Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Reduce water and electricity consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial waste heat type low-temperature multi-effect sea water desaltation system and sea water desaltation method thereof

ActiveCN104402079ALower discharge temperatureEmission reductionGeneral water supply conservationSeawater treatmentResource utilizationEngineering

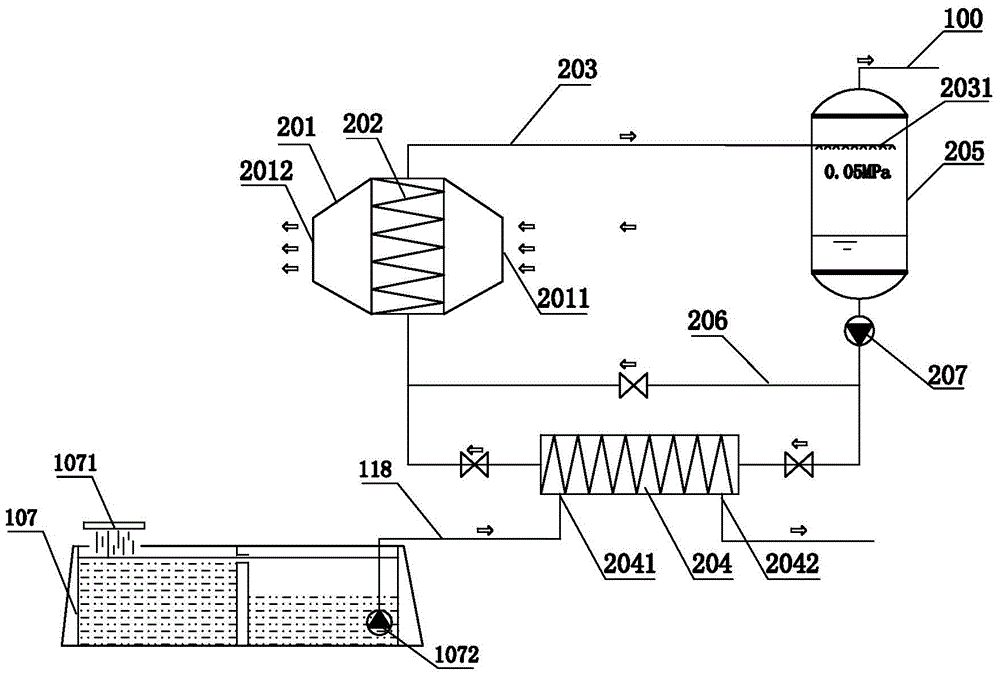

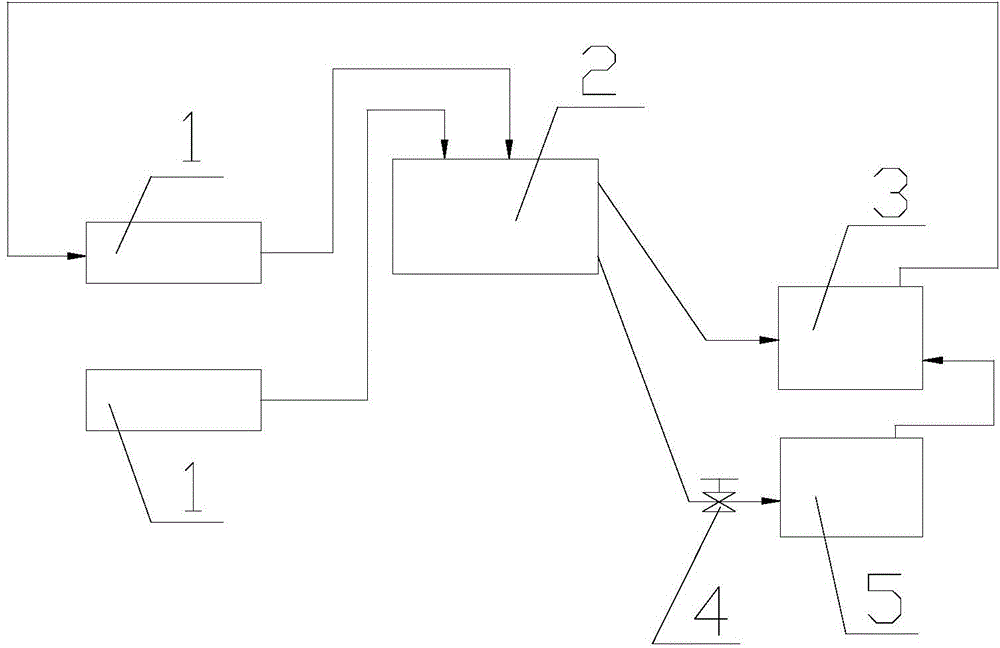

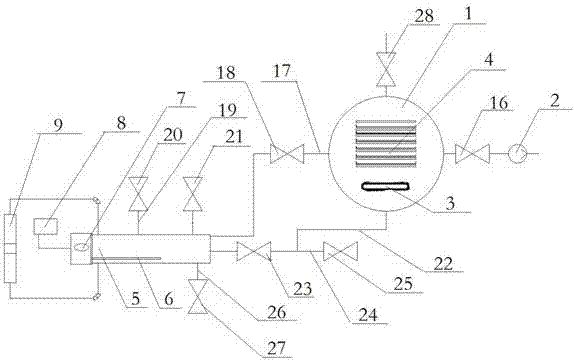

The invention discloses an industrial waste heat type low-temperature multi-effect sea water desaltation system and a sea water desaltation method. The system comprises a flue gas waste heat recovery device used for preparing heat source steam and preheating seawater and a low-temperature multi-effect sea water desaltation device which utilizes the heat source steam to realize sea water desaltation treatment; the low-temperature multi-effect sea water desaltation device comprises a first-effect evaporator, a plurality of intermediate-effect evaporator, a final-effect evaporator and a condenser; the condenser is connected with a vacuum-pumping device; the first-effect evaporator is connected with a feeding seawater pipe on which a plurality of preheaters are serially arranged; a fresh water pipe between every two adjacent evaporators penetrates the preheaters. According to the invention, in-order water supply is adopted, so that the scaling and corrosion problems are solved, equipment cleaning and maintenance are reduced, and therefore the sea water desaltation cost is low; the low-temperature multi-effect sea water desaltation device is combined with exhaust heat utilization, so that comprehensive resource utilization is realized, the flue gas discharge temperature is lowered, the desulphurization efficiency is favorably improved and emission of pollutants is reduced.

Owner:WEIFANG LIANXING NEW MATERIAL TECH

Machining method of wrapped structural flax and polyester filament section color composite yarn and composite yarn

The invention provides a machining method of a wrapped structural flax and polyester filament section color composite yarn and a composite yarn. A section color effect principle of fusing and twistingtwo yarns with different colors, a specific false twisting effect of core yarns when a hollow ingot is subjected to wrap spinning of an externally-wrapped yarn and the core yarns are wound, a twist instability principle of the specific false twisting effect and an uneven distribution principle of a twist on a plucked yarn are comprehensively utilized; by enabling double core yarns to generate anirregular section color effect and adopting the colorless excellent-transparency filament (monofilament or less-number multifilament) externally-wrapped yarn to carry out wrapping consolidation, the flax composite yarn with section color characteristics is obtained. Wrinkle resistance of flax fabric can be effectively improved, yarn hairiness is reduced, hairiness regeneration is reduced, weavability is improved, section color appearance is given to the yarn and the fabric thereof, and the fabric is woven in a dyeing-free and sizing-free mode.

Owner:JIAXING UNIV

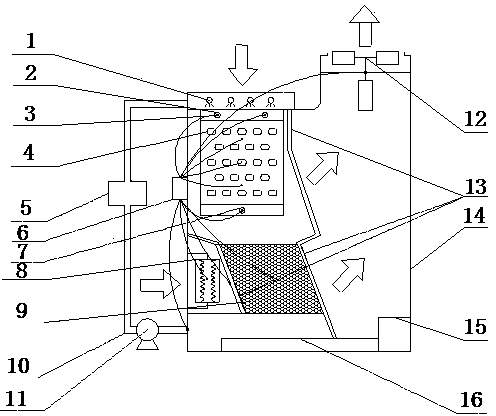

Novel evaporative condenser

InactiveCN104214999APrecise temperature controlSatisfy the requirement of precise temperature controlEvaporators/condensersRefrigeration safety arrangementPolyvinyl chlorideTemperature monitoring

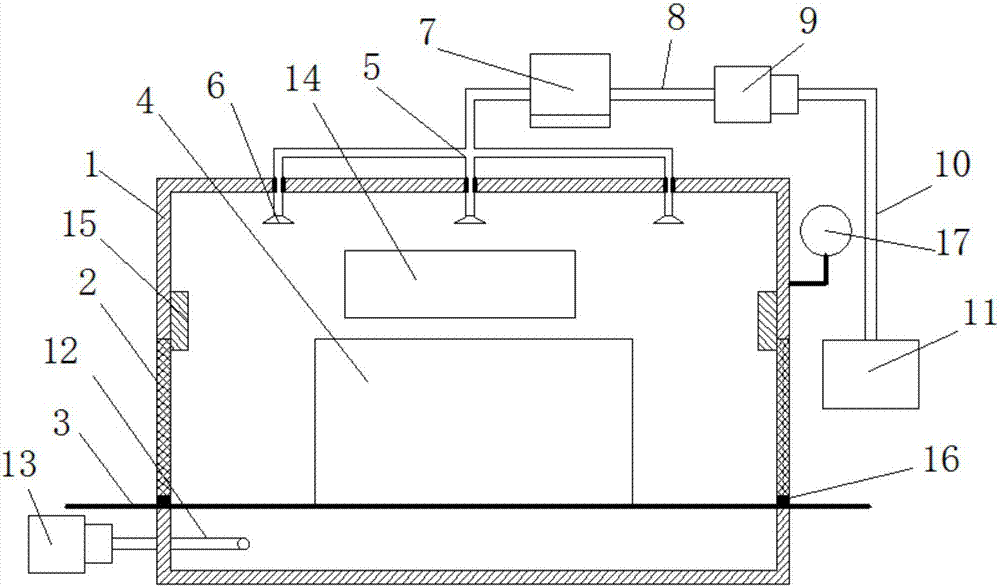

The invention relates to a novel evaporative condenser. The device consists of a spraying system, a refrigerant inlet, a temperature probe, a flat condensing coil with a plate fin, an electronic scale remover, a multi-point temperature monitoring module, a refrigerant outlet, a heating device, a PVC (Polyvinyl Chloride) heat dissipation filler, a water inlet pipe, a circulating pump, a fan, a water baffle, a condenser metal shell, a repair pedal and a catch basin. According to the device, a novel flat circular coil provided with the condensing plate fin is adopted, so that the heat exchange efficiency of the condenser is improved by changing the structure of the condensing coil and the fin; the electric heating device is additionally arranged in an air inlet passage at the bottom of the condenser, and the multi-point temperature monitoring module is arranged on the side face of the condenser shell to perform real-time monitoring on the temperature at each region in the condenser, so that the relation among the temperature, the air quantity and the spray water quantity is established to realize accurate temperature control over the system, the water consumption and the power consumption are reduced while the heat exchange efficiency is improved to fulfil the aim of energy conservation.

Owner:SHANGHAI OCEAN UNIV

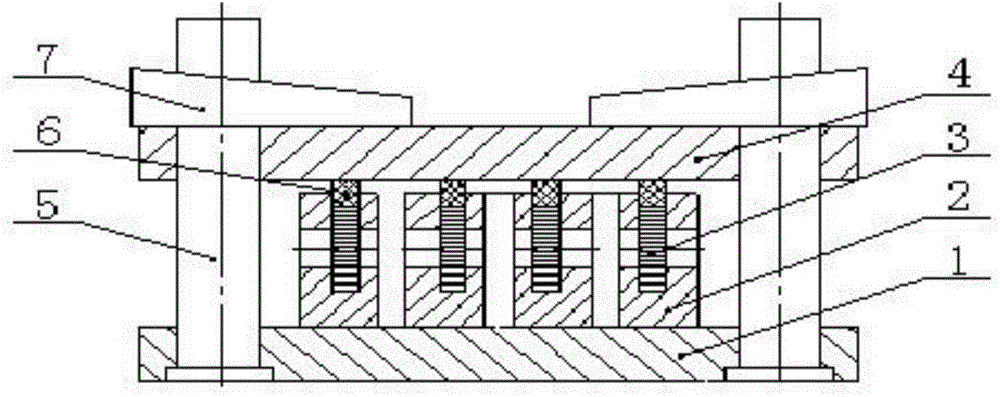

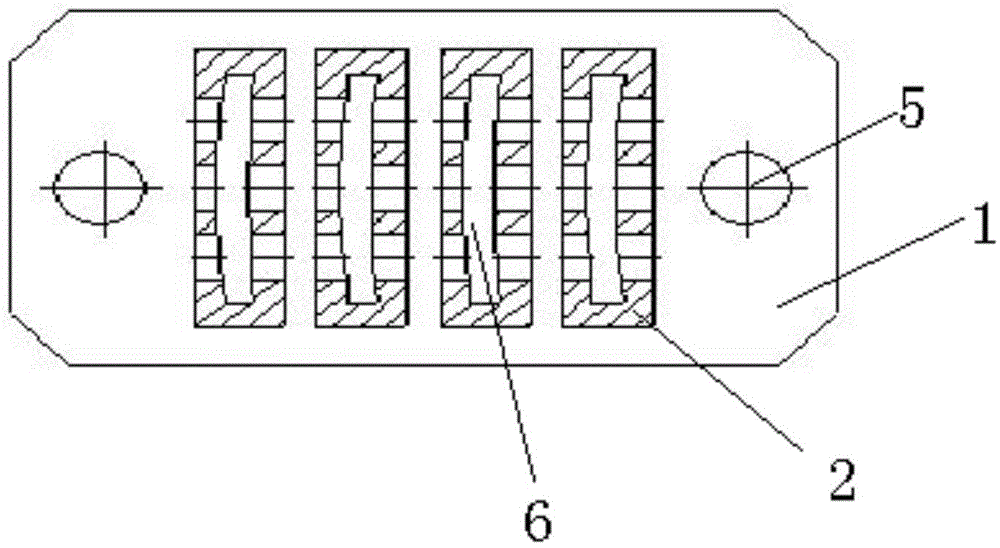

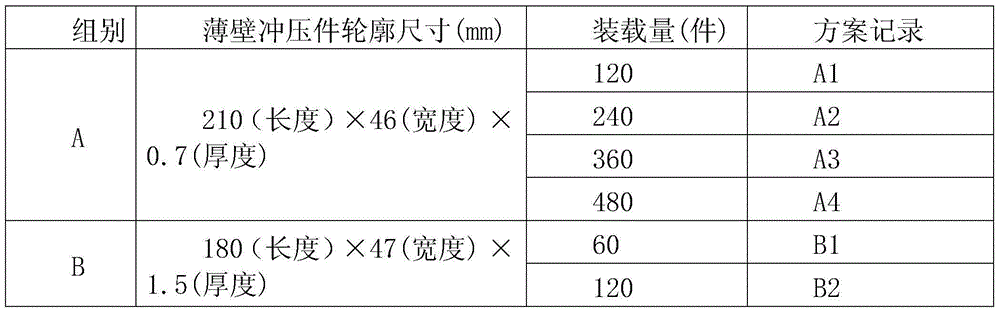

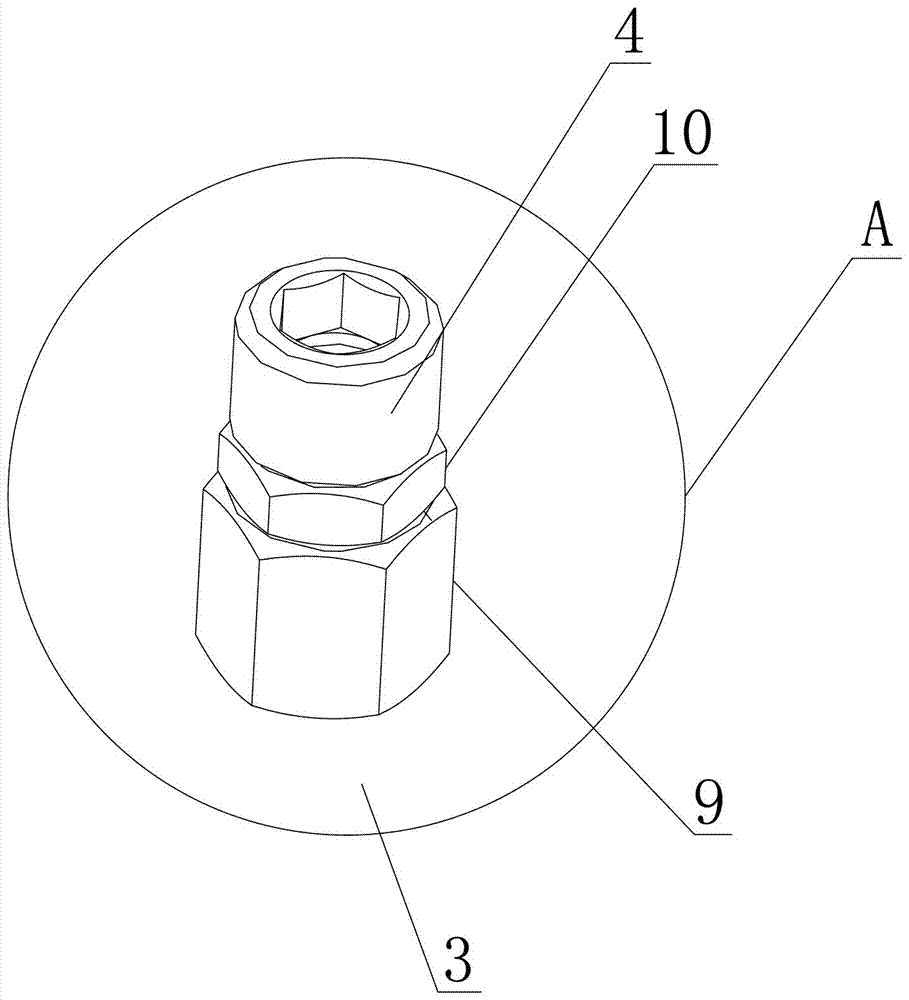

Hot sizing device and hot sizing method for thin-wall stamping part

ActiveCN104451047AAvoid misalignmentAvoid scrappingFurnace typesHeat treatment furnacesEngineeringMechanical engineering

The invention discloses a hot sizing device and hot sizing method for a thin-wall stamping part, and aims at solving the problems of warping and deformation of the thin-wall stamping part which is subjected to hot sizing to improve the production efficiency and reduce the production cost. The adopted technical scheme is as follows: the hot sizing device comprises a bottom plate (1) and positioning pins (5), wherein the positioning pins (5) are fixedly arranged at two ends of the bottom plate (1); the bottom plate (1) is provided with a plurality of loading boxes (2), a plurality of thin-wall stamping parts (3) can be placed in the loading boxes (2) in a stacked way, cavities inside the loading boxes (2) are matched with the thin-wall stamping parts (3) in size structure, and the stacked height of the plurality of thin-wall stamping parts (3) is aligned to the upper planes of the loading boxes (2); and the upper ends of the loading boxes (2) are provided with press plates (4), and the press plates (4) are sleeved on the positioning pins (5) so as to press the thin-wall stamping parts (3) in holes of the loading boxes (2).

Owner:AECC AVIATION POWER CO LTD

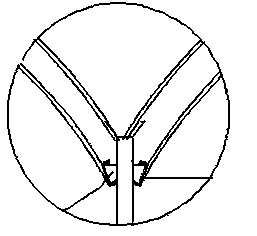

Process for producing magnetic ring

InactiveCN102856067AReduce investmentReduce water and electricity consumptionEdge grinding machinesInductances/transformers/magnets manufactureEngineeringEnergy consumption

The invention discloses a process for procuring a magnetic ring. The production process comprises the following operation steps: 1) pressing into a blank; 2) full-automatically chamfering the blank; and 3) sintering and moulding the blank, wherein the step 2) of full-automatically chamfering the blank is the process of chamfering the magnetic ring blank by using the full-automatic chamfering separator. The process for procuring the magnetic ring has the beneficial effects of simple technical route, few apparatus investment, and full-automatic chamfering process; the working efficiency can be effectively improved, the labour is saved, and the cost is reduced; the chips and dust are recycled, and the production process is green and environment-friendly, can reduce the hydroelectric energy consumption and save the cost and has excellent application foreground.

Owner:深圳市金核科技股份有限公司

Mixed culture method for hippocampi and sea cucumbers

InactiveCN102657114APrevent siphonReduce wasteClimate change adaptationAnimal feeding stuffMixed cultureBiological property

The invention discloses a mixed culture method for hippocampi and sea cucumbers. According to the method, a culture draft is made according to the respectively biologic features of the hippocampi and the sea cucumbers, so the hippocampi and the sea cucumbers can be in mixed culture in the same region for forming a situation in spaces without mutual interference, meanwhile, bait and water body waste can be avoided, the culture complementation is formed, further, the culture cost is obviously reduced, and the culture efficiency is improved. The mixed culture method has the advantages that the operation is easy, and the controllability is high, and the method is suitable for large-scale business-like culture popularization.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Application of ramie softener in flogging procedure of degumming process

InactiveCN1831215AReduce water and electricity consumptionIncrease profitVegetable materialEngineeringPower consumption

The invention relates to the use of ramie softener, especially the application in ramie boiling off beating process. The softener takes the place of beater to remove the colloid, crumb, rest alkali adhering on ramie fiber. It can decrease the power consumption and labor intensity, increase yield of the product, decrease noise, improves stability and quality.

Owner:CHONGQING FULING KINGLONG

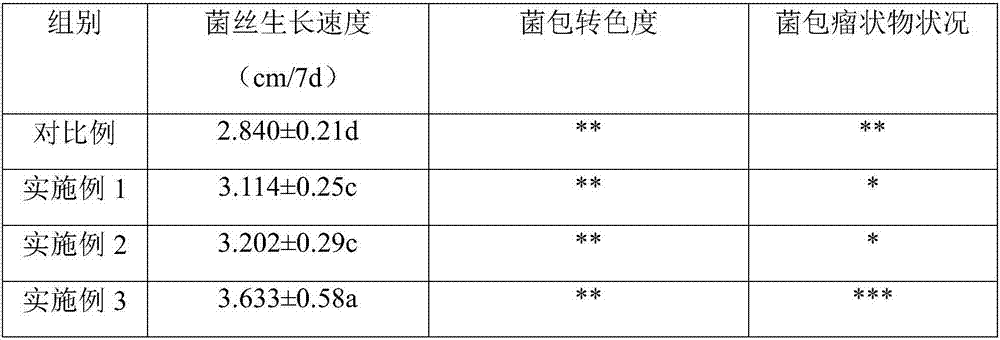

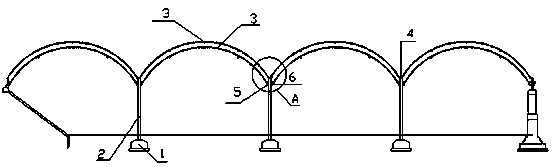

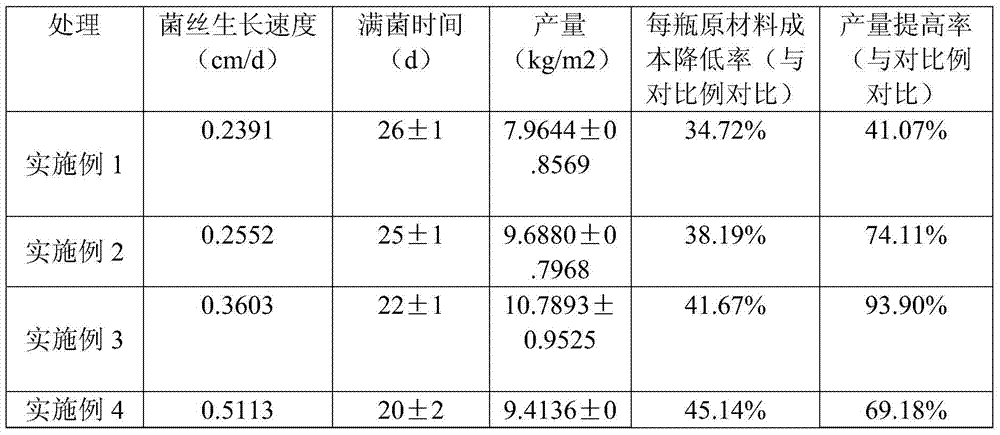

Needle mushroom culture material

The invention discloses a needle mushroom culture material. The needle mushroom culture material comprises large-scale methane residues serving as main raw materials and also comprises one or more of sawdust, corncobs or cottonseed hulls, and bran and gypsum. The culture material is used for cultivating the needle mushroom, so that the cost of the raw materials produced in a needle mushroom plant is reduced, the production cycle is shortened, energy consumption is reduced, the residues, namely methane residues, generated by large-scale fermentation of the methane can be recycled, and the circulation chain of biomass energy is lengthened.

Owner:SHANGHAI ACAD OF AGRI SCI

Plasticizing treatment method of copper-zinc alloy

ActiveCN104046974AAvoid pollutionReduce water and electricity consumptionMetallic material coating processesEpoxyPlasticizer

The invention discloses a copper-zinc alloy plasticizing process for increasing the binding force of copper-zinc alloy with epoxy resin. The process comprises the following steps: 1) cleaning and oil removal: removing dirt and grease on the surface of the copper-zinc alloy; 2) micro-etching: conducting micro-etching on the surface of the copper-zinc alloy by a chemical method, so as to increase the reaction area of copper-zinc alloy with plasticizer; and 3) plasticization: depositing a layer of an azole copper zinc mixture generated from reaction of epoxy chloropropane, pentyl benzimidazole with copper zinc on the copper-zinc alloy surface subjected to micro-etching, the mixture layer has strong bonding force with epoxy resin. The copper-zinc alloy treated by the invention can be directly laminated with epoxy resin; and compared with the traditional sand blasting process, the method saves power consumption, reduces a lot of manual work, improves production efficiency, and avoids the dust and noise pollution.

Owner:重庆中昆新材料科技有限公司

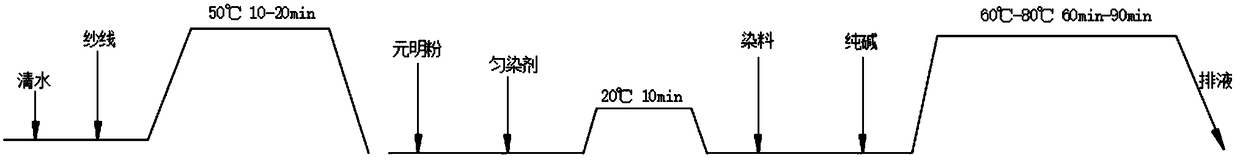

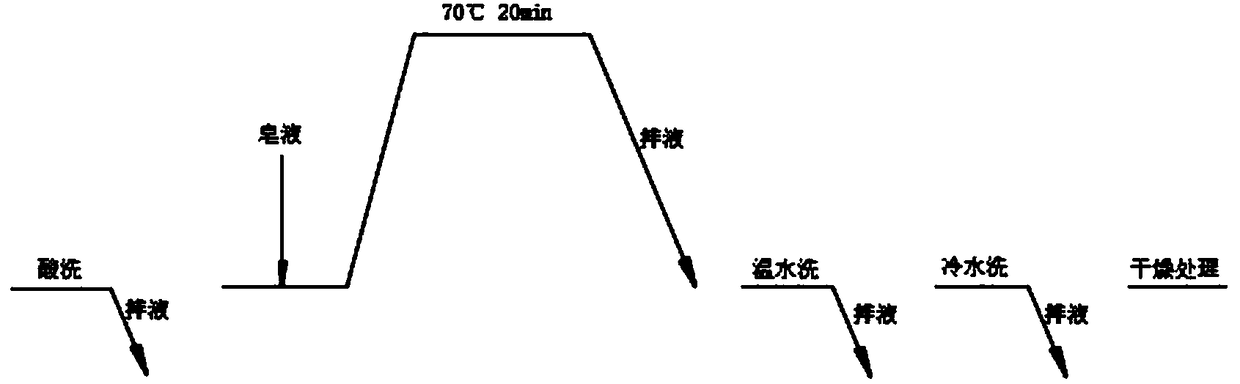

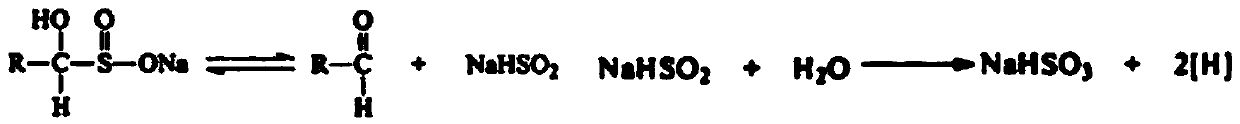

Active one-bath dyeing process of wool-flax blended yarns

The invention discloses an active one-bath dyeing process of wool-flax blended yarns, wherein the process includes the following steps: step 1, yarn pretreatment; step two, yarn dying: firstly, addinganhydrous sodium sulfate and a leveling agent, then dyeing, next adding sodium carbonate with equal amount and equal time, and fixing a color; step three, yarn soaping including water washing, acid and alkali neutralization and soaping; and step four, yarn posttreatment including water washing and drying treatment. According to the active one-bath dyeing process of the wool-flax blended yarns, through the simple pretreatment process, the yarns obtain good affinity moistening effects and the cost of water and electric energy consumption is reduced; in the dyeing process of the yarns, a cottonactive dye is used, neutral salt anhydrous sodium sulfate is used for promoting dyeing, sodium carbonate is used for fixing the color, the amphoteric ion leveling agent is used for improving the isochromatic property of the wool-flax blended product, and the low temperature environment-friendly soaping agent used in the soaping process not only reduces the water and electric energy consumption ofthe whole soaping step, but also makes the whole dyeing process more environmentally friendly.

Owner:ZHANGJIAGANG YANGZI DYEING & FINISHING CO LTD

Paint for heat-insulation and water-proof composite coating and construction process of paint

InactiveCN107955438AAcid resistantAnti-corrosionClimate change adaptationPassive housesElectricityInsulation layer

The invention belongs to the field of building paint and particularly relates to paint for a heat-insulation and water-proof composite coating and a construction process of the paint. The paint comprises water-proof-layer paint and heat-insulation-layer paint, wherein the water-proof-layer paint is prepared from a water-proof-layer liquid material, a water-proof-layer powder material and non-wovenfabric. The construction process comprises early-stage preparation and construction. The construction process is applied under the condition that a main body structure of a building is not damaged, the water-proof period of the heat-insulation and water-proof composite coating is as long as the service life of the building, internal temperature of the building keeps constant under the condition of high temperature of sunlight, and a heat insulation layer not only can reduce internal temperature of a house, but also can reduce the whole urban heat island effect. The heat-insulation and water-proof composite coating has the unique advantages of resistance to acid, base, corrosion and aging, heat insulation, prolonged service life of the building and the like, the renovation and maintenanceprobabilities are low, water and electricity consumption is reduced, and the coating is more economical, more energy-saving and more environmentally friendly.

Owner:张正伟

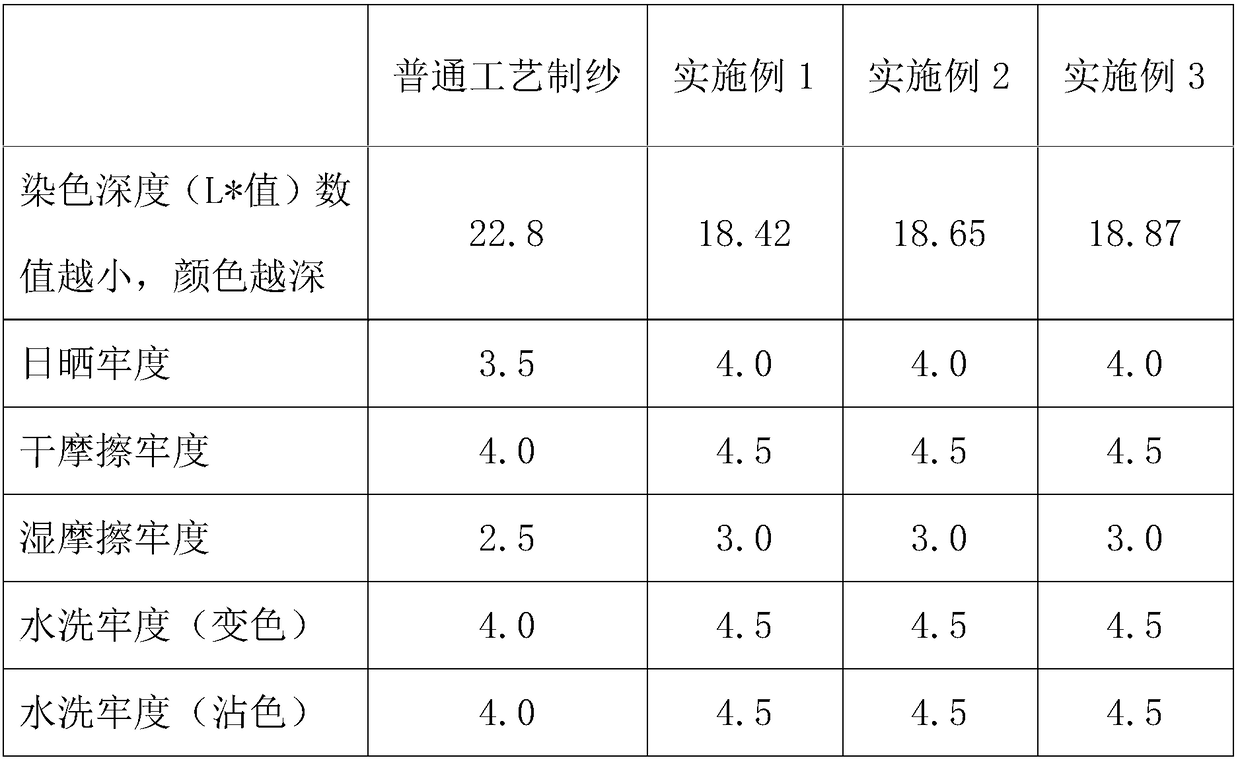

High-color-fastness dyeing technology for polyester-cotton knitted fabric

InactiveCN109629255AAvoid sticking backHigh color fastnessOrganic chemistryDyeing processDisperse dyeColour fastness

The invention discloses a high-color-fastness dyeing technology for a polyester-cotton knitted fabric, and relates to the field of printing and dyeing. The technology is characterized by comprising the following steps of S1, pre-treatment; S2, primary dyeing, S3, cleaning, wherein surface dye on the polyester-cotton knitted fabric is removed by a cleaning agent for 8-10 min at the temperature of 92-98 DEG C, and the concentration of the cleaning agent is 1.5-2 / L; S4, secondary dyeing; S5, discharging; the cleaning agent is prepared from, by weight, 42-48 parts of a reducing agent, 10-12 partsof an anti-staining agent and 25-30 parts of sodium hydroxide; the anti-staining agent is prepared from isomeric alcohol ethoxylates, sodium tripolyphosphate and isopropanol, and the weight ratio of isomeric alcohol ethoxylates to sodium tripolyphosphate to isopropanol is 1:1:1.5. In the cleaning process in S3, the cleaning agent contains the anti-staining agent, therefore after the reducing agentremoves dispersed dye on the surfaces of fibers, the anti-staining agent can react with the dispersed dye, the dispersed dye cannot be attached to cotton fibers or polyester fibers, the removing effect is good, reduction cleaning does not need to be conducted many times, the efficiency is high, and water and electricity are saved.

Owner:HANGZHOU ZHUODA PRINTING & DYEING CO LTD

Melon, fruit and vegetable washing machine by new method

InactiveCN1985683AIncrease the amount of washingReduce water and electricity consumptionClimate change adaptationFood treatmentPulp and paper industryAtmospheric pressure

The melon, fruit and vegetable washing machine operating in new water and power saving method consists mainly of a casing, an upper cover, washing containers, washing baskets and an external air source. It features that after two washing baskets with melon, fruit and vegetable to be washed are loaded separately into two washing containers, proper amount of water and detergent are added into the first washing container, the upper cover is covered and air is sprayed into the first washing container, so as to raise the pressure inside the first container and to force the washing liquid to pass through the circulating pipe and spray to the second container until the second container is raised to a preset position; the spray valve and the discharge valve are then switched to the opposite position for the air to be sprayed to the second container; and so on to reach the washing aim.

Owner:张作森

Method for reinforcing abrasive resistance of copper faucet

ActiveCN104060260AAvoid pollutionReduce water and electricity consumptionMetallic material coating processesAzoleBenzimidazole

The invention discloses a technology for increasing abrasive resistance of a copper faucet by a soaking method. The technology comprises the following steps: 1) cleaning and degreasing, namely removing smudge and fat on the copper surface; 2) microetching, namely carrying out microetching on the copper surface by adopting a chemical method, and increasing the reaction area of a copper faucet work-piece; and 3) abrasive resistance treatment, depositing a layer of benzimidazole and diphenyl imidazole on the surface of the micro-etched copper faucet to react with copper, so as to generate a copper azole mixture. The copper azole mixture and copper have strong binding force, and good abrasive resistance. The copper faucet processed by the method is good in abrasive resistance. Compared with the traditional painting process, water and electricity consumption is saved, a lot of manpower is reduced, the production efficiency is improved, and pollution of formaldehyde is avoided.

Owner:苏州美吉纳纳米新材料科技有限公司

Factorized high-efficiency mushroom production culture material and preparation method thereof

ActiveCN106882990AEnsure consistencyEnsure porosityCalcareous fertilisersBioloigcal waste fertilisersAdditive ingredientGranularity

The invention relates to a factorized high-efficiency mushroom production culture material and a preparation method thereof. The factorized high-efficiency mushroom production culture material is prepared from the following ingredients by weight percent: 70 to 80% of saw dust, 10 to 20% of bran and 1 to 10% of gypsum, wherein the saw dust includes first-level saw dust, second-level saw dust and third-level saw dust which has different granularities. The preparation method comprises the steps of fully mixing the raw materials according to a proportion and then adding water to evenly stir. The factorized high-efficiency mushroom production culture material disclosed by the invention optimizes the matching of saw dust in a factorized mushroom production formula, improves spawn running speed of hypha in factorized mushroom production, shortens a factorized production period, improves mushroom yield and quality, improves biotransformation efficiency of factorized production, increases earnings of a producer and has good application prospect.

Owner:SHANGHAI ACAD OF AGRI SCI

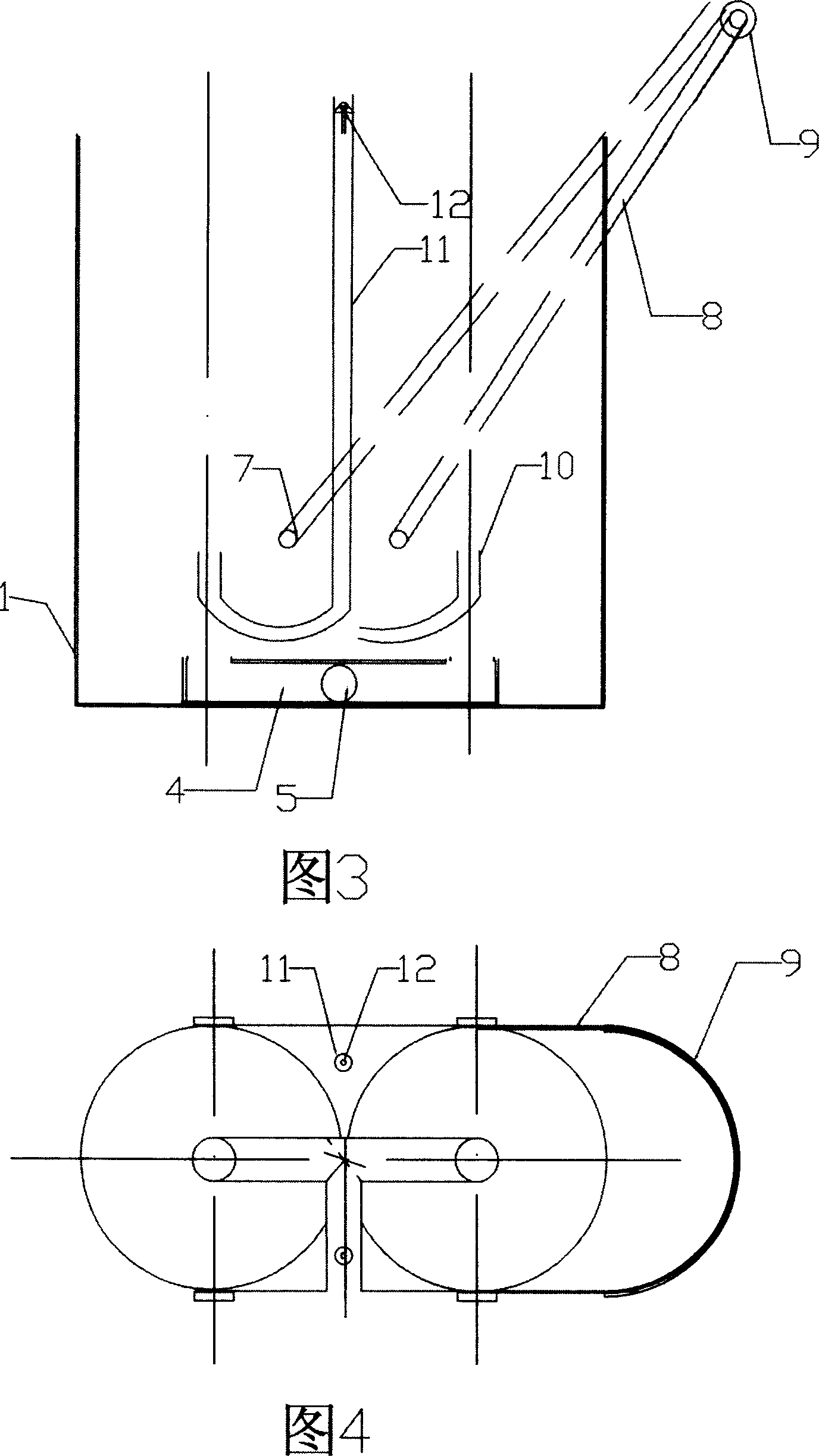

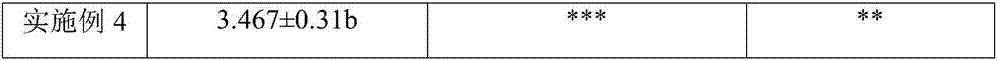

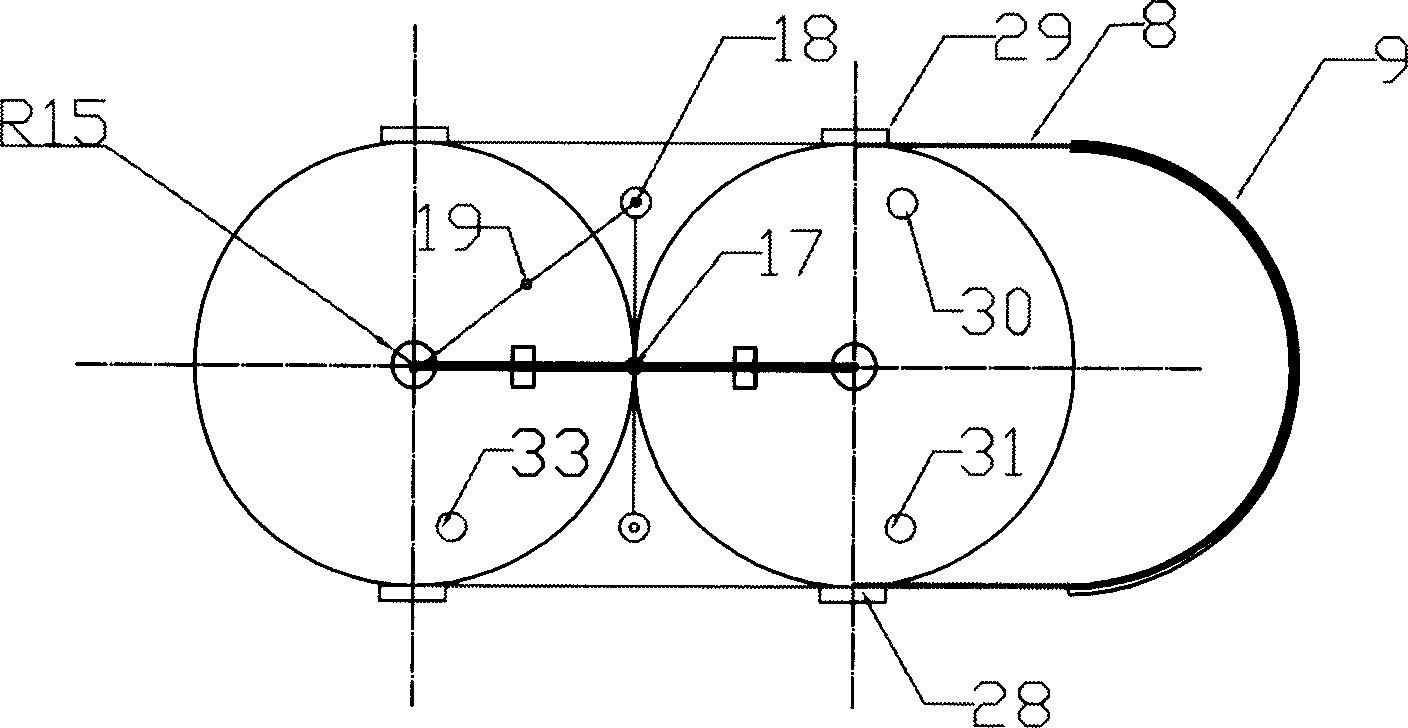

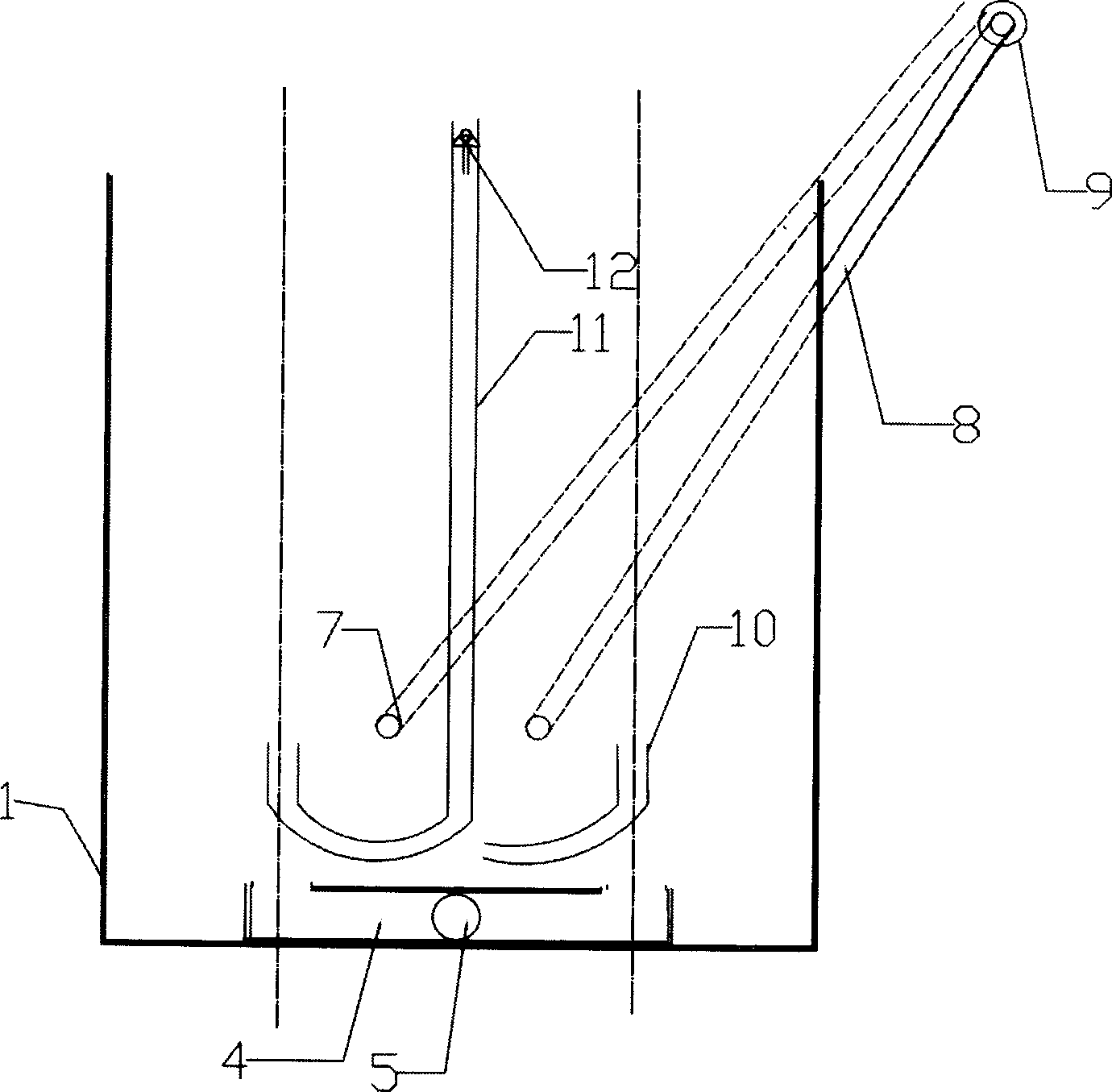

Double-layer hollow wintering greenhouse for industrial aquaculture of Takifuguobscurus

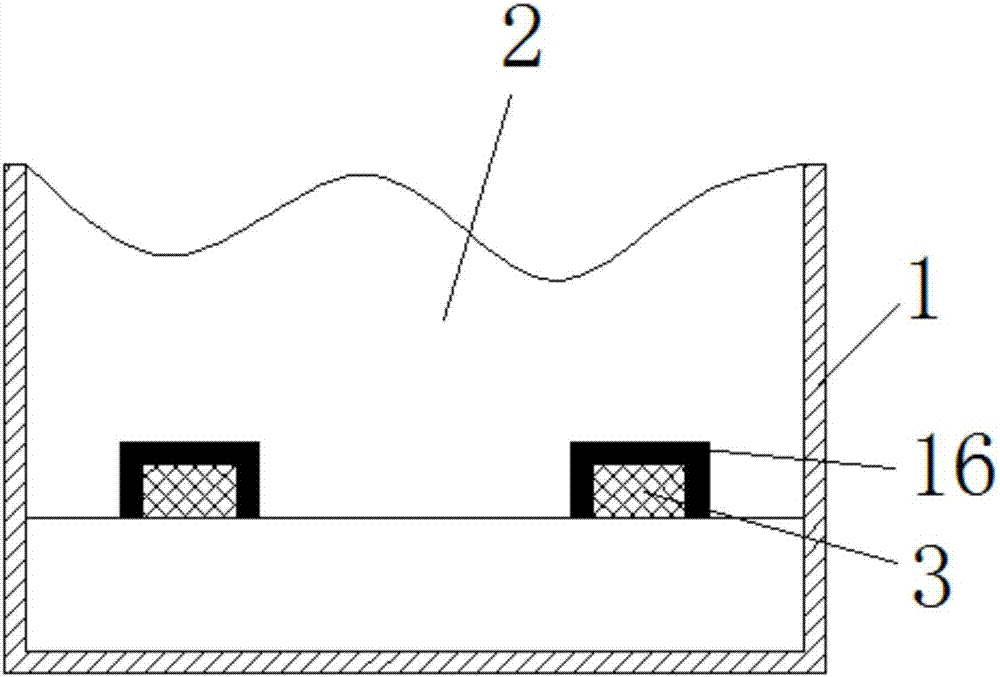

InactiveCN104206318AFast growthReduce water and electricity consumptionClimate change adaptationPisciculture and aquariaGreenhouseTakifugu obscurus

The invention discloses a double-layer hollow wintering greenhouse for industrial aquaculture of Takifuguobscurus. The double-layer hollow wintering greenhouse is formed by combining a plurality of frame structures, wherein the frame structures comprise foundations, columns, double-layer arch tubes and gutters; the columns are arranged on the foundations; the gutters are arranged in the columns; the double-layer arch tubes used for connection are arranged among the adjacent columns and covered films respectively, and the films are fixed on the double-layer arch tubes. According to the double-layer hollow wintering greenhouse for industrial aquaculture of the Takifuguobscurus, the heat transfer coefficient is greatly reduced, and a heat preservation effect is realized, so that the growth rate of the Takifuguobscurus is accelerated, water and electricity consumption is reduced, and a higher value is created for an enterprise.

Owner:JIANGSU ZHONGYANG GRP

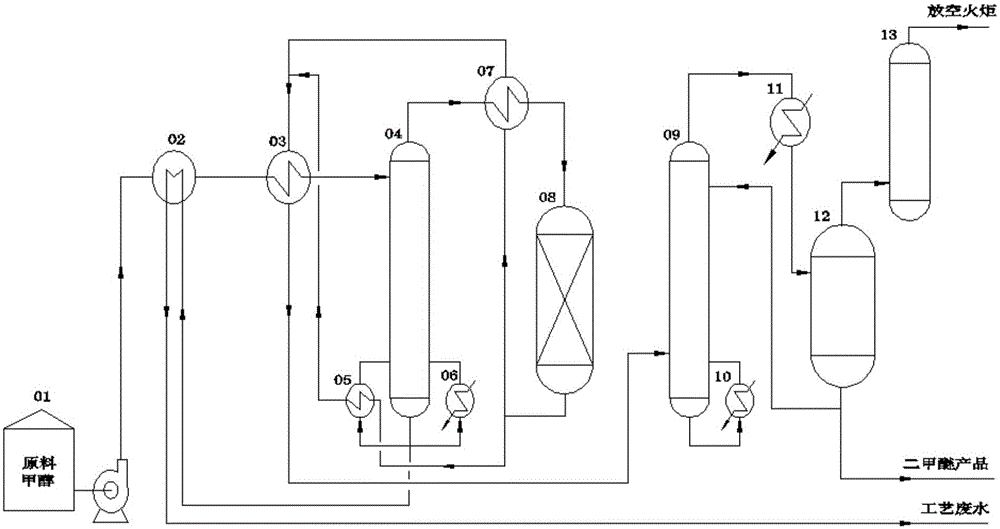

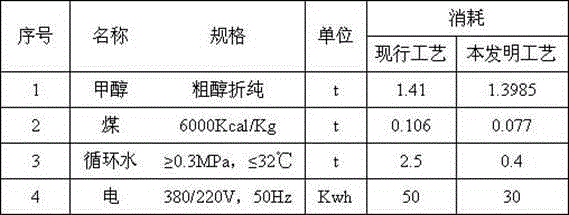

Method for low energy consumption preparation of dimethyl ether from methanol

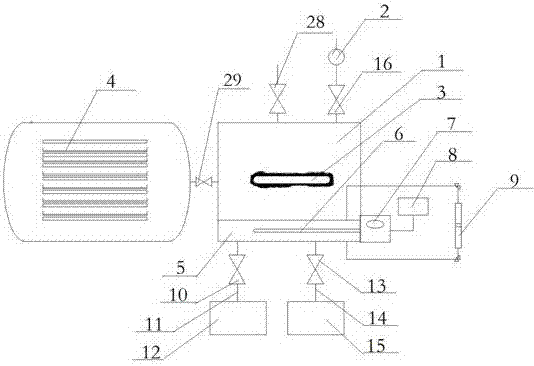

ActiveCN106316800AReduce external heat supplyAvoid consumptionEther separation/purificationEther preparation by compound dehydrationReboilerWastewater

The invention relates to a method for low energy consumption preparation of dimethyl ether from methanol, and belongs to the field of chemical engineering. The method comprises the following steps: 1, methanol from a tank area undergoes two-stage preheating by a wastewater cooler and a methanol preheater; 2, the preheated methanol is vaporized by a vaporizing tower, the vaporized methanol enters a reactor, reaction gas obtained after a reaction is divided into two flows, one of the two flows enters the methanol preheater, and the other flow enters one reboiler in the vaporizing tower; 3, the two reaction gas flows with the heat being partially used meet before entering a secondary methanol preheater, and exchange heat, and the obtained gas enters a rectifying tower from the bottom in a gas form; and 4, rectifying tower top dimethyl ether is cooled by an evaporative condenser, the cooled dimethyl ether enters a dimethyl ether refluxing tank, one part of the dimethyl ether is refluxed, and one part of the dimethyl ether is extracted as a product. Compared with the prior art, the method has the advantages of reasonable and full utilization of heat generated in the whole production system, saving of a large amount of process cooling water, optimized process route, reduction of the device investment, and suitableness for large-scale industrialization.

Owner:HEBEI JICHUN CHEM CO LTD

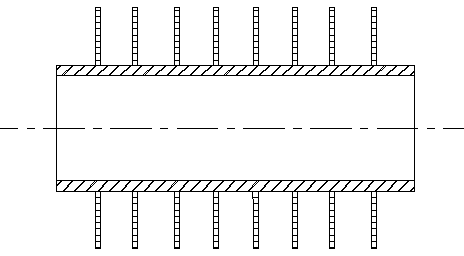

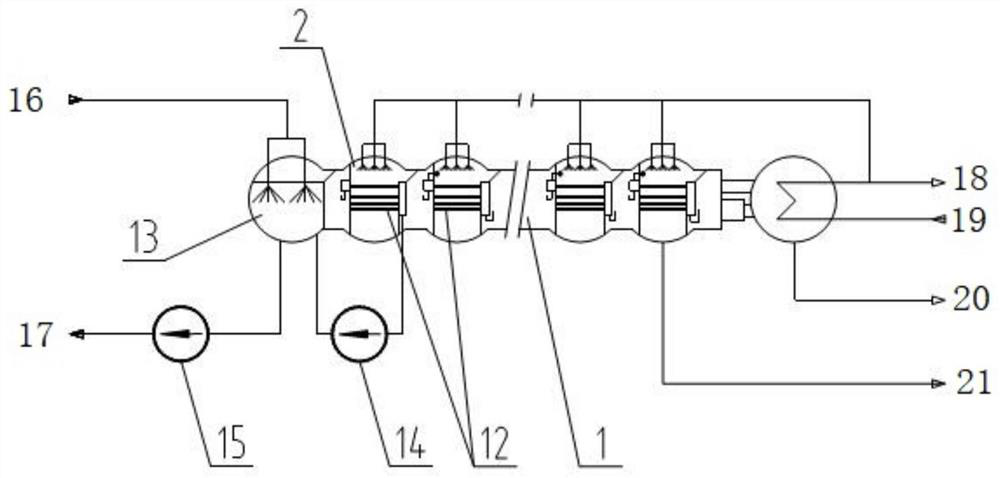

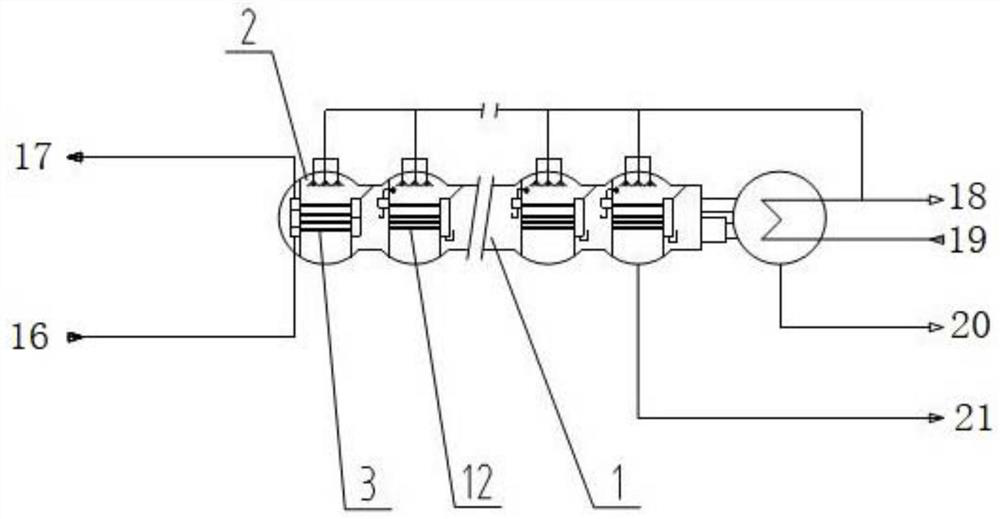

Hot water heating low-temperature multi-effect distillation seawater desalination device

PendingCN112573604AUnique heat exchange tube bundle structureSmall pressure lossWater treatment parameter controlGeneral water supply conservationWater productionSeawater

The invention relates to a hot water heating low-temperature multi-effect distillation seawater desalination device, and belongs to the technical field of seawater treatment. The system comprises a low-temperature multi-effect evaporator; wherein a unique heat exchange tube bundle structure is arranged in an evaporator shell of the first effect of an evaporator of the low-temperature multi-effectevaporator, and a spraying device is arranged above a heat exchange tube bundle. Based on the design of the longitudinal channels in the heat exchange tube bundle, the influence of secondary steam flowing on falling film liquid distribution is reduced, and normal operation and efficient heat transfer of hot water heating falling film evaporation are guaranteed; the hot water directly enters a first-effect heat exchange tube of the evaporator to serve as a heating heat source, pressure loss of the hot water entering and exiting the low-temperature multi-effect distillation seawater desalinationdevice can be reduced, a large-flow high-lift hot water return pump is not needed, and water production power consumption of seawater desalination is reduced; therefore, a hot water spraying system is not needed, the first effect of the evaporator does not generate condensed water, and the system is simple and convenient to maintain; besides, the system is free of a hot water flash evaporation devic, so that the equipment investment and occupied area of seawater desalination are reduced.

Owner:SHANGHAI POWER STATION ACCESSORY MACHINERY PLANT CO LTD

Method and apparatus for preparing pure water by continuous electricity deionizing

InactiveCN1267364CReduce manufacturing costContinuous and stable productionDispersed particle separationWater/sewage treatment by ion-exchangeElectricityIon exchange

The invention relates to a process and apparatus for making pure water by consecution electrical deionizing, wherein four same EDI devices are employed, wherein three of them are in series connection for making pure water, the other EDI apparatus is used as the regeneration device of ion exchange agent. According to the invention, the three procedures of ion exchange adsorption, ion directional transfer and electrochemical regeneration are arranged in different EDI devices, thus making them work under optimum status. The EDI devices in the invention can lower the EDI manufacturing cost substantially.

Owner:彭昌盛 +2

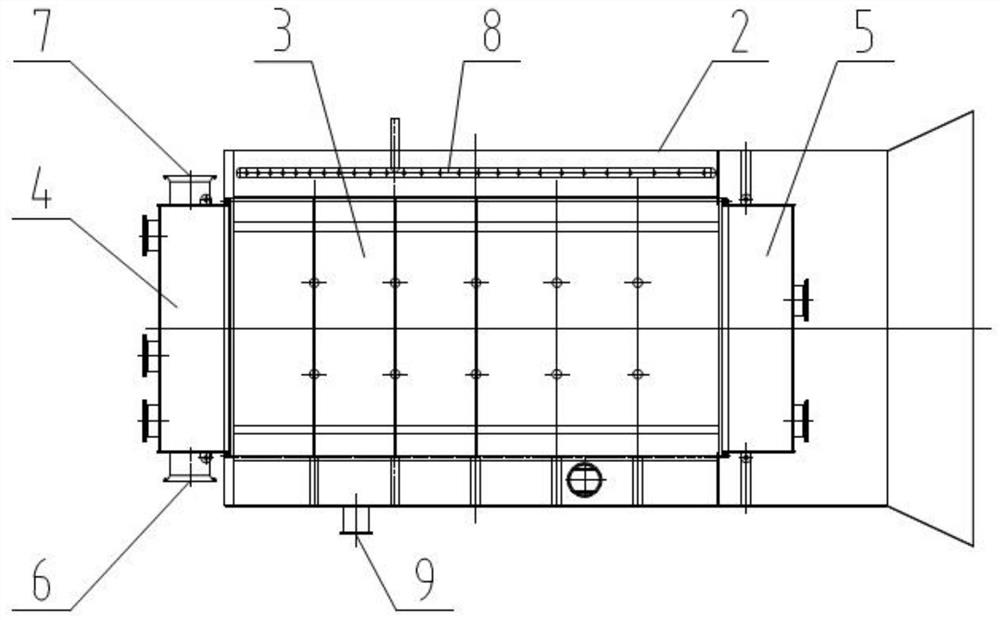

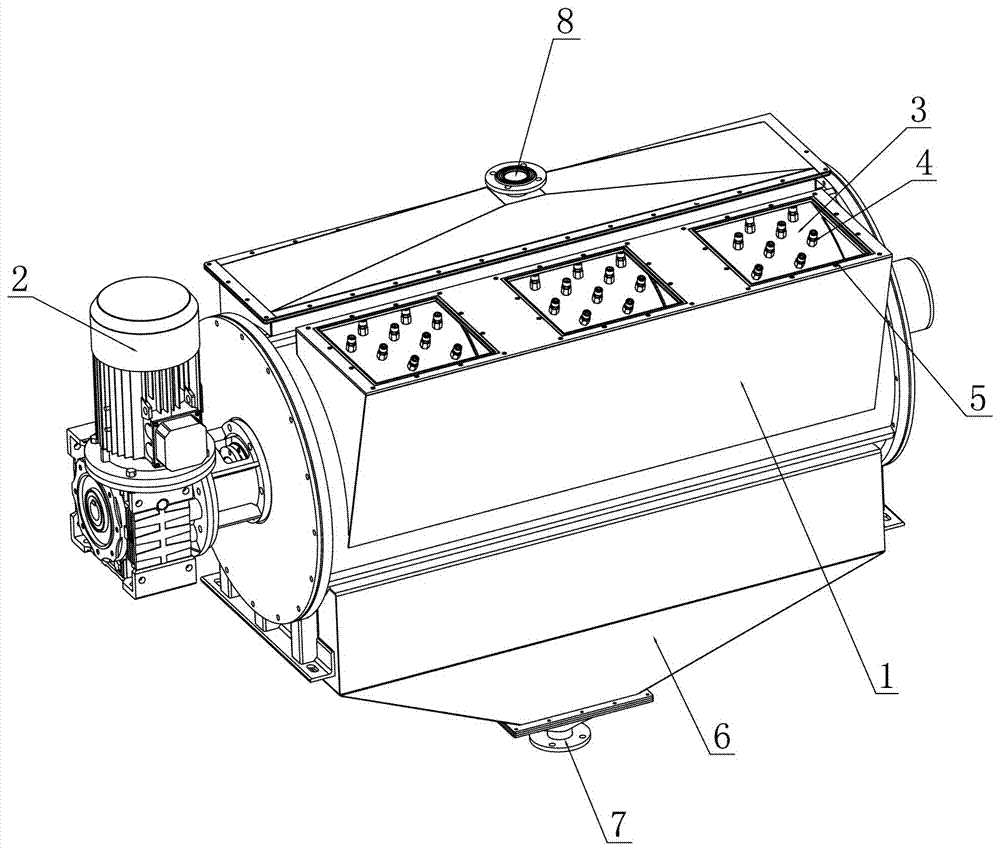

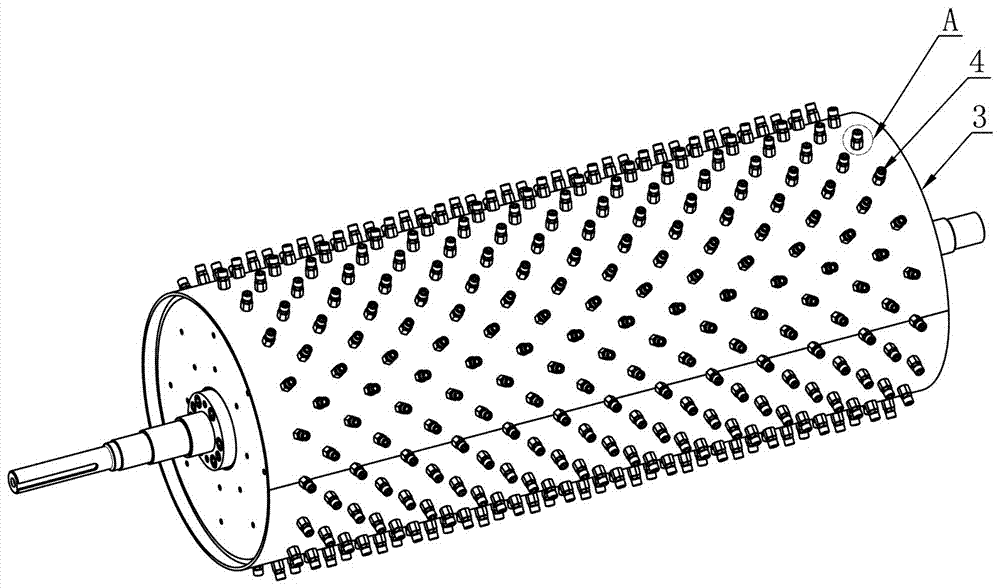

Rinsing device used in plastic film cleaning and recycling production line

The invention discloses a rinsing device used in a plastic film cleaning and recycling production line. The rinsing device comprises a shell, a roller which is driven by a speed reducing motor to rotate is movably supported between a front side plate and a back side plate of the shell through a pair of bearings and bearing pedestals, and a plurality of bolts are spirally arranged on the outer circumferential wall of the roller in the axial direction at intervals; a feeding inlet is formed in the top of the shell, a discharging outlet is formed in the back end of the shell, a water outlet is formed in the bottom of the shell, a discharging control valve is arranged at the discharging outlet of shell, and the water outlet of the shell is covered with a perforated plate; an impurity storing hopper of which a top feeding inlet communicates with the water outlet of the shell in a butt-joint mode is arranged under the shell, an unloading control valve is arranged at a bottom unloading outlet of the impurity storing hopper, and a cleaning agent adding mechanism capable of adding a cleaning agent into the shell is arranged on the shell. The rinsing device has the advantages of being good in cleaning effect, high in cleaning efficiency and small in occupation area.

Owner:ZHANGJIAGANG BEIER MACHINERY

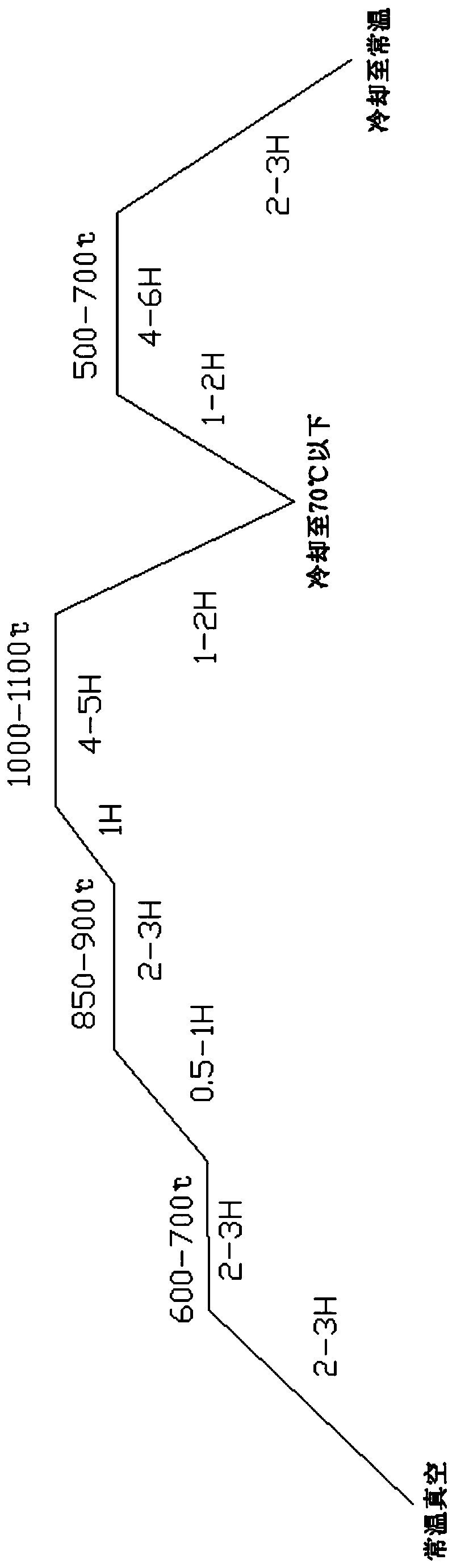

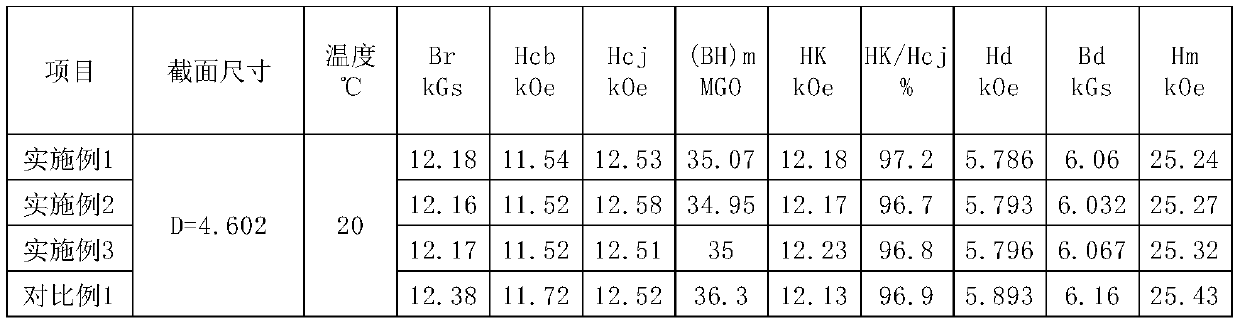

Sintering process of lanthanum cerium-containing sintered NdFeB

InactiveCN110323023AOptimizing the sintering processUtilization doubledInductances/transformers/magnets manufactureMagnetic materialsCeriumDehydrogenation

The invention discloses a sintering process of a lanthanum cerium-containing sintered NdFeB. The sintering process comprises the following steps of (1) performing deflation dehydrogenation, in which ablank is sent into a vacuum sintering furnace, a temperature is raised to 600-700 DEG C, and heat preservation is performed; (2) performing secondary deflation, in which the temperature is raised to850-900 DEG C, and heat preservation is performed; (3) performing high-temperature compactness, in which the temperature is raised to 1,000-1,100 DEG C, and heat preservation is performed; and (4) performing one-step aging and tempering, in which cooling is performed to 70 DEG C or below, the temperature is raised to 500-700 DEG C, cooling is performed to a room temperature after heat preservation, and a blank product is obtained. The sintering process of the lanthanum cerium-containing sintered NdFeB is optimized and transformed, the one-step aging process is taken, the aging temperature eachstage is determined, the sintering period is greatly reduced (the reduction period is 10 hours or above), water and power consumption is saved, the power charge is reduced by approximate one third, meanwhile, the utilization rate of sintering equipment is doubled, and no influenced is generated on the magnetic performance of the product.

Owner:宁波合盛磁业有限公司

Coal pyrolysis, pyrolysis gas heating and schreyerite reduction coupled system and method

PendingCN107267701AIncrease metallization rateAvoid affecting the furnace conditionShaft furnaceShaft furnaceCoal pyrolysis

The invention relates to a system and method for coupling coal pyrolysis, ceramic radiant tube heating and vanadium-titanium ore reduction process. The system includes a coal pyrolysis furnace, a heating furnace and a shaft furnace; the coal pyrolysis furnace includes a coal pyrolysis charge bin and coal pyrolysis gas outlet; the heating furnace is a ceramic radiant tube gas heating device, which includes a coal pyrolysis gas inlet and a reducing gas outlet, and the coal pyrolysis gas inlet and the coal pyrolysis gas outlet pass through pyrolysis The gas pipeline is connected; the shaft furnace includes a gas injection port, a shaft furnace bunker and a shaft furnace discharge port, the shaft furnace bin is arranged on the top of the shaft furnace, and the gas injection port is arranged in the middle of the shaft furnace and connected to the shaft furnace The reducing gas outlet is connected. By organically combining coal chemical industry with metallurgical production, the present invention improves resource utilization, reduces production equipment, reduces the production cost and energy consumption of reducing gas semi-coke produced by vanadium-titanium DRI, low-quality coal, and medium-low rank coal, and improves production competitiveness.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

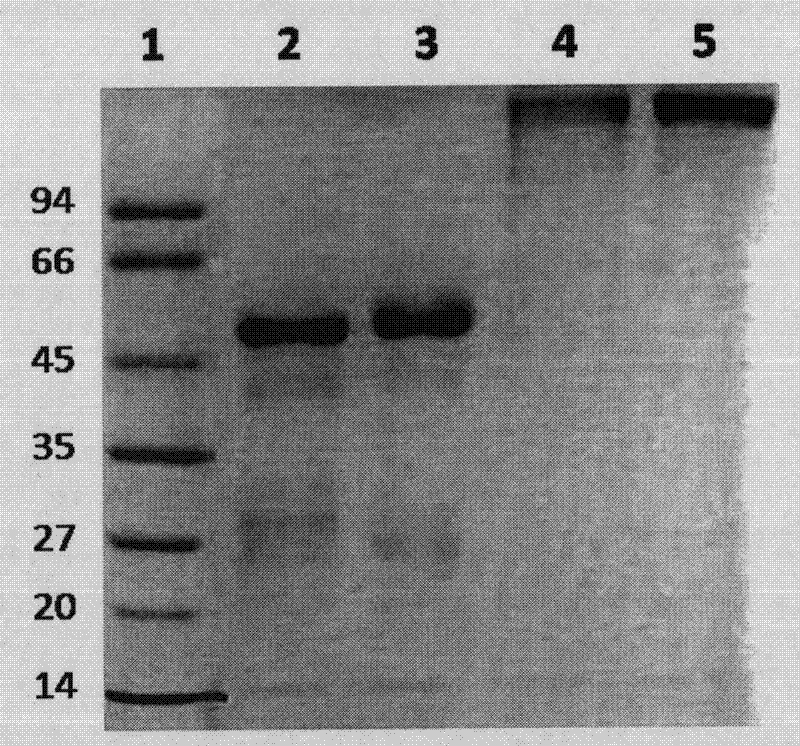

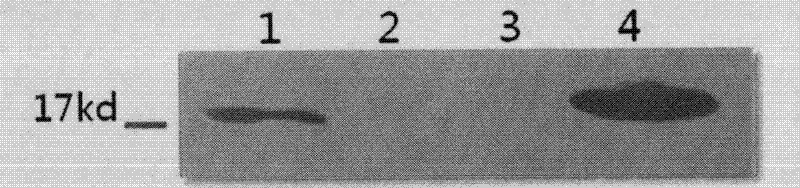

Myoglobin immunoadsorbent and immunoadsorption device

InactiveCN102526726AStrong specificityReduce dependencyOther blood circulation devicesMuscular disorderImmunosorbentsHaemodialysis machine

The invention discloses a myoglobin immunoadsorbent which comprises a solid phase carrier and a myoglobin polyclonal antibody coupled with the carrier; the myoglobin polyclonal antibody is a polyclonal antibody obtained by using a compound as an immunogen, wherein the compound is formed by crosslinking keyhole limpet hemocyanin with antigenic peptide; the amino acid sequence of the antigenic peptide is shown in sequence table SEQ ID:No.5. The invention also discloses a myoglobin immunoadsorption column which uses the myoglobin immunoadsorbent as a filler, a myoglobin immunoadsorption device containing the myoglobin immunoadsorption column, and a first aid tool kit. The immunoadsorbent and the device of the invention are established in a convenient blood perfusion treatment mode, can realize myoglobin adsorption with high specificity, and are especially suitable for on-site rescue of rhabdomyolysis. Compared with modes of hemodialysis or hemofiltration, the whole blood perfusion mode has less water and electricity consumption, is easier to realize, and more meets the requirements of disaster accident on-site rescue.

Owner:GENERAL HOSPITAL OF PLA

Dishwasher with novel modality

InactiveCN1765315AIncrease the amount of washingReduce water and electricity consumptionTableware washing/rinsing machinesWater pipePneumatic pressure

Disclosed a new dish-washing machine comprises a casing, an upper cover, a washing bladder, a washing bracket and an external gas source. It is characterized in that two washing brackets fully with dishes are arranged into two washing bladders; adding a certain amount of water and scour into the first washing bladder to be covered with upper cover and connected to the gas source which whiffs to the washed matters; the pressure in the first bladder increases to spray the scour via the circulation pipe to the washed matters in the second matter; when the water level in the second bladder reaches preset position, the whiff switch valve and the spray switch valve are replaced each other in the same time, then, the airflow is sprayed to the washed matters in the second bladder to reach the purpose of circulation washing.

Owner:QINGDAO WULIANG ELECTRONICS PROD DEV

High-efficient energy-saving reverse osmosis filtration system

InactiveCN104692548AReduce stepsAvoid maintenance proceduresMultistage water/sewage treatmentElectricityReverse osmosis

The invention provides a high-efficient energy-saving reverse osmosis filtration system. The high-efficient energy-saving reverse osmosis filtration system is characterized by comprising a secondary filtration system and a plurality of primary filtration systems, wherein a plurality of sand filters, a plurality of protectors and a plurality of groups of reverse osmosis filters are arranged in any one of the primary filtration system; a plurality of protectors and a plurality of osmosis filters are arranged in the secondary filtration systems. According to the high-efficient energy-saving reverse osmosis filtration system, an ion exchanger of an original system and the sand filter tank of a third set of equipment are eliminated, so that operation and maintenance processes of the ion exchanger are omitted, cleaning and maintenance processes of the sand filter tank are also omitted, and the water and electricity consumption is reduced; meanwhile, the repairing capitals of the equipment and the human input are eliminated, the sewage treatment quantity meets the production requirement, and the pass percent of water quality in the process is greatly improved.

Owner:TIANJIN TIANHUAN FINE INST OF CHEM ENG

Water storage system of integrated overflow water storage tank

InactiveCN104692491AReduce in quantitySimple structureWater/sewage treatment bu osmosis/dialysisReverse osmosisWater storageElectricity

The invention aims to provide a water storage system of an integrated overflow water storage tank. The technical scheme is that the water storage system of the integrated overflow water storage tank is characterized by consisting of groups of primary reverse osmosis devices, a secondary reverse osmosis raw water storage tank, a deep well water pond and a circulating water pond, wherein the secondary reverse osmosis raw water storage tank is placed higher than the deep well water pond and the circulating water pond; an adjusting valve is additionally mounted between the deep well water pond and the circulating water pond to adjust water quantity; and the body of the secondary reverse osmosis raw water storage tank is sealed and heightened, so that the water level difference that two overflow pipes respectively reach the circulating water pond and the deep well water pond is realized, and the water balance of the whole system is adjusted by controlling the water quantity of the overflow pipes to the circulating water pond, therefore, the quantity of the pipelines is effectively reduced, the material input and the maintenance cost are lowered, the pipelines are simple in structure and easy to operate, the balance degree of controllability of the circulating water pond is improved, the control precision is high, the utilization ratio of circulating water is improved, and the water and electricity consumption is effectively reduced.

Owner:TIANJIN TIANHUAN FINE INST OF CHEM ENG

Efficient textile lint wetting box

InactiveCN107142631AAll aspects of humidificationImprove humidification efficiencyTextile treatment containersTextile treatment by spraying/projectingElectricityTemperature control

The invention discloses an efficient textile lint wetting box and belongs to the field of textile. The efficient textile lint wetting box comprises a wetting box housing and a water storage tank, a hydraulic booster is connected to the wetting box housing, an operating chamber door is connected to the wetting box housing, a slide guide is fixed to the wetting box housing and is connected with a tray, a vacuum pump is arranged on the left of the wetting box housing, an intake port of the vacuum pump is connected with an exhaust pipe, a water suction pipe is connected to the water storage tank, a water suction pump is connected to the water suction pipe, an outflow end of the water suction pump is connected with an outflow pipe, the outflow pipe is connected with a heating atomizing box, and the exhaust end of the heating atomizing box is connected with an air feed pipe which is connected with a wetting nozzle. After lint enters the wetting box, the wetting box is vacuumized, wetting air for temperature control is then released, moisture regain in cotton processing is precisely controlled, the lint is wetted more comprehensively, wetting efficiency is improved greatly, and water and electricity consumption is lowered.

Owner:谭威

Vacuum freeze drying device and method

PendingCN107990635AShorten the cycle of freeze-dryingReduce water and electricity consumptionDrying solid materials without heatCorrosion preventionElectricityFreeze-drying

The invention discloses a vacuum freeze drying device. The vacuum freeze drying device comprises a vacuum chamber, a material bin, a condenser coil, a water storage container and a heating device; thevacuum chamber respectively communicates with the material bin and the water storage container; the condenser coil is arranged in the vacuum chamber; a liquid level sensor is arranged in the water storage container, and is externally connected with a liquid level controller; a heating end of the heating device is positioned in the water storage container; a temperature sensor is externally connected with a temperature displayer; and a heater and a refrigerator are arranged in the material bin. The ice melting process is performed in a vacuum container before product drying by one hour; when the product drying process is finished, the ice melting process is also finished; the vacuum freeze drying device can be directly used in the next phase, so that the product freeze drying period is shortened; and in the ice melting process, vaporized heat of water under vacuum conditions is used for providing heat to ice layers, so that water and electricity energy consumption caused by hot water spraying or hot water dipping is greatly reduced.

Owner:SHANGHAI PUDONG FREEZE DRYER EQUIP

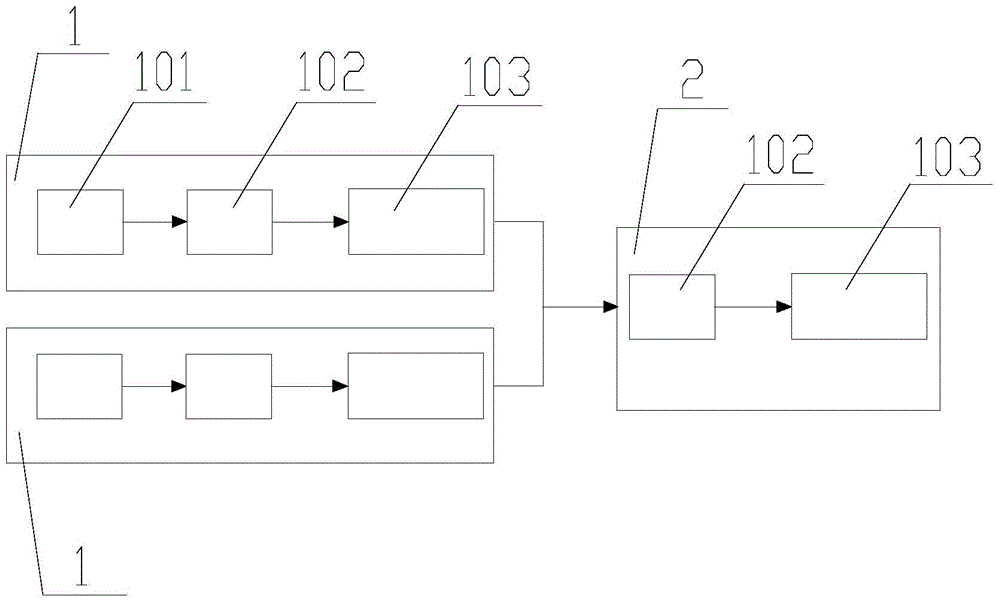

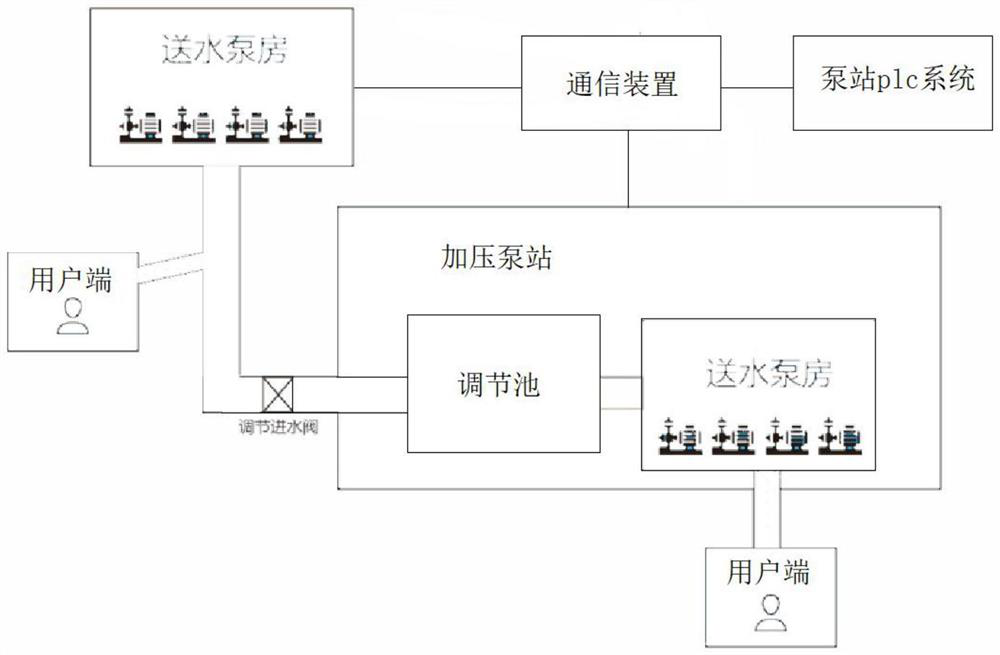

Water plant energy saving method and system based on water supply booster pump station flow closed-loop control

InactiveCN113404125AReduce water and electricity consumptionService pipe systemsWater mainsLoop controlStream flow

The invention discloses a water plant energy-saving method and system based on water supply booster pump station flow closed-loop control. The method comprises the following steps of 1, setting the flow of a booster pump station water supply area to be 0, and carrying out the statistics on the instantaneous flow S1 of a water plant after a tip pipe network is cut off; 2, dividing a day into N water supply interval sections according to the standard that S1 is divided into a time period H1 according to starting of a single variable-frequency constant-pressure water supply pump, a time period H2 according to starting of a two-pump combination and a time period H3 according to of starting a second two-pump combination in a water plant; 3, applying segmentation time in the previous step to water inlet time segmentation of a pump station; 4, calculating the actual water supply total amount S total of the booster pump station according to experience; and 5, taking the maximum flow of water plant pump sets of the N water supply interval sections and the actual flow S1 to calculate the water inlet instantaneous flow of the segmented interval of the booster pump station. The water supply capacity of a water plant water supply pump is utilized to the maximum extent, the water plant water supply pump operates efficiently, and water supply power consumption of the water plant is greatly reduced.

Owner:海盐县三地自来水有限公司

A kind of compost for Coprinus comatus factory production

The invention discloses compost for the industrialized production of coprinus comatus. The compost comprises the following components in percentage by weight: 50-70% of biogas residue, 5-40% of corncob, 13% of bran, 5% of corn flour and 2% of gypsum. By using the compost provided by the invention for cultivating the coprinus comatus, the raw material costs for production of the coprinus comatus is reduced, the production cycle can be shortened, the yield can be improved, the energy consumption can be reduced, the biogas residue, the residue of large-scale methane fermentation can be recycle, and the circular chain of biomass energy can be prolonged.

Owner:SHANGHAI ACAD OF AGRI SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com