Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

187results about How to "Low solvent content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

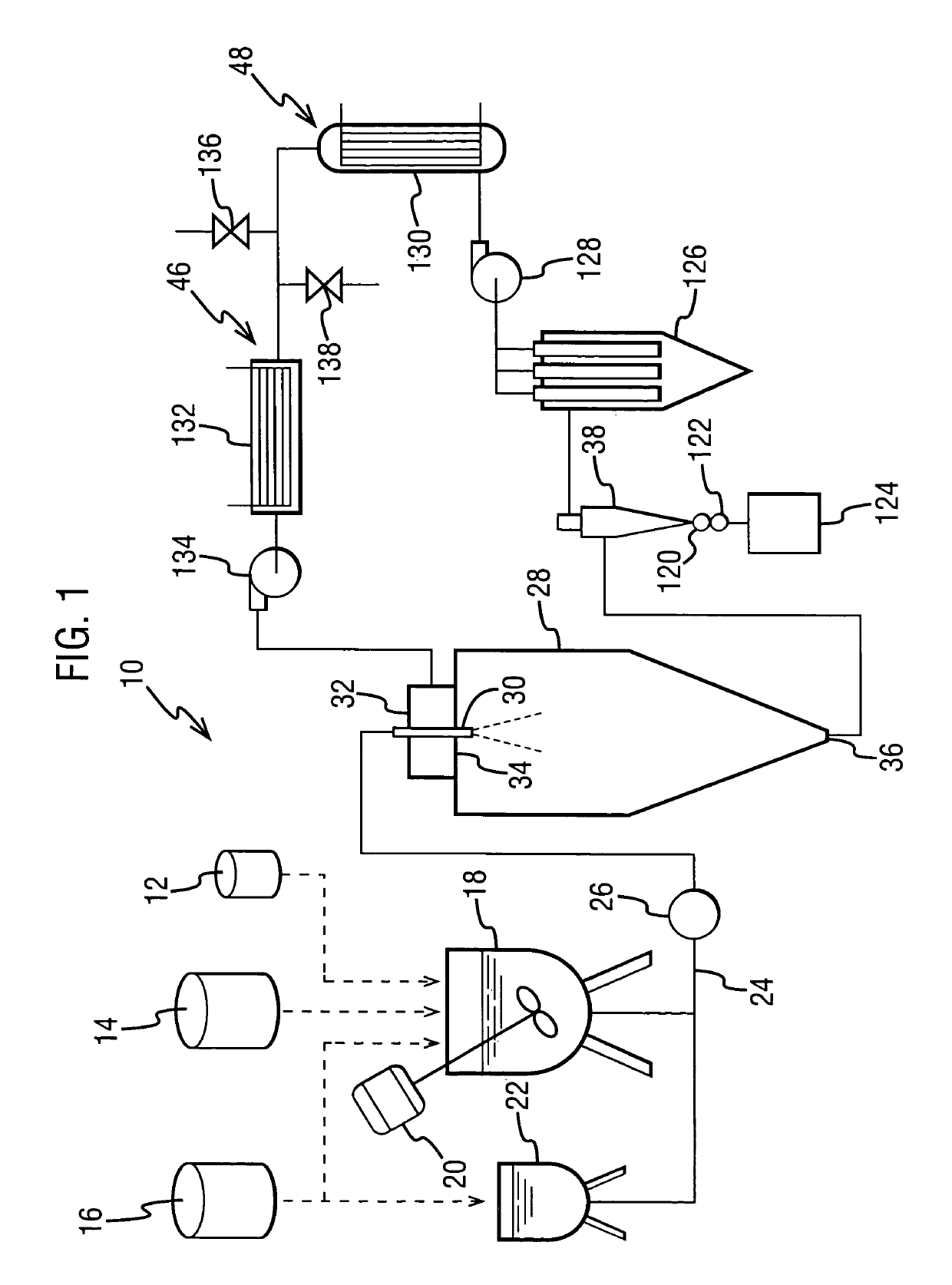

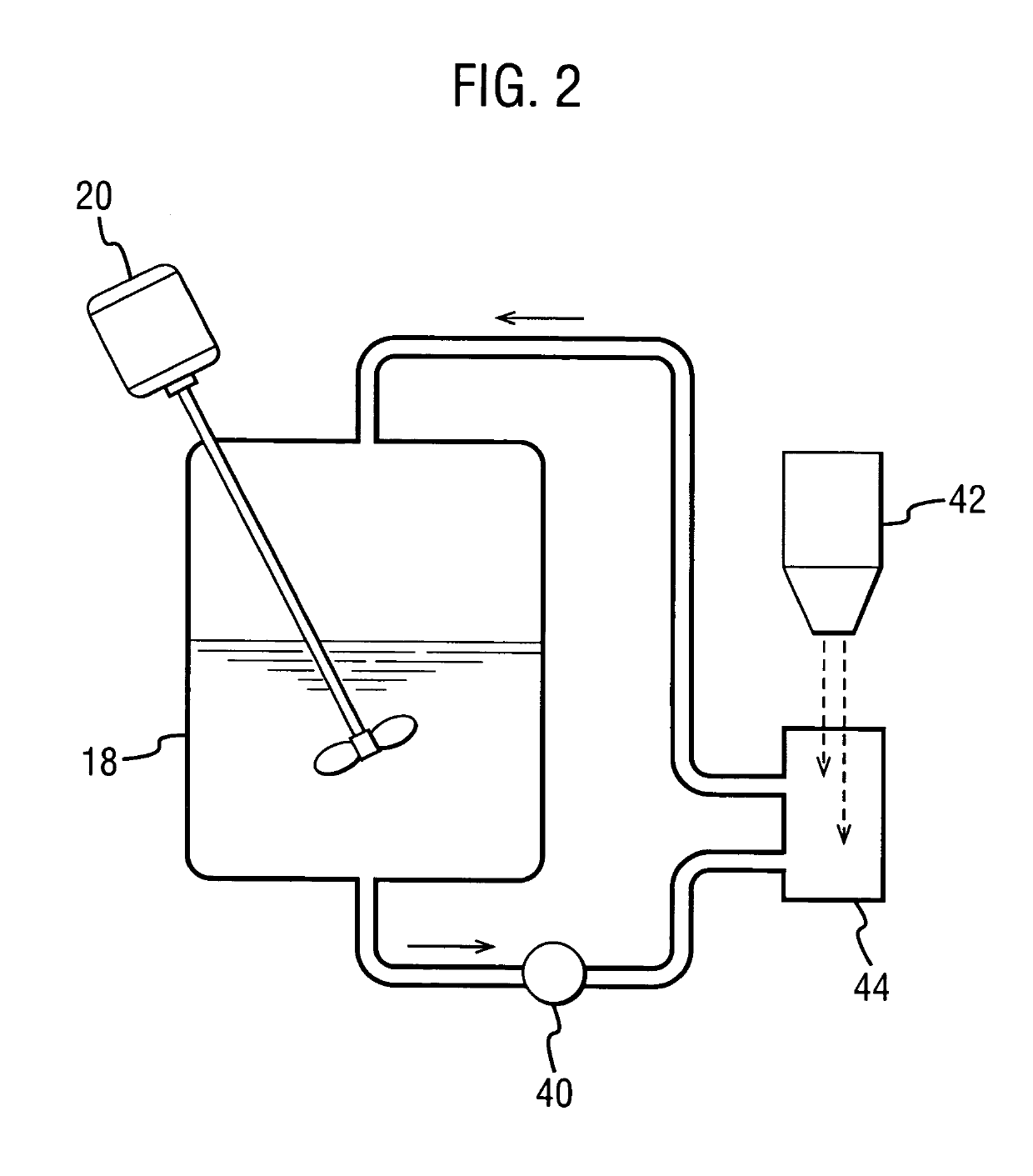

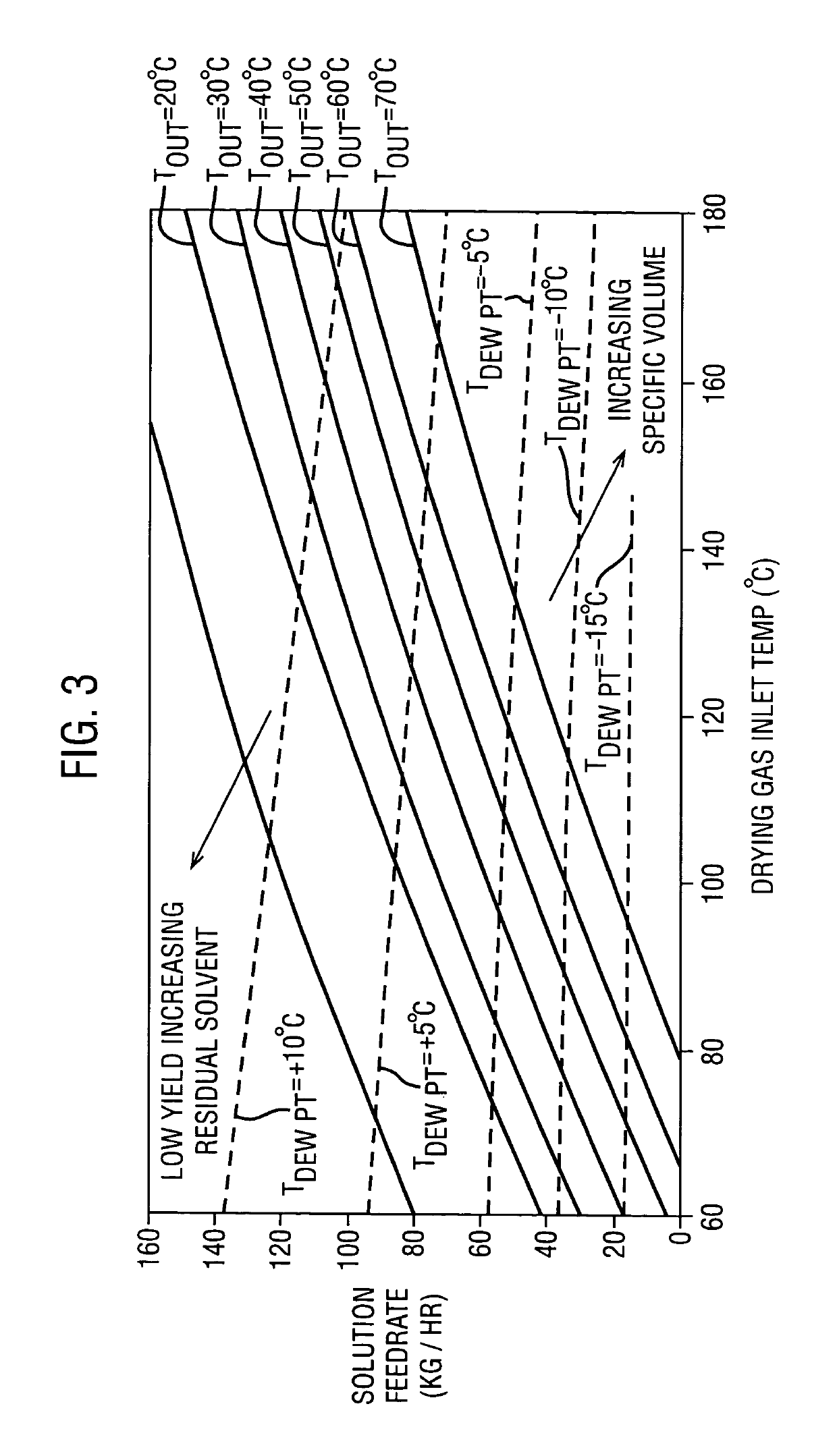

Spray drying processes for forming solid amorphous dispersions of drugs and polymers

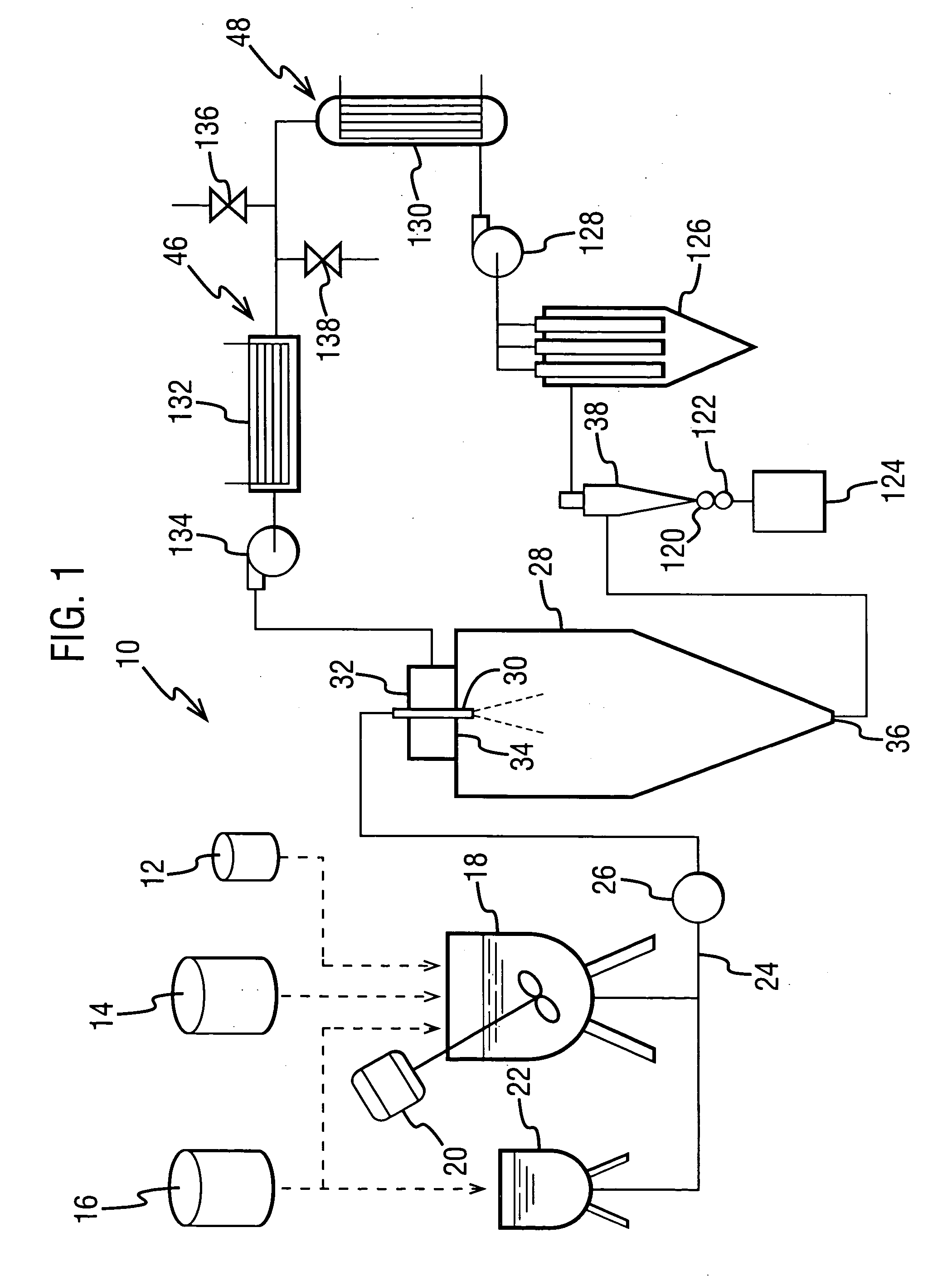

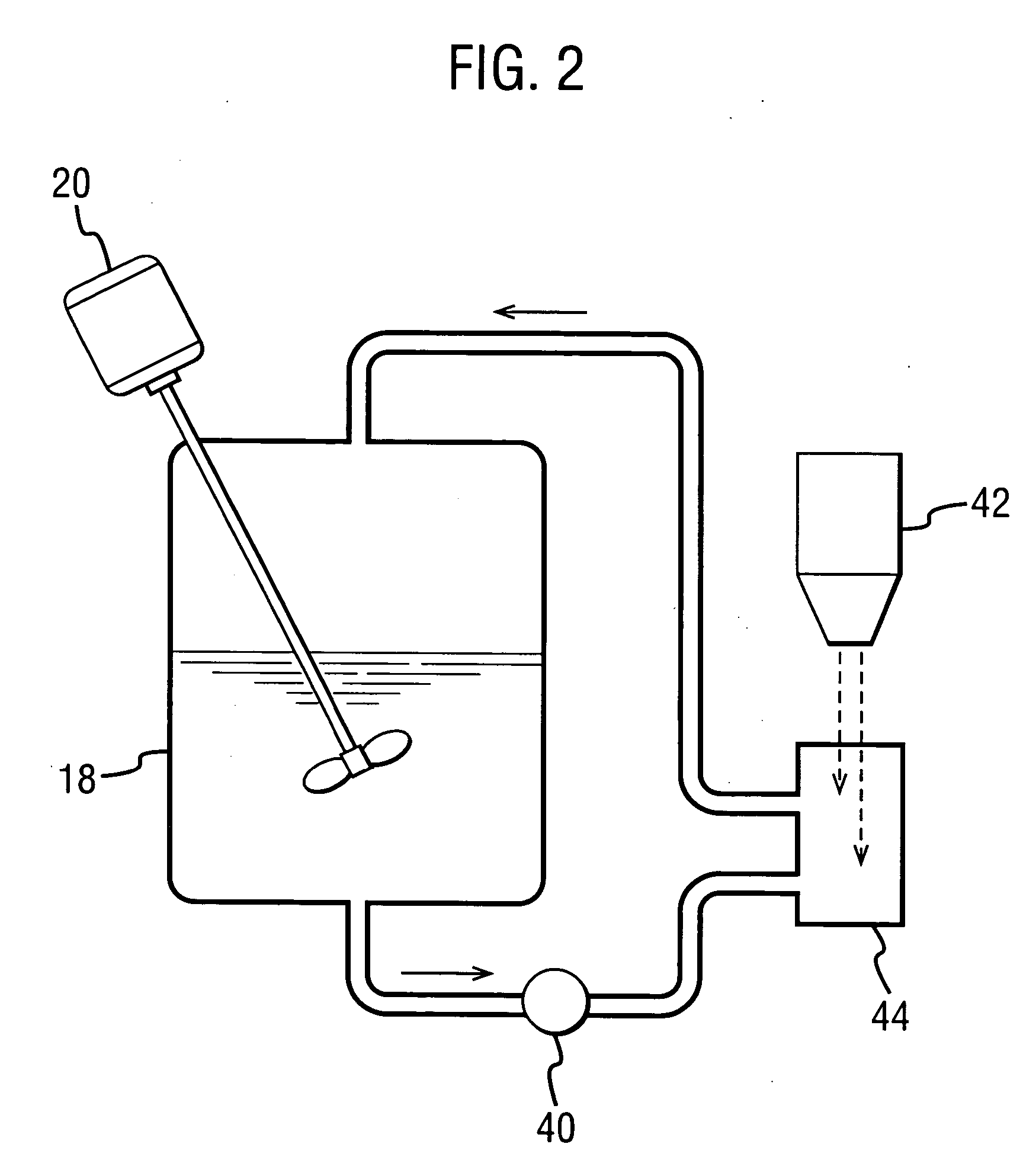

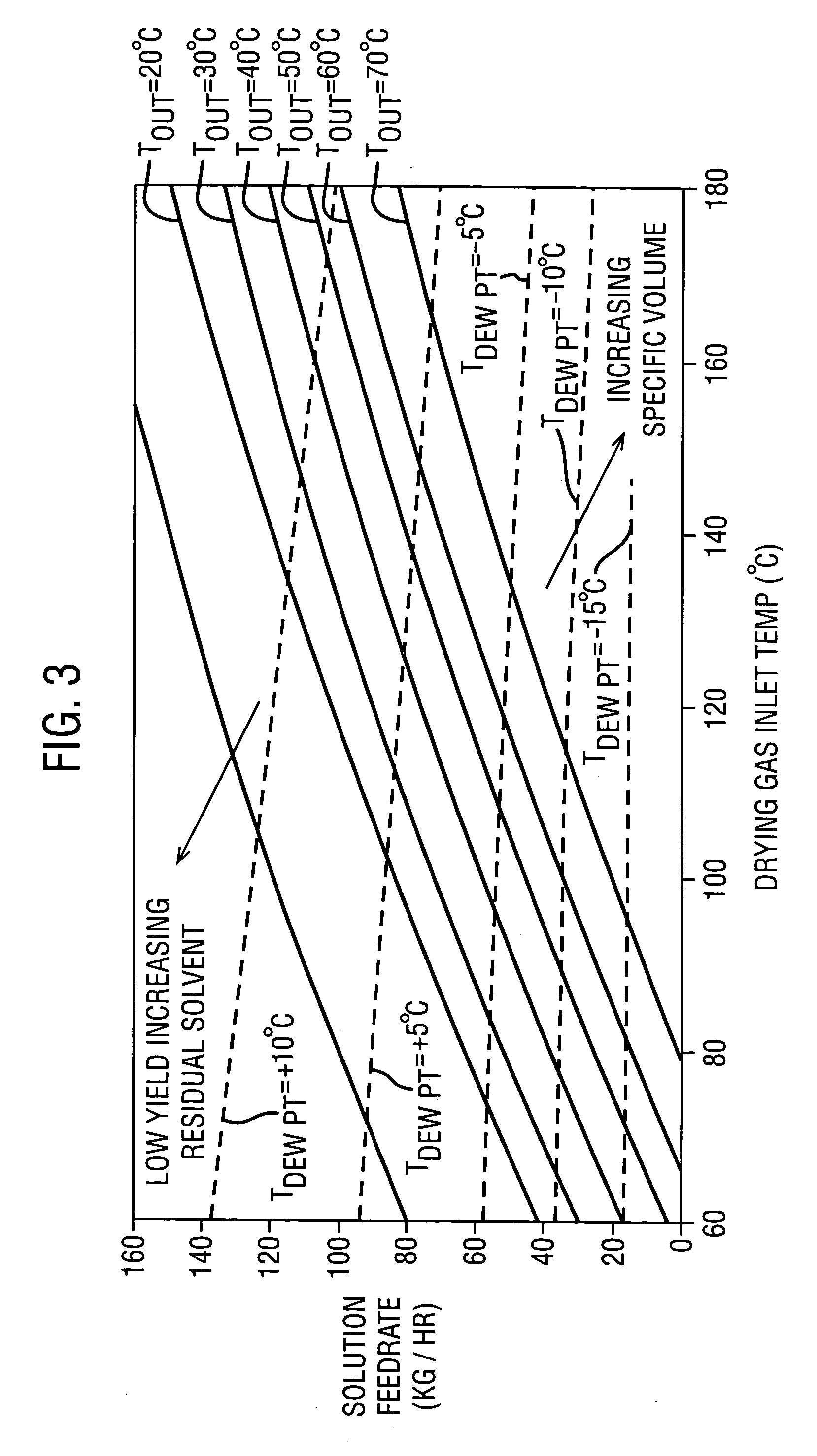

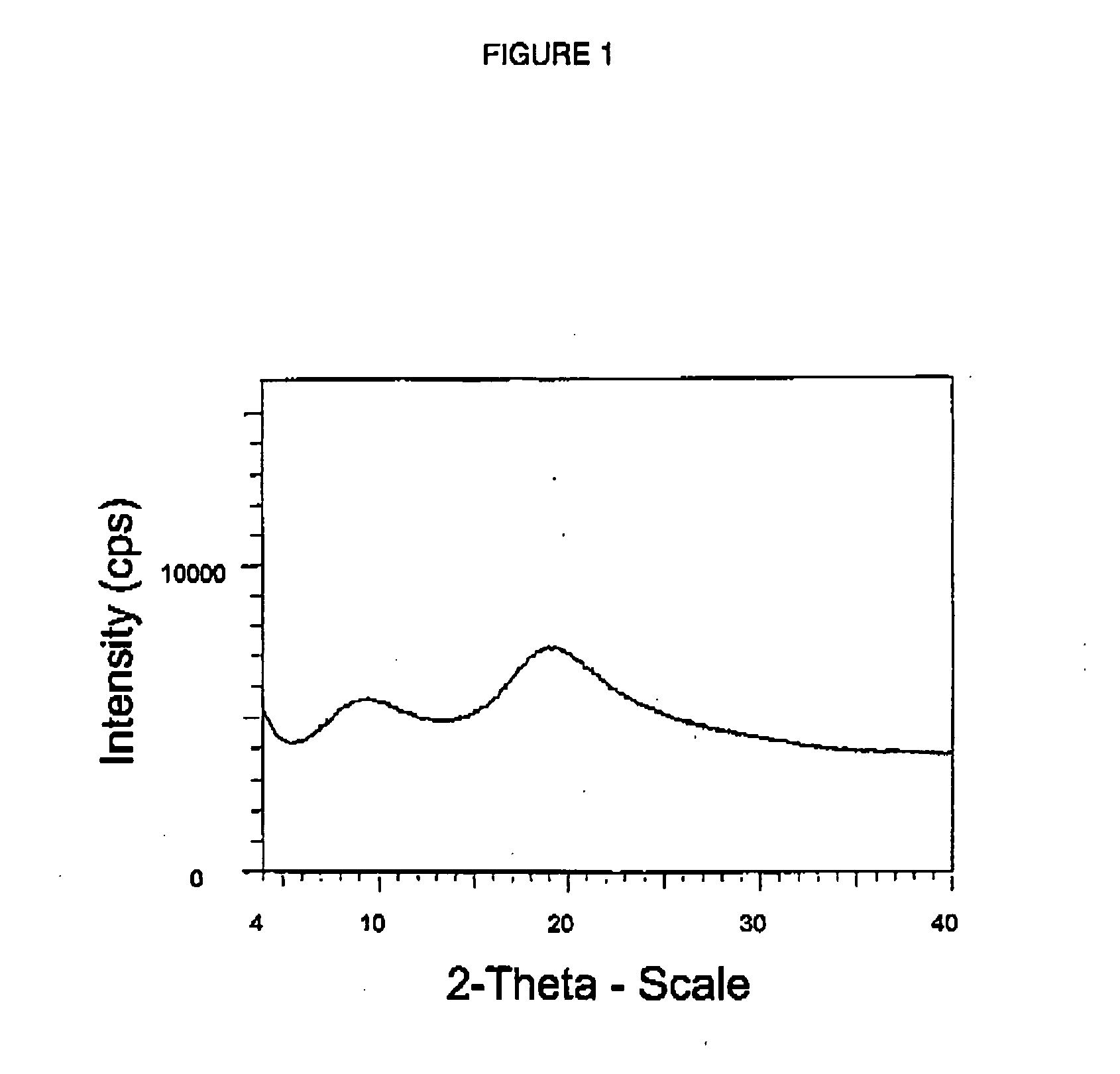

ActiveUS20050031692A1Reduce accumulationFast evaporationPowder deliveryMetabolism disorderDrugPolymer chemistry

Spray drying processes are used to form pharmaceutical compositions comprising a solid amorphous dispersion of a drug and a polymer.

Owner:LONZA BEND INC

Lithium rechargeable battery

ActiveUS20070020525A1Excellent thermal and electrical propertyLittle thicknessCell electrodesSecondary cellsPorous membraneNon aqueous electrolytes

A lithium rechargeable battery includes a separator that shows excellent safety characteristics such as short circuit resistance and heat resistance. The lithium rechargeable battery includes a cathode, an anode, a separator that separates the cathode and the anode from each other, and a non-aqueous electrolyte, wherein the separator includes a porous membrane formed of a ceramic material and a binder, and wherein the binder includes at least one crystalline resin having a crystal melting temperature of 250° C. or higher or at least one non-crystalline resin having an initial decomposition temperature of 250° C. or higher.

Owner:SAMSUNG SDI CO LTD

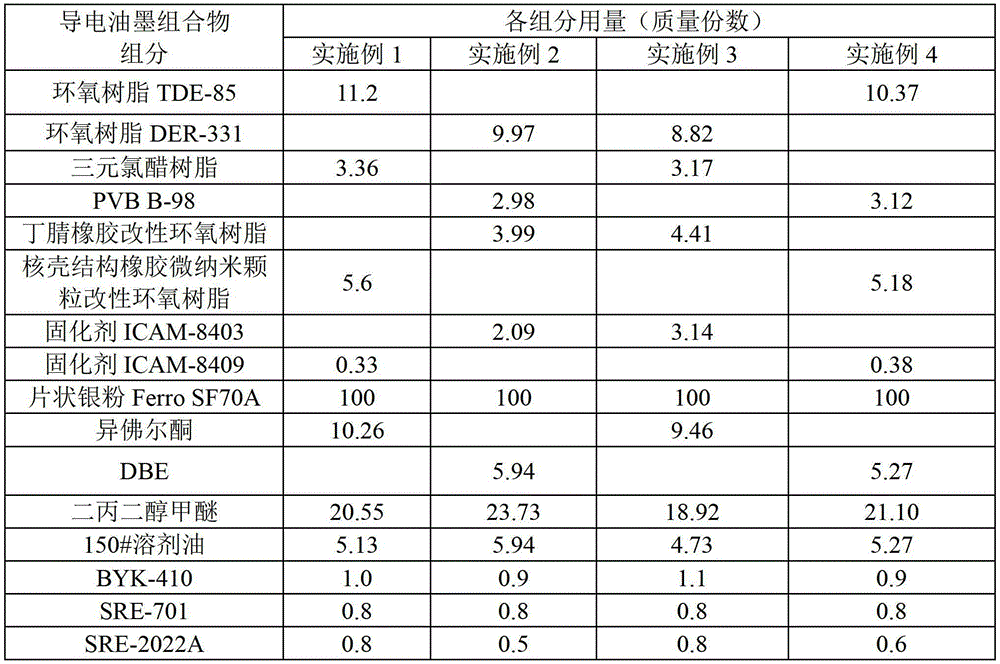

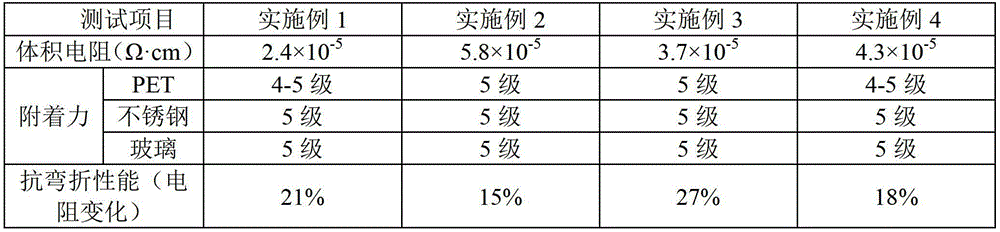

Screen printing conductive printing ink composition and preparation method thereof

The invention discloses a screen printing conductive printing ink composition which comprises the following components in percentage by mass: 20-70 percent of conductive material powder, 1-20 percent of epoxy resin, 0.2-15 percent of epoxy resin latent curing agent, 1-30 percent of thermoplastic resin, 5-60 percent of organic solvent and 0-5 percent of epoxy resin flexibilizer. The preparation method comprises the following steps: mixing the thermoplastic resin powder and the organic solvent, mixing the epoxy resin, the epoxy resin flexibilizer and the epoxy resin latent curing agent to obtain a thermoplastic resin system, adding the conductive material powder to the thermoplastic resin system, mixing the conductive material powder with the thermoplastic resin system; and finally, adding the organic solvent to regulate the viscosity, thus obtaining the screen printing conductive printing ink composition. The product has the advantages of high mechanical strength, stable electrical properties, excellent chemical resistance, high base material adhesion force, low volatile organic compound (VOC) content and the like.

Owner:NAT UNIV OF DEFENSE TECH +1

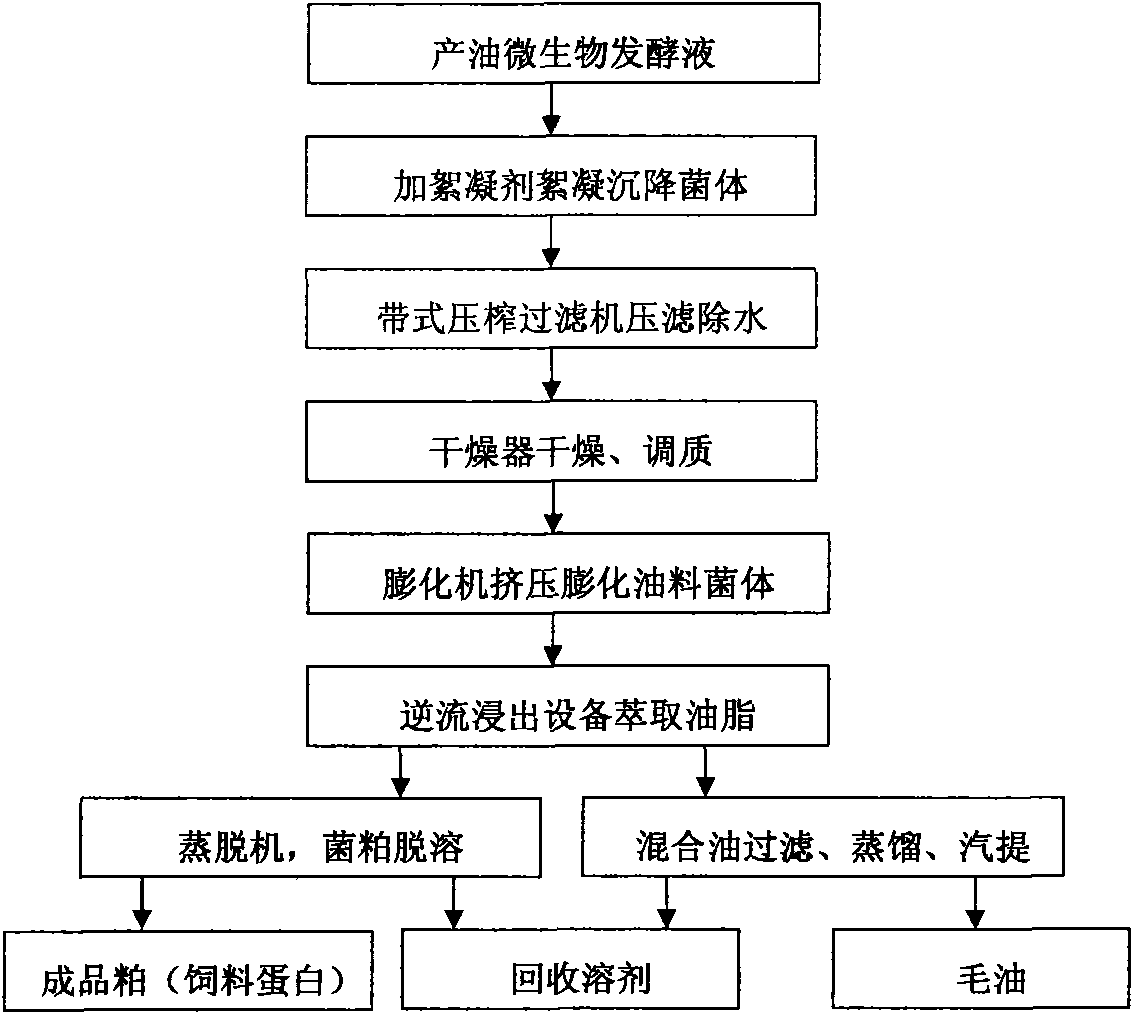

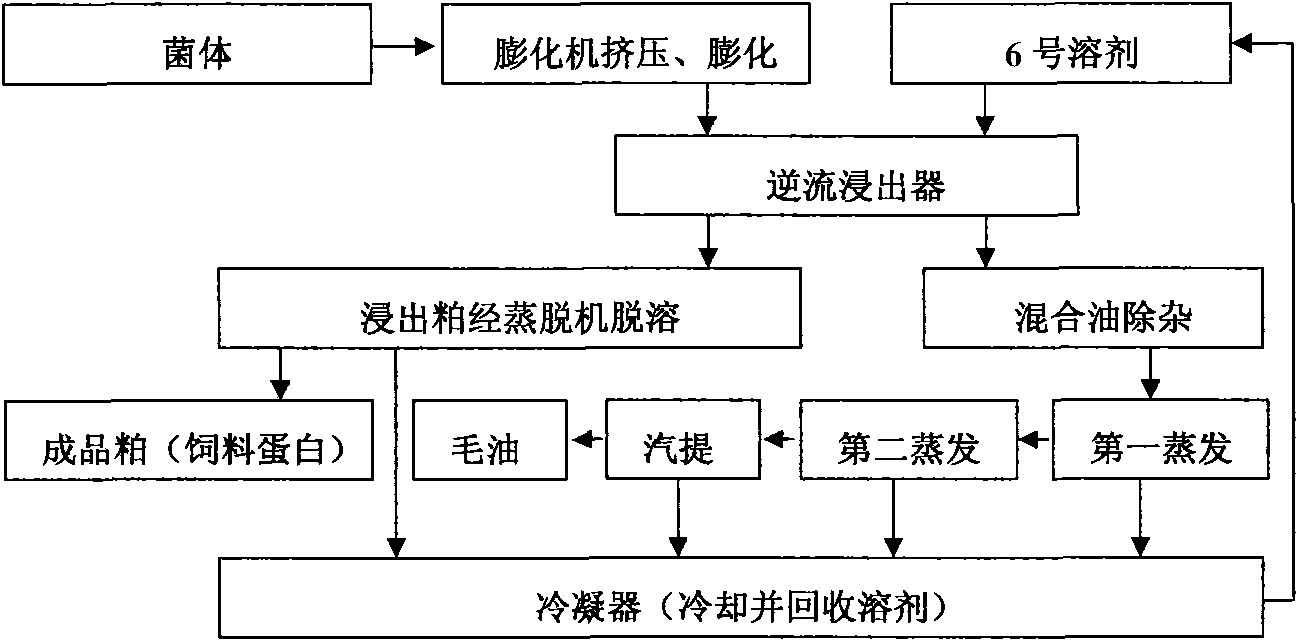

Method for preparing microbial oil and fat

InactiveCN101560440ASimple processImprove product qualityFermentationFatty-oils/fats productionOil and greaseMicrobial oil

The invention discloses a method for preparing microbial oil and fat, which comprises the following steps: (1) collecting microbial thalli; (2) performing filter pressing on the thalli obtained in the step (1) to obtain wet bacterial mud; (3) performing thermal refining, namely drying the wet bacterial mud obtained in the step (2) to remove most of free moisture and partial bound water in cells, and adjusting the temperature and the moisture content of the obtained dried thalli; (4) performing extrusion swelling, namely putting the dried thalli obtained in the step (3) into an extrusion swelling machine for extrusion and swelling; and (5) extracting and soaking the oil-bearing material dried thalli obtained in the step (4) to obtain mixed oil and soaked thalli residues. The method has the advantages of simple process, large handling capacity, low energy consumption and high product quality, and belongs to the field of oil and fat preparation.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of modified cation waterborne polyurethane emulsion containing hydrophilic and hydrophobic side long chains and product thereof

The invention relates to a preparation method of modified cation waterborne polyurethane emulsion containing hydrophilic and hydrophobic side long chains and a product thereof. The method comprises the following steps that raw materials are prepared; polyester glycol dehydration pretreatment is carried out; polyester glycol obtained after dehydration pretreatment is subjected to a prepolymerization reaction with an end alkyl polysiloxane linear body, a nonionic chain extender, a functionality chain extender and diisocyanate under catalyzing of a polymerization catalyst so that a prepolymer can be obtained; the prepolymer reacts with a nonionic chain extender and a part diluent to prepare an intermediate; the intermediate reacts with a silane coupling agent, and is emulsified to prepare the modified cation waterborne polyurethane emulsion. The product is a polyester type cation waterborne polyurethane high-polymer material containing hydrophilic and hydrophobic side long chains, wherein polysiloxane is embedded into a main chain of the material, a side chain is grafted with long-chain polyether and long-chain alkyl, and the silane coupling agent is connected into the tail end of the material; the film-forming ability is high, and serving as a film, the emulsion has obvious water-repellent, antifouling and easy dirt-removing abilities, is excellent in compatibility with a cation softening agent, and has an excellent low-temperature soft feature; the product is safe, environmentally friendly and convenient to use.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

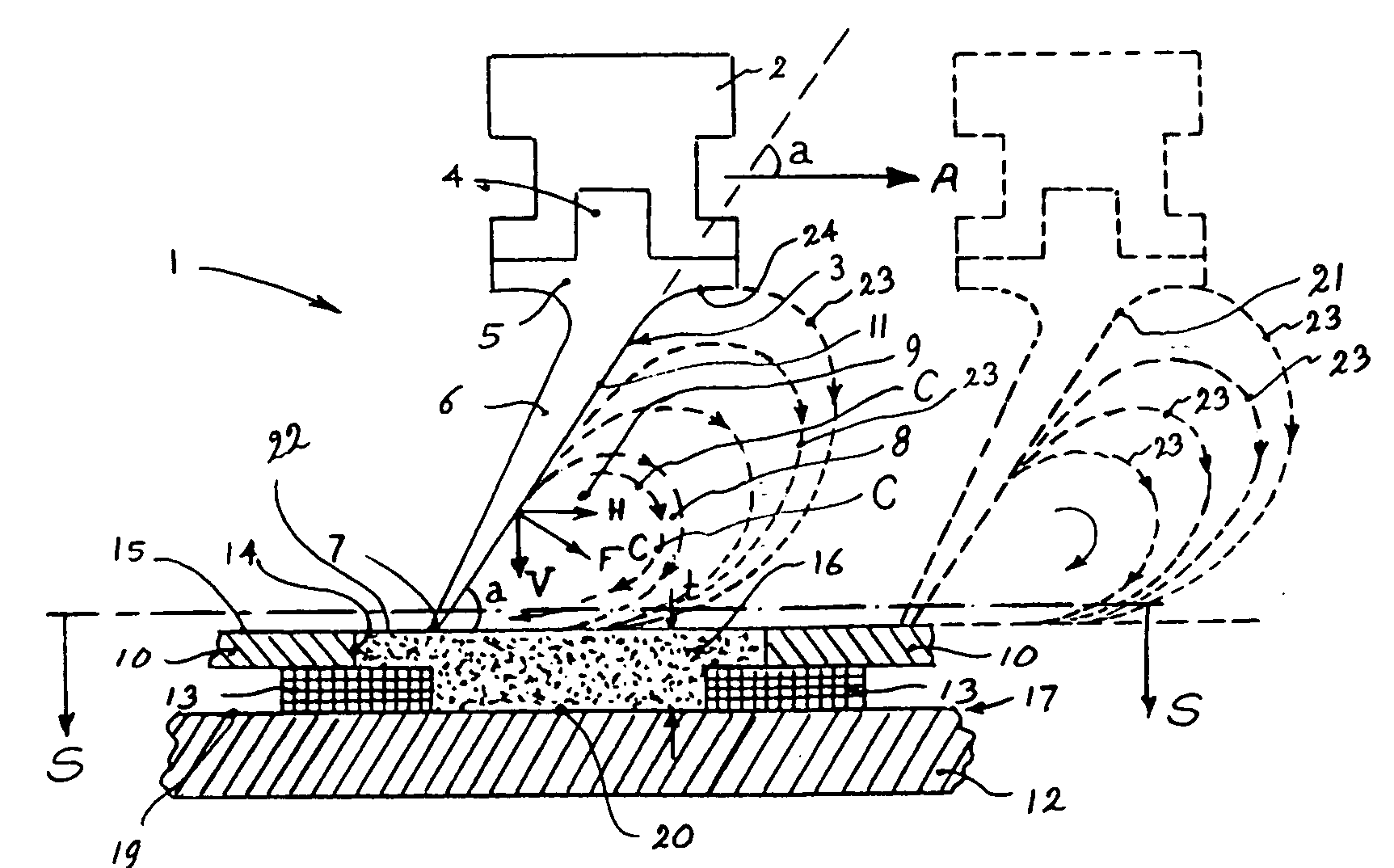

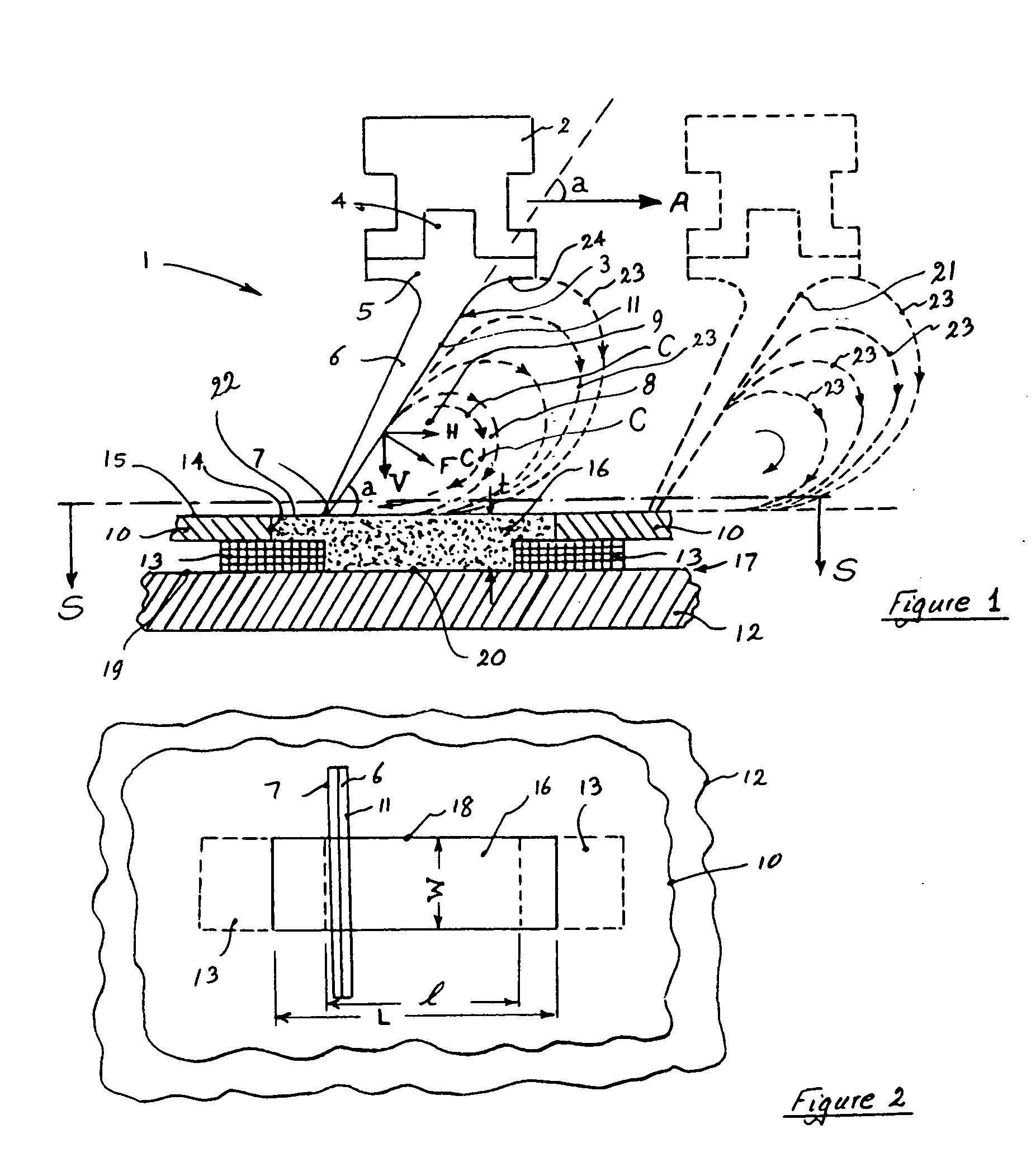

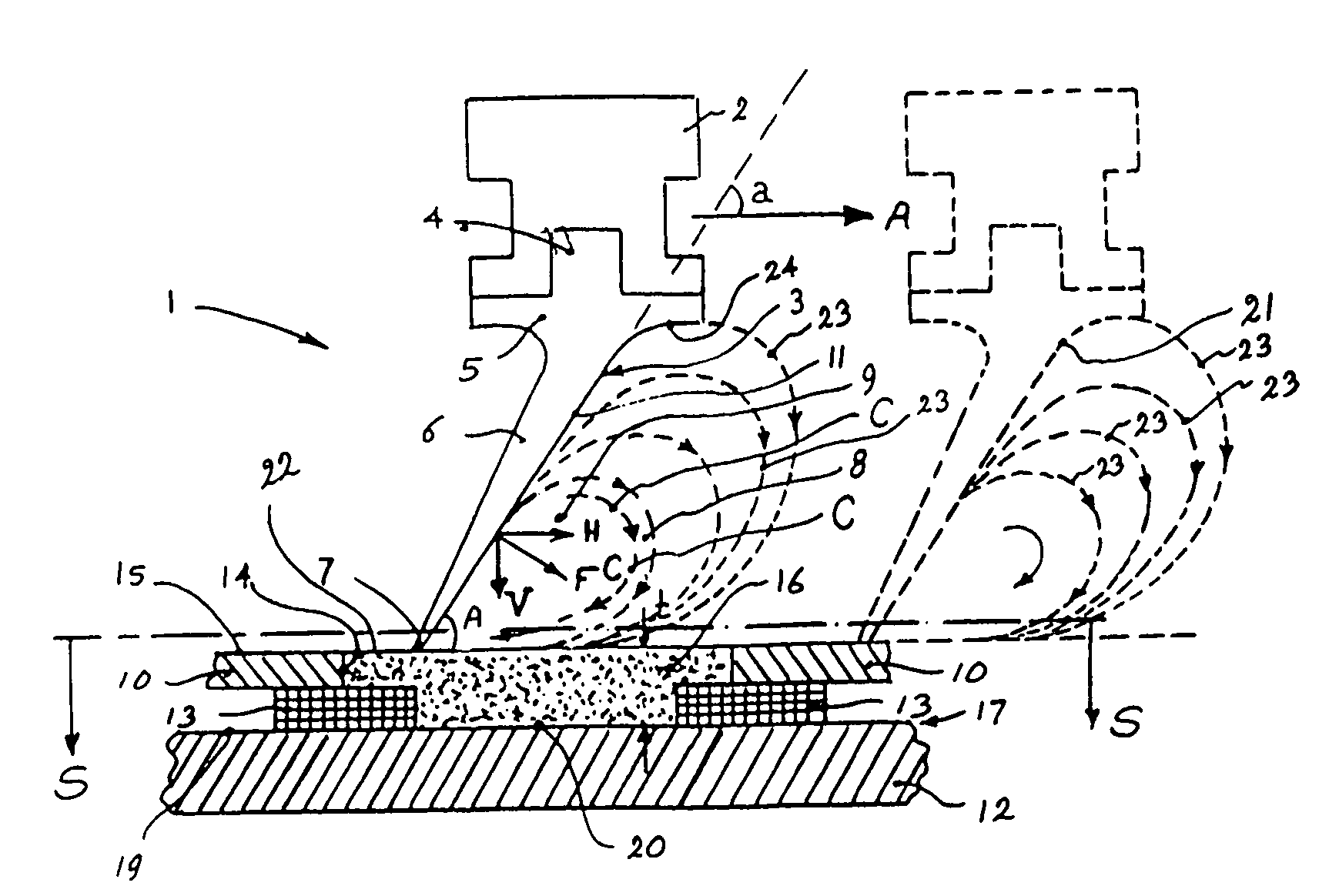

Polymer thick-film resistive paste, a polymer thick-film resistor and a method and an apparatus for the manufacture thereof

InactiveUS20050051360A1Low/insignificant dimensional and shape changeHigh solid contentPretreated surfacesLiquid/solution decomposition chemical coatingPolymer sciencePrinted circuit board

The present invention teaches formulations, apparatus and a method of applying high thixotropic index polymer thick-film resistive pastes for making polymer thick-film resistors with improved tolerances by providing a squeegee with a blade tilted at an angle of 10 to 85 to the surface of the printed circuit board thus causing a fluid rotational motion within the bead of the polymer thick-film resistive paste as the squeegee blade moves relative to the printed circuit board. This rotational motion increases the shear strain rate experienced by the paste within the bead and results in a more effective filling of the resistor-shaped cavity without including air bubbles, experiencing elastic recovery of the paste and, without surface fractures of the paste.

Owner:EMBED TECH

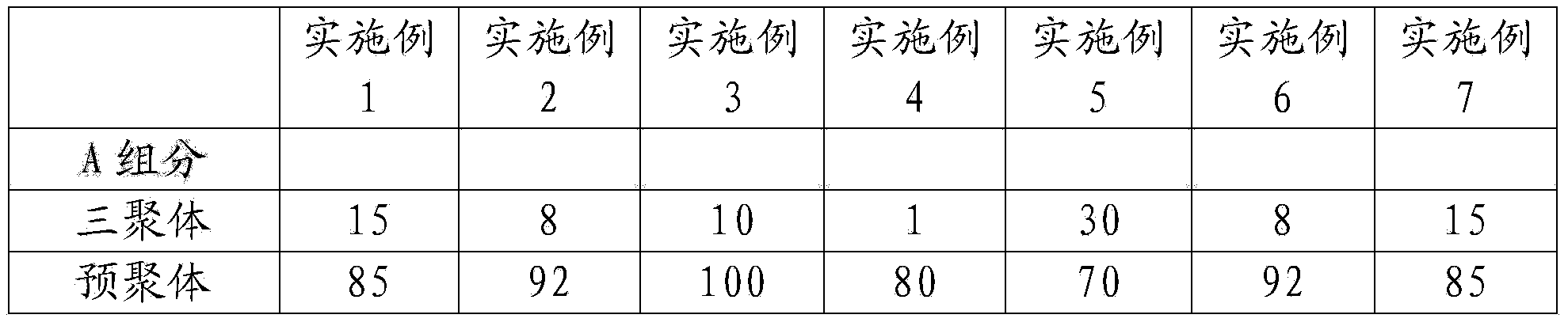

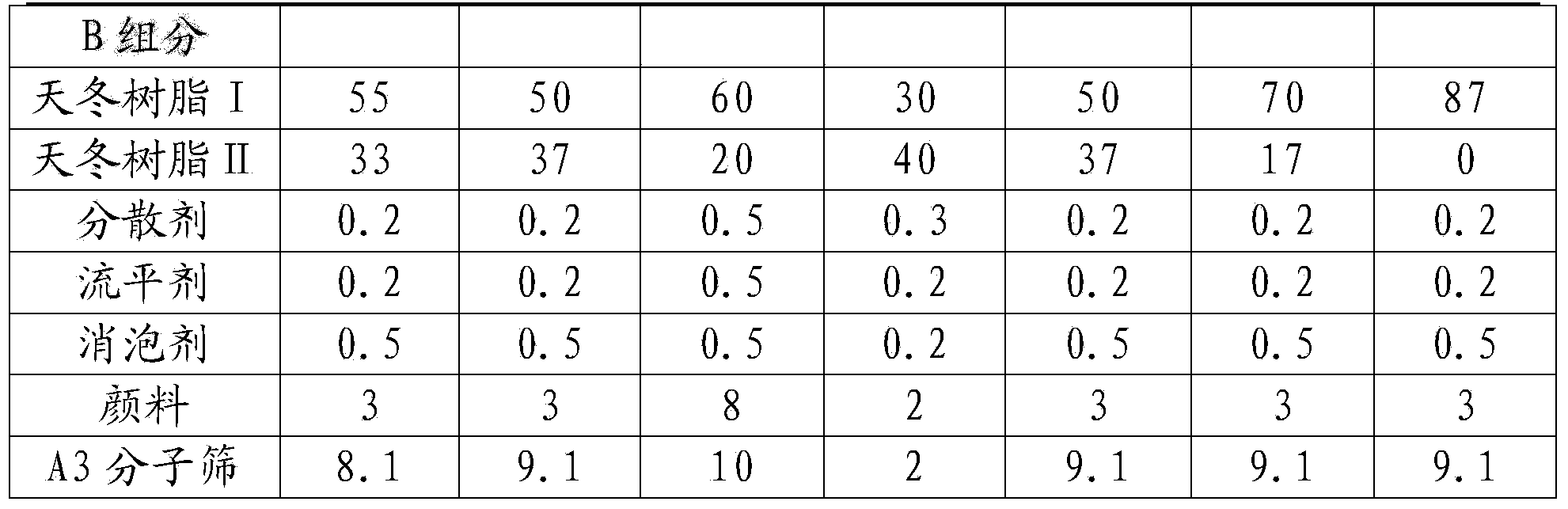

Elastic waterproof polyurea coating as well as preparation method and application method thereof

ActiveCN103820014ALow solvent contentLong application periodLiquid surface applicatorsPolyurea/polyurethane coatingsDisinfectantPolyurea

The invention belongs to the technical field of coating production and particularly relates to an elastic waterproof polyurea coating as well as a preparation method and application method thereof. The coating comprises a component A and a component B, wherein the component A comprises the main ingredients of aliphatic polyisocyanate trimer and an elastic isocyanate curing agent; the component B comprises the main ingredient of dimerization type asparaginic acid ester polyurea resin; the component A and the component B are packaged independently; a base coat layer is uniformly coated with the component A and the component B. The polyurea coating provided by the invention has the advantages as follows: the construction time of the polyurea coating is prolonged, the wettability is improved, and the performance of thick coating construction is provided, so that special polyurea coating equipment and special constructors are not required, the construction is facilitated, and the formed film has excellent elasticity. The polyurea coating can be dried after being coated for two hours, is high in curing speed, can be used outdoors, has excellent water resistance and chemical corrosion resistance of a swimming pool disinfectant, and can be soaked in water for a long time without cracking and leakage.

Owner:深圳市威尔地坪材料有限公司

Low temperature drying methods for forming drug-containing polymeric compositions

The present invention relates to a process for reducing solvent contents in drug-containing polymeric compositions. Specifically, the solvent contents in the drug-containing polymeric compositions are first reduced by one or more conventional drying methods, to a range from about 0.5 wt % to about 10 wt % of the total weight of the polymeric composition. Subsequently, the drug-containing polymeric compositions are further treated by one or more low temperature (i.e., having processing temperatures of less than 60° C.) drying methods for further reduction of the solvent content to less than 10,000 ppm.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

Water-absorbent resin and its production process

ActiveUS20060276598A1Improve balancePromote absorptionLayered productsAbsorbent padsOrganic solventPolymer science

Objects of the present invention are: to provide a water-absorbent resin which exhibits excellent balances between water absorption performances; and further to provide a process by which a water-absorbent resin having excellent absorption properties can be produced even if no hydrophilic organic solvent is used, or even if its amount is extremely reduced, when carrying out the surface-crosslinking treatment; and further to provide a water-absorbent resin optimum to absorbent articles such as diapers. As a means of achieving these objects, the process according to the present invention for production of the water-absorbent resin comprises: a step (1) of polymerizing a monomer component including an acid-group-containing unsaturated monomer as an essential component to thereby obtain a hydrogel polymer; a step (2) of drying and pulverizing the hydrogel polymer to thereby obtain a water-absorbent resin powder; a step (3) of adding a surface-crosslink-treating agent to the water-absorbent resin powder, wherein the surface-crosslink-treating agent includes a surface-crosslinking agent and water as essential components and has a hydrophilic organic solvent content of 0 to 10 mass % relative to the surface-crosslink-treating agent; and a step (4) of heating the resultant mixture to thereby carry out surface-crosslinking treatment; wherein a time of from the end of the step (3) till the beginning of the step (4) is within 5 minutes.

Owner:NIPPON SHOKUBAI CO LTD

Preparation method and product of modified polyurethane flexible high-molecular emulsion containing side long chain alkyl

ActiveCN104774307AGood flexibilityImprove low temperature resistancePolyurea/polyurethane coatingsPolyolefinTriol

The invention relates to a preparation method and product of a modified polyurethane flexible high-molecular emulsion containing side long chain alkyl. The preparation method comprises the following steps: preparing raw materials including a polymeric monomer, a modifying agent, an auxiliary agent and water; performing dehydration pretreatment on polyether triol and polyether glycol; performing prepolymerization; performing chain extension; sealing ends; and emulsifying to prepare a modified polyurethane flexible high-molecular emulsion product containing side long chain alkyl. According to the modified polyurethane flexible high-molecular emulsion disclosed by the invention, polysiloxane chain links and polyolefin chain links are embedded into a skeleton structure of the modified polyurethane flexible high-molecular emulsion, and polyurethane high molecules are modified by using long chain alkyl. The obtained modified polyurethane flexible high-molecular emulsion containing side long chain alkyl has a certain density of long chain crosslinking and side long chain alkyl, has excellent stability, can be applied to dry coating processing of various substrate coatings and artificial leathers, and ensures that significant water-repellent and anti-fouling abilities, extremely excellent extension performance, excellent low-temperature high flexibility and anti-bending performance of product coating films can be achieved; and the product is safe and environment-friendly, and is convenient to use.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

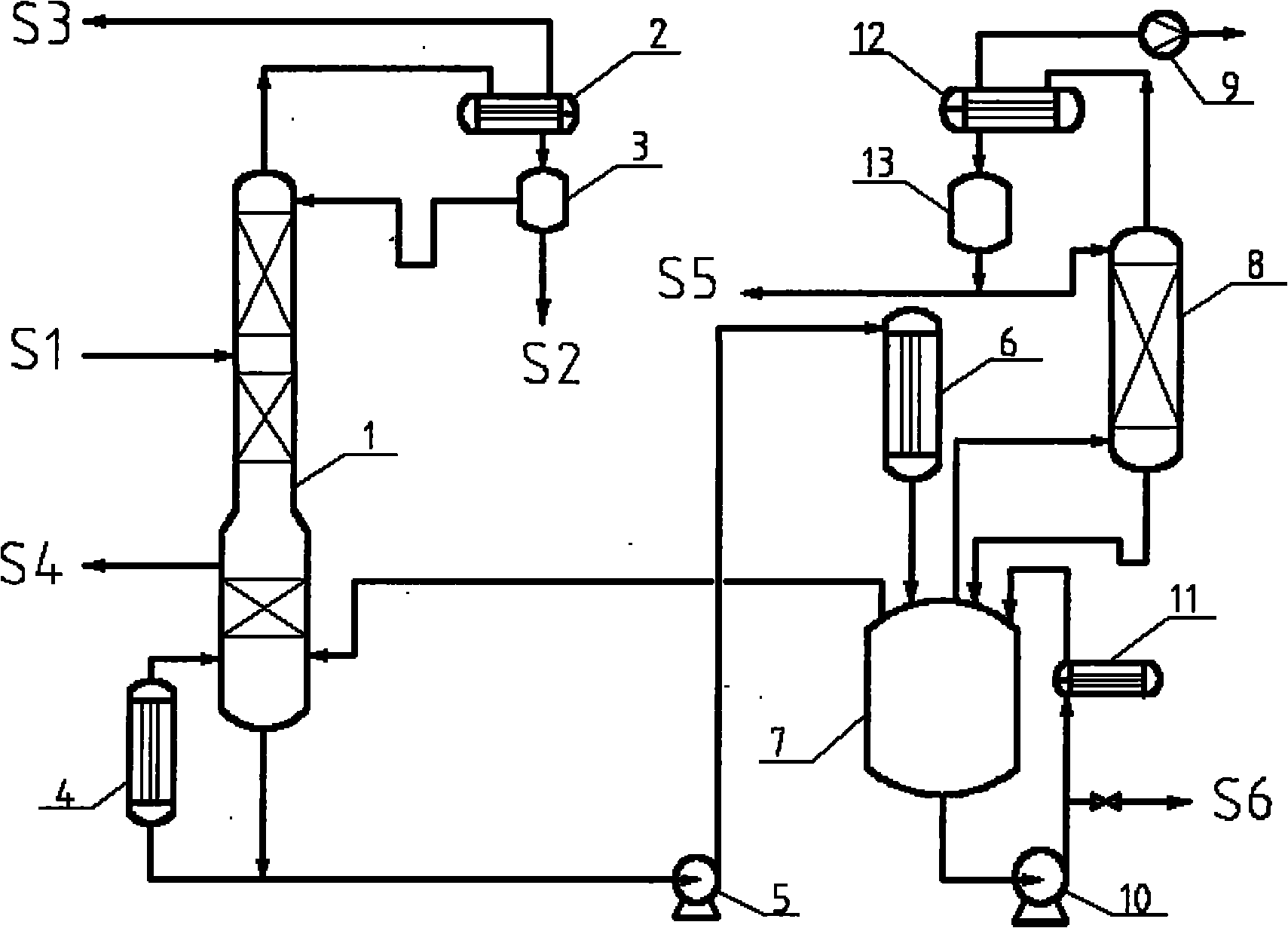

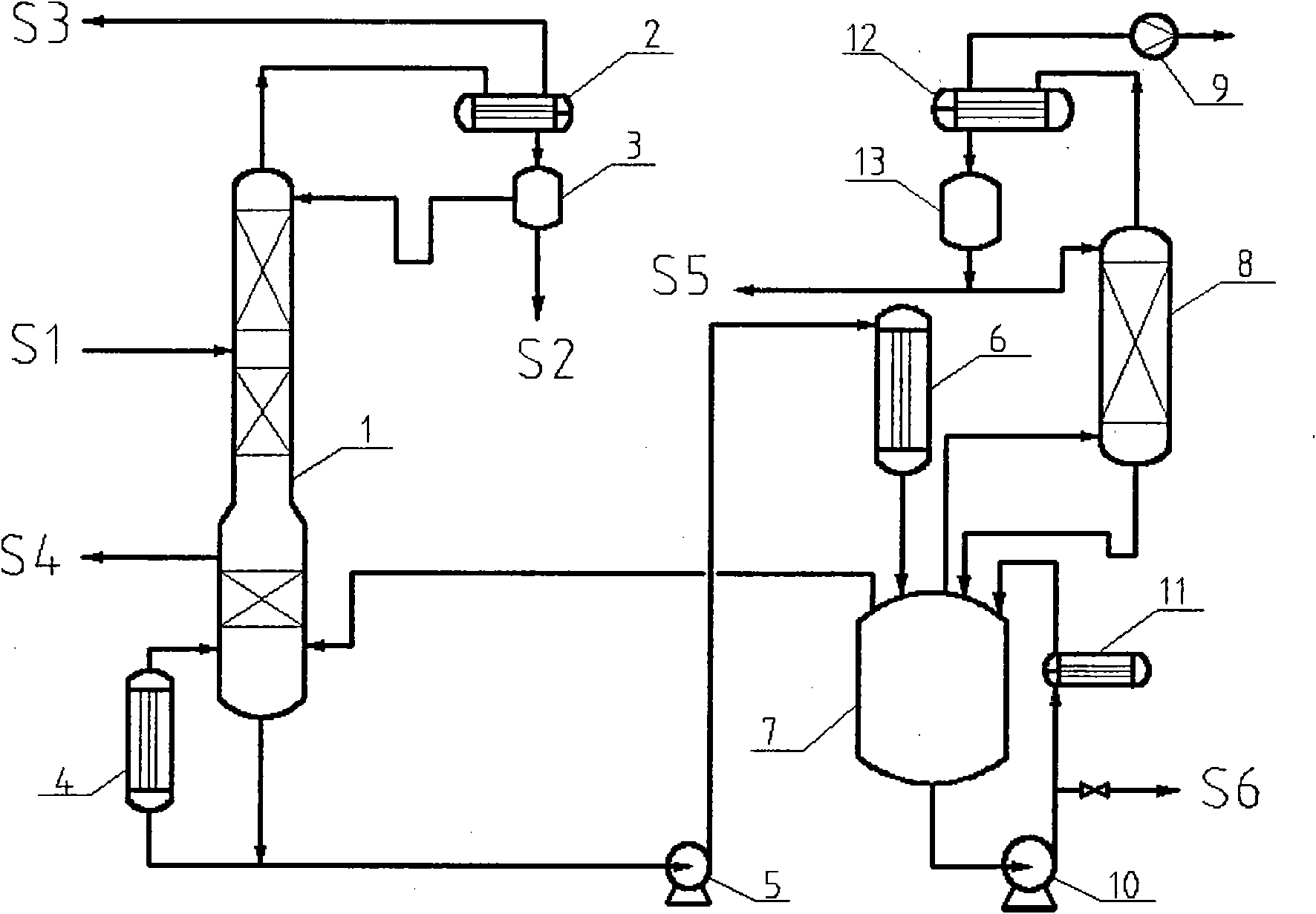

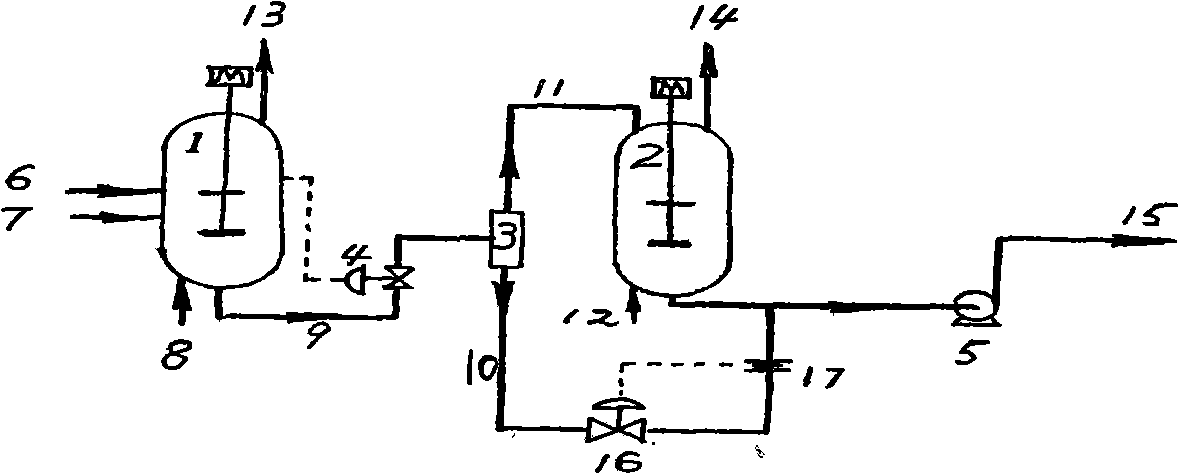

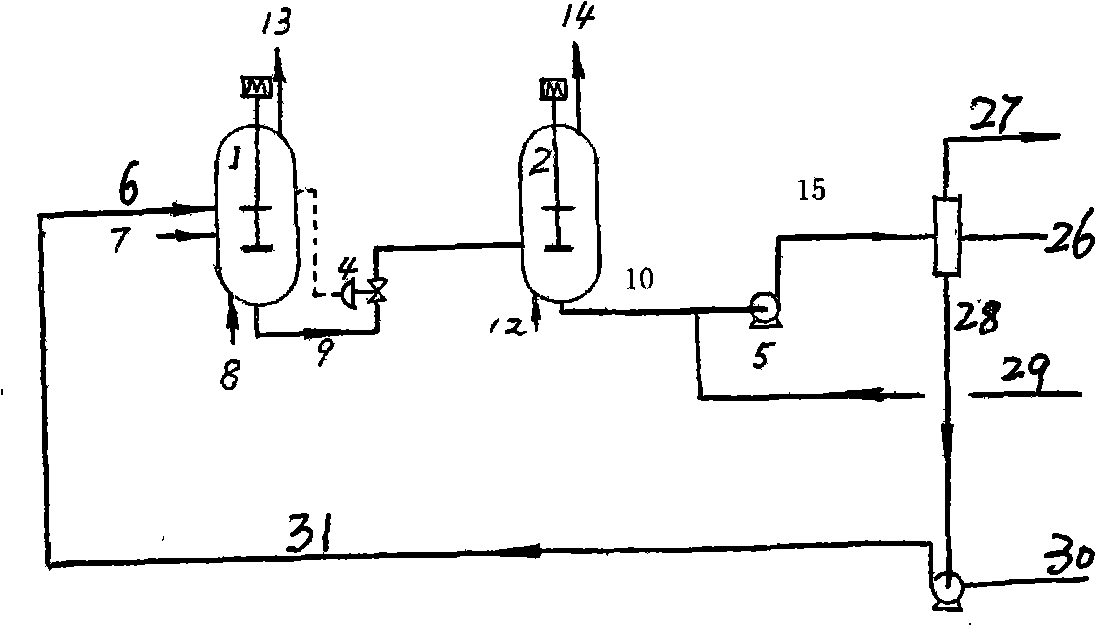

Refining and reclaiming technology of tail gas absorption solvent in production of toluene diisocyanate

InactiveCN101870666AContinuous and stable feedingContinuous and stable dischargeDispersed particle separationDistillation purification/separationToluene diisocyanateGas phase

The invention relates to a refining and reclaiming technology of a tail gas absorption solvent in the production of toluene diisocyanate (TDI). The solvent containing little phosgene, toluene diisocyanate and di-Et-1,3-benzenedicarboxylate (DEIP) performs two-stage refinement in an atmospheric refining tower and a vacuum refining tower, and a falling-film evaporator and a storage tank are arranged between the two towers. The overhead non-condensable gas phase of the atmospheric refining tower is returned to a phosgene absorption tower to recycle phosgene, the refined solvent is drawn from theside of the atmospheric refining tower, the temperature of the tower bottom is controlled to be 3-8 DEG C higher than the boiling point of the solvent, the discharged material of the tower bottom enters the falling-film evaporator, the evaporating temperature is 20-30 DEG C higher than the boiling point of the solvent, the unevaporated material enters the storage tank for storage, the material inthe storage tank performs batch vacuum rectification under the absolute pressure of 0.1-0.25bar, and the unevaporated residual material enters the residue evaporator of a TDI device to recycle TDI and DEIP. By using the solvent refining technology provided by the invention, the useful components in the solvent can be completely recycled, and the technology has the advantages of simple and stable operation and lower cost and energy consumption.

Owner:QINGDAO UNIV OF SCI & TECH +1

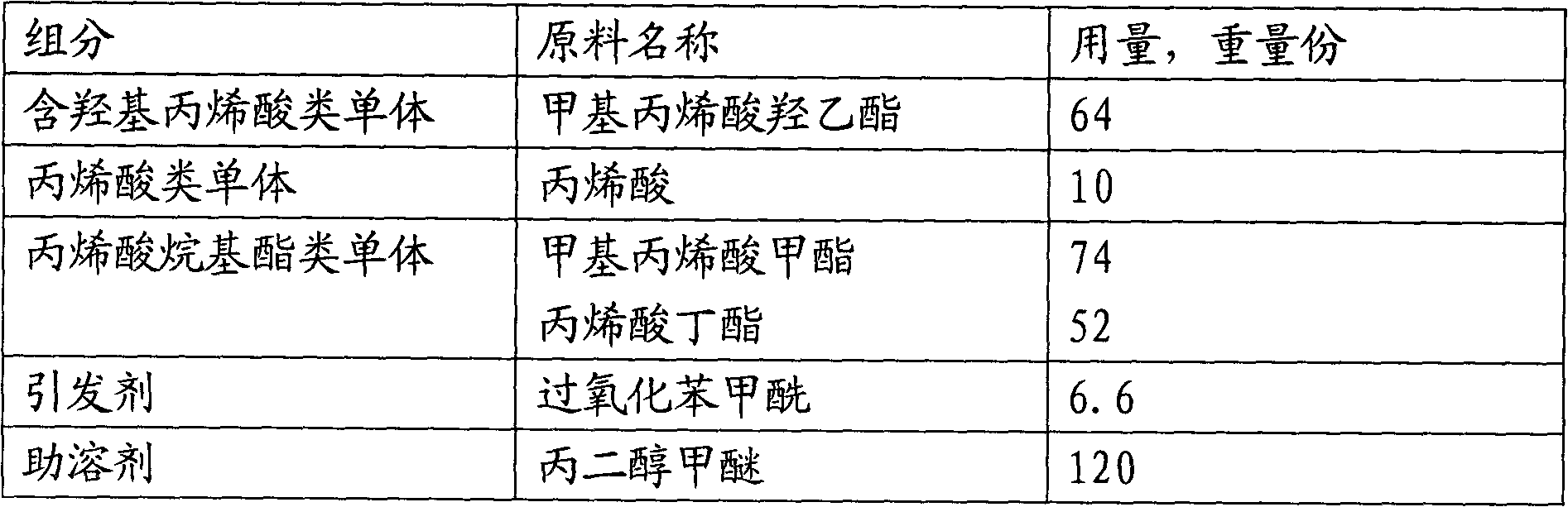

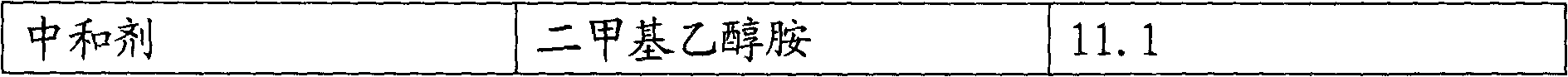

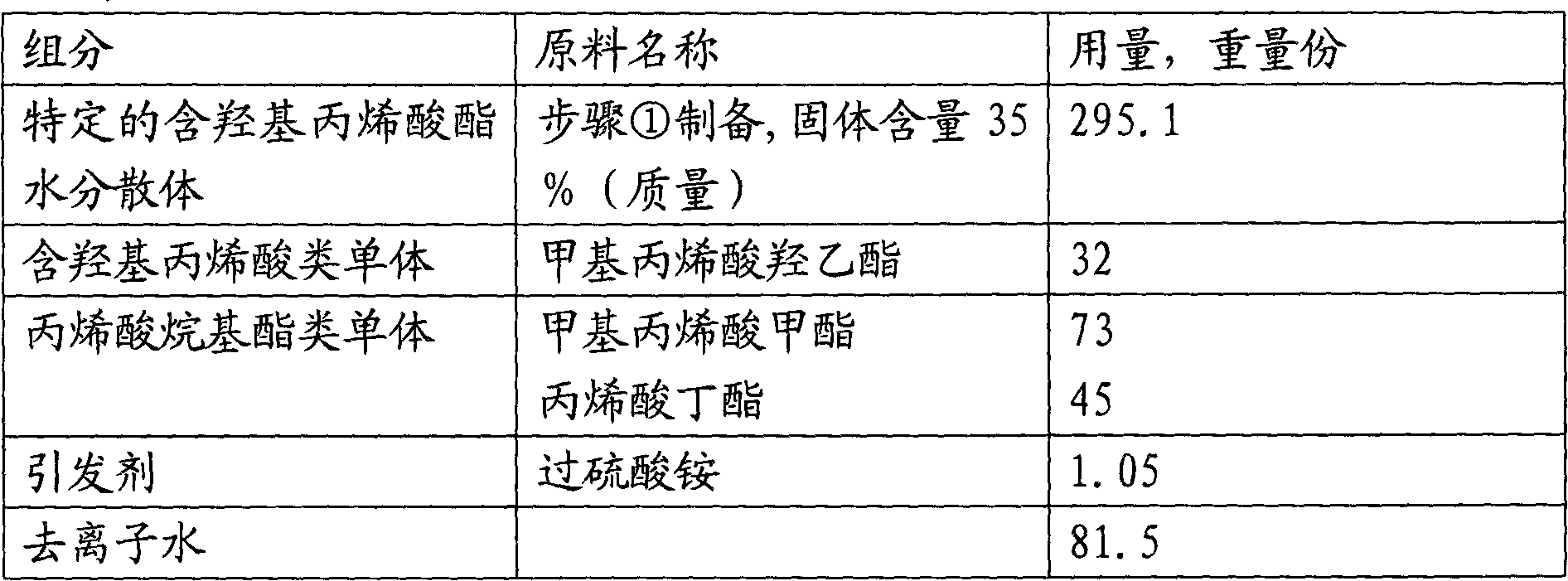

Hydroxyl-containing water-based acrylic ester polymer and preparation method thereof

The invention relates to a hydroxyl-containing water-based acrylic ester polymer and a preparation method thereof. The hydroxyl-containing water-based acrylic ester polymer is synthesized by two steps of: firstly, preparing a specific hydroxyl-containing acrylic ester aqueous dispersion; and secondly, carrying out free base polymerization on the specific hydroxyl-containing acrylic ester aqueous dispersion and 10-30 parts of hydroxyl-containing acrylic ester monomers, 30-50 parts of methacrylate monomers, 0.1-0.5 part of ammonium persulfate and / or potassium persulfate initiator and 30-50 parts of deionized water, wherein the percentage of Mn is mote than or equal to 10,000; the hydroxyl-containing water-based acrylic ester polymer has low content of solvent, high content of solid, low viscosity and low acid value; and the weight ratio of the specific hydroxyl-containing acrylic ester aqueous dispersion to the monomers and the initiator used for the free base polymerization with the specific hydroxyl-containing acrylic ester aqueous dispersion is 1:(1.40-2.0) counted according to the solid content. The hydroxyl-containing water-based acrylic ester polymer can be used for preparing a dual-component waterborne polymerization coating, or can be used for preparing a waterborne amino baking coating and has the advantages of high luster of a paint film, weather resistance, corrosion resistance, low VOC (Volatile Organic Compounds) and wide application range; and a preparation process is stable and controllable.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

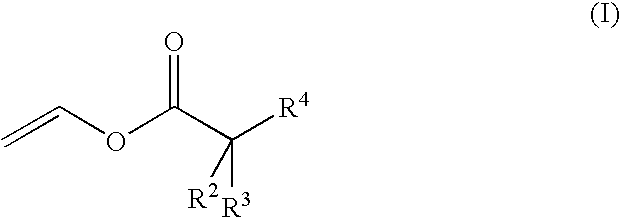

Aqueous copolymer dispersions with reactive diluent

ActiveUS20060205857A1Good storage stabilityImprove the level ofData processing applicationsCoatingsMeth-Polyol

The present invention relates to aqueous copolymer dispersions containing A) one or more hydroxy-functional copolymers synthesized from a) one or more OH-free (meth)acrylic esters and / or vinylaromatics, b) one or more hydroxy-functional (meth)acrylic esters, c) one or more ionic and / or potential ionic monomers capable of free-radical copolymerization, and d) one or more optionally monomers other than components a) to c) that are capable of free-radical copolymerization, and B) one or more hydroxy-functional polycarbonate polyols as reactive diluent. The present invention also relates to a process for preparing these aqueous copolymer dispersions and to their use in coating compositions.

Owner:COVESTRO DEUTSCHLAND AG

Spray drying processes for forming solid amorphous dispersions of drugs and polymers

InactiveUS10383941B2Fast evaporationMaximize productionPowder deliveryMetabolism disorderPolymer chemistryPolymer

Spray drying processes are used to form pharmaceutical compositions comprising a solid amorphous dispersion of a drug and a polymer.

Owner:LONZA BEND INC

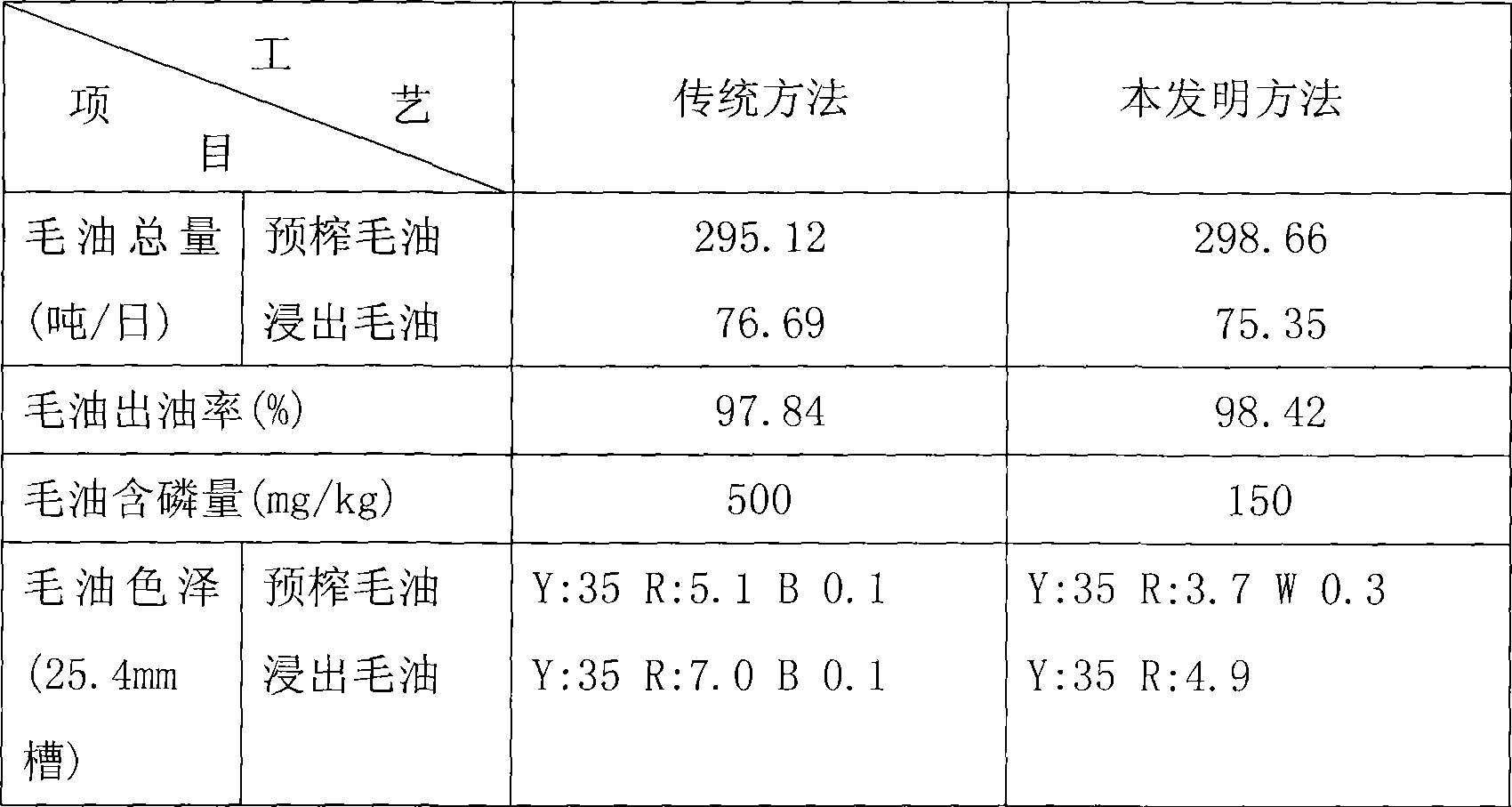

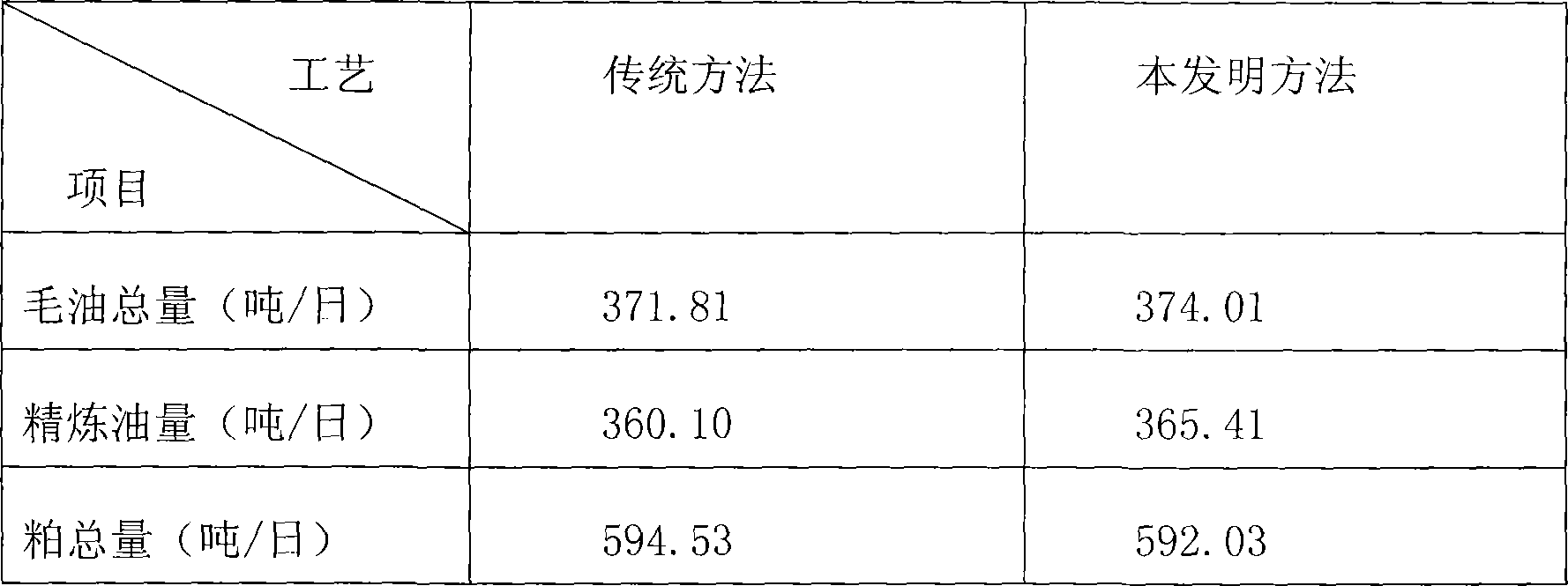

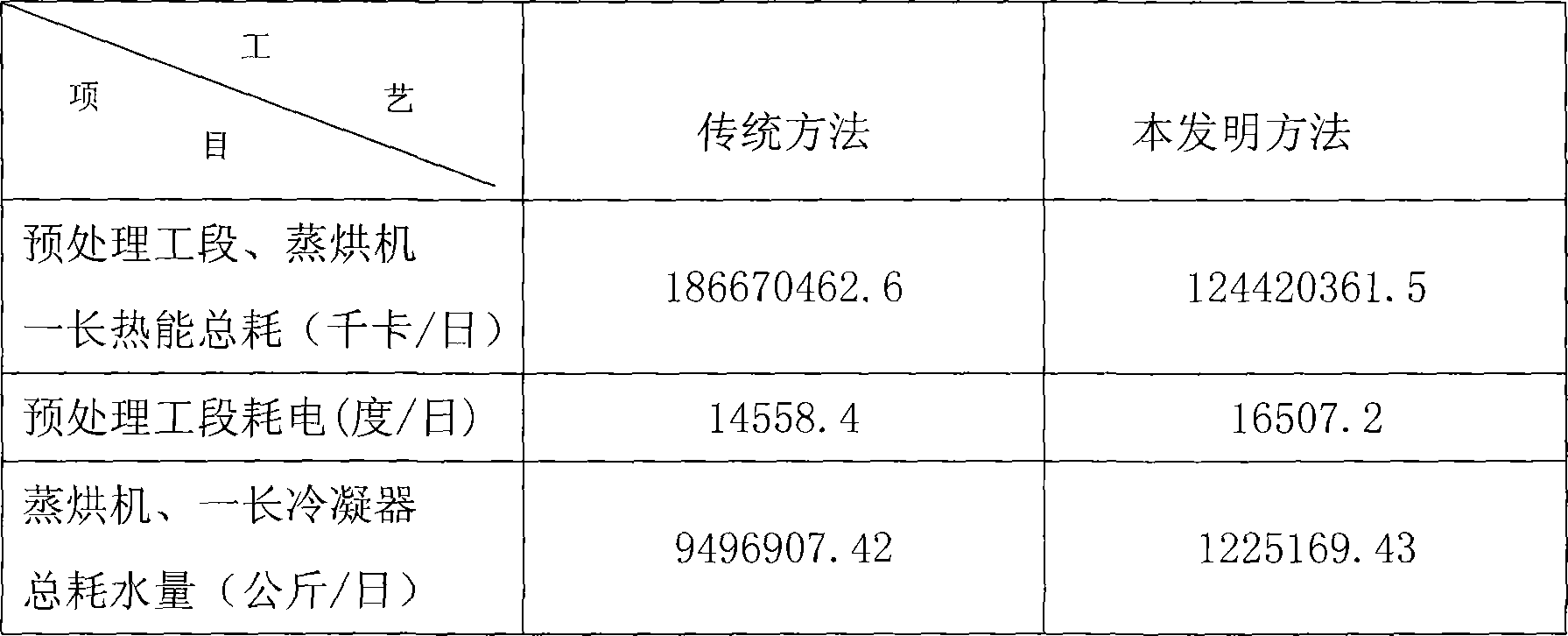

Swelling pre-squeezing leaching preparation method for high oil-containing material

InactiveCN101235340AAvoid excessive denaturationReduces loss of lysineFatty-oils/fats productionWater contentOil content

The invention relates to a high oil-content oil material expanding prepressing leaching oil preparation method, which is characterized in that the method comprises the following steps, firstly, cleaning, cleaning oiling to remove impurities, secondly, tempering, adjusting the water content of oiling whose impurities are removed, thirdly, rolling slab, rolling oiling whose water content is adjusted into material slab, fourthly, squeezing and swelling, squeezing and swelling, the material slab, fifthly, drying, drying the material slab which is squeezed and swelled, sixthly, prepressing, prepressing the material slab which is dried to press one portion of oil, seventhly, leaching, leaching prepressed cake of the oil which is prepressed to get another portion of oil and meal from solvent extraction. A squeezing and swelling step in the invention is utilized to replace a cooking step in the existing method, which improves the quality and amounts of prepressing crude palm oil, increases handling capacity of a prepress expeller, and reduces power consumption and abrasion of a prepress expeller. The method of the invention is mainly applicable for oil preparation enterprises which utilize high oil-content oiling such as rapeseed and the like to be raw material.

Owner:中机康元粮油装备(北京)有限公司 +1

Process for forming amorphous atorvastatin

ActiveUS20050032880A1Improve solubilityImprove processing efficiencyBiocideNervous disorderSolventAtorvastatin

Forming amorphous atorvastatin comprises the steps of dissolving atorvastatin in a hydroxylic solvent, followed by rapidly evaporating the solvent. In another aspect, a composition comprises particles of amorphous atorvastatin and a core.

Owner:UPJOHN US 1 LLC

Method of applying a polymer thick-film resistive paste for making polymer thick-film resistor having improved tolerances

InactiveUS7575778B2Low/insignificant dimensional and shape changeHigh solid contentPretreated surfacesLiquid/solution decomposition chemical coatingElectrical resistance and conductanceEngineering

The present invention teaches formulations, apparatus and a method of applying high thixotropic index polymer thick-film resistive pastes for making polymer thick-film resistors with improved tolerances by providing a squeegee with a blade tilted at an angle of 10° to 85° to the surface of the printed circuit board thus causing a fluid rotational motion within the bead of the polymer thick-film resistive paste as the squeegee blade moves relative to the printed circuit board. This rotational motion increases the shear strain rate experienced by the paste within the bead and results in a more effective filling of the resistor-shaped cavity without including air bubbles, experiencing elastic recovery of the paste and, without surface fractures of the paste.

Owner:EMBED TECH

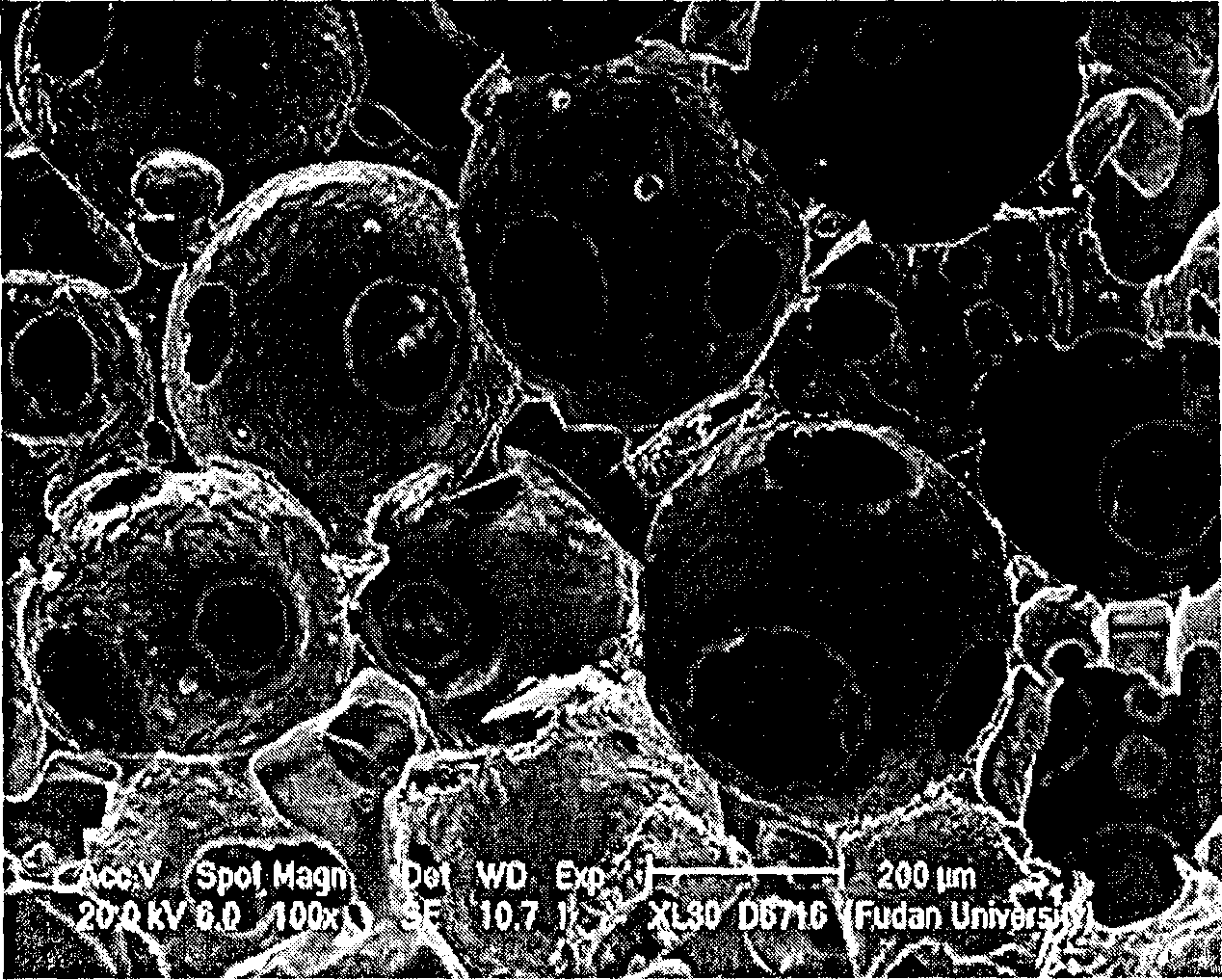

Porous rack with spherical pores and its molding prepn process

InactiveCN1486754ALiquidGood shape retentionPharmaceutical containersMedical packagingSpherical poreBiological materials

The present invention belongs to the field of polymer material and biological material technology, and is especially one porous rack with spherical pores and its molding preparation process. The 3D porous rack is prepared with polymer material as base material and through molding at normal temperature. The simple process may be used in preparing both rack with simple and regular outer appearance and rack with complicated and irregular outer appearance. The prepared porous rack may be relatively thick and has regular spherical pore structure of porosity over 90%, and the pores are communicated mutually and homogeneously distributed. The rack has high mechanical strength, and is suitable as 3D porous cell rack in tissue engineering and in other application fields.

Owner:FUDAN UNIV

Preparation method of high solid content epoxy modified acrylic resin emulsion

The invention relates to a method capable of preparing epoxy modified acrylic resin emulsion with solid content of greater than 60 percent. The method comprises the following steps of: preparing seed liquor; and adding pre-emulsion and an initiator in batches to finally obtain the epoxy modified acrylic resin emulsion with solid content of greater than 60 percent. According to the technology provided by the invention, the epoxy resin is introduced into the acrylic resin; the new resin shows the advantages of the epoxy resin and the acrylic resin and overcomes the defects of the epoxy resin and the acrylic resin respectively; and the resin prepared by the invention belongs to a high solid resin, has the advantages of material saving, transportation cost saving, low solvent content, improved safety and health, reduced energy consumption for production and use of a coating, thicker filming due to one-time brushing and capability of saving brushing time, and has broad industrial application prospect and can be used for the fields of ships, automobiles and the like.

Owner:广东德鑫翔远高新材料有限公司 +1

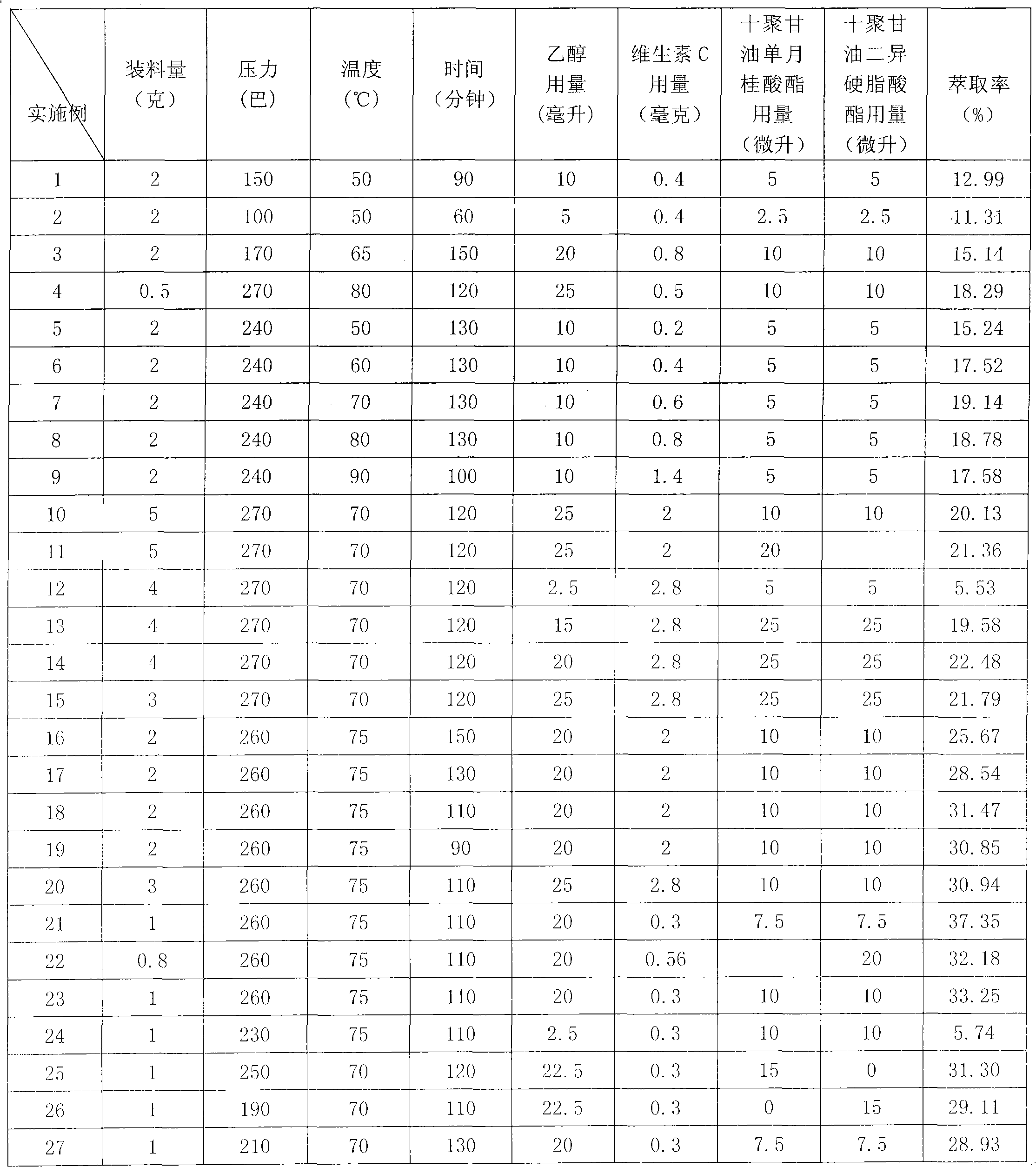

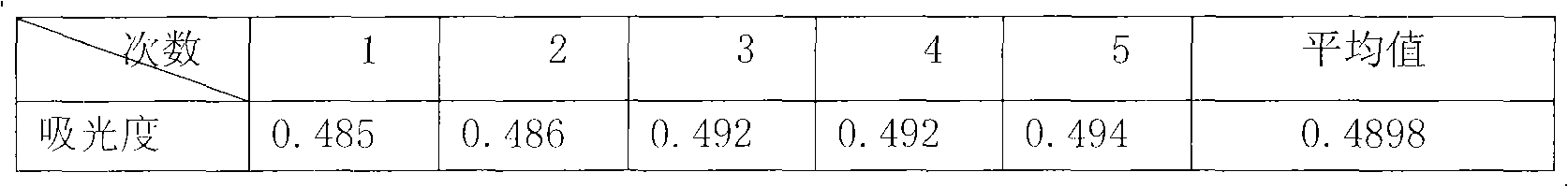

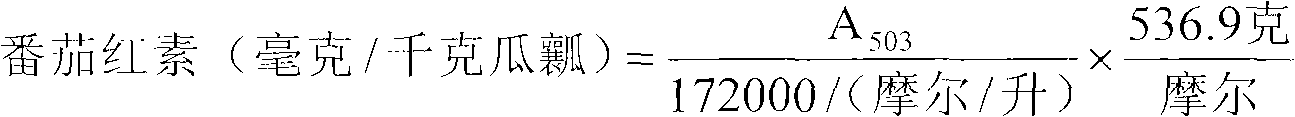

Method for supercritical carbon dioxide extraction of lycopene in watermelon

InactiveCN101891580AHigh yieldLow solvent contentNatural dyesExtraction purification/separationVitamin CLycopene

The invention discloses a method for supercritical carbon dioxide fluid extraction of lycopene in watermelons, comprising the following steps: pretreating the watermelons, carrying out supercritical carbon dioxide extraction with proper granularity at the pressure of 210-270bar and temperature of 60-80 DEG C for 100-150 minutes, wherein ethanol is used as an entrainer, the amount of the ethanol is 30-40% of the volume of an extraction kettle, and the charging amount of watermelon solid powder is 10-20% of the volume of the supercritical carbon dioxide extraction kettle; wherein vitamin C and polyglycerol fatty acid ester are used as addictives during the supercritical extraction process, and then repeatedly collecting materials after extraction is completed. The method for supercritical carbon dioxide fluid extraction of the lycopene in the watermelons can help improve the extraction yield of the lycopene up to 37%, and the extraction product has low solvent content and less environmental pollution in production process.

Owner:ZHENGZHOU UNIV

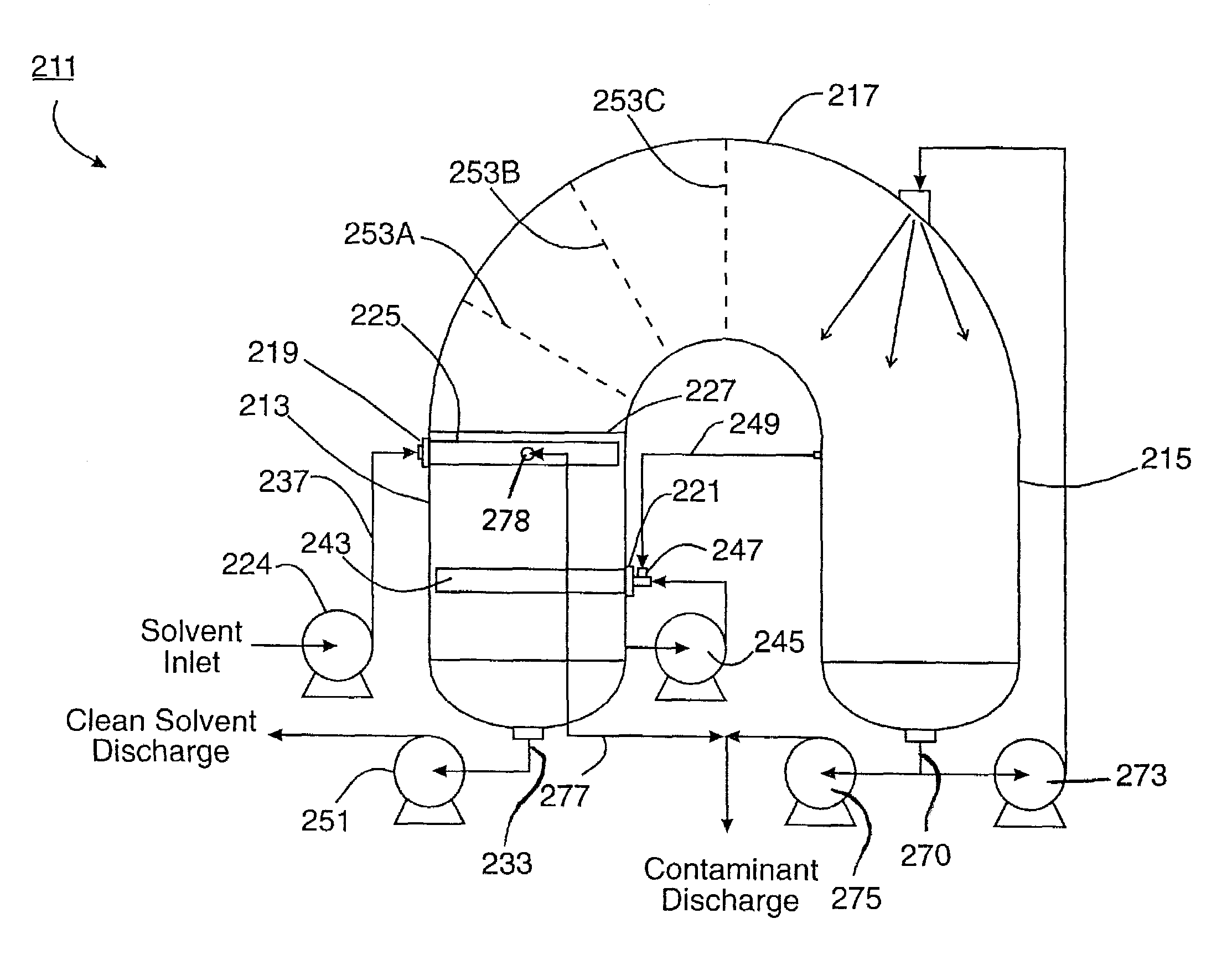

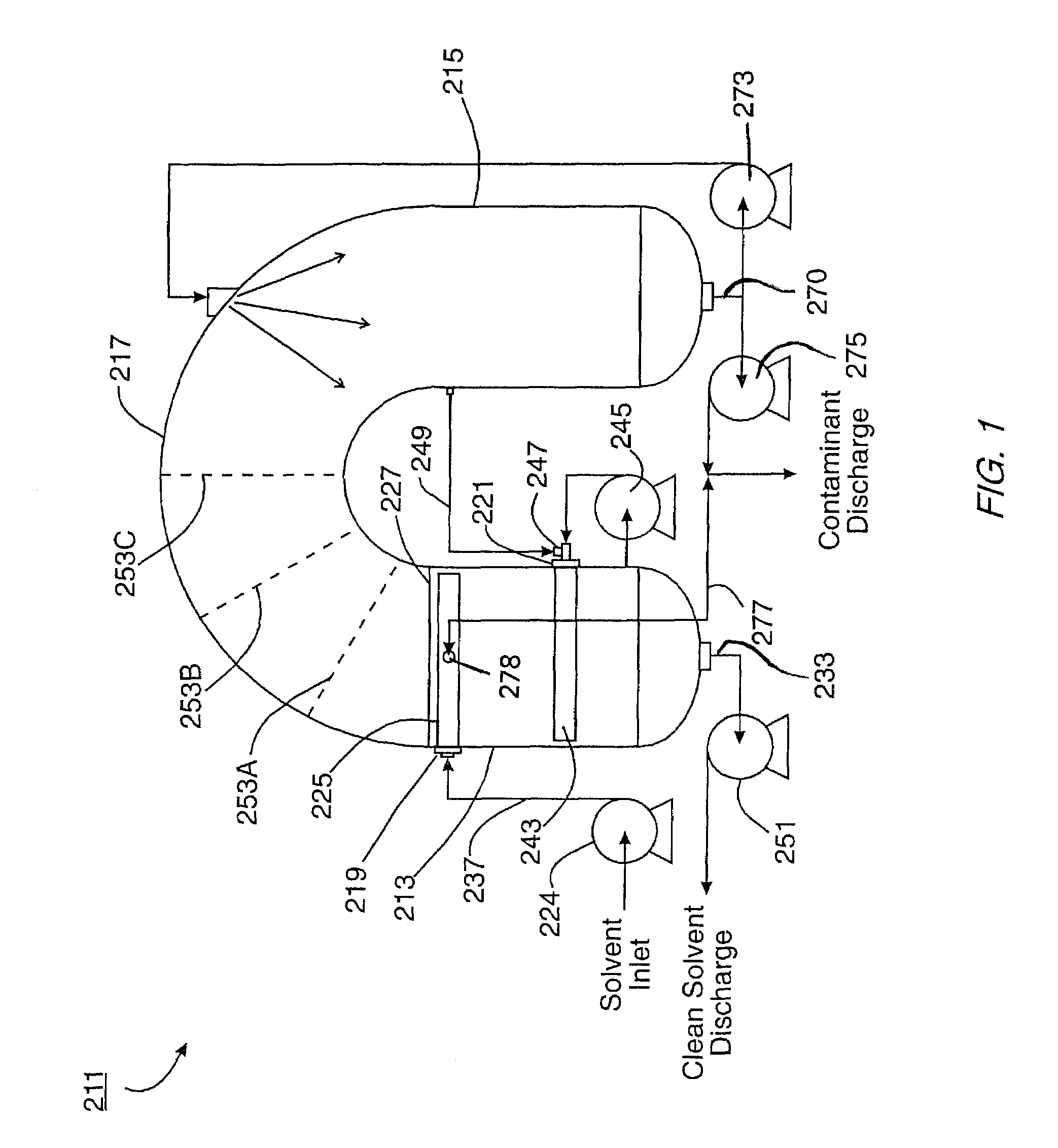

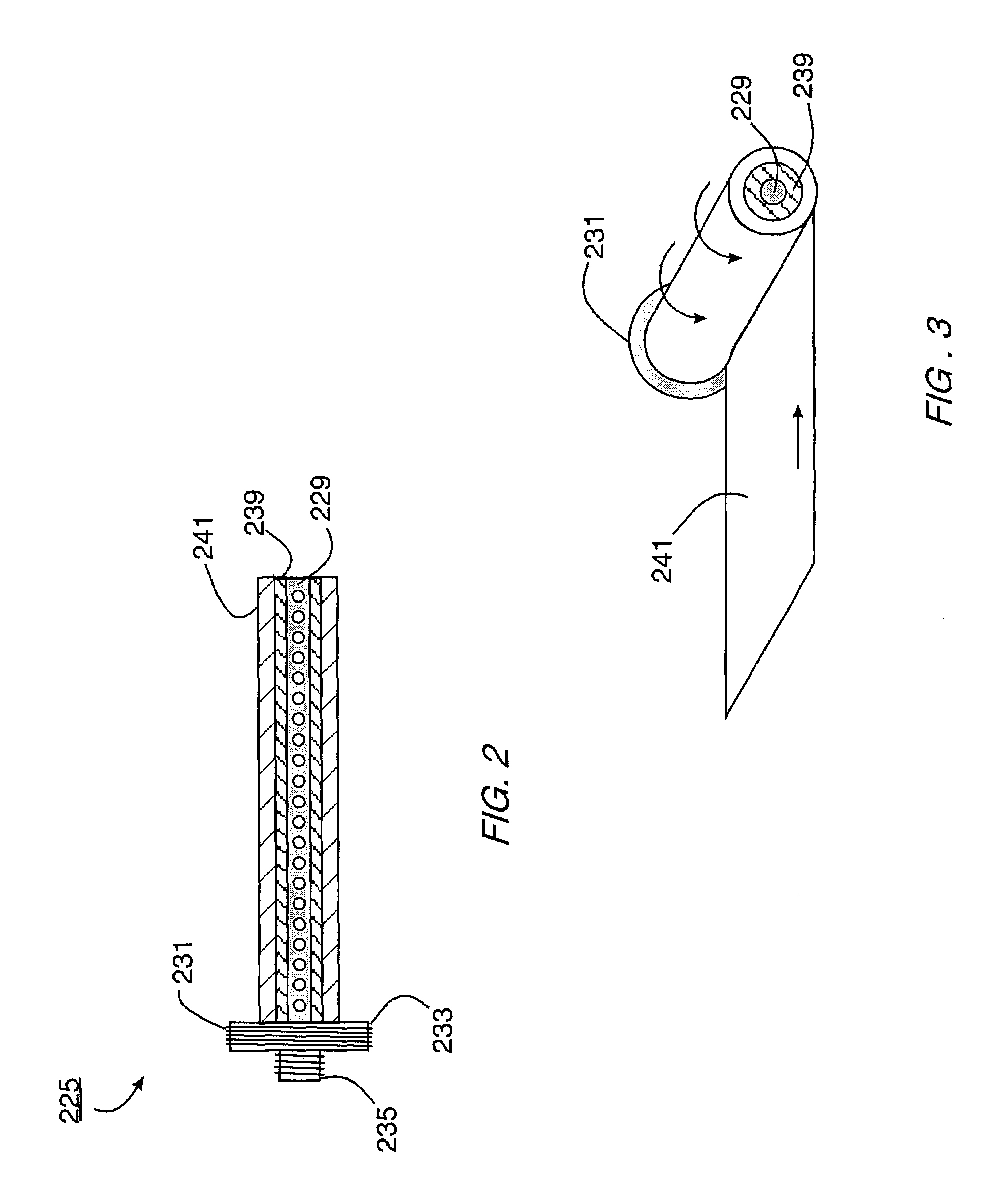

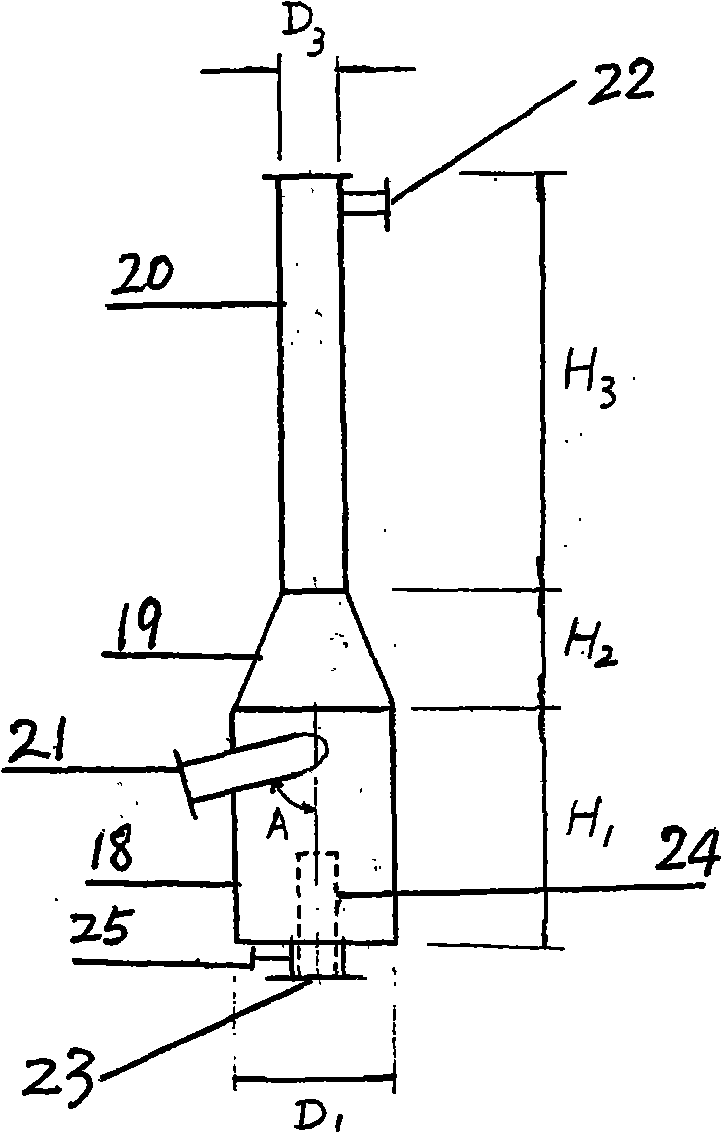

Method and apparatus for removing foaming contaminants from hydrocarbon processing solvents

InactiveUS6974542B2Improving mass transferEnhanced mass transferCombination devicesUsing liquid separation agentPush outSolvent

A column of solvent containing foaming contaminants is provided. Gas is educted into the solvent in the column so as to generate foam in the column. The gas is educted into the column independently of the input flow of solvent into the solvent using a pumparound arrangement with the solvent. Foam generation continues so as to push the foam up in the column, wherein much of the solvent that is in the foam is allowed to drain back down into the column. The foam passes through concentrators which increase the residency time of the foam in the column to further dry the foam and to create larger bubbles. The drier foam is pushed out of the column and into a container. The foam is broken up into gas and the liquid foaming contaminants. The gas is recirculated for injection into the column even after foaming has stopped. The foaming contaminants are concentrated at the surface level of the solvent in the column. These contaminants are removed from the column. A liquid separator separates immiscible liquids, such as oil, from the solvent.

Owner:MPR SERVICES INC

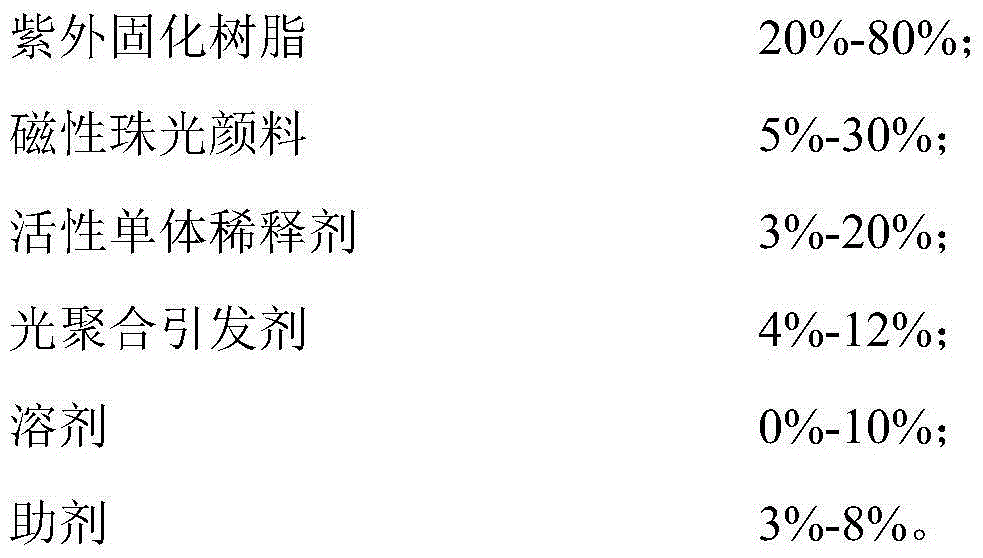

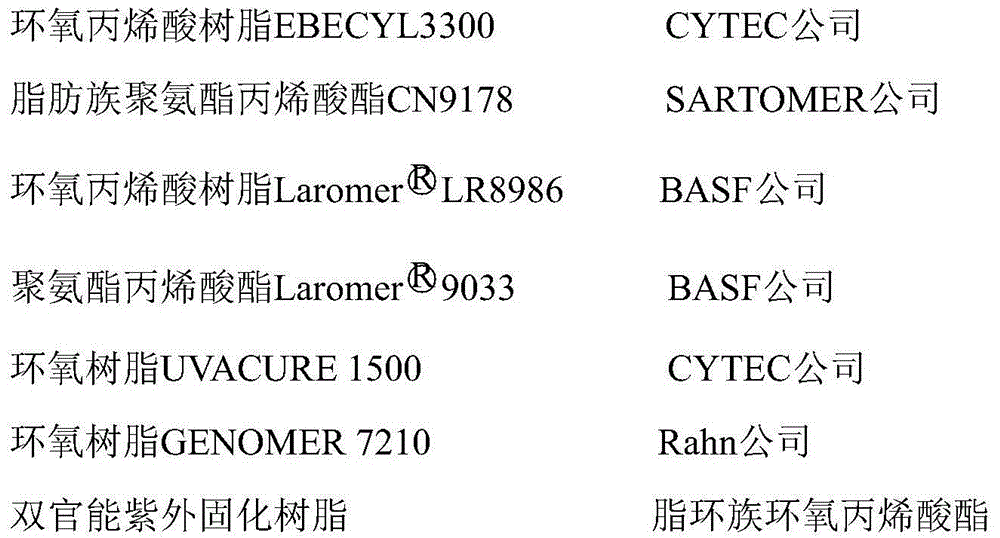

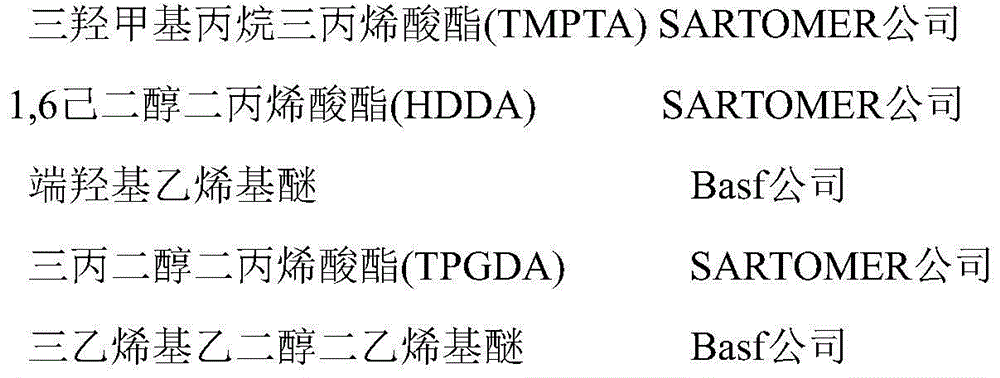

Cationic-radical UV (Ultraviolet)-cured magnetic pearly-luster silk screen ink and preparation method thereof

The invention discloses a cationic-radical UV (Ultraviolet)-cured pearly-luster silk screen ink and a preparation method thereof. The ink is prepared from the following components in percentage by weight: 20 to 80% of UV-cured resin, 5 to 30% of magnetic pearly-luster pigment, 3 to 20% of active monomer diluents, 4 to 12% of photoplymerization, 0 to 10% of solvent, and 3 to 8% of additive. The cationic-radical UV-cured magnetic pearly-luster silk screen ink has a dynamic optical effect that pear luster changes as the change changes and is easily recognized by the public; in addition, the ink has a post-curing characteristic through which the problem of easy falling and bubbling of the surface of an ink film at the part in which sheet-shaped magnetic pigments are vertically arranged can be solved.

Owner:CHINA BANKNOTE INK +1

Prepn. of polyacrylonitrile-base high-performance raw carbon fiber

InactiveCN1167838CReduce gel particlesReduce intensityFibre chemical featuresItaconic acidMineralogy

The present invention relates to the preparation of high-performance polyacrylonitrile-based carbon fiber. Acrylonitrile, itaconic acid and methyl methacrylate in a certain weight proportion are reacted to obtain spinning dope, and the spinning dope is made into greign fiber of high-performance carbon fiber through filtering, solidification, water washing, drafting in hot water, oiling, drying and densifying, re-oiling, drying and densifying for the second time, steam drafting and drying setting. The present invention has the advantages of high drafting rate, homogeneous fibre structure, and small mechanical performance variation coefficient.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

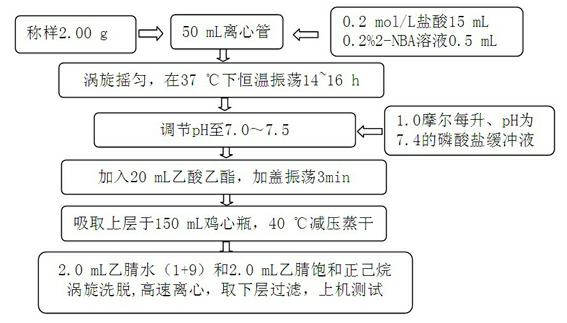

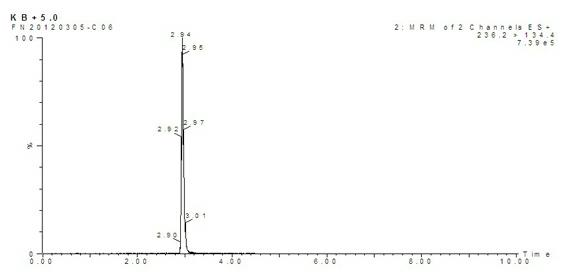

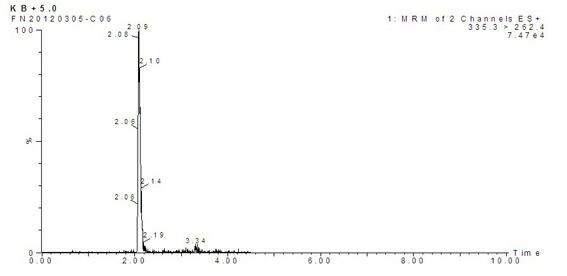

Pretreatment method for detecting nitrofuran metabolites in aquatic product

InactiveCN102621252ALow solvent contentImprove elutionComponent separationChromatographic separationRotary evaporator

The invention discloses a pretreatment method for detecting nitrofuran metabolites in an aquatic product. The method comprises the following steps of: weighing a sample to be detected, dissolving, derivating, extracting, and performing chromatographic separation. A constant temperature oscillator, a reduced pressure rotary evaporator, a silica gel chromatographic column and a high speed refrigerated centrifuge are used in the method. A sample solution prepared by the method can be directly detected by liquid chromatography-tandem mass spectrometry. Compared with the conventional national standard method, the pretreatment method has the advantages of low cost, high repeatability and the like, is simply and effectively operated, is high in operability, is expected to be popularized and applied to environmental protection industry, commodity inspection, entry-exit inspection and quarantine and the like on a large scale, and is obvious in economic and social benefits.

Owner:FUJIAN CCIC FAIRREACH FOOD SAFETY TESTING

Preparing method of cathode piece for lithium-ion capacitor

InactiveCN108428564AAdd depthImprove uniformityHybrid capacitor electrodesDouble layer capacitorsCapacitanceCarbon coating

The invention discloses a preparing method of cathode piece for a lithium-ion capacitor, comprising the steps (1) cathode active materials, SLMP, a conductive agent, a binding agent are fully blendedin a solvent, obtaining soft-mud-shaped crude products; (2) the soft-mud-shaped crude products obtained in the step (1) undergo step-by-step hot pressing, generating rough films with low solvent content, and then the rough films undergo vacuum drying and finish rolling, obtaining dry electrode films containing SLMP; (3) the dry electrode film of the step (2) is applied to carbon-coating copper foil in a heating manner, obtaining a cathode piece for a lithium-ion capacitor. The invention is advantageous in that the disadvantages of the prior art that bonding is poor, compaction density is low,and product lithium-embedding depth and uniformity are poor can be resolved; the obtained cathode piece for the lithium-ion capacitor are assembled with EDLC positive plates, separators, electrolyte and a housing, obtaining a lithium-ion capacitor body, which has high volume capacitance, small internal resistance and long cycling service lifetime after formation.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD +1

Process for preparing water dispersible negative-type photosensitive compositions

InactiveUS6306557B1Treatment can be decreasedReduce wastePhotosensitive materialsRadiation applicationsEmulsionWater dispersible

The present invention discloses a process for preparing a water-dispersible photosensitive composition, including the steps of: (a) adding an unsaturated photomonomer and / or a plasticizer to a carboxyl-group bearing acrylic resin solution which contains at least an organic solvent; (b) distilling and removing said organic solvent to form a resin paste; (c) dissolving a photoinitiator and an alkaline into said resin paste; (d: adding deionized water and mixing thoroughly to form an emulsion; and (e) adjusting the viscosity or said emulsion with a water-soluble resin.

Owner:IND TECH RES INST

Preparing method for ultra-high molecular weight polyethylene fibers and washing device

ActiveCN104790050ALow solvent contentHigh strength of finished productArtificial filament washing/dryingWet spinning methodsSolventToxicity

The invention discloses a preparing method for ultra-high molecular weight polyethylene fibers. The method specifically includes the following steps that firstly, a spinning solution is prepared; secondly, spinning is conducted; thirdly, extracting is conducted; fourthly, drying is conducted; fifthly, drafting is conducted; a washing step is added between the third step and the fourth step, and according to the washing step, thread lines which are discharged from an extracting groove are washed in a washing groove, a second solvent and a residual first solvent which are carried on the surfaces of the thread lines are removed, and the washed thread lines are sent to the four step to be dried. According to the preparing method for ultra-high molecular weight polyethylene fibers, the washing technology is added after extracting in an existing preparation technology processes for ultra-high molecular weight polyethylene fibers, and the preparing method for ultra-high molecular weight polyethylene fibers has the advantages that the fibers are lower in solvent content rate, manufactured finished products are higher in strength, the hand feeling is soft, and subsequent processing is facilitated; the production process of the technology is safe, toxicity and pollution are avoided, and environment friendliness is facilitated; the solvent is recycled, the solvent dosage is reduced, and cost is saved; the technology is simple, the process is short, and operation is convenient. The invention further discloses a washing device used in the preparing method.

Owner:SURREY HI TECH INC

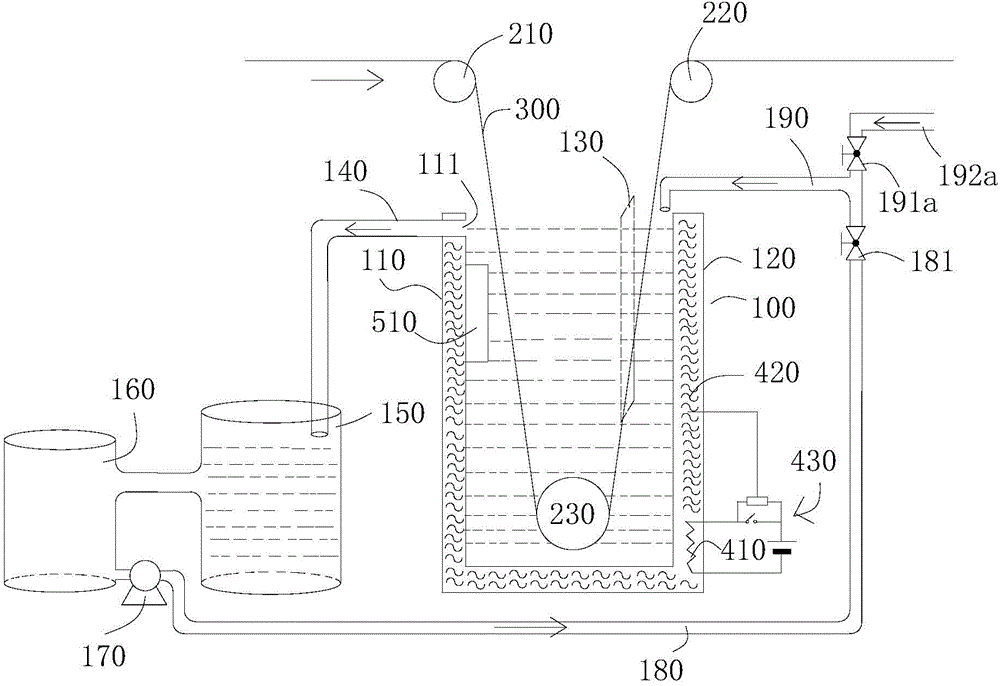

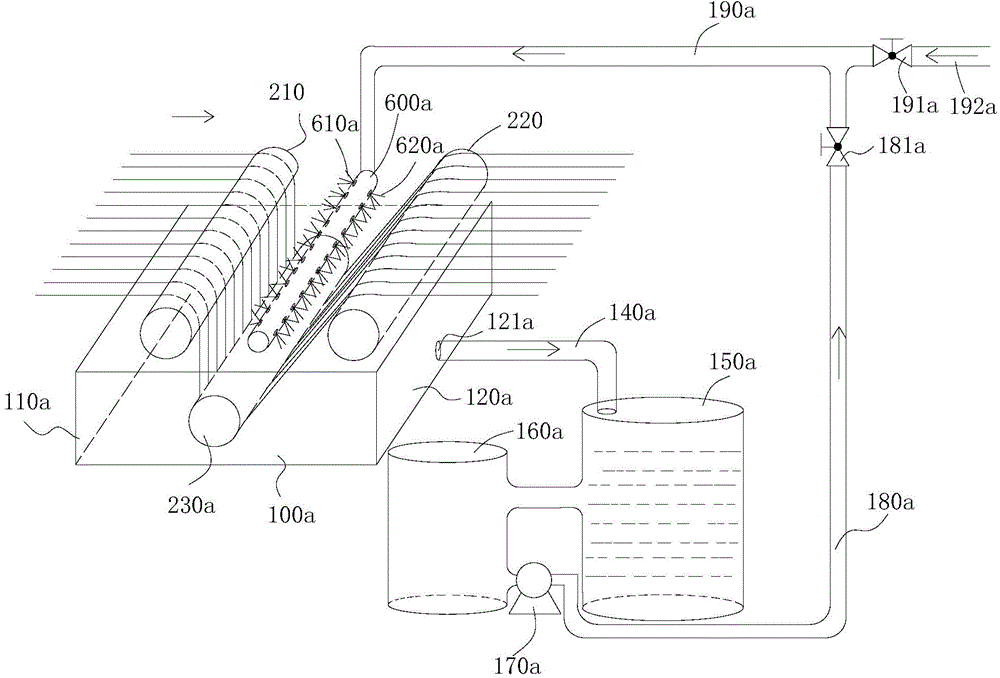

Polymer solution steam stripping flocculation separation method and apparatus

ActiveCN101314086AFully condensedLow solvent contentChemical industrySteam distillationCondensation processFlocculation

The invention belongs to the polymer production technical field, relating to a highly-efficient energy-saving method for separating a polymer solution of synthetic rubber, synthetic resin and plastic by stripping condensation and a device for carrying out the same. A concentration separator for polymer grainy water is arranged on a polymer grainy water pipe between a first condensation boiler and a second condensation boiler which are in serial connection in a two-boiler condensation process of a polymer solution to increase the polymer concentration of the polymer grainy water, and carry out phrase separation in the concentration separator; the concentration separator is arranged vertically, and consists of a cylindrical suspension section at the lower part, a cone-shaped transition section in the middle and a cylindrical lifting section at the upper part which are communicated; a metal wire net cage is arranged outside the export pipe of the concentration water at the bottom of the suspension section, a steam lifting pipe is arranged at the lower part of the lifting section; the device can improve the condensation effect, obviously reduces the content of the remaining solvent of polymer particles, has remarkable economic benefits, and reduces environmental pollution caused by the solvent.

Owner:FUSHUN YIKESI NEW MATERIAL

Rubber toughened SBS aldehyde removed all-purpose adhesive and preparation method thereof

InactiveCN101294053ADowngrade hazardPurify indoor airMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceThermoplastic elastomer

The invention relates to a rubber-toughened SBS formaldehyde-free universal adhesive and the preparation method thereof. The rubber-toughened SBS formaldehyde-free universal adhesive is characterized in that the adhesive is composed of linear butadiene-styrene thermoplastic elastomer 3% to 5%, star-shaped butadiene-styrene thermoplastic elastomer 7% to 9%, styrene-butadiene rubber 2.7% to 3.7%, petroleum resin 20.8% to 24.8%, formaldehyde-removing additive 1.4% to 2.6%, antioxidant 1.2% to 1.8%, petroleum ether 37% to 43%, oil solvent 16.5% to 19.5% and essence 0.4% to 0.6%. The preparation method comprises the following steps: (1) weighting the above materials according to the ratio; (2) adding styrene-butadiene rubber in the step (1) into a mixing roll machine for plasticizing, thin-passing and discharging sheets, adding the sheet material into a vertical high-speed stirring kettle, adding the oil solvent in the step (1) into the high-speed stirring kettle, dissolving, and stirring until the sheet material is dissolved completely to obtain the semi-product; and (3) respectively adding the residual material components into the stirring kettle implementing step (2), stirring and dissolving to obtain the final product. The rubber-toughened SBS formaldehyde-free universal adhesive can remove free formaldehyde released from boards and has the remarkable effects on protecting environment and maintaining human health during house decoration.

Owner:GUANGDONG MAYDOS BUILDING MATERIALS LTD CO

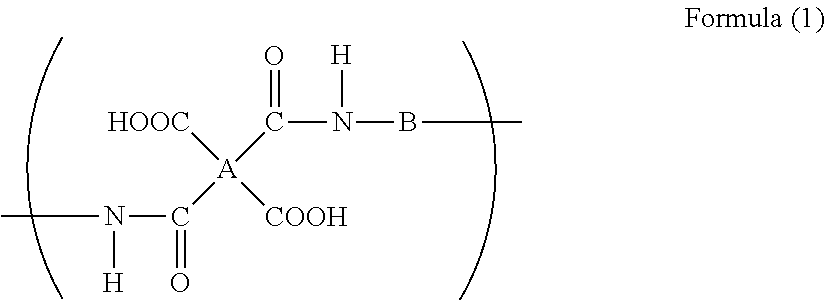

Aqueous polyimide precursor solution composition and method for producing aqueous polyimide precursor solution

InactiveUS20140363687A1High transparencyMaintain good propertiesSynthetic resin layered productsCeramic shaping apparatusPolyamic acidCarboxylic acid

An aqueous polyimide precursor solution composition in which a polyamic acid which is obtained by reacting a tetracarboxylic acid component and a diamine component is dissolved in an aqueous solvent together with an imidazole in an amount of 1.6 moles or more per mole of the tetracarboxylic acid component of the polyamic acid.

Owner:UBE IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com