Telescopic paint room heating device

A technology for heating devices and paint booths, which is applied to devices for coating liquid on surfaces, industrial buildings, and pre-treated surfaces. Maintenance costs, fast and efficient heating process, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

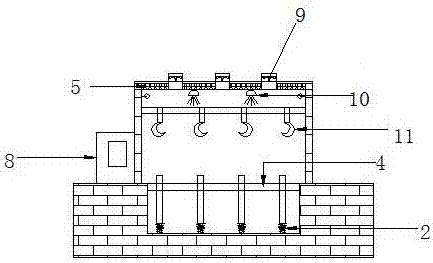

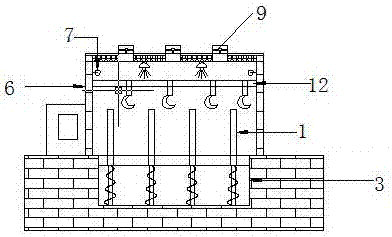

[0015] Embodiment 1: see figure 1 , figure 2 , a retractable paint room heating device, the retractable paint room heating device includes a heating component, a room body component, a temperature control component, a ventilation component and a lifting component; the heating device is located in the room body component; The ventilation component is located on the upper part of the room body component; the lifting component is fixed on the inner wall of the room body component; the temperature control component is partially located on the inner wall of the room body component, and the rest is located outside the room body component. The design structure is simple and clear, and the components are closely connected without mutual influence, which not only has a long service life but also facilitates production and installation. The heating component includes an electric heating column 1, a spring hydraulic rod 2, an electric heating column foundation 3 and a steel floor 4; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com