Sintering process of lanthanum cerium-containing sintered NdFeB

A neodymium-iron-boron and lanthanum-cerium technology, which is applied in the field of iron-boron magnet material preparation, can solve the problems of magnetic performance influence, magnet composition deviation, iron-boron grain growth, etc., so as to save electricity costs, shorten the sintering time period, and save water and electricity. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The formula of raw embryo (brand N35) is in the present embodiment:

[0028] N35 PrN Gd LaCe B Cu Al co Zr Fe and unavoidable impurities Proportion 15% 2% 15% 1% 0.10% 0.80% 0.80% 0.30% margin

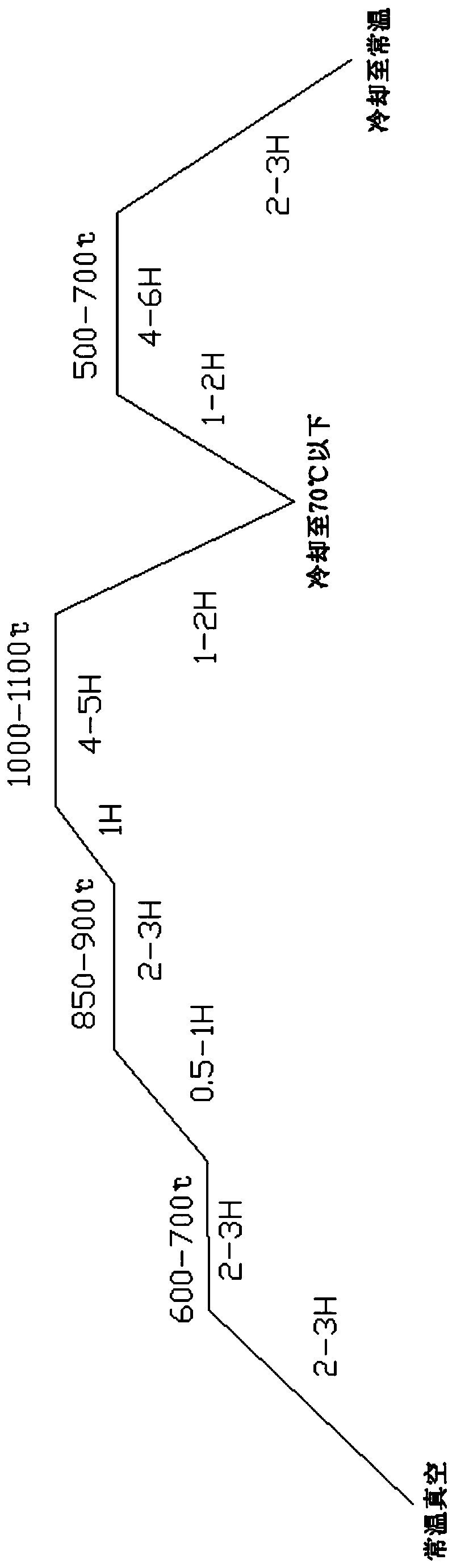

[0029] The flow chart of the sintering stage of the green embryo is as follows: figure 2 As shown, the specific sintering process is: the vacuum sintering furnace is vacuumed to 3.0*10 -2 Pa, heat up to 650°C in 2.5h, heat up to 890°C for 2.5h→0.8h, heat up to 1033°C for 2.5h→1h, heat up for 5h→1.5h, cool to below 70°C→1.5h, heat up to 560°C, hold for 5h → 2.5h to cool to room temperature to obtain a blank.

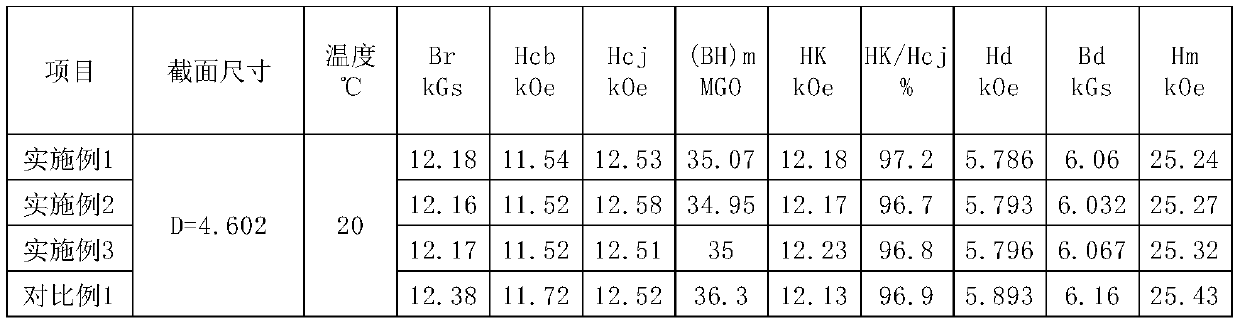

[0030] The magnetic properties of the blanks obtained are shown in Table 1.

Embodiment 2

[0032] The green embryo formula in the present embodiment is the same as embodiment 1, and the green embryo sintering process is as follows figure 2 As shown, the specific sintering process is: the vacuum sintering furnace is vacuumed to 3.0*10 -2 Pa, heat up to 600°C in 2 hours, keep warm for 2h→0.5h and heat up to 850°C, keep warm for 2h→0.8h and heat up to 1000°C, keep warm for 4h→cool to below 70°C within 1h→1h heat up to 500°C, keep warm for 4h→2h cooling To normal temperature, get blank.

[0033] The magnetic properties of the blanks obtained are shown in Table 1.

Embodiment 3

[0035] The green embryo formula in the present embodiment is the same as embodiment 1, and the green embryo sintering process is as follows figure 2 As shown, the specific sintering process is: the vacuum sintering furnace is vacuumed to 3.0*10 -2 Pa, heat up to 700°C in 3h, keep warm for 3h→0.8h and heat up to 900°C, keep warm for 3h→1h and heat up to 1100°C, keep warm for 4.5h→cool to below 70°C within 2h→2h heat up to 700°C, keep warm for 6h→3h cooling To normal temperature, get blank.

[0036] The magnetic properties of the blanks obtained are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com