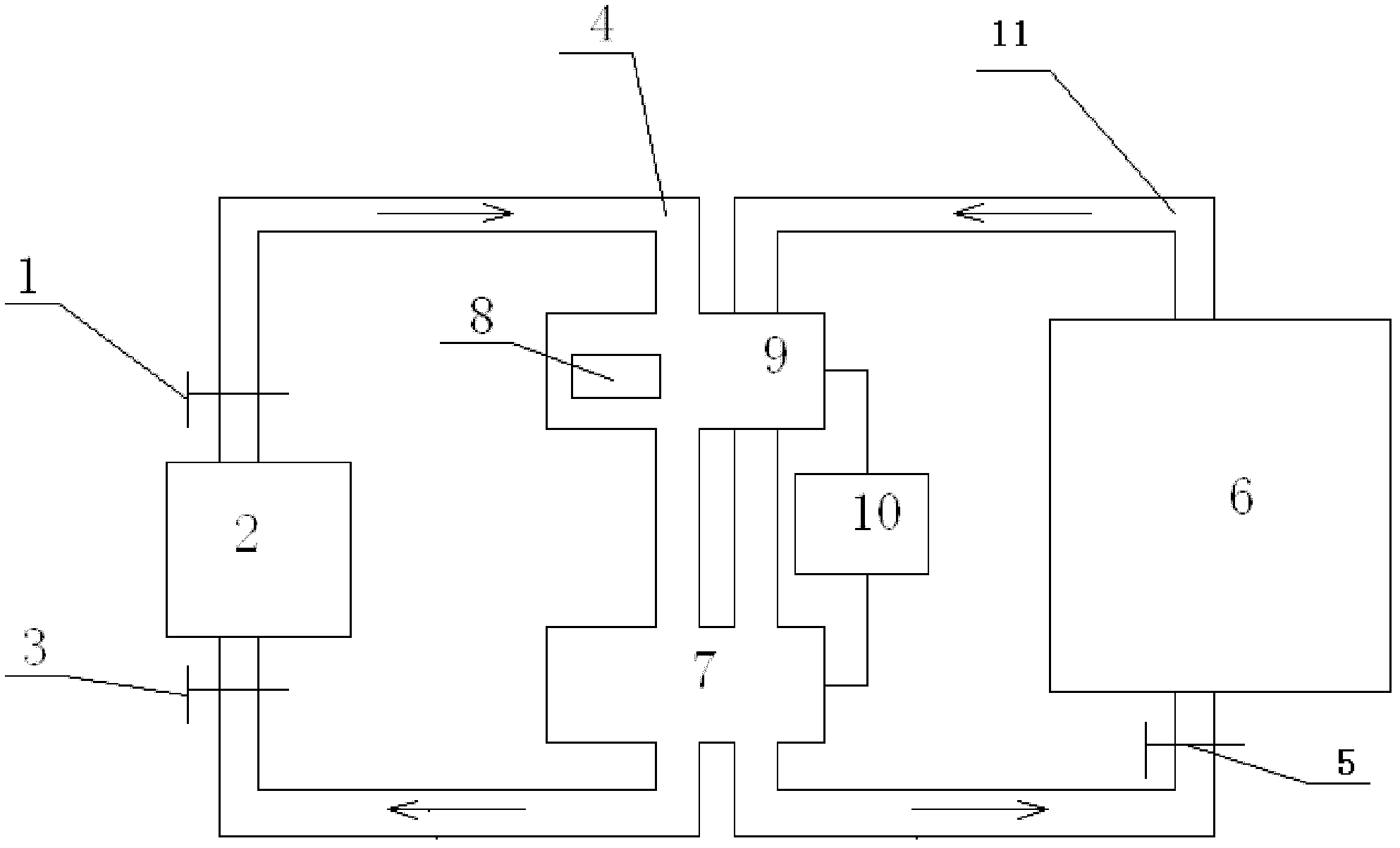

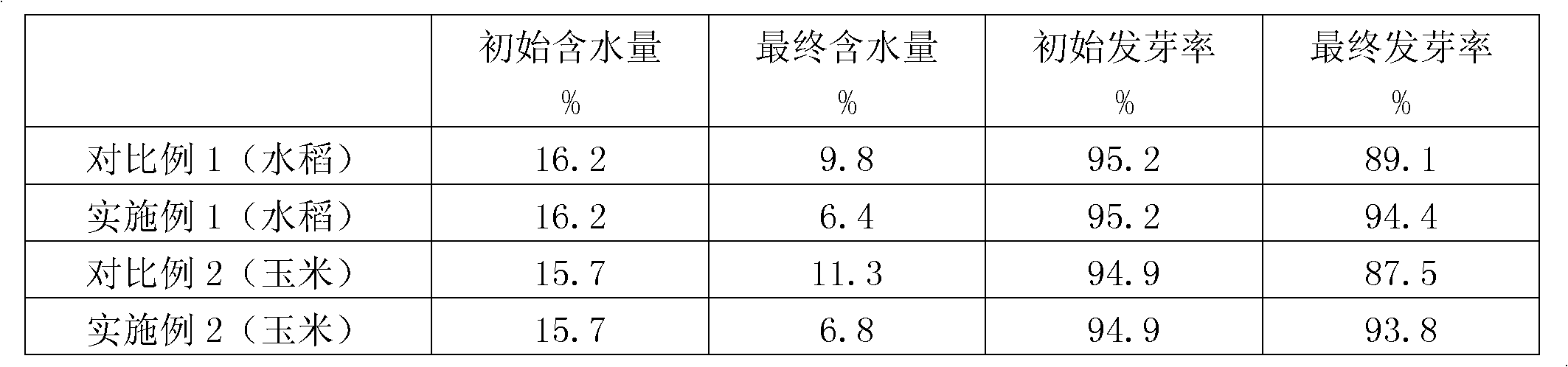

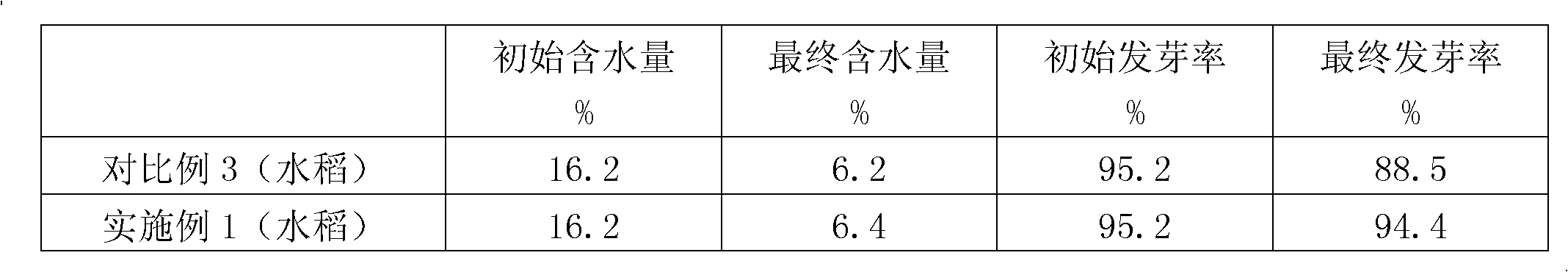

Safety drying method and drying device for long-term seed storage

ActiveCN102523846AEasy to store at low temperatureOptimize the drying processAgriculture tools and machinesDrying gas arrangementsEngineeringRefrigerated temperature

The invention relates to a safety drying method and a drying device for long-term seed storage. Five steps of predrying, preheating, drying, tempering and packaging are performed to seeds to safely reduce water content of the seeds to 5-7%, and the seeds are then quickly and hermetically stored in a seed box or seed bag to facilitate next low-temperature storage. The invention further provides the drying device used with the drying method. Main instruments such as a drying chamber, a drying box, a refrigerator, a dehumidifier, a temperature-humidity controller and the like are reasonably distributed and utilized, so that the drying process is optimized and drying efficiency is improved.

Owner:SHANDONG CROP GERMPLASM CENT

Graphene-containing graphene/ceramic conductive composite material and preparation method thereof

ActiveCN108774052AImprove density and strengthImprove conductivityAdditive manufacturing apparatusGraphiteCvd grapheneConductive materials

The invention discloses a graphene-containing graphene / ceramic conductive composite material and a preparation method thereof, and belongs to the field of preparation of conductive materials. The preparation method mainly comprises the following steps: preparation of a graphite skeleton, strengthening treatment of the skeleton, preparation of a ceramic slurry, casting and drying of graphite / ceramic, and sintering. The graphite / ceramic conductive composite material prepared through the method is prepared by directly controlling composition components and the size structure of the graphite and improving the strengthening post-treatment of the conductive performance of the graphite skeleton, the sintering process and the drying process. The addition of graphene improves the internal loose porous structure problem of the graphite skeleton, increases conductive pathways, improves the strength of the graphite skeleton, and improves the conductive performance of the material while ensuring mechanical performances. The graphite / ceramic composite material has the conductive performance of the graphite, and also has the structure characteristics of ceramic.

Owner:CHINA THREE GORGES UNIV

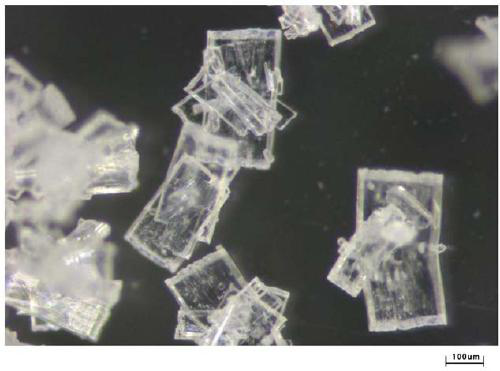

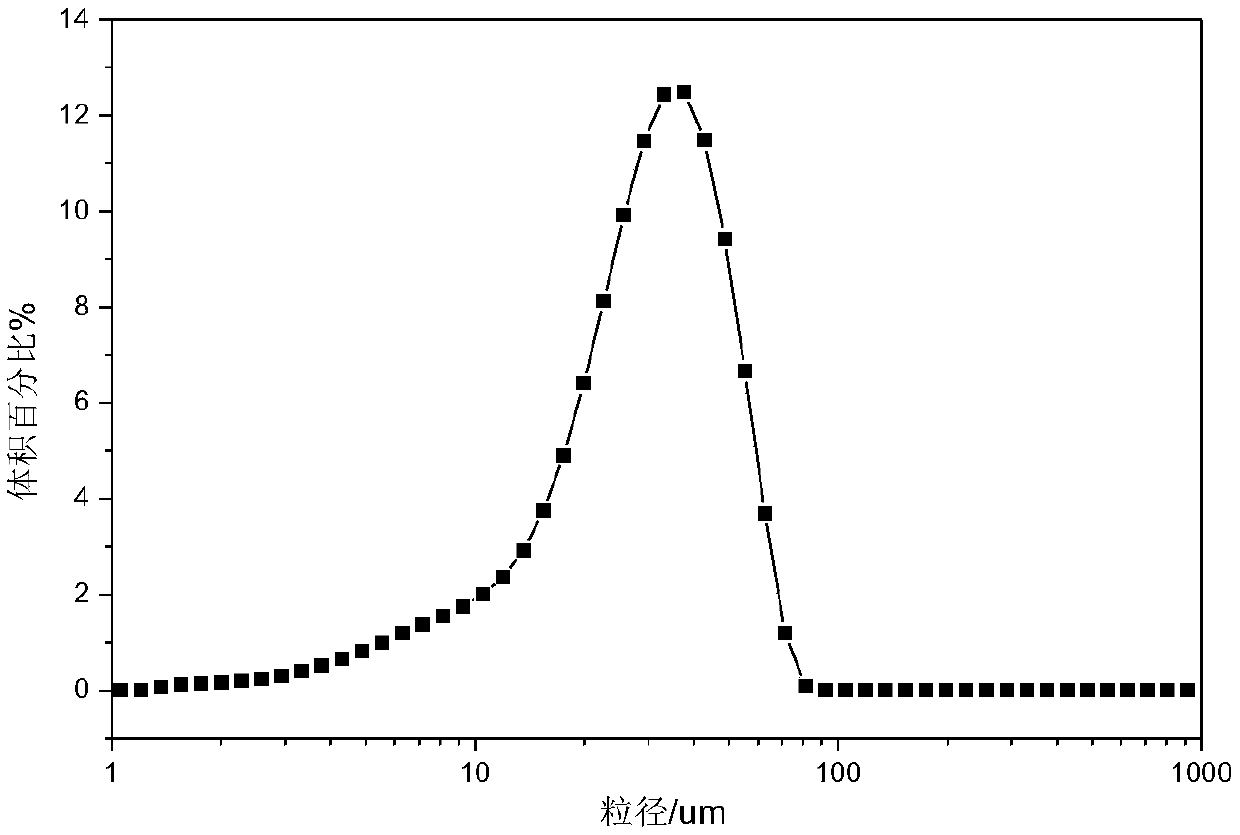

Crystallization method for improving crystal habit of ethyl vanillin by adding polyvinylpyrrolidone

ActiveCN109534978AFine granularityIncreasing the thicknessCarbonyl compound separation/purificationMagmaFiltration

The invention relates to a crystallization method for improving the crystal habit of ethyl vanillin by adding polyvinylpyrrolidone. The method includes: adding an ethyl vanillin crude product and polyvinylpyrrolidone into a mixed solvent, performing stirring and heating to 35DEG C-50DEG C for dissolution, after the solid is completely dissolved, performing cooling to 15DEG C-25DEG C, adding ethylvanillin seed crystal, conducting grain growing for 10-40min, then performing cooling to 0DEG C-10DEG C, filtering the magma and conducting drying to obtain a ethyl vanillin crystal. The ethyl vanillin product prepared by the method provided by the invention has nonbreakable crystal, is thick flake shaped, has a height-to-width ratio of 0.11-0.25, large particle size, a main particle size of 275-508microm, a tap density up to 0.31-0.47g / mL, good fluidity and a repose angle of 37-47DEG C. The product obtained by the method is easy for filtration and drying, and is beneficial to storage and transportation, thus greatly improving the market competitiveness of the product.

Owner:TIANJIN UNIV

Special steel drainage agent and preparation method thereof

ActiveCN109202055AAppropriate refractorinessImprove liquidityMelt-holding vesselsGranularityNuclear power

The invention provides a special steel drainage agent and a preparation method thereof and belongs to the technical field of metallurgical fireproof materials. The special steel drainage agent is prepared by following raw materials of, by weight, 22-75 parts of natural zircon sand with granularity of 0.1-0.5mm, 8-40 parts of chrome ore with granularity of 0.1-0.5mm, 15-35 parts of desert sand withgranularity of 0.3-0.6mm and 1-3 parts of liquid graphite. According to the invention, the pouring rate of a product can be effectively improved; compared with the existing drainage agent, the automatic pouring rate can be improved by 10% or over and the basic automatic pouring rate can reach 100%; requirements are met that there are many types of special steel currently, the difference of components is big and long-time smelting is required; and the drainage agent and better drainage effects for steel types in war industry, nuclear power and special high-quality products are achieved.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

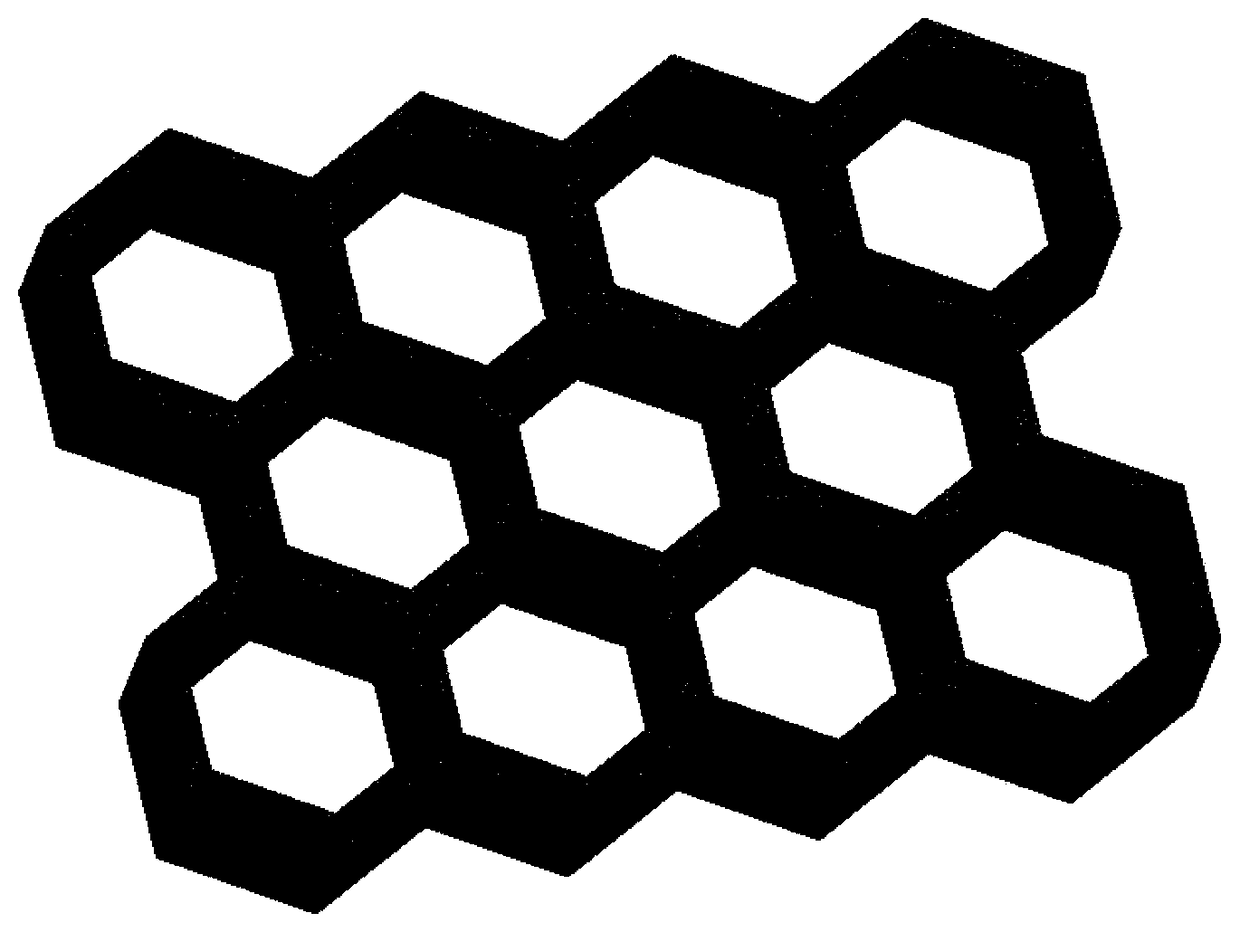

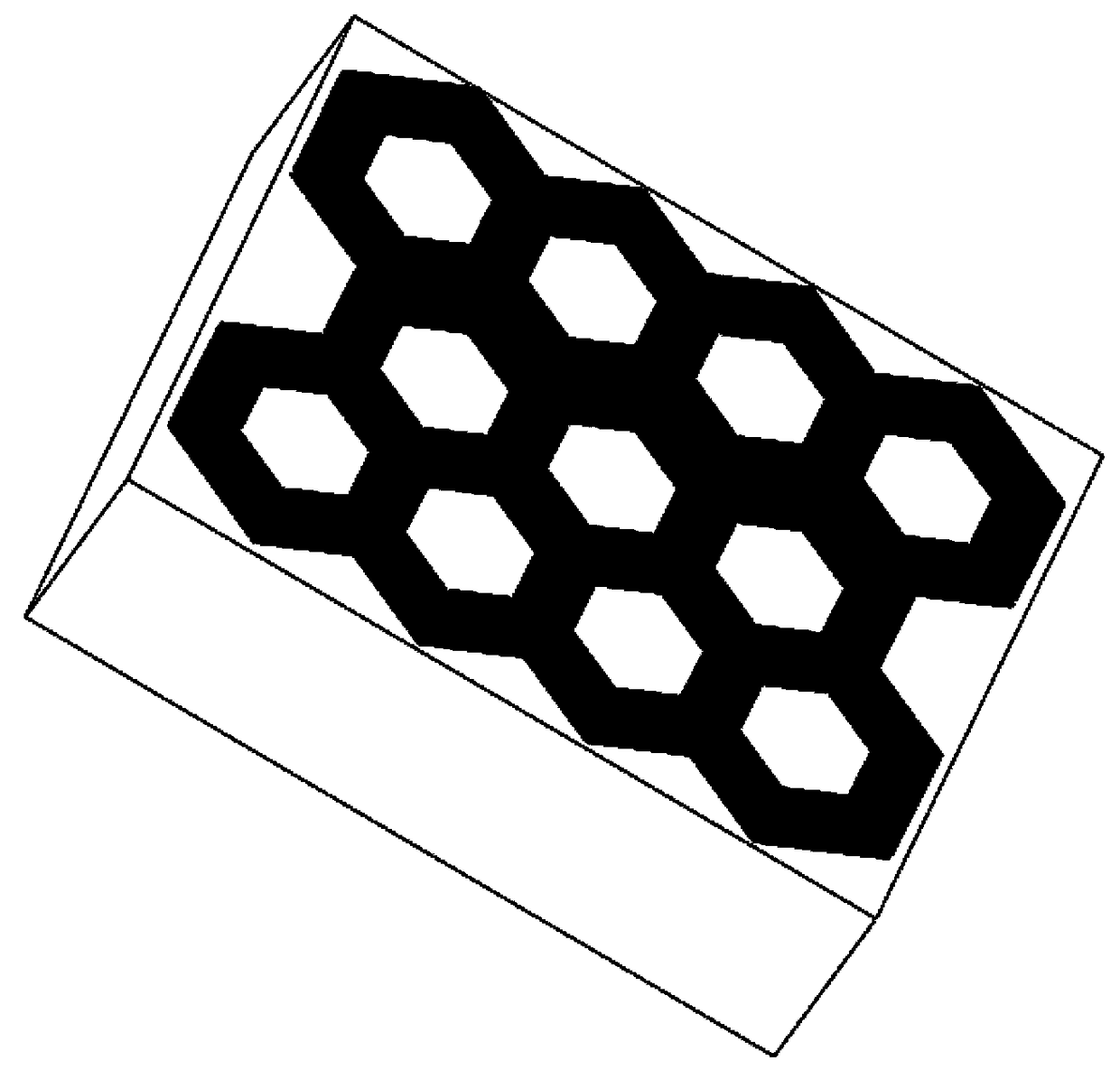

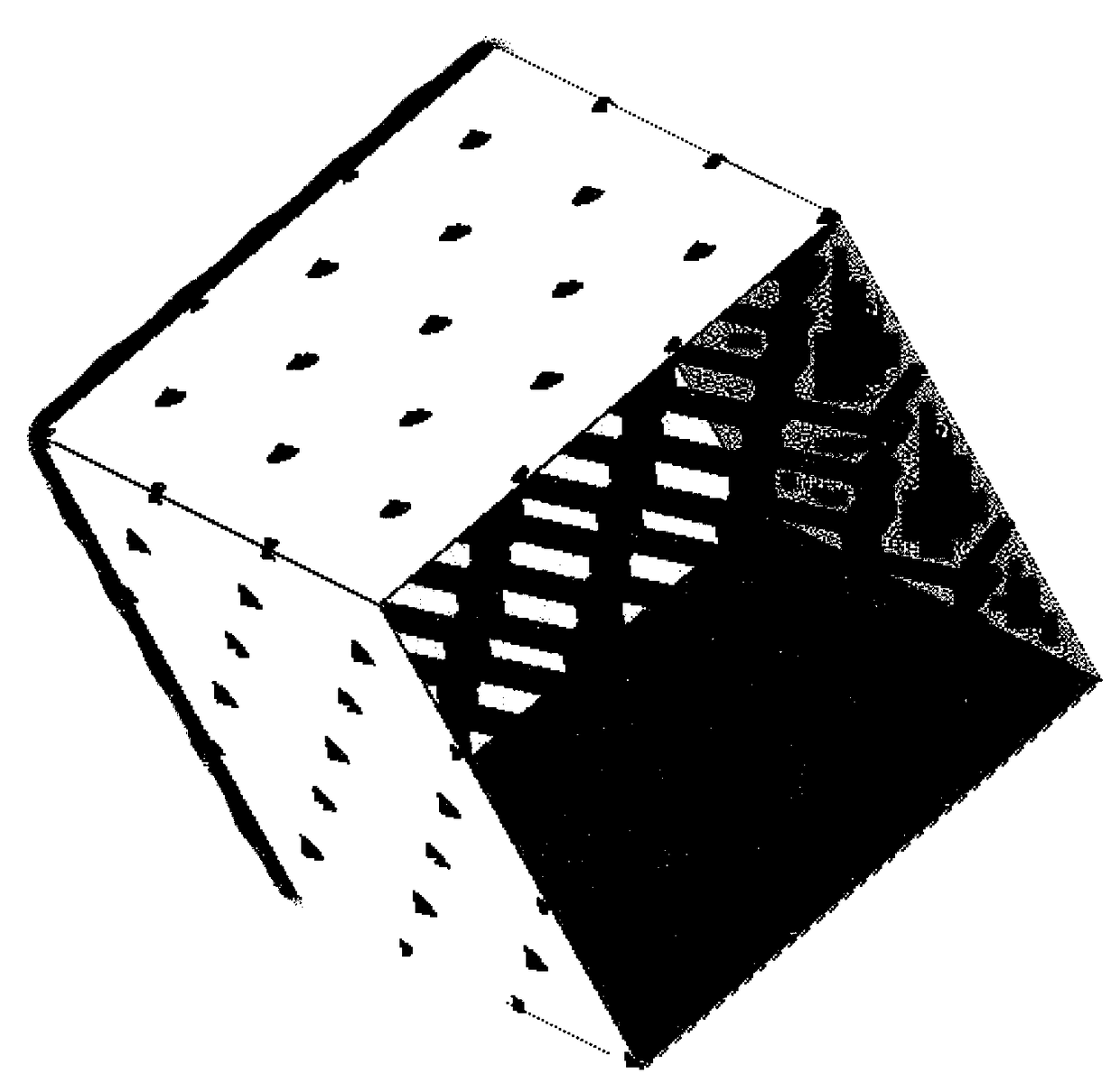

Ceramic with spatial three-dimensional conductive network structure and preparation method thereof

The invention discloses a ceramic with a spatial three-dimensional conductive network structure and a preparation method thereof, and belongs to the field of preparation of conductive materials. The preparation method mainly includes four steps of designing and strengthening treatment of a graphite framework three-dimensional structure, preparation of ceramic slurry, pouring process and drying andsintering process. A graphite / alumina ceramic composite material prepared by the method can be directly prepared by control of the composition, the size structure and post-treatment of the graphite and the improvement of the sintering process and the drying process. Under the premise that the conductivity is improved, the mechanical properties are guaranteed to achieve on-demand distribution of the graphite. The graphite / alumina ceramic composite material can have the conductivity of the graphite and structure characteristics of the ceramic, such as chemical stability, high temperature resistance, oxidation resistance, radiation resistance, corrosion resistance and the like, thereby having broad application prospects.

Owner:CHINA THREE GORGES UNIV

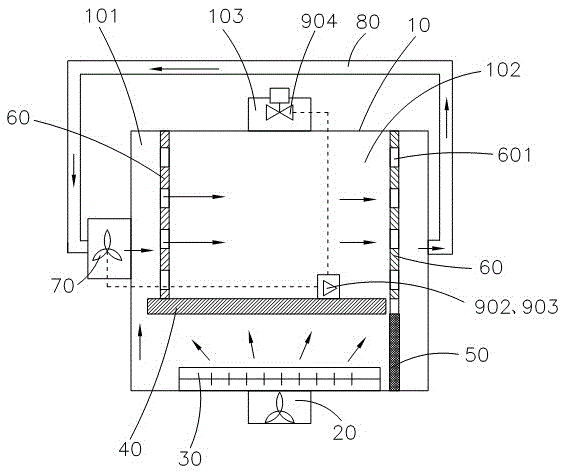

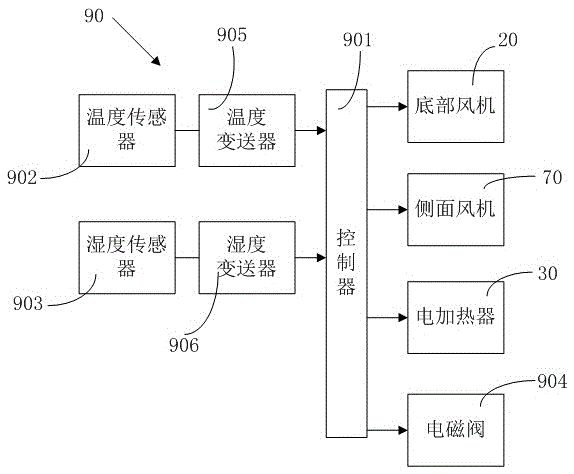

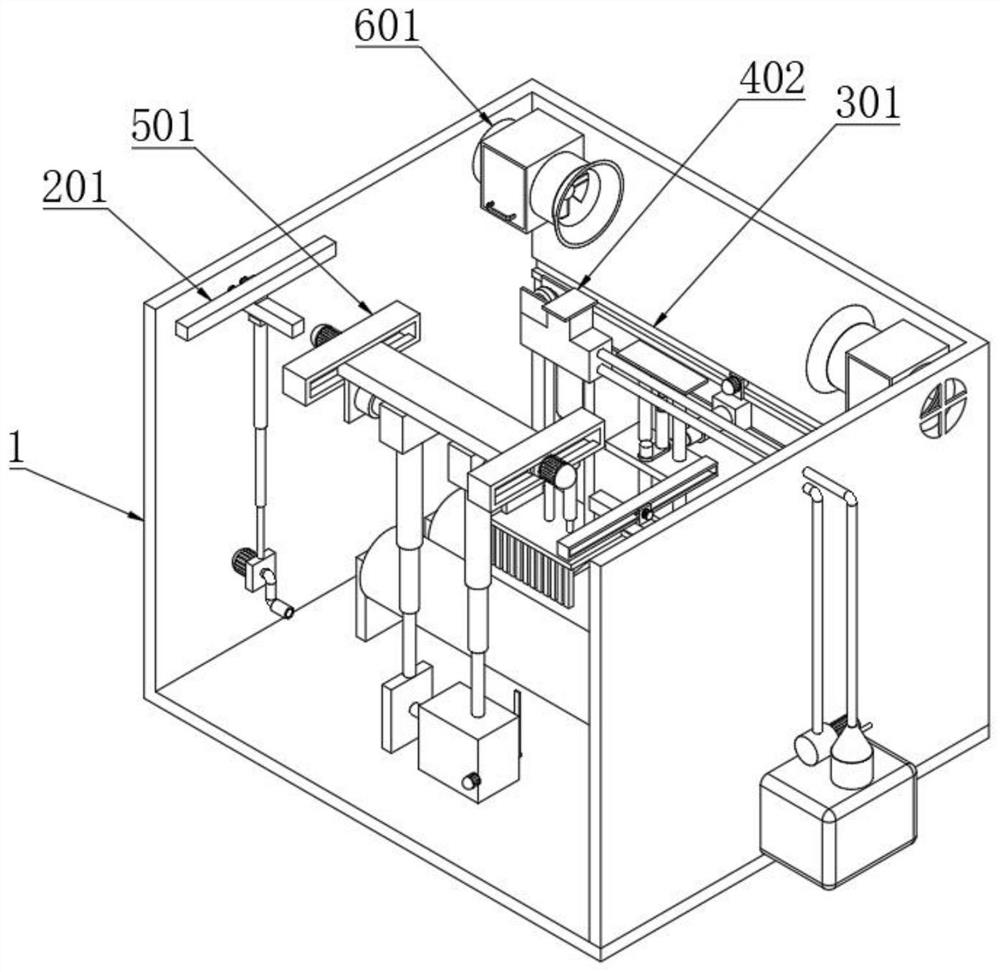

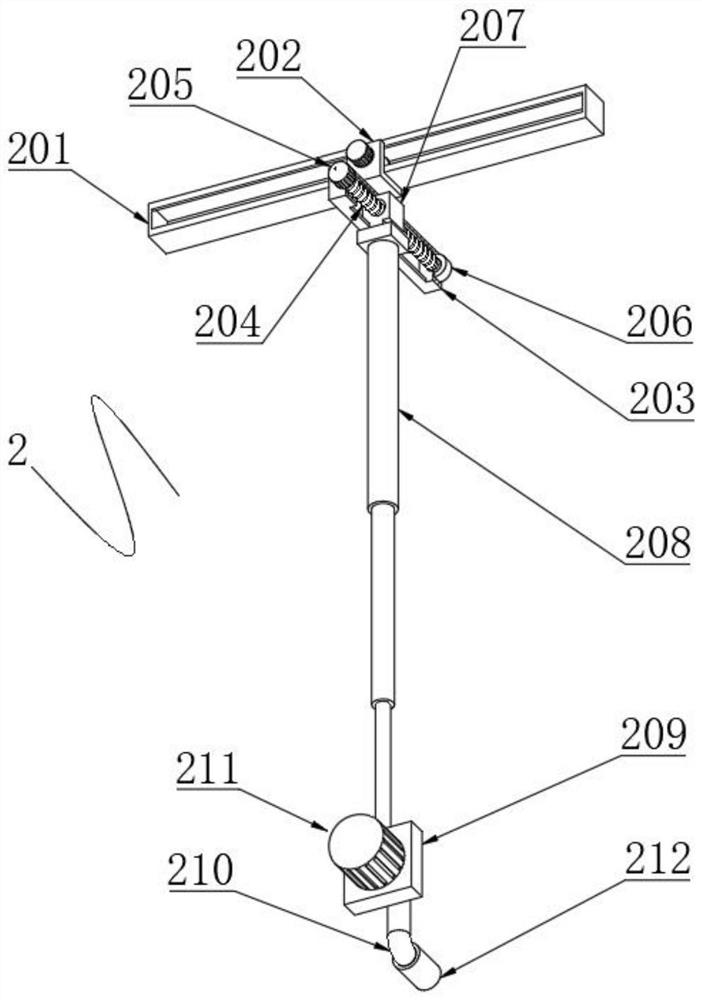

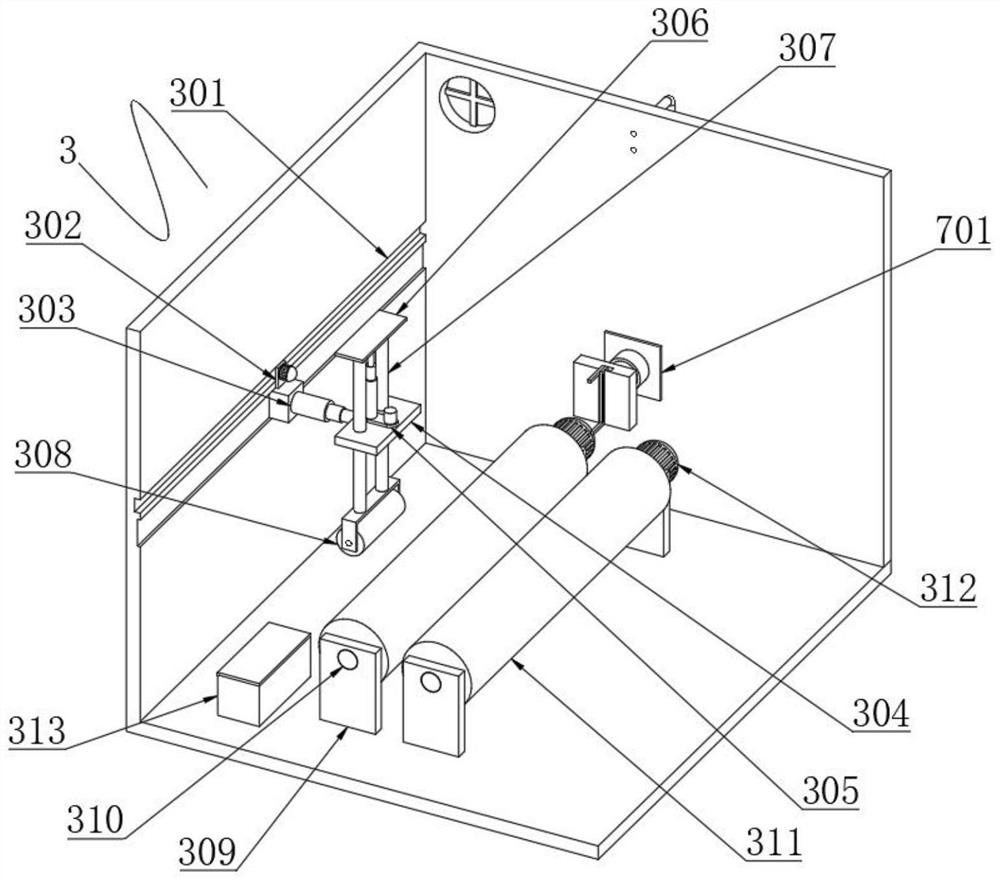

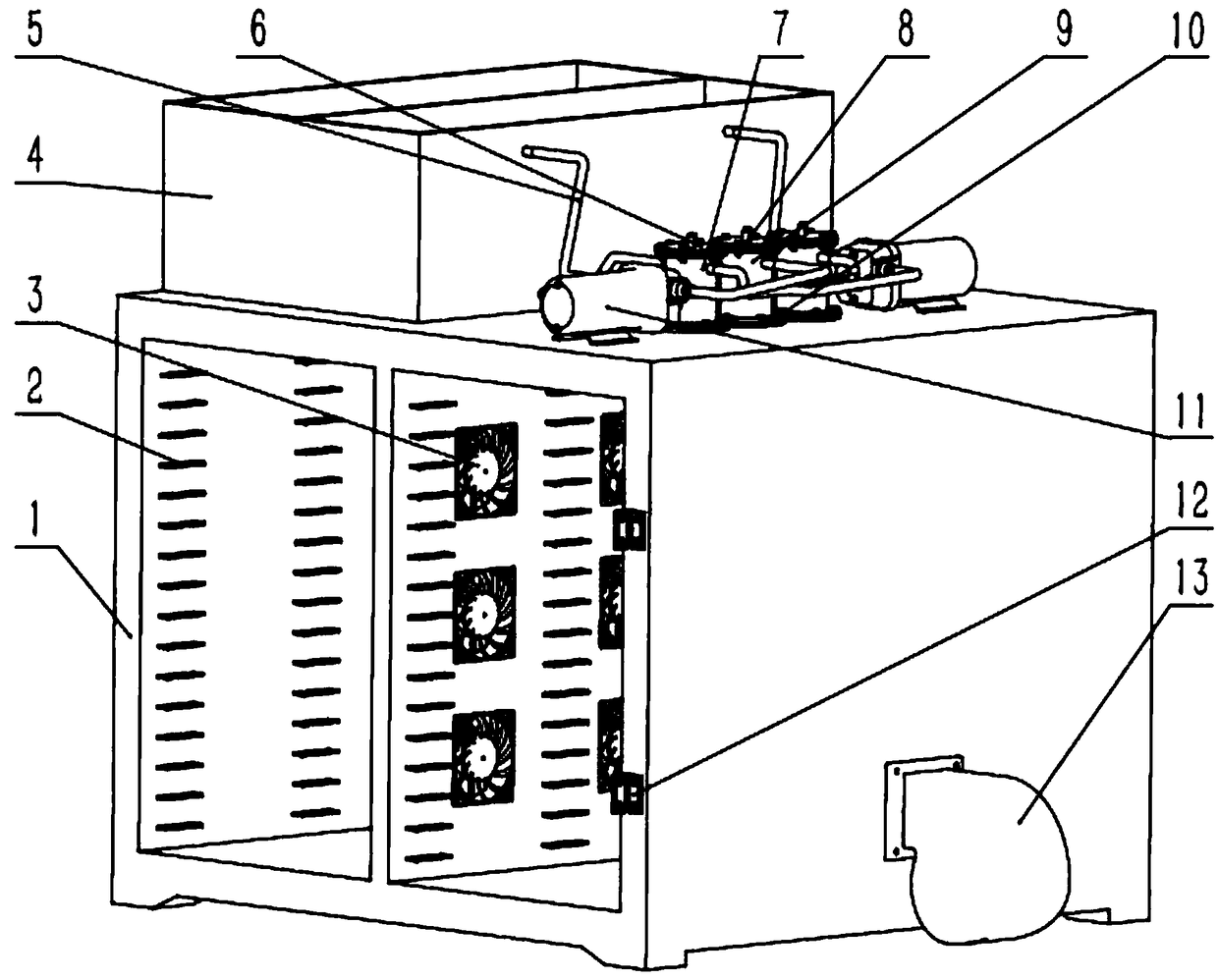

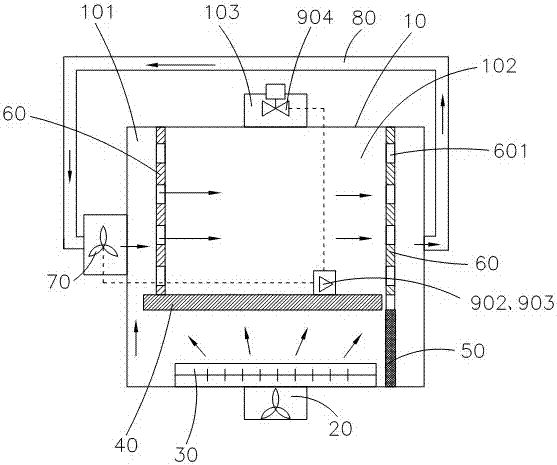

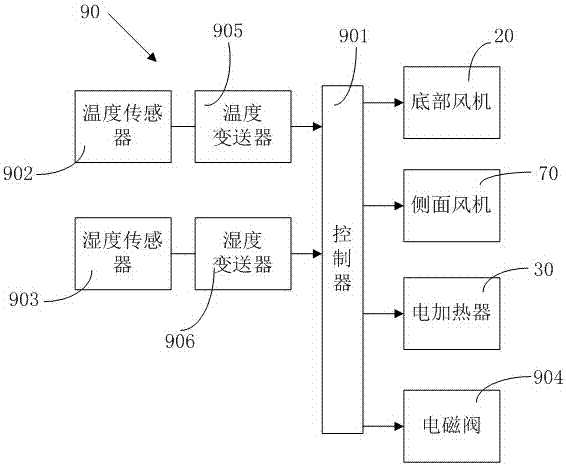

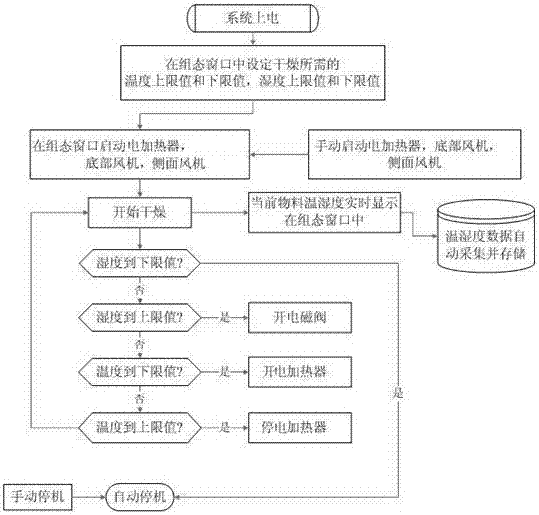

Energy-saving small hot air drier

ActiveCN105546951AEasy extractionEasy to storeDrying gas arrangementsDrying solid materialsElectricityAerospace engineering

The invention provides an energy-saving small hot air drier. An outer box is provided with an inner cavity; a bottom draught fan is arranged at the bottom of the outer box; an electric heater and an air pipe connected with the bottom draught fan are oppositely arranged; an air pressing plate is located over the electric heater, and gaps are formed between at least one end of the air pressing plate and the two side walls of the outer box; a sealing plate is located on one side of the electric heater; two partition plates are provided with holes and arranged in a spaced mode, and a drying chamber is formed among the partition plates and the air pressing plate; a side-face draught fan is arranged on one side of the outer box, and an air outlet of the side-face draught fan and the drying chamber are oppositely arranged; an air exhaust outlet is formed in the top of the outer box and communicated with the inner cavity of the outer box; one end of a circulating air pipe is connected to the side wall, opposite to the side-face draught fan, of the outer box, and the other end of the circulating air pipe is connected with an air inlet of the side-face draught fan. The energy-saving small hot air drier is simple in overall structure, high in practicability, easy to use and popularize and good in drying effect.

Owner:山东百佳食品有限公司

Pipeline preparation device based on building electrical firefighting

ActiveCN111734919AScientific and reasonable structureSafe to useHollow article cleaningPretreated surfacesFirefightingCorrosion prevention

The invention discloses a pipeline preparation device based on building electrical firefighting. The device comprises a fixed rack; a lifting door is installed on one side of the fixed rack; a feedingmechanism is arranged inside the fixed rack; the feeding mechanism comprises a sliding rod, a sliding plate, a connecting rod, a threaded rod, a threaded motor, a rotary disc, a sliding block, a lifting hydraulic rod, a connecting plate, an S-shaped rotating shaft, a rotating shaft motor, and an antiskid sleeve. According to the feeding mechanism, through the sliding rod, the sliding plate, the connecting plate, the threaded rod, the threaded motor, the rotary disc, the sliding block and the lifting hydraulic sleeve, a worker can conveniently move the position of the connecting plate toward multiple directions, and through the S-shaped rotating shaft, the rotating shaft motor and the antiskid sleeve, the worker can realize convenient clamping and transportation of a pipeline, so manual transportation of the pipeline by the worker is avoided, the difficulty of pipeline transportation of the worker is lowered, and therefore working efficiency of the worker in anti-corrosion manufacturing of the pipeline is improved.

Owner:JILIN JIANZHU UNIVERSITY

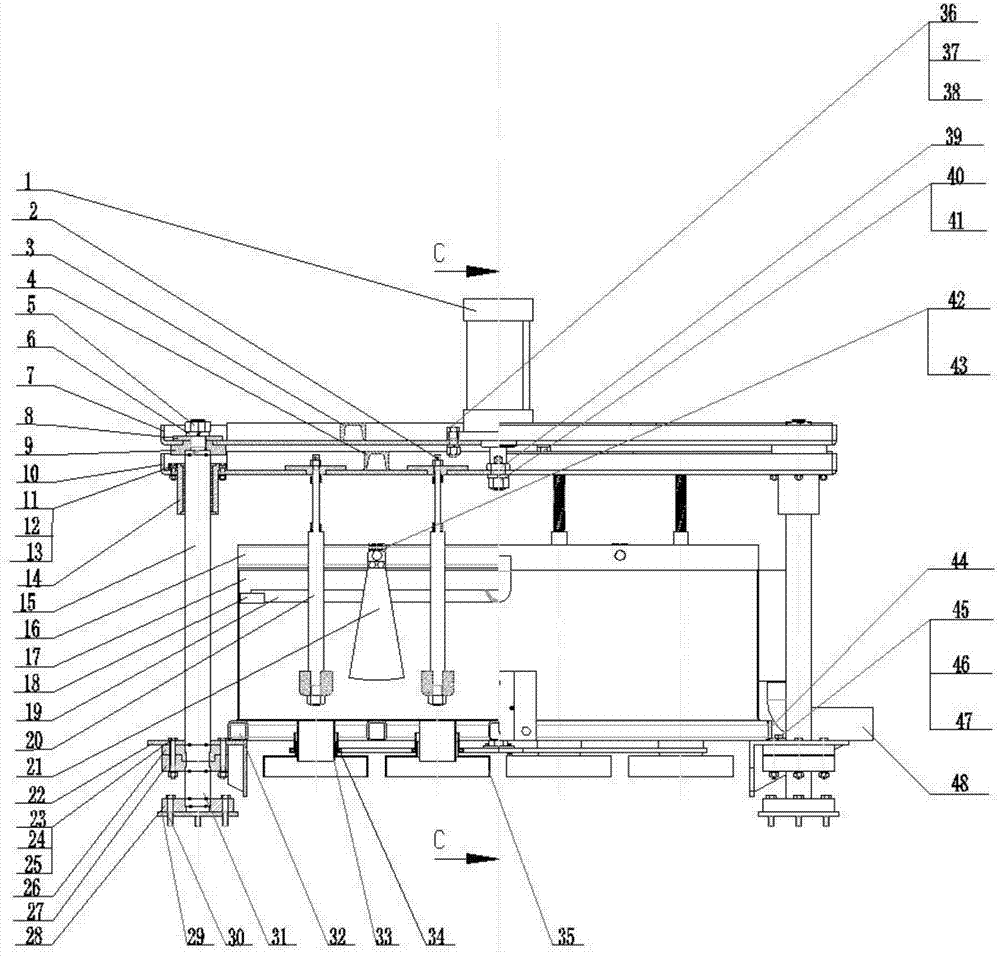

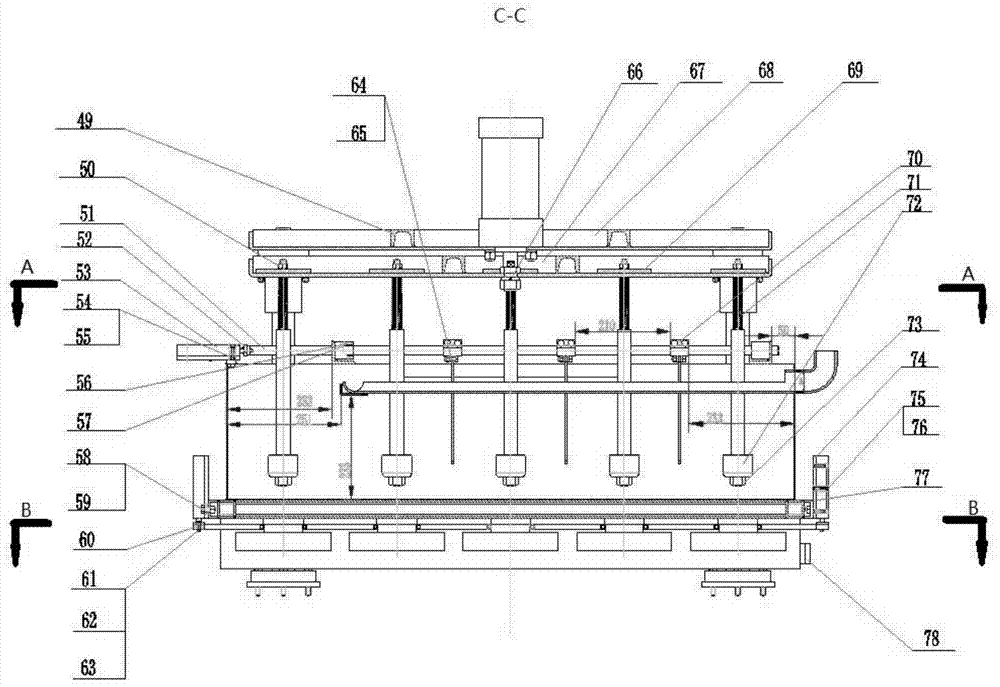

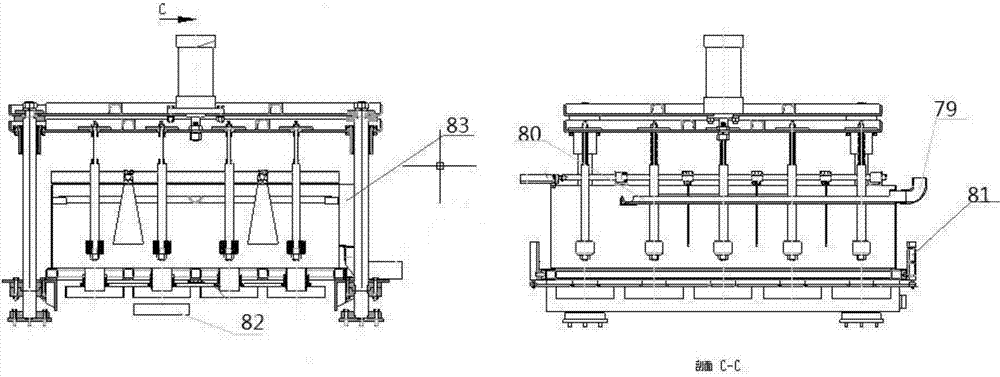

Round cake type nori dehydrating, blanking and forming equipment and forming method

ActiveCN104256733AEasy to set upGuaranteed uniformityFood shapingFood preparationAgricultural engineering

The invention discloses round cake type nori dehydrating, blanking and forming equipment, which comprises a machine frame, a blanking mechanism and a receiving device; the machine frame comprises four lower upright posts fixed on the ground and an upper upright post connected with the four lower upright posts; the upper upright post passes through a lateral plate, an upper guide sleeve and a cushion plate in sequence; a trough reinforcing frame is arranged over the lateral plate; a cylinder fixing plate and a lower cylinder movable plate are fixed on the top of the upper upright post; the blanking mechanism comprises a trough, a pull rod system and a stirring system; the trough is arranged on the trough reinforcing frame; the front and rear sides of the trough are respectively connected with the lateral plate; an upper cylinder is arranged at the rear of the trough and fixed on the cylinder fixing plate; and an upper cylinder piston rod in the upper cylinder passes through the cylinder fixing plate and is connected with the lower cylinder movable plate. The invention further discloses a method for blanking and forming nori by using the forming equipment; after the nori and water are sufficiently stirred and mixed in the trough, blanking and forming are carried out through the blanking mechanism, and therefore, the problems of being non-uniform in feed liquid preparation and low in cake making efficiency and only capable of producing thin cakes of the existing device are solved.

Owner:SHAANXI UNIV OF SCI & TECH

Lithium ion battery silicon-carbon negative electrode binder, and negative electrode sheet and preparation method thereof

ActiveCN112038633AOptimize the drying processReduces total drying timeElectrode thermal treatmentSecondary cellsPhysical chemistryALLYL SUCROSE

The invention relates to the technical field of lithium ion batteries, provides a lithium ion battery silicon-carbon negative electrode binder, and a negative electrode sheet and a preparation methodthereof, and aims to solve the problems of uneven distribution of a binder in the longitudinal direction of an electrode sheet, reduction of the adhesive force of a coating layer and high production cost easily caused by a traditional negative electrode coating and baking process. The lithium ion battery silicon-carbon negative electrode binder is selected from one or a combination of two of polyallylamine hydrochloride and polyacrylic acid polybenzimidazole. According to the invention, by adopting the novel polymer binder and optimizing the electrode sheet drying process, the migration of thebinder in the electrode sheet is effectively inhibited, the longitudinal distribution uniformity of the binder in the negative electrode sheet is improved, the battery performance is improved, the electrode sheet baking time is shortened, and the battery manufacturing cost is reduced.

Owner:WANXIANG 123 CO LTD

Drying process for high-strength and high-modulus ultrahigh molecular weight polyethylene fibre

InactiveCN101525775ALow solvent contentOptimize the drying processArtificial filament washing/dryingMonocomponent polyolefin artificial filamentState of artFiber

The invention relates to a drying process for a high-strength and high-modulus ultrahigh molecular weight polyethylene fibre. The drying process adopts a drying system by hot-blast forced circulation; and adopted drying equipment comprises a tank type or a corridor form. Compared with the prior art, the drying process improves a drying process of the production of a ultrahigh molecular weight polyethylene fibre, adopts the hot-blast forced circulation, greatly improves the drying efficiency, reduces the solventcontent of fibre yarn in the drawing process, establishes a good foundation for improving the drawing speed in the drawing procedure and the product quality, and can obtain the high-strength (more than 35 g / d) ultrahigh molecular weight polyethylene fibre.

Owner:SURREY HI TECH INC

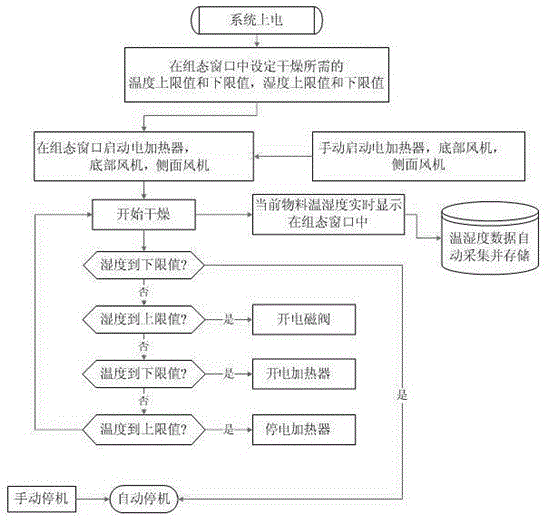

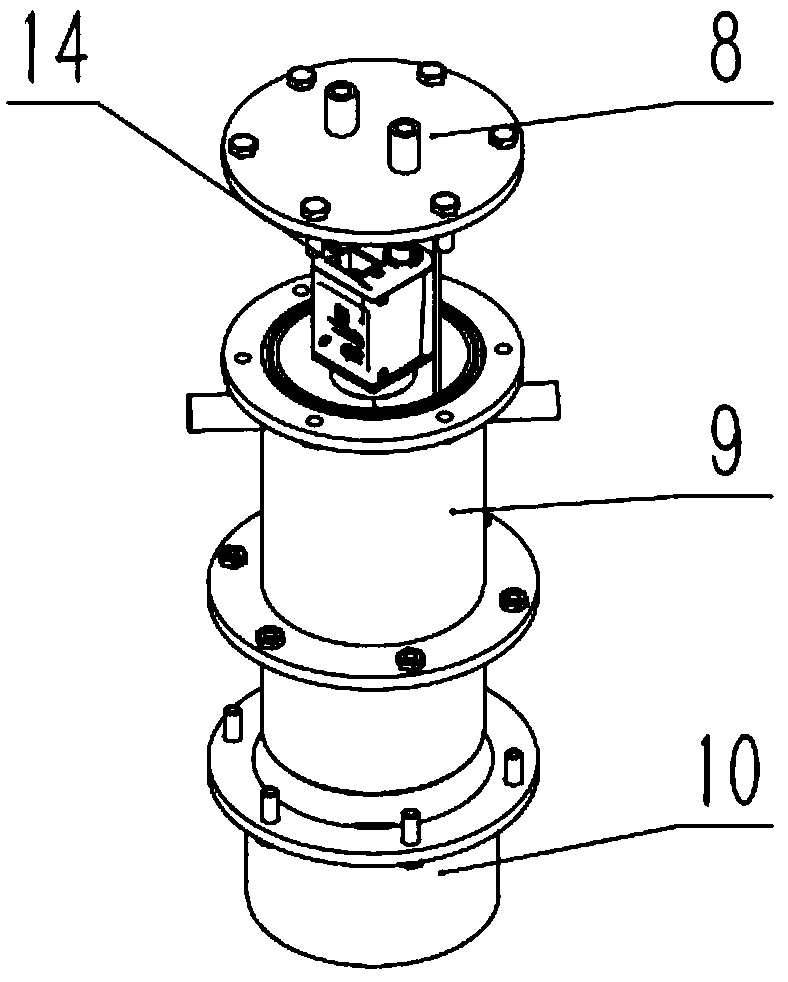

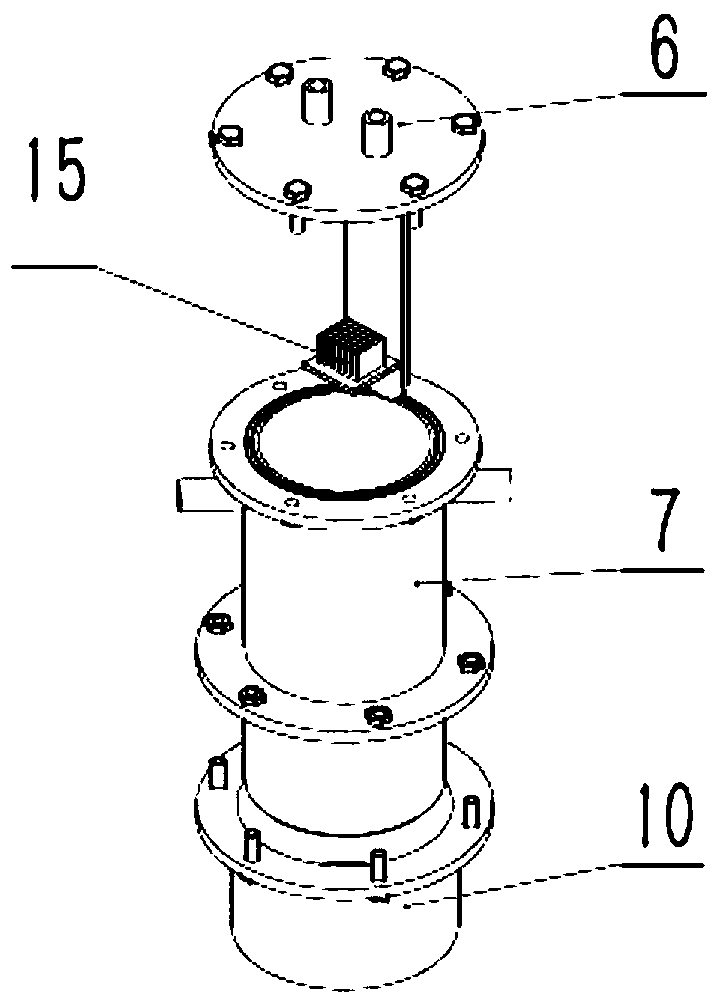

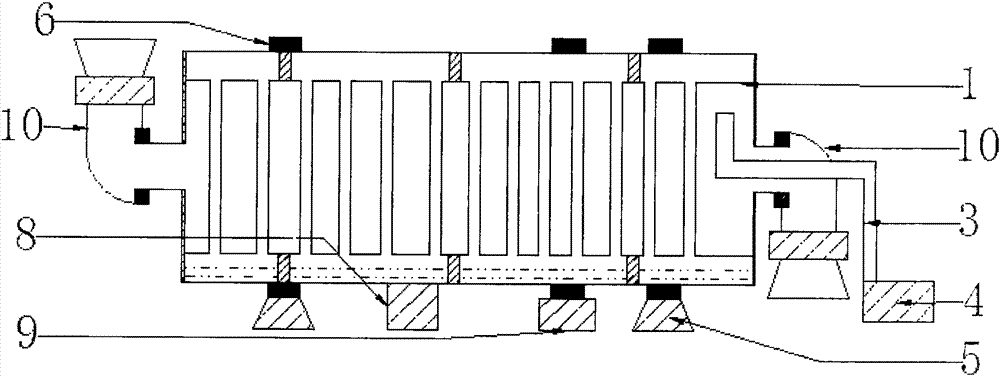

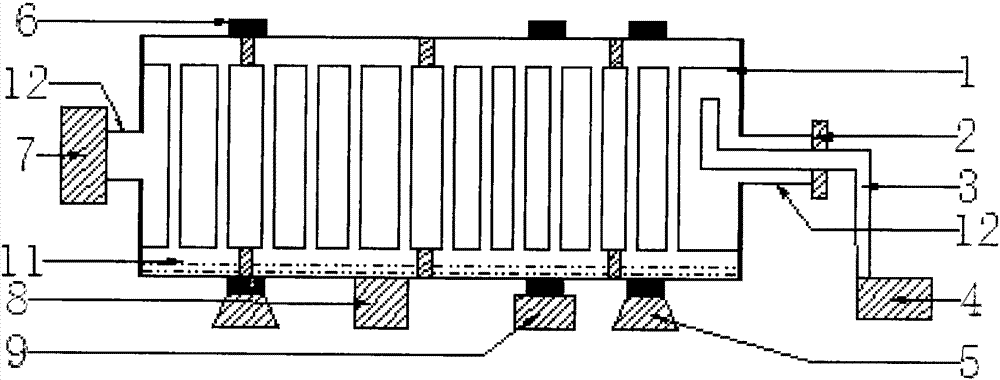

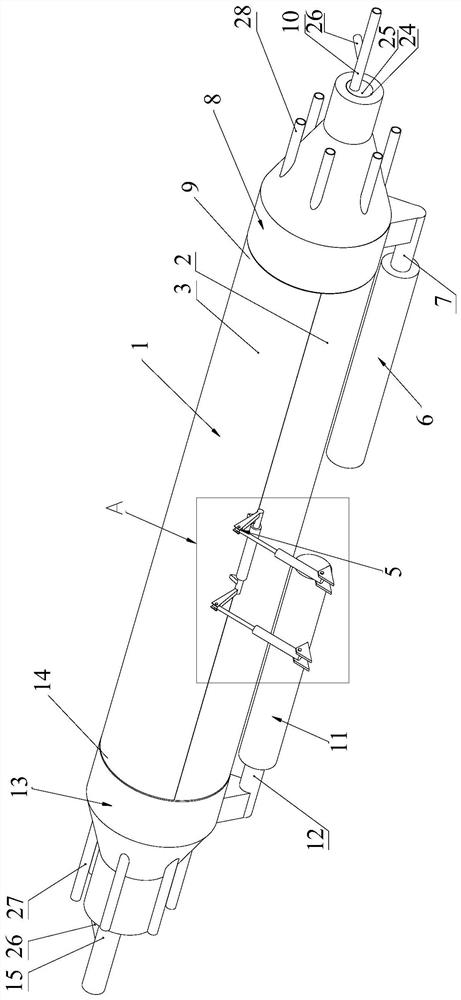

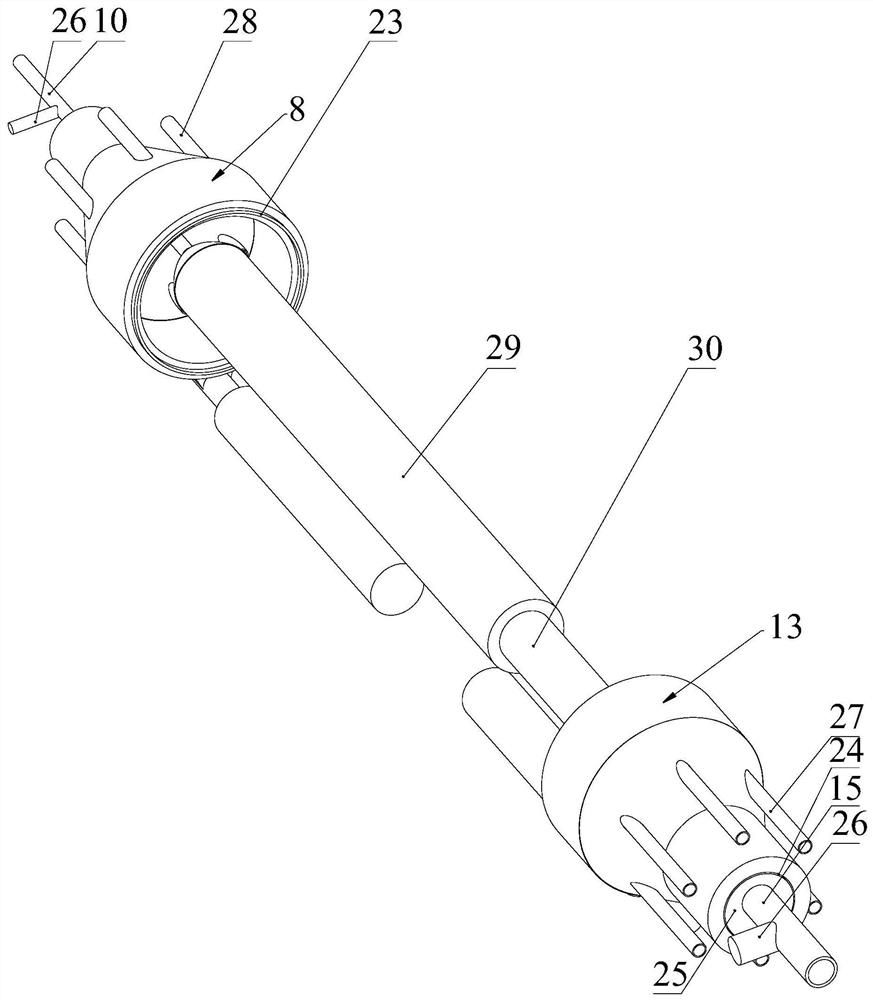

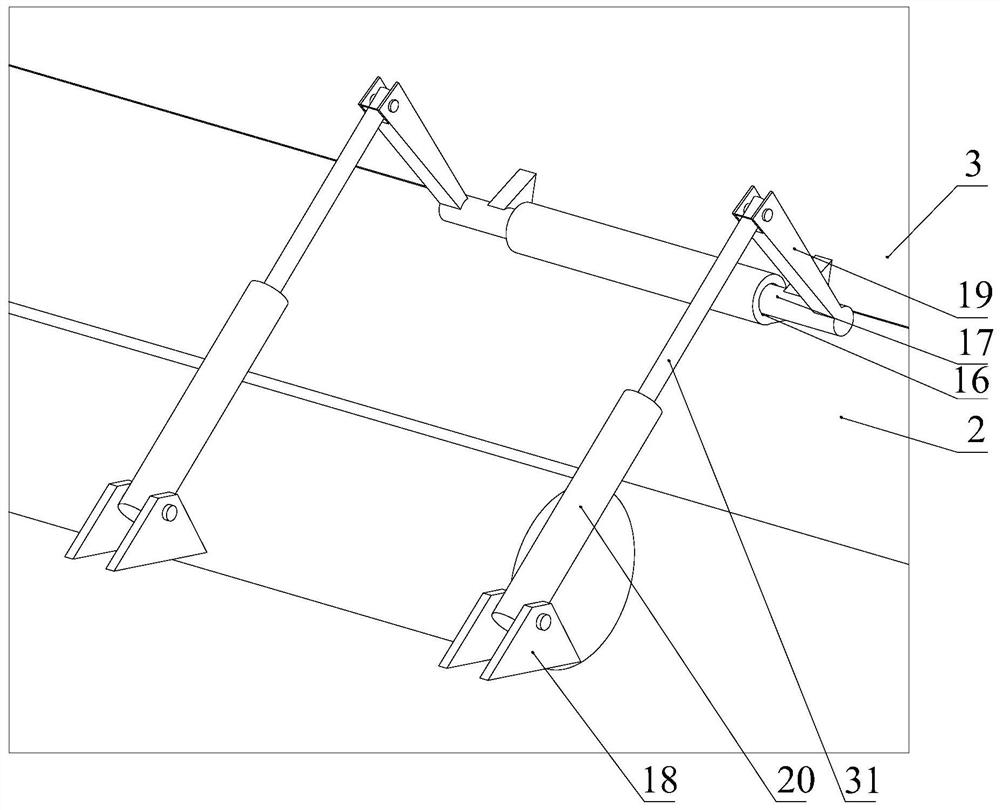

Humidity and temperature process controllable hot air drying machine vision on-line detection system and method

ActiveCN109115772ASolve the problem of high memory usageEliminate the effects ofInvestigation of vegetal materialWater storage tankEngineering

The invention provides a humidity and temperature process controllable hot air drying machine vision on-line detection system and a method. The humidity and temperature process controllable hot air drying machine vision on-line detection system mainly comprises a water storage tank (4), a cooling water pipe (5), a light source fixing pedestal (6), a light source cooling housing (7), an industrialcamera fixing pedestal (8), an industrial cooling housing (9), cooling housing fixing flanges (10), a cooling water pump (11), an industrial camera and a lens (14), and a light source (15); the humidity and temperature process controllable hot air drying machine vision on-line detection system can be used for image acquisition, is capable of separating a drying chamber from the industrial camera,and avoiding denaturation influences of high temperature on the industrial camera, the lens, and the light source. The invention also discloses the method using the humidity and temperature process controllable hot air drying machine vision on-line detection system. The method is used for controlling industrial camera image acquiring frequency, real-time obtaining of material shape and color, regulating and controlling indoor humidity and temperature. Machine vision on-line detection method is adopted to detect the shape and the color, compared with a method used for measuring material size using a vernier caliper and detecting material color with a color difference meter, the advantages are that: measuring precision and efficiency are increased.

Owner:CHINA AGRI UNIV

Baking process for lithium ion battery electrode plate containing water-based binding agent

InactiveCN106981685AOptimize the drying processSimple drying processFinal product manufactureElectrolyte accumulators manufactureWater basedRoom temperature

The invention discloses a baking process for a lithium ion battery electrode plate containing a water-based binding agent. The baking process comprises the following steps of (1) drying the electrode plate coated with paste for 1-2 hours under a vacuum condition and at a temperature of 100-110 DEG C; (2) reducing a temperature of the electrode plate in the step (1) to a room temperature and then drying the electrode plate for 15-30 minutes; and (3) drying the electrode plate in the step (2) for 3-4 hours at a temperature of 80-90 DEG C. The drying process of the electrode plate is optimized and improved, three steps of high-temperature rapid drying, room-temperature drying and low-temperature permanent drying are employed, the process is simple in step and high in maneuverability, so that the drying time is greatly reduced, and drying is thorough; and the electrode plate is not liable to crack or powder is not liable to fall off during the drying process, and the electrochemical performance of the battery is favorably improved.

Owner:长兴天晟能源科技有限公司

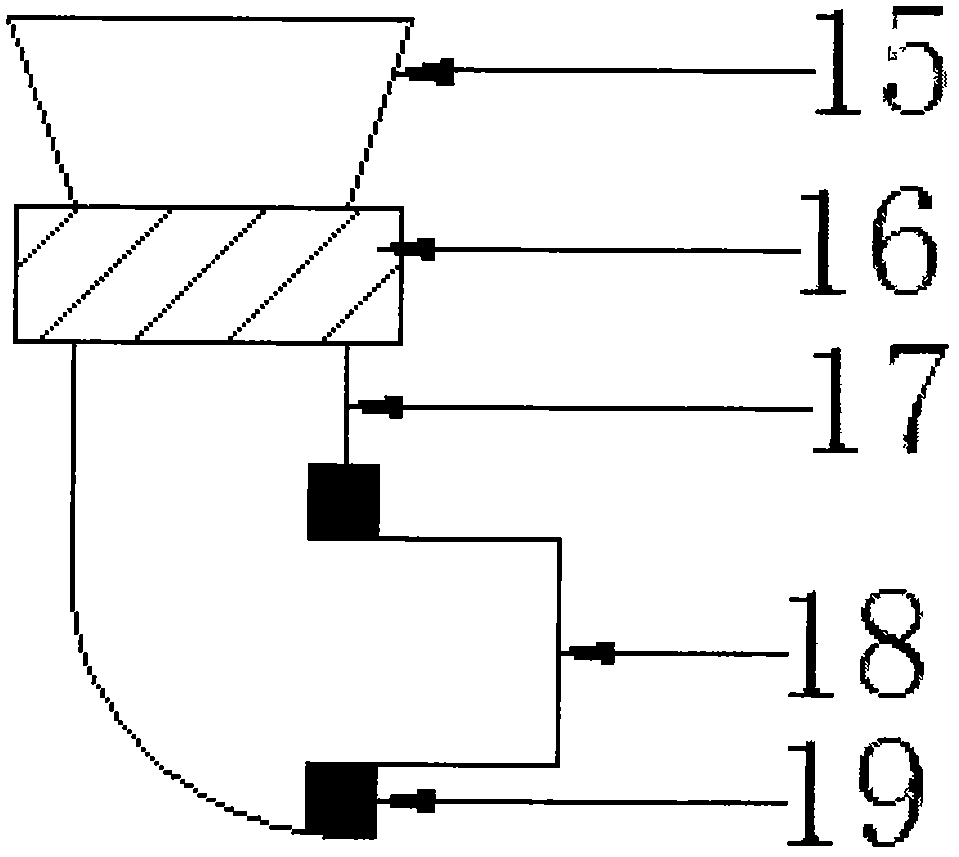

Continuous heat-pipe roller vacuum drying machine

InactiveCN106940122AEasy to manufactureOptimize the drying processDrying solid materials without heatDrying machines with non-progressive movementsThermal energySpiral blade

The invention provides a continuous heat-pipe roller vacuum drying machine. The continuous heat-pipe roller vacuum drying machine comprises a circulating heat-pipe roller vacuum drying machine and high-airtightness discharging devices. The high-airtightness discharging devices are installed in a feeding inlet and a discharging outlet of the circulating heat-pipe roller vacuum drying machine. Materials can continuously enter a heat-pipe type roller and leave from the heat-pipe type roller, a certain degree of vacuum of the interior of the heat-pipe type roller is kept through pumping of a vacuum unit, the water evaporation boiling point is low, and therefore the heat energy needed by material drying can be greatly reduced. The heat energy is conducted and dissipated through an inner shell and heat-dissipating pipes of the heat-pipe type roller, and can directly carry out heat conduction and heat exchange on the materials, and therefore the effective utilization ratio of the heat energy is improved, the material drying efficiency is improved, and the purpose of rapid material drying is achieved. The heat-dissipating pipes and spiral blades have the function of material stirring, wet materials are not prone to caking in the drying process, no drying dead angles of the materials exist, and the drying quality of the materials is optimized, and energy-saving and emission-reducing environmentally-friendly drying is achieved.

Owner:程长春

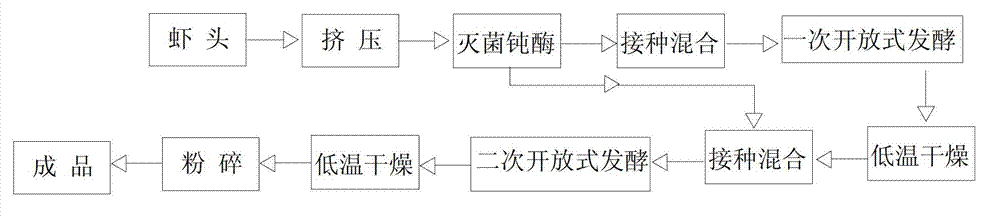

Method for preparing fermented fodder with shrimp heads

The invention belongs to the field of fodder processing, particularly relates to a method for preparing fermented fodder with shrimp heads. The method comprises the following steps that the shrimp heads are extruded and separated into shrimp shells and shrimp paste; then the obtained shrimp paste is sterilized and the enzyme is inactivated, and the shrimp paste is mixed with the fodder; meanwhile, compound fermentation bacteria and accessories are added in; fermentation is carried out through an open fermentation method; after fermentation, the materials are dried and discharged; the first fermented materials are mixed with the sterilized and enzyme-inactivated shrimp paste twice; meanwhile, the compound fermentation bacteria and the accessories are added in; secondary fermentation is carried out through the open fermentation method; after the fermentation, the materials are dried and discharged; and finally the materials are crushed and packaged into a finished product. According to the method for preparing fermented fodder with shrimp heads, the material turning and the ventilation do not need to be carried out regularly, so that fermentation procedures are simplified and labor forces are saved; in addition, the content of such nutrient substances as organic acid, protein, and small peptide in the fodder is higher than that in one-time fermented fodder, the product uniformity is correspondingly improved, so that the used amount of fermentation carriers is reduced, and the production cost is also reduced.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

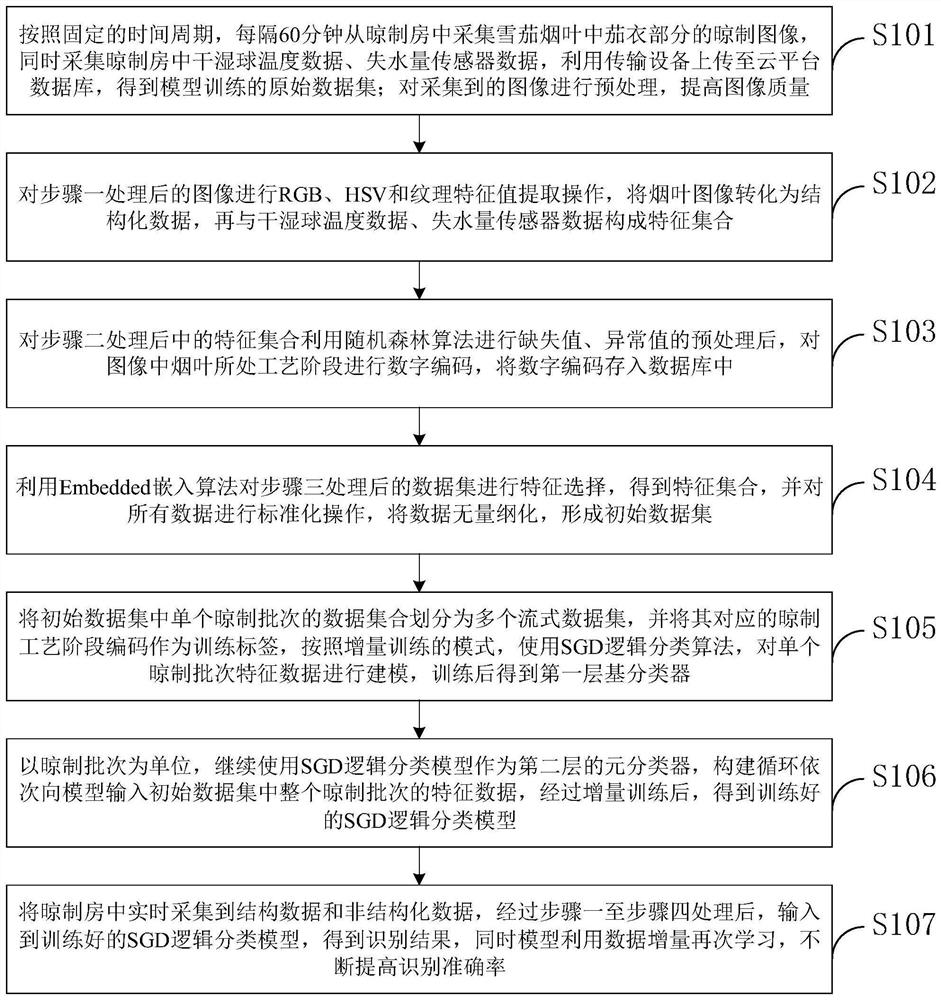

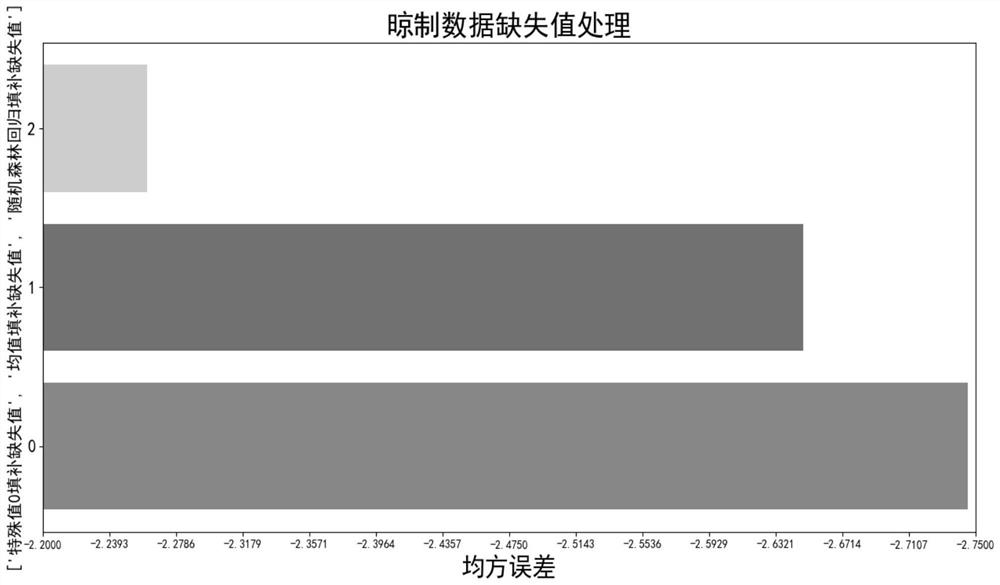

Cigar tobacco leaf air-curing process stage identification method based on incremental learning

PendingCN114359697AImprove training efficiencySolve the noise problemCharacter and pattern recognitionEngineeringIncremental learning

The invention belongs to the technical field of tobacco leaf air-curing, discloses a cigar tobacco leaf air-curing process stage identification method based on incremental learning, and provides a fusion model for identifying a tobacco leaf air-curing process stage by adopting an incremental learning mode based on an SGD logic classification algorithm. According to the model, data can be subjected to preprocessing and feature selection in combination with airing data characteristics collected by an airing room, and through an incremental training learning mode, the accuracy of judging the airing process stage is gradually improved, the tobacco airing process is optimized, the working pressure of tobacco growers is relieved, and the economic benefits of tobacco are improved. According to the method, a large amount of effective information is filled for tobacco leaf data features, the subsequent model prediction accuracy is improved, the problem of a large amount of noise in air-curing data is solved, and the model training efficiency is improved; the air-curing process stage is rapidly judged in real time, and meanwhile, the model learns again by utilizing subsequent data increment, so that the tobacco air-curing process is improved, and remote, intelligent and accurate air-curing is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

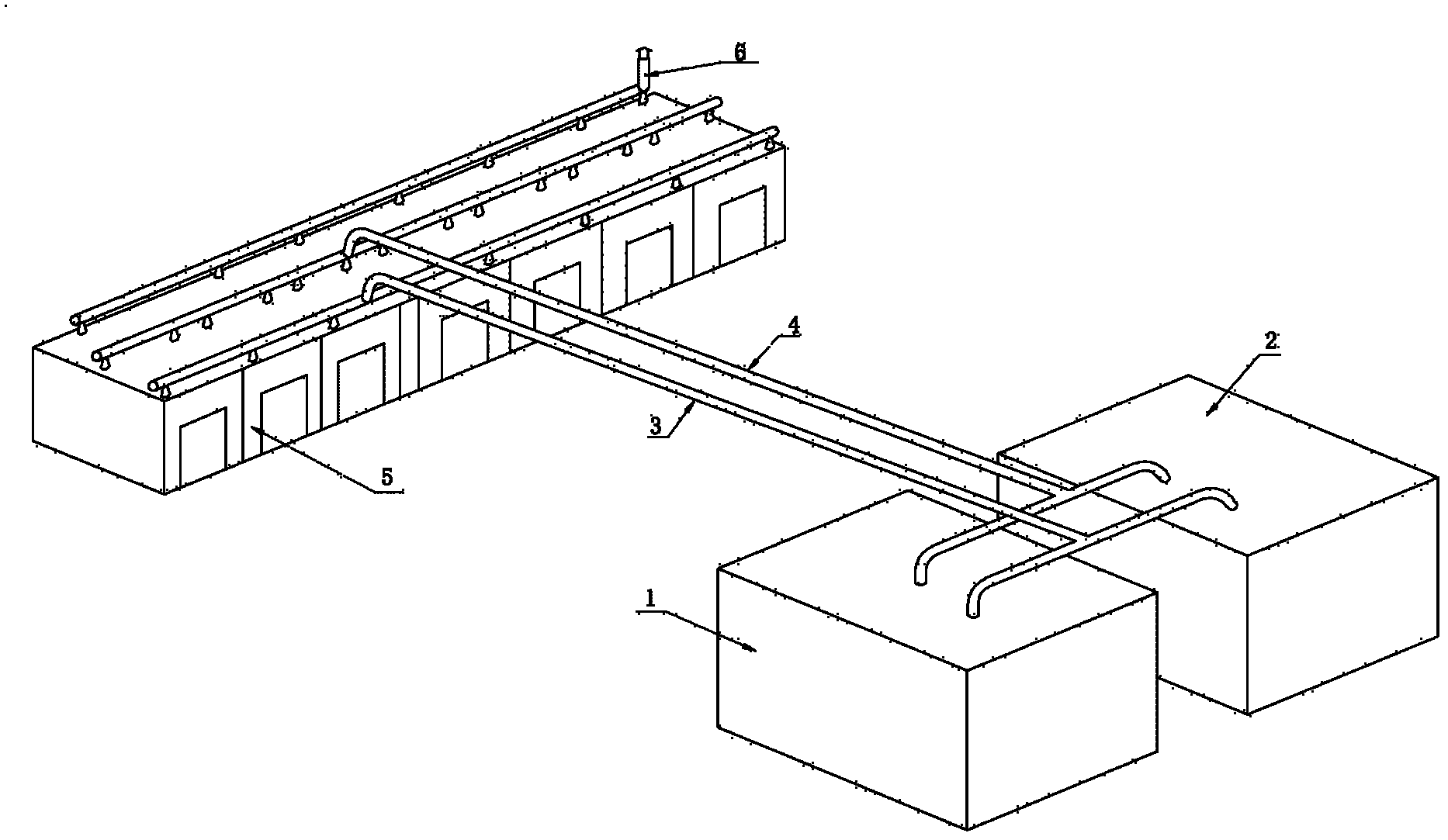

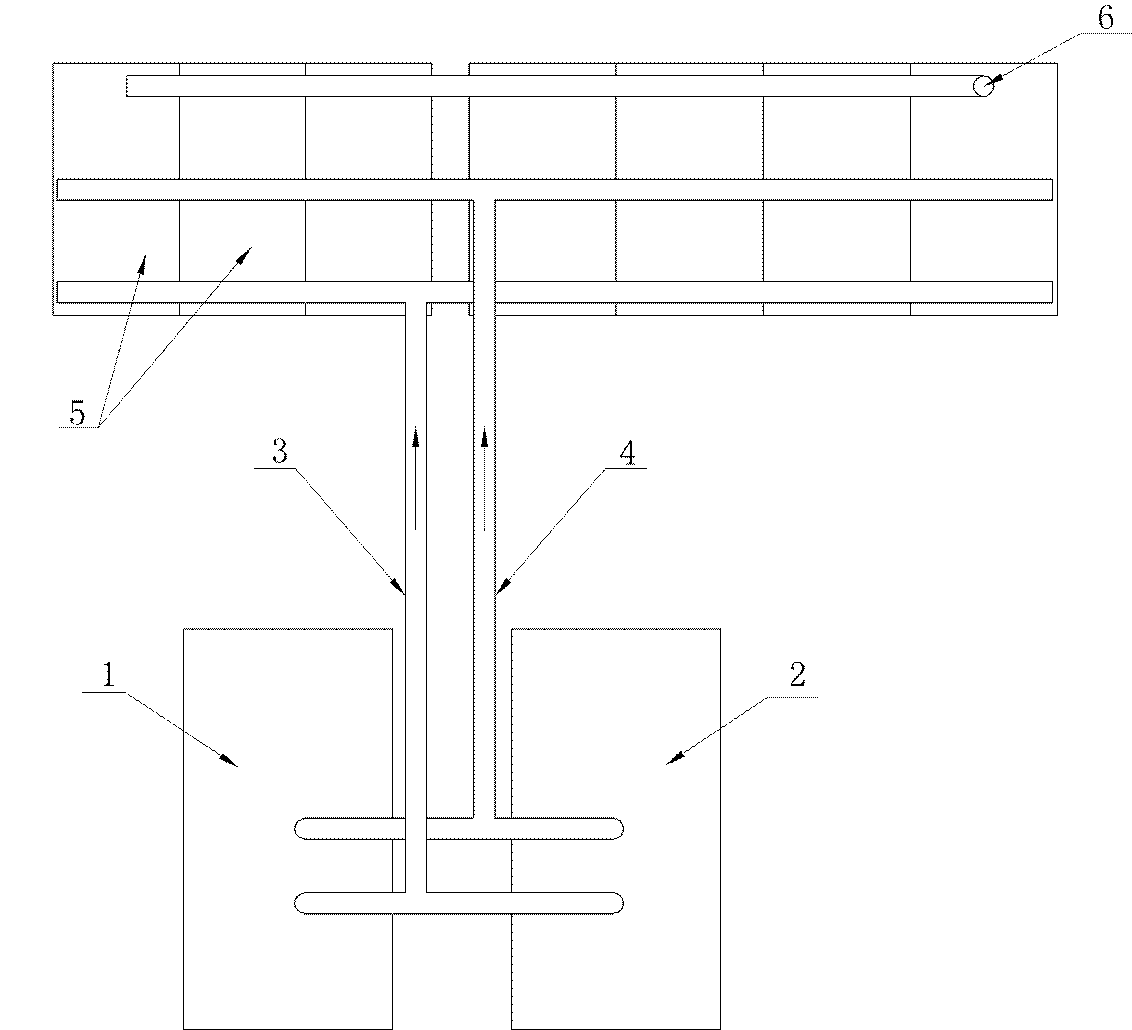

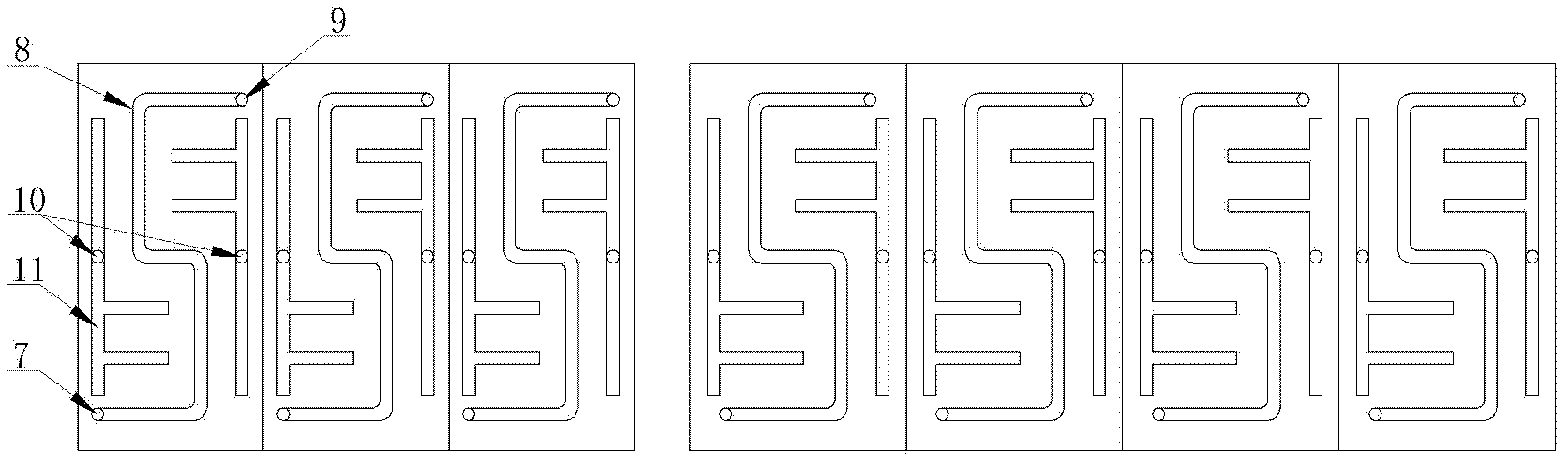

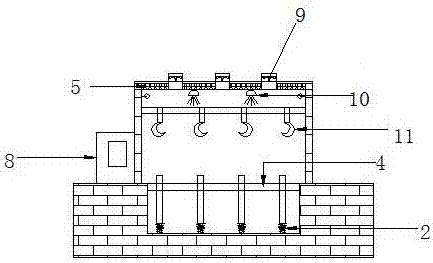

Method and device utilizing kiln waste heat for rapidly drying electrotechnical porcelain

InactiveCN102519237AShorten the production cycleOptimize the drying processDrying gas arrangementsDrying chambers/containersHot air ovenProcess engineering

The invention relates to a method and a device utilizing kiln waste heat for rapidly drying electrotechnical porcelain, wherein the kiln waste heat is fully utilized with the assistance of an air heater serving as a heat source, and then is transferred to an underground pipe network of a drying house through two kiln waste heat utilization systems; during the time from the ignition of the kiln to the stop of the kiln, one of the heat source auxiliary transference system is utilized for transferring heat radially through the underground pipe network of the drying house; and when the kiln is stopped, the other heat source auxiliary transference system is utilized for directly transferring heat through the underground pipe network of the drying house. In the invention, the drying time is reduced to 48 to 96 hours, the turnaround time of the drying house per month increases to 6 to 10 times, as a result, not only is the production period greatly shortened, but also the waste heat is fully completely utilized at the same time; and the heat energy circulates repeatedly from the bottom to the top to form thermal current, so that the heat efficiency is improved and the drying effect is extremely remarkable.

Owner:殷杨合

Manufacturing method of optical fiber preform

ActiveCN112340979AEasy to adjustEasy to operateGlass making apparatusExhaust pipeIndustrial engineering

The invention discloses a manufacturing method of an optical fiber preform. The manufacturing method comprises a process of drying a sleeve, and the process of drying the sleeve comprises the following steps: 1) putting the sleeve into a drying pipe which can be opened and closed, and closing the drying pipe after putting the sleeve into the drying pipe; (2) attaching two plugs to the two end faces of the drying pipe in a sealed mode respectively, movably installing an air inlet pipe on one plug and used for receiving air used for drying the sleeve, and movably installing an exhaust pipe on the other plug; and 3) adjusting the axial position of the air inlet pipe to enable one end of the air inlet pipe to extend into the sleeve. A plastic sleeve is replaced with the drying pipe and the plug, the position of the air inlet pipe can be conveniently and reliably adjusted through the air inlet pipe arranged on the plug in a sliding mode, and therefore it is guaranteed that one end of the air inlet pipe extends into the sleeve, and efficient drying operation is achieved; the method is convenient to operate, waste can be prevented, and the environment is protected.

Owner:HANGZHOU FUTONG COMM TECH CO LTD

Manufacturing process for high-strength corrugated board

InactiveCN107618210AHigh strengthHigh yieldMechanical working/deformationPulp beating methodsCardboardCrack resistance

The invention relates to a manufacturing process for a high-strength corrugated board. The manufacturing process is improved from an original paper production process to a drying process in a number of aspects, the high strength of the corrugated cardboard is ensured, the crack resistance is high, the rupture resistance and tear resistance are good, and the service life is long. The original paperproduction process is improved, a traditional chemical mechanical method and mechanical method are replaced with an explosion pulping, and obtained original paper has the characteristics of being high in strength, high in yield, low in cost, lower in energy consumption and the like; and a preparation process of a high-strength adhesive is improved, the problem that a starch adhesive is prone to being dilute and unstable in performance in the process of recycling is solved, the situation that the bonding strength and edge crush strength of the corrugated board are decreased due to the fact that the corrugated board produced by using the starch adhesive is prone to getting damp and being soft is avoided, the strength of the corrugated board is improved, preparing and laminating technologiesare improved, the strength of the corrugated board is further improved structurally, a drying technology is improved, and the corrugated board has higher strength and is tightly combined.

Owner:安吉志达包装厂

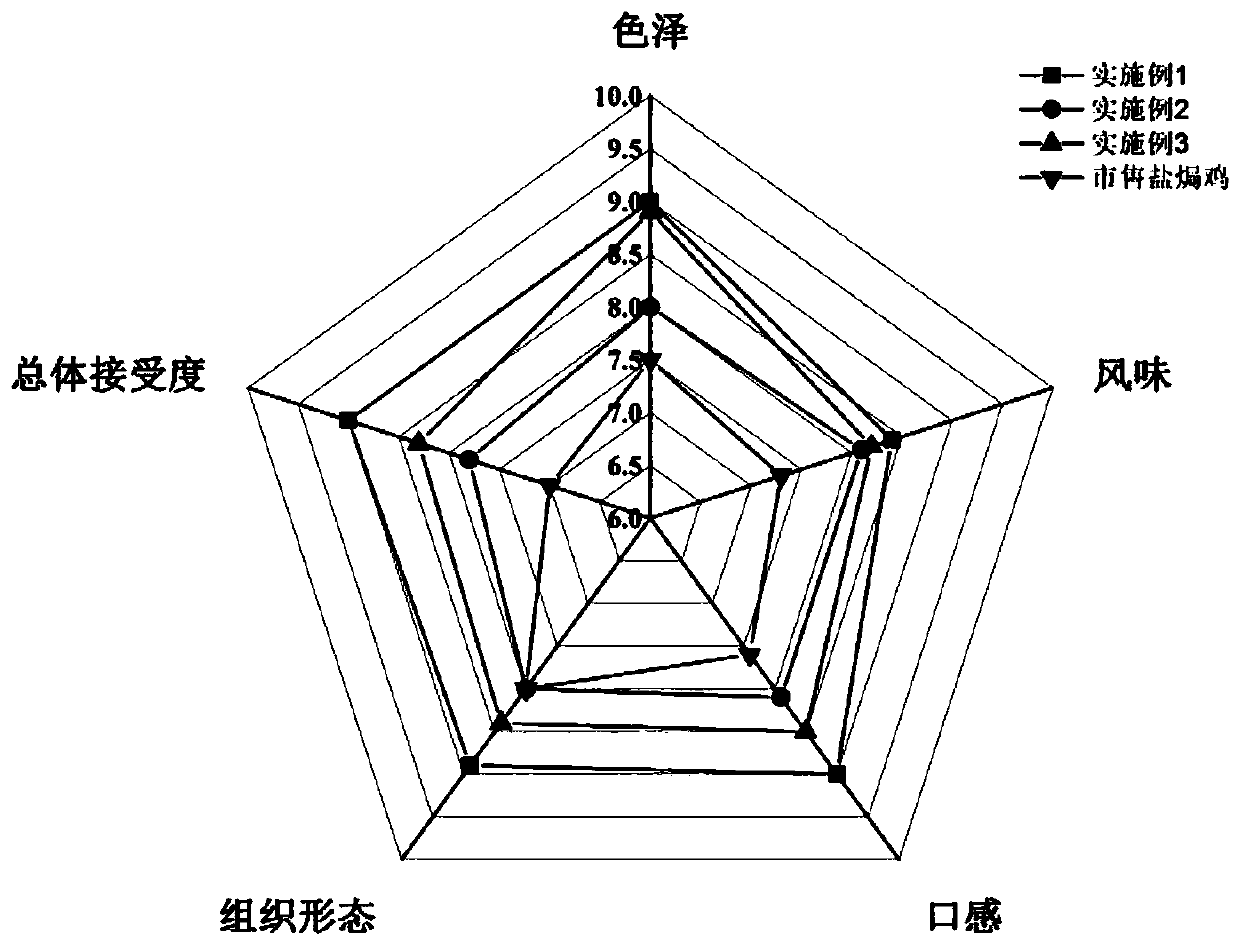

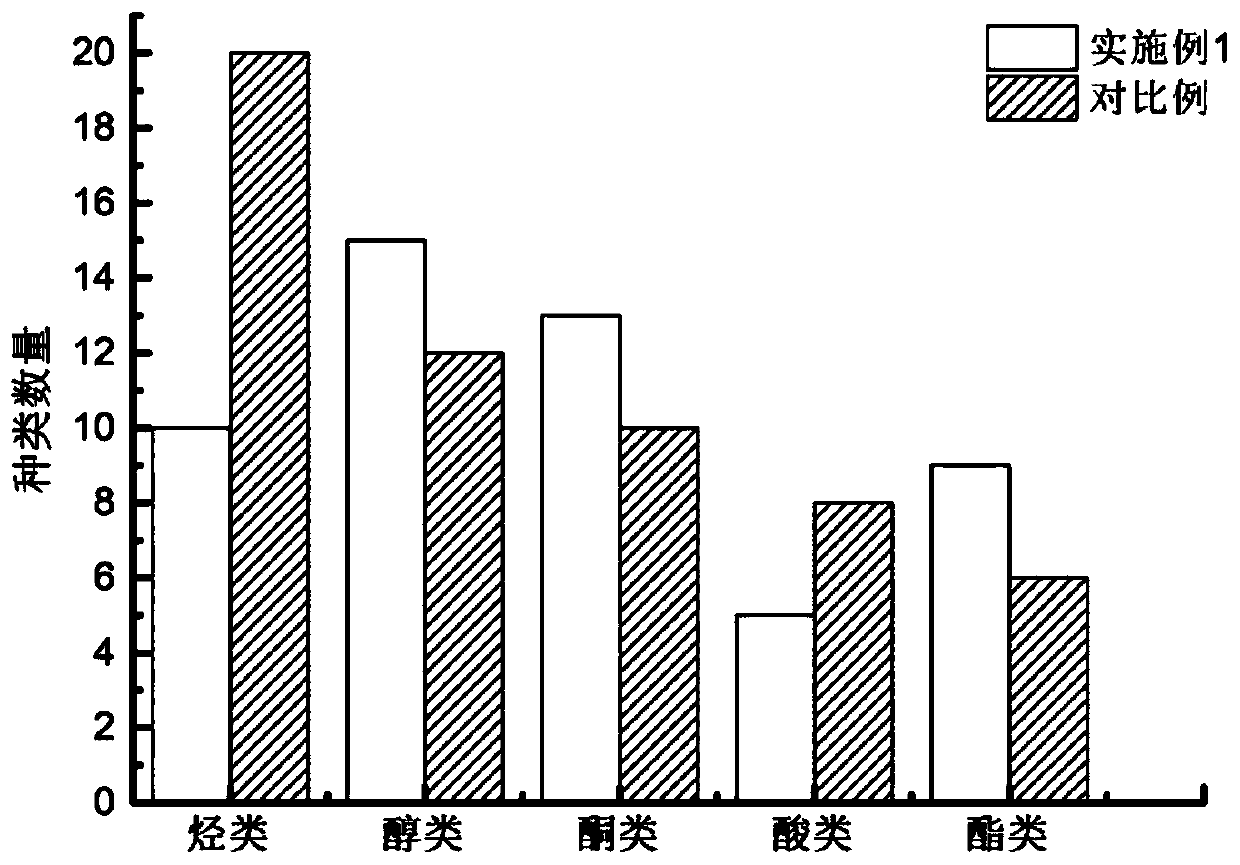

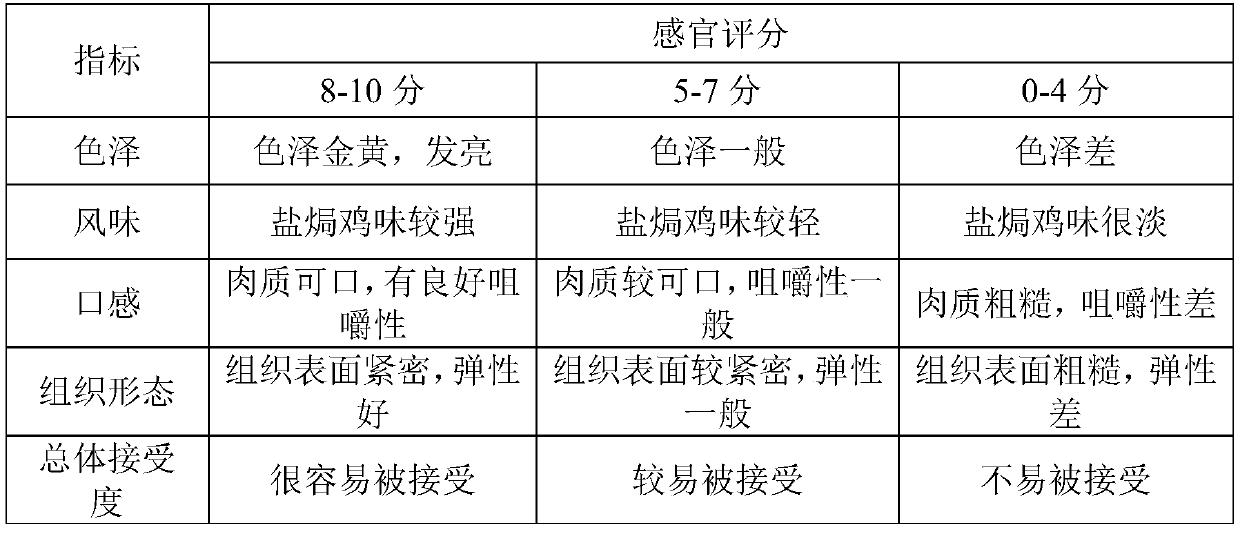

Preparation method for improving flavor of low-sodium salt roasted chicken

PendingCN111011743AReduce usageRealize the pursuitFood thermal treatmentClimate change adaptationBiotechnologyRoast chicken

The invention discloses a preparation method for improving the flavor of a low-sodium salt roasted chicken. According to the method, potassium chloride is compounded with disodium 5'-guanylate to serve as a partial sodium chloride substitute; an intermittent vacuum rolling and kneading mode is combined with a standing pickling process, gradient cold air-drying treatment is carried out after pickling is finished, color protection coating treatment is carried out after medium and low temperature drying is carried out and then salt baking is carried out to obtain the low-sodium salt roasted chicken product. According to the invention, the dosage of edible salt can be reduced by 40% to conform to the pursuit of consumers for low-sodium and low-salt foods; the air-drying process is optimized and thus the water activity of the salt roasted chicken reaches the optimal stage beneficial to formation of flavor substances, so that the fat oxidation in the salt roasting process is promoted and thequality and flavor of the product are remarkably improved. The prepared low-sodium salt roasted chicken is smooth in skin, strong in odor and golden in color. According to the preparation method, theproduction efficiency of the salt roasted chicken is greatly improved while the special flavor and taste of the traditional salt roasted chicken are maintained and inherited, and industrial production can be realized.

Owner:ZHONGKAI UNIV OF AGRI & ENG +1

Telescopic paint room heating device

PendingCN106984507AAvoid accidental collisionStable supportPretreated surfacesCoatingsTemperature controlEngineering

The invention relates to a telescopic paint room heating device. The telescopic paint room heating device is characterized by comprising a heating component, a room body component, a temperature control component, a ventilation component and a lifting and transporting component; the heating component is located in the room body component; the ventilation component is located on the upper portion of the room body component; the lifting and transporting component is fixed to the inner wall of the room body component; one portion of the temperature control component is located on the inner wall of the room body component, and the rest portion of the temperature control component is located on the outer side of the room body component; the heating component comprises electric heating columns, spring hydraulic rods, an electric heating column foundation and a steel floor; the electric heating columns are arranged on the spring hydraulic rods; the spring hydraulic rods are fixed to the bottom of the electric heating column foundation; and the steel floor is laid at the top end of the electric heating column foundation. According to the technical scheme, the telescopic paint room heating device is quick in heating, constant in temperature and good in sealing performance, and a paint face is not prone to being contaminated in the roasting process.

Owner:丁俭华

Production technology of polyester super-delustred flat filaments

InactiveCN110565180AImproving slice drying processLow drying temperatureArtificial filament physical treatmentFilament/thread formingWater contentPre filtering

A production technology of polyester super-delustred flat filaments includes the following production technological processes that (1) a full-dull chip is subjected to pre-crystallization and drying,and the dried chip is placed in a spiral extruding machine for spinning melt extrusion; (2) the fused mixture is filtered through a pre-filter, and then the filtered mixture is weighed by a metering pump; (3) the weighed mixture is conveyed into an FDY hot roller spinning assembly to be sprayed, and the sprayed filaments are cooled and formed through side air blowing; (4) the cooled and formed filaments are oiled by an oil nozzle, and a preservative is added into an oiling agent; (5) the filaments oiled by the oil nozzle are integrated into tows through an interlacing machine, and finally thefilaments are wound through a winding head, wherein a first hot roller temperature is 55-65 DEG C, and a second hot roller temperature is 55-65 DEG C. The technology improves the chip drying technology, properly lowers the drying temperature, prolongs the drying time, and reduces the water content. An FDY one-step method production line is adopted, it is ensured that the quality of products is excellent, broken ends and broken filaments are reduced, and the production cost is reduced.

Owner:JIANG SU TIANDI CHEM FIBER

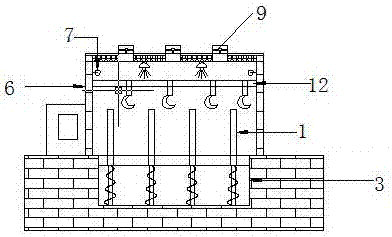

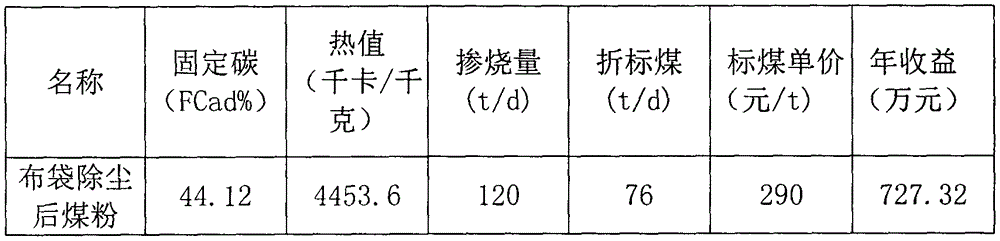

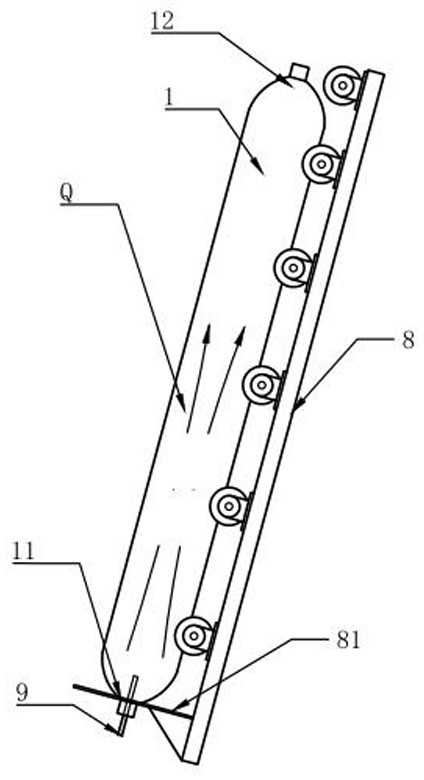

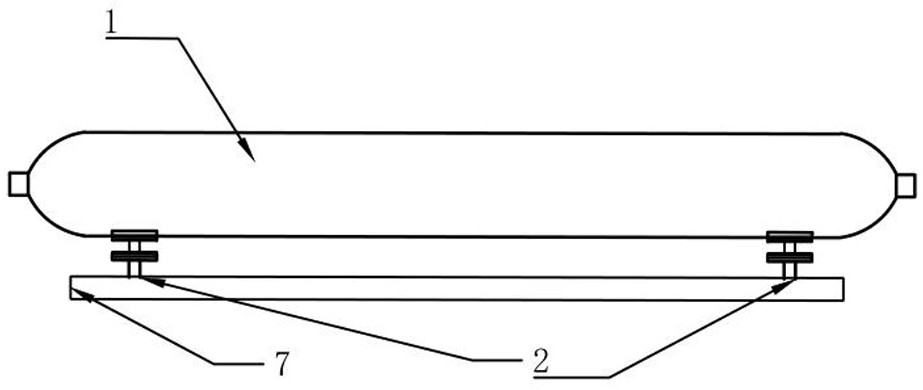

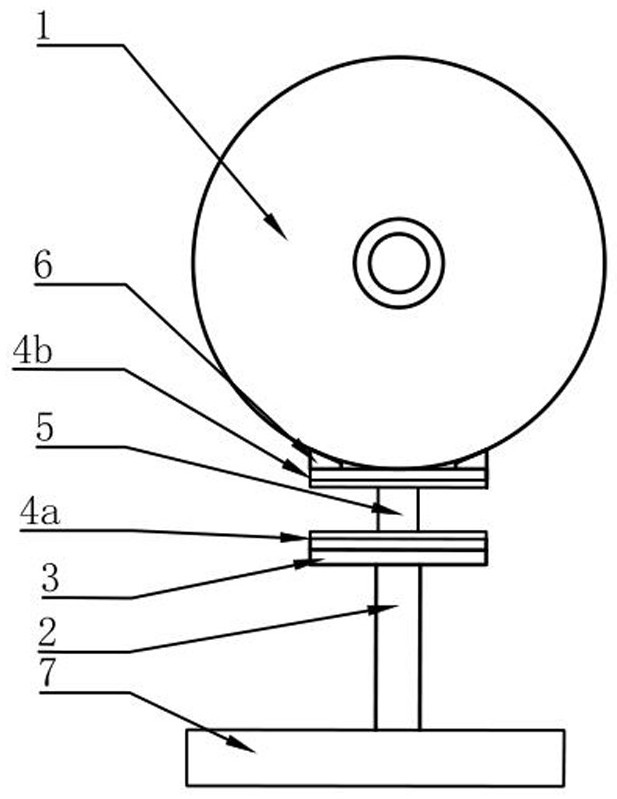

Dust removal and collection method for lignite drying system

InactiveCN105021020AOptimize the drying processImprove recycling ratesDrying solid materialsEngineeringCollection methods

The invention relates to a dust removal and collection method for a lignite drying system. A cloth bag is adopted in the method for removing dust, dust in dry tail gas is collected and used, and the dry dust is removed, recycled and then conveyed into a boiler for utilization in a pneumatic conveying manner.

Owner:呼伦贝尔东能化工有限公司

Water pressure weighing and drying method for gas cylinder

PendingCN113588436AOptimize the drying processWith characteristicsDrying gas arrangementsMaterial strength using tensile/compressive forcesGas cylinderControl engineering

The invention discloses a water pressure weighing and drying method for a gas cylinder. The water pressure weighing and drying method comprises two main procedures, namely a water pressure test accompanying weighing and water pouring and drying after the water pressure test is completed. A turbine elevator is mounted on a water pressure roll-over stand of a testing machine, and a pressure sensor module is fixedly mounted on the inner side of the top of the turbine elevator, so that the turbine elevator is used for controlling the height lifting of a gas cylinder, and a water pressure test and two times of weighing before and after the water pressure test are realized under the condition of single hoisting and feeding; and ventilation switching control and flow direction of drainage drying are improved, so that complete drying and discharging of an inner cavity can be completed at a high speed. According to the application of the method, two times of automatic weighing and reading after hoisting and feeding are achieved on the premise that an existing water pressure test is normally carried out through equipment transformation, meanwhile, the drying process is improved for the gas cylinder subjected to the water pressure test, the drying time is shortened by 50% or above, and better product drying quality and interior appearance quality are obtained with lower production cost and safety risk.

Owner:SINOMA SCI & TECHSUZHOU

Energy saving small hot air dryer

ActiveCN105546951BEasy extractionEasy to storeDrying gas arrangementsDrying solid materialsElectricityAir dryer

The invention provides an energy-saving small hot air drier. An outer box is provided with an inner cavity; a bottom draught fan is arranged at the bottom of the outer box; an electric heater and an air pipe connected with the bottom draught fan are oppositely arranged; an air pressing plate is located over the electric heater, and gaps are formed between at least one end of the air pressing plate and the two side walls of the outer box; a sealing plate is located on one side of the electric heater; two partition plates are provided with holes and arranged in a spaced mode, and a drying chamber is formed among the partition plates and the air pressing plate; a side-face draught fan is arranged on one side of the outer box, and an air outlet of the side-face draught fan and the drying chamber are oppositely arranged; an air exhaust outlet is formed in the top of the outer box and communicated with the inner cavity of the outer box; one end of a circulating air pipe is connected to the side wall, opposite to the side-face draught fan, of the outer box, and the other end of the circulating air pipe is connected with an air inlet of the side-face draught fan. The energy-saving small hot air drier is simple in overall structure, high in practicability, easy to use and popularize and good in drying effect.

Owner:山东百佳食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com