Graphene-containing graphene/ceramic conductive composite material and preparation method thereof

A technology of conductive composite materials and ceramic materials, applied in the direction of graphite, chemical instruments and methods, additive processing, etc., can solve the problems affecting the electrical and mechanical properties of composite materials, the mismatch between mechanical properties and electrical conductivity, and the reduction of mechanical properties of composite materials and other problems, to achieve the effect of improving sintering process and drying process, ensuring strength and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Provided Al 2 o 3 , CuO, MgO powder, SiO 2 Powder, TiO 2 The raw material purity of the powder is greater than 99.0%. The mass fraction of graphite is 15%-25% of the ceramic powder, the purity of the graphite is greater than 99.85%, the particle size is ≤50 μm, the number of graphene layers is 2-6, and the average sheet diameter is 80-200nm.

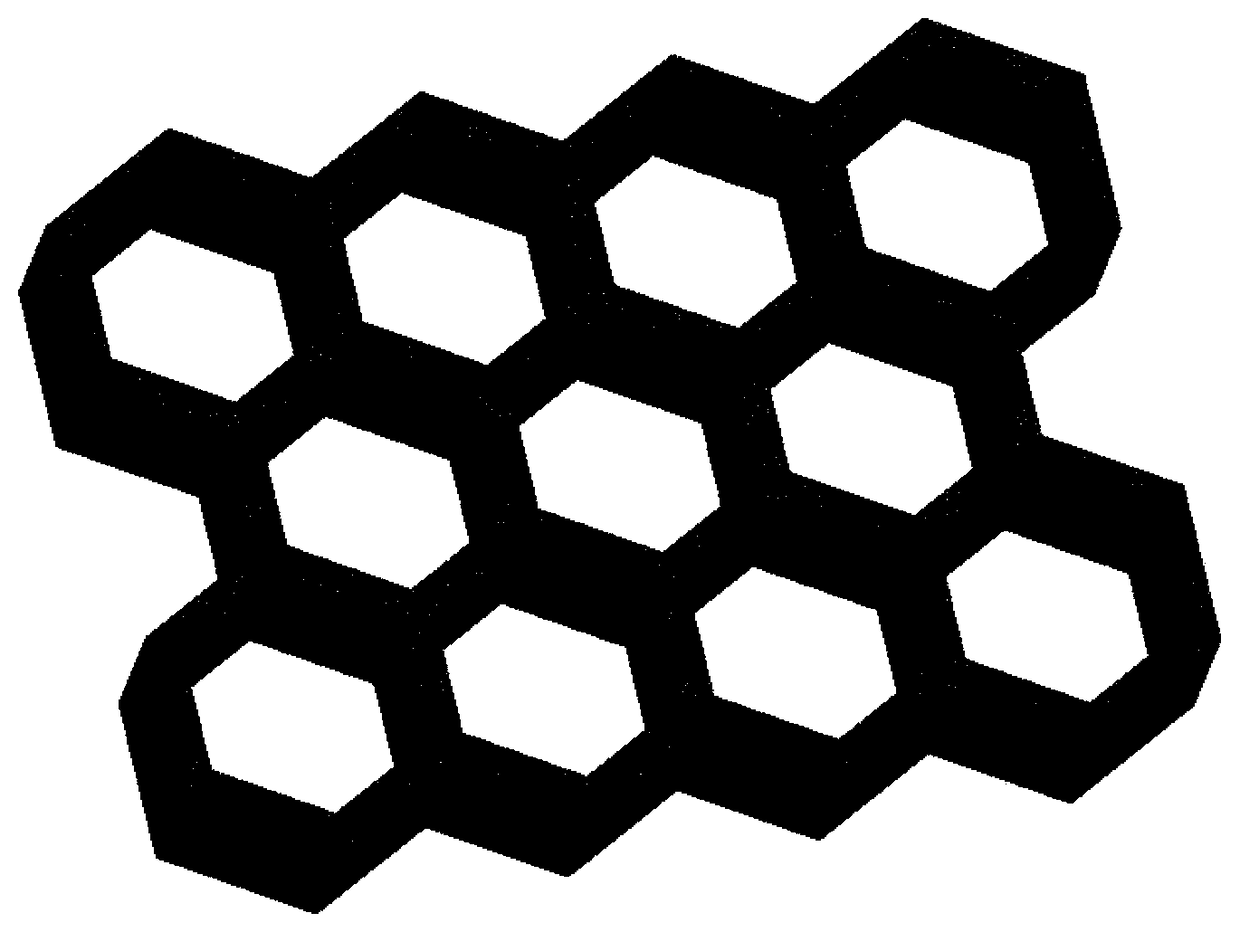

[0022] 1) Preparation of graphite skeleton: Mix flake graphite powder and bonding powder in a ratio of 7:3, use a laser sintering 3D printer to print according to the graphite skeleton drawing of the designed space structure, the graphite skeleton is a honeycomb structure, with good Stability and strength, such as figure 1 shown. The size of the skeleton is 0.6mm, and the length of the side is 5mm. Then the graphite skeleton is impregnated with phenolic resin and epoxy resin to increase the strength and carbonization of the graphite skeleton to improve its stability. The mass ratio of phenolic resin and epoxy resin in the imp...

Embodiment 2

[0030] Provided Al 2 o 3 , CuO, MgO powder, SiO 2 Powder, TiO 2 The raw material purity of the powder is greater than 99.0%. The mass fraction of graphite is 15%-25% of the ceramic powder, the purity of the graphite is greater than 99.85%, the particle size is ≤50 μm, the number of graphene layers is 2-6, and the average sheet diameter is 80-200nm.

[0031] 1) Preparation of graphite skeleton: Mix flake graphite powder and bonding powder in a ratio of 6:3, use a laser sintering 3D printer to print according to the graphite skeleton drawing of the designed space structure, the graphite skeleton is a honeycomb structure, has a good Stability and strength, such as figure 1 shown. The size of the skeleton is 0.6mm, and the length of the side is 5mm. Then the graphite skeleton is impregnated with phenolic resin and epoxy resin to increase the strength and carbonization of the graphite skeleton to improve its stability. The mass ratio of phenolic resin and epoxy resin in the im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Average film diameter | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com