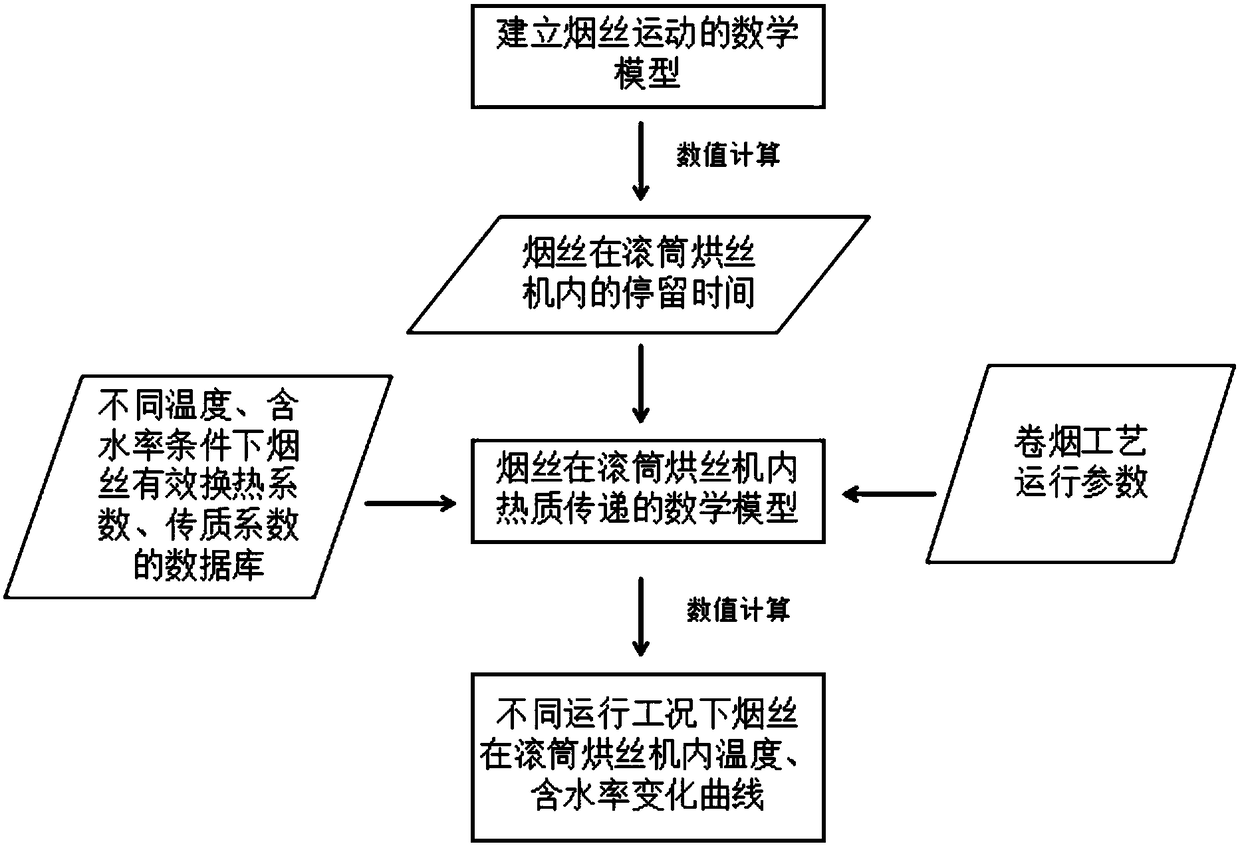

Numerical method for predicting heat and mass transfer law of tobacco shreds in drum dryer

A drum silk drying machine and heat and mass transfer technology, applied in the fields of tobacco and chemical industry, can solve the problems of heavy workload, high energy consumption, high cost, etc., to improve production efficiency, high measurement accuracy, reduce production energy consumption and environmental protection pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

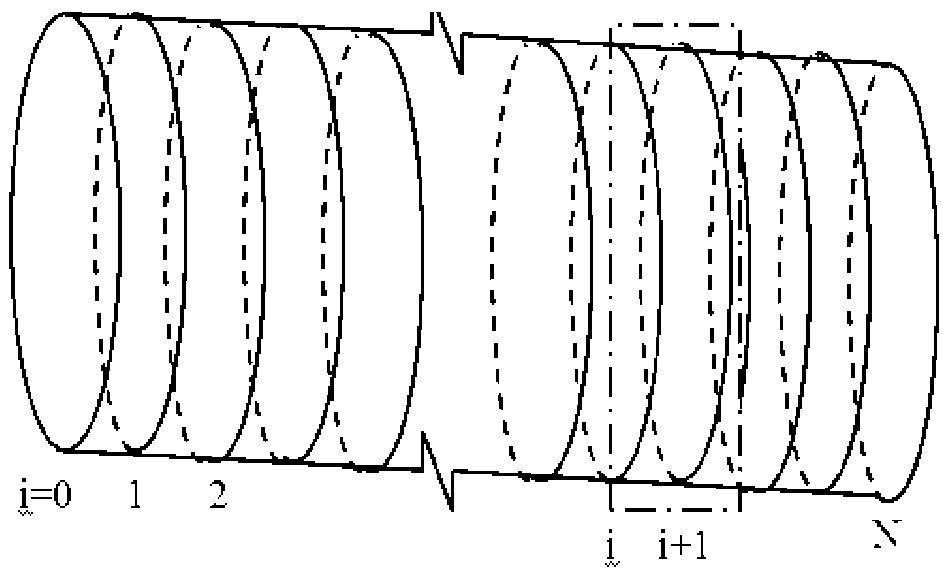

[0027] Such as figure 2 As shown, the drum is divided into several micro-units along the axial direction, based on the following heat conduction, convective heat transfer and convective mass transfer formulas, the energy and mass conservation equations are set for the heat and mass transfer process in each unit, assuming that the shredded tobacco in the drum is in a stable state flow state;

[0028] ΣQ in =∑Q out (1)

[0029] Q 1 (i-1)+Q 2 (i-1)+H p (i-1)+H g (i-1)=H p (i)+H g (i) (2)

[0030] Q 1 (i-1)=α 1 f 1 (T w -T p (i-1)) (3)

[0031] Q 2 (i-1)=α 2 f 2 (T w -T g (i-1)) (4)

[0032] h p (i-1)=W dp (C dp +X(i-1)C H2O )(T p (i-1)-T ref ) (5)

[0033] h g (i-1)=W dg (C dg +Y(i-1)C V )(T g (i-1)-T ref )+W dg Y(i-1)r (6)

[0034]

[0035]

[0036] Among them, F 1 The range is 1 / 2 to 2 / 3 of the surface area of the drum, here we take 0.6; F2 Generally, it is 1 / 3~1 / 2 of the surface area of the drum, and 0.4 is taken here;

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com